Home / Design solutions / Ceiling design / The wall behind or near the fireplace or stove - how to decorate it?

When a fireplace or stove is lit, the wall near it becomes heated. This is unsafe if the walls and floor where the stove or fireplace is located are not properly finished. This part of the house structure must be insulated with fireproof materials that can completely prevent fire. In addition, you need to take into account the requirements for installing heating devices - the distance from the partitions.

Insulation options

There are many non-combustible materials that can be used in this case. The easiest way to protect all surfaces from heat is to place a protective box around a red brick heat source. It is able to protect structures from heat and easily tolerates thermal effects. However, this decoration of the wall around the stove in the house looks a little unaesthetic and you can choose other materials:

- Porcelain tiles and tiles.

- Fiber cement boards.

- Factory-made protective screens.

- Metal sheets.

- Artificial or natural stone.

The easiest way to work is with a ready-made protective screen - you just need to select it according to size and install it on site. This option is also good because such finishing of walls near the stove or fireplace is done in the shortest possible time and without “dirty” or “wet” finishing work. The remaining options are more labor-intensive and have some nuances. Therefore, they need to be considered in more detail.

When is this required?

There are times when there is no need to protect walls. If the stove is located at a safe distance from the wall from a fire safety point of view, the installation of protective screens and other measures can be neglected. The distance from the walls that is required to reduce the heat from the source varies:

- A stove laid in a quarter of a brick should be located no closer than 35-40 cm from the wall;

- A metal stove without lining should be placed a meter away and no closer;

- A metal one with a lined furnace can be installed 70-75cm from the wall.

However, not every steam room has the opportunity to fulfill these requirements, due to the small area. The layout of steam rooms with an area of 6-8 m² can hardly accommodate the necessary set of items for the steaming procedure. Therefore, the need to insulate walls with special sheathing is relevant.

Tags: stove, wall, thermal insulation

« Previous entry

Tile and porcelain stoneware

These two materials are best suited for insulation in this case, as they have a beautiful appearance and will not spoil the interior. However, in terms of labor intensity and costs, this will be the most complex method of registration. You will have to prepare the surface, stick the tiles and only then install the stove in place. At the same time, you will have to do without heat for some time, since the work is carried out in several stages and each takes time.

Minerite or fiber cement boards

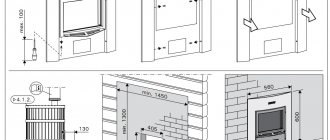

This material is suitable for those cases when there is no desire to waste time on laying tiles or assembling a complex protective structure. The plates are mounted directly on the wall or on a specially prepared metal profile structure. In the first option, the plates are simply attached with self-tapping screws or using clamps. With clamps, a ventilation gap of three to five millimeters remains between the wall and the assembled surface, which further increases safety.

The second method is more complicated, but such finishing of the walls near the stove in the house will protect them much better from the heat. On the surface, using a construction stapler, basalt cardboard with a foil coating is attached, with foil inside the room. Metal profiles are attached through the cardboard to fix the external decorative panels. Decorative slabs are attached to the profiles in such a way that they do not reach the ceiling a few centimeters. This gap is necessary to compensate for possible shrinkage of the house. Ventilation holes are made in the bottom of the slabs, which can be covered with a decorative grille.

Steel case

Steel is also a fire-resistant material. It cannot be left untreated, as it will instantly rust in a bathhouse. When finishing the space around the stove with steel, you need to keep in mind that unlike brick, tiles and stone, steel does not insulate heat at all.

A protective portal around the stove made only of steel will be completely pointless, since it will not be able to fulfill its main task - to protect wooden walls from overheating. In order for this function to be fulfilled, it is necessary to provide a good heat-insulating layer of another material, and then cover it with a facing steel sheet.

This heat-insulating separation layer is created from mineralite. Other fire retardant insulation materials can also be used. Simple mineral wool is not suitable, since after getting wet once it shrinks in volume, and this defect cannot be corrected by anything.

The insulation near the stove should not get wet. You need to take care of its waterproofing. Moreover, this waterproofing should only be on the side of the cold wall, but not on the side of the stove.

Steel has a metallic luster. This effect can be used to greatly increase the efficiency of the portal.

If made from uncoated polished stainless steel, it will act as an infrared reflector.

A similar element can very often be seen in electric fireplaces, heating stoves and any other heating devices.

The main difficulty of this solution is the need to use only stainless steel. Compared to ordinary steel, it costs 10 times more, but the total thickness of the sheets for the reflective screen can be small.

Stainless steel perfectly withstands any humidity. It can even be placed in rooms such as a steam room in a bathhouse; the decoration around the stove will be compact and with a modern design. In a steam room, all interior elements are usually made only from wood. Stainless steel would be appropriate next to a metal stove-stove.

Metal sheet

This protection option can be used when the distance between the walls of the stove or fireplace and the protected surface is more than 20 centimeters. The sheet is simply attached to the surface so that its edges protrude beyond the edges of the heating device by 30 centimeters on each side. The option is unreliable and is not recommended for use if the heat source is not removed from the partitions at the specified distance - the risk of fire remains.

Stone

This type of wall decoration behind the stove or fireplace is very beautiful. However, this is also the most expensive finishing method if natural material is used. Artificial stone is cheaper, but it also falls into the category of expensive decoration. The surface is prepared using standard technology, and the heating device is installed after all finishing has been completed.

What else to consider

To avoid any troubles during the operation of the furnace, you need to take into account the requirements of SNiP in all cases - even with installed protection, even without it. They are simple and compliance with these rules guarantees you the necessary level of protection:

- The distance from unprotected wooden walls to the heating device is 1000 mm.

- If the wall is protected by a material equivalent in thermal conductivity to brick - 130 mm.

- If the floor is not protected by anything, then the distance to the bottom side of the heater should be at least 140 mm.

The floor is best protected with ceramic tiles or porcelain stoneware. You can also use a mineralite slab or a regular sheet of metal. It is most important to protect the area directly in front of the firebox door, as embers can fall out and cause a fire. Directly under the heating device, the floor covering does not heat up particularly strongly and if a distance of 4 - 15 centimeters to the bottom of the oven is maintained, additional protection may not be needed there.

Covering bathhouse walls with non-combustible insulating materials

To prevent the walls from overheating, you can use materials with increased thermal insulation properties and inertness to high temperatures. Two types of materials are used:

- reflective;

- fireproof with lining.

The first type includes materials for wall cladding, consisting of thermal insulation with fire-resistant properties and a metal covering in the form of a sheet.

Insulating walls with reflective sheathing

A protective cake with reflective materials is done this way. First, the thermal insulation is attached using ceramic bushings directly to the wooden walls, then it is sewn up with a stainless steel sheet.

Advice! It is better not to use galvanized metal, since heating may release heavy metals harmful to the human body.

Stainless steel with a polished surface reflects the heat flow inside the steam room, reducing heat loss. In this case, reflected heat is more useful than direct heat. For thermal insulation use:

- basalt cardboard or cotton wool, the only material with increased hygroscopicity, non-flammable, environmentally friendly;

- asbestos cardboard, which reliably protects against flames and has a long service life;

- mineralite, an artificial material made specifically for these purposes.

Protective sheathing requires ventilation gaps of 2 cm from the wall to the insulation, 2 cm from the insulation to the steel sheet. If it is necessary to install the stove as close to the wall as possible, make a double skin of non-combustible insulation, use ceramic bushings to maintain gaps of 2-3 cm and sew them up with a steel sheet.

Insulation with cladding

Measures to protect walls with cladding are necessary in order to preserve the interior decoration of the room. They are more expensive, but no one has canceled the aesthetic advantages of the bathhouse. It is based on tile cladding, which is laid on fire-resistant cladding made of gypsum plasterboard, non-deformable gypsum-based cardboard with fiberglass, mineralite, non-flammable cement-fiber material, moisture-resistant and resistant to biochemical influences, LSU, fiberglass material bound with magnesium additives, resistant to high temperatures, high humidity. Heat-resistant glue is used for installation.

Advice! Use heat-resistant reinforced Terracotta glue, made from fireclay dust bound with kaolin additives, intended for tiling stoves, fireplaces, and all heated surfaces.

The recommended facing materials are quite varied, the best of them are:

- terracotta tiles, they are made from specially fired clay, which gives increased heat resistance and durability;

- clinker, denser clay tiles with a surface of various colors, similar to facing bricks;

- tiles, also made from clay, having an original embossed surface;

- porcelain stoneware made from a mixture of clays, kaolins, quartz sand, feldspars by high-temperature firing under a pressure of 400-500 kg/cm², with imitation of stone, wood, durable artificial material;

- soap chloride, a rock mineral consisting of talc, magnesite and chlorite, an environmentally friendly natural material that does not absorb moisture at all, has an attractive appearance, does not crumble, and is not afraid of high temperatures.

Advice! Use soap chloride to finish the steam room, this mineral has a healing effect on the human body, regulates blood pressure, stimulates cerebral circulation, expels viruses and microbes due to the release of vitamin D when heated.

All of the listed tiles are an element of protection that forms a cake, the basis of which is a fire-resistant material. Just like a screen, sheet material is installed on ceramic bushings with a gap of 2-3 cm from the wall. The minimum distance to the heat source from the tile should be 20cm.

Protection with cladding decorates the room, creates a positive mood, and helps to increase the efficiency of procedures. And most importantly, properly installed insulation prevents wooden walls from overheating and catching fire. Have a nice steam!