Installation of a ceiling-passage assembly requires certain skills and abilities from the performer. Home craftsmen with insufficient experience can make a number of serious mistakes. And what is typical is that most of them occur at the places where the chimney exits the wall or where it intersects with the roof.

It should be noted that this unit is very important and any mistake in its installation can lead to various undesirable consequences, including fire and fire.

Varieties

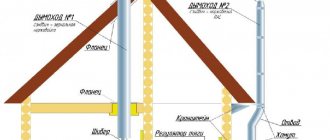

Chimney pipes can be classified into several types depending on their location:

- Indigenous - located at some distance from the stove and connected to it through a sleeve. This option is convenient due to the fact that the chimney can be connected to several stoves.

- Wall - in most cases they are built into the main wall, but in some cases they are run along it.

- Mounted - built over the stove.

Thus, its passage through the wall or ceiling will depend on exactly how the polyurethane foam pipe coming from the furnace is structured. But in most cases, preference is given to mounted chimneys.

Rules that should not be ignored

As noted above, chimney installation does not allow for negligence and must be carried out with full responsibility. To do this, it is worth considering a number of rules:

- Before installing a chimney, it is necessary to carefully plan its location so as not to damage the main components of the roof. In addition, there should be no more than 3 turns.

- The length of the horizontal section of the pipe coming from the furnace should not exceed 1 meter.

- When installing a metal pipe, it is necessary to provide a gap to flammable finishing elements (from 1.5 meters, no less).

- The chimney must be installed in such a way that its cut does not face the leeward side. Otherwise, the force of natural traction will be noticeably reduced.

- It must be possible to clean the pipe in the chimney duct. This is a very important condition.

As professionals note, single-walled polyurethane foam pipes must be additionally protected with thermal insulation material.

In this case, the outside heat-insulating layer must, in turn, be protected with a metal casing (made of galvanized steel). This measure will avoid fire and condensation. Which materials can be used will be discussed in the next section.

Rules for passing through the ceiling

When planning the size of the chimney, consider several rules:

- Immediately after exiting the sauna stove, you can only install a thick-walled metal pipe without insulation. Its height must be at least a meter: the outlet temperatures are too high, so even stainless steel and mineral wool cannot withstand it. Above, you can use sandwich pipes.

- A pipe in a protective sheath is passed through the ceiling. This may be a factory-made sandwich, but you can insulate a single wall yourself.

Another option on how to protect walls and ceilings from heat - There should be no joints at the intersection of floors: only before or after. Choose the height of the sections so that all connections can be visually inspected.

- The maximum length of the horizontal section is 1 meter.

- There are no more than 3 elbows on the entire chimney.

- The pipe should not be rigidly attached to the ceiling. As temperatures change, it changes size and must be able to move freely.

Using basalt wool

Basalt wool can be used as a heat insulator, but before purchasing you need to make sure that it can withstand high temperatures (more than 600 °C). Many experts tend to agree that this is not the best option. And there is a certain explanation for this.

The fact is that during the manufacture of this insulation, resins are used as a binder, which, when exposed to high temperatures, begin to release formaldehyde.

In addition, after attaching the ceiling-passage assembly, condensation sometimes forms in the chimney, and when moisture interacts with mineral wool, it loses its heat-protective properties. These qualities can be restored as moisture evaporates, but only partially.

Organization of passage

In most cases, a special sandwich pipe is used to construct chimneys. It is a structure of two pipes of different diameters, nested one inside the other. Between them, non-flammable heat-insulating material is laid. The outer shell is made of thin metal, and the inner part is made of thicker steel.

The passage through the ceiling of such a sandwich chimney is carried out in the same way as a regular pipe. Perhaps there will be a little less work on arranging the passageway. You can use either a ready-made solution already made at the factory or assemble the required unit yourself.

In any case, it is necessary to first prepare the place where the entire device will be installed. A square hole is cut in the ceiling, with a side of about 45 centimeters. This size is large enough to fit a standard chimney through.

The ceiling assembly itself for the passage must be lined outside and inside with a heat insulator capable of withstanding high temperatures. The most popular for such purposes is special basalt wool.

According to the size of the square part of the assembly, approximate lines are drawn on the ceiling. The opening should be located strictly above the stove pipe. The hole itself is cut out slightly smaller than the connecting square plate. It is necessary to leave such a gap so that it is possible to attach it to the ceiling with self-tapping screws. The finished opening is lined with the same heat-insulating material as the passage unit.

The finished assembly must be inserted into this hole to check all connections. Before bringing the chimney through the ceiling and finally securing it, you need to make sure that the pipe is vertical and that it is located exactly in the center of the opening.

If you look from the top floor or attic, you can see that there are voids in the passageway. They are filled with non-flammable heat insulator. You can use expanded clay, clay or leftover basalt wool. The main thing is to fill the void very tightly.

To have a more complete idea of what the entire assembly looks like in section and what the passage for the chimney through the ceiling looks like, you can look at the drawing below.

The diagram shows the main elements of the chimney and passage unit, as well as parts of the ceiling through which the passage was made. The pipe is passed through the roof in a similar way. The only difference will be the hole in the square metal plate - it will not be round, but oval, since it will be located at an angle.

Sand

Until recently, sand was used in everyday life for these purposes. However, this option had a significant drawback due to the nature of the material - fine grain. Therefore, over the period of operation, sand spilled out through small cracks.

In this regard, the stove had to be periodically cleaned and the unit had to be filled again.

Other ways to avoid severe overheating

As some private property owners note, there is no point in thermally insulating the passageway. In their humble opinion, you can do without it. In addition, if the space is not filled with anything, this will prevent overheating and burning of a certain part of the chimney. And due to the ventilation created in this place, the pipe section will cool down noticeably faster.

In reality, this option for organizing a ceiling-passage assembly can be successfully challenged. The thing is that a hot pipe emits heat, which causes the nearby wood to dry out, which ultimately does not benefit the material. Fire can occur even at lower temperatures (+ 50°C). Therefore, it is necessary to take care of the necessary measures, for which you can resort to several methods:

- Installation of a water jacket on the chimney - the heated liquid can be used for heating. You just need to install a special tank and remove water from the pipes.

- You can simply install just one container where the water will be heated. You just need to make sure that it does not boil, and also periodically drain and add liquid.

Ultimately, the temperature in the chimney can be significantly reduced, as well as the risk of fire in building materials.

In addition to water, you can resort to air cooling of the ceiling-passage unit. To do this, you need to place another pipe on top of the chimney (so that one is in the other). And in their upper and lower parts you should put a grille for the passage of air flow.

Norms and requirements

High-quality installation of the chimney passage through the roof is so important for the safety of the building and residents that the state has officially established the rules and regulations for its arrangement. A document that takes into account sanitary, hygienic, fire, corrosion and other loads on the structure and materials is called SNiP 41-03-2003 “Thermal insulation of equipment and pipelines”.

The pipe installation through the roof is planned during the construction phase. If the stove is reconstructed, replaced or repaired during operation, the chimney is usually left in its old place. The fundamental condition for a high-quality chimney is the location of the pipe relative to the roof ridge.

To ensure optimal traction, the best place to bring the pipe to the roof is its highest point - the ridge. This allows the main part of the pipe to be routed through the attic, which protects it from moisture and cold. The difficulty lies in the fact that it is necessary to violate the integrity of the horizontal beam by installing additional supports on both sides of the chimney. More often, the pipe is installed at a short distance, which makes it possible to limit the street part of the pipe to a minimum of fifty centimeters.

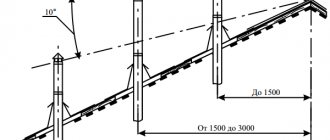

There is the following dependence of the height of the chimney on its distance from the ridge:

- the distance to the ridge does not exceed 1.5 m - the pipe rises 50 cm above it;

- distance from 1.5 to 3 m - it is enough to bring the chimney flush with the ridge;

- when the chimney outlet is more than 3 m away from the ridge, the height of the pipe may be lower than the top point of the roof (the difference should be an angle of 10 degrees).

The optimal pipe height is from 0.5 m to 1.5 m. The outlet is located between the rafters, so as not to violate their integrity and leave a distance of 15-25 cm to them.

Note! The worst location for the pipe outlet to the roof is in the recess between two slopes in a complex building (in the valley).

If the direct vertical exit of the pipe occurs at such a merger of two roofs, then the roof penetration should be shifted half a meter to the side, adding a horizontal section to the chimney (up to 1 m). Snow and ice accumulate in the recess in winter, which creates an additional threat for leaks.

We recommend that you familiarize yourself with: Dimensions and types of PVC sewer pipes and adapters for connecting them

An unfortunate location for the roof penetration for the chimney is the lower part of the roof. Here the pipe can be damaged when masses of snow and ice melt. In addition, a large section of the pipe has to be taken outside to ensure normal draft, which contributes to its freezing and the formation of condensation on the internal walls.

Metal knot

Today, sandwich type pipes are widely used. Essentially, these are two metal cylinders of different diameters inserted into one another.

But how to do everything? The work will be carried out as follows:

- First, you need to purchase a ready-made metal feedthrough, which is otherwise called a box due to the characteristic shape of the cube. It can also be made independently from galvanized iron, taking into account the diameter of the pipe and the thickness of the ceiling material. In this case, the diameter of the hole should be slightly smaller than the size of the chimney of the ceiling-passage unit.

- The next step is to prepare the pipe for installation. Due to the thinness of the metal, it is not able to isolate the heating chimney from combustible material. For this you can use basalt fiber with a foil surface. It is glued to the inner walls of the box, as well as to those parts that will come into contact with the ceiling.

- A place is marked on the ceiling, which is subsequently cut out with a jigsaw.

- Now you can install the box.

- A special metal panel (often made of stainless steel) with a hole cut in the middle should be fixed to the ceiling, and its diameter should correspond to the size of the circle in the box.

- At the final stage of arranging the ceiling-passage assembly, you should arrange a chimney on the floor of the second floor (if it is a house) or attic (whether it is a one-story house or a bathhouse). This is done using the same panel or metal sheet with a hole cut out in the middle.

- The location of the pipe must be calculated in such a way that the junction of its two parts does not fall on the internal cavity of the box, which is already located in the ceiling. It should be lower or higher.

As previously noted, instead of basalt fiber it is better to use other materials - sand (although also not the best option), clay, expanded clay.

The material will not only serve as insulation, but will also be a good heat insulator.

What are the dangers of errors when installing penetrations through the roof?

There is an opinion that the efficiency and safety of an individual heating system depends on the design of the stove and the skill of the stove maker. Few people think that complete combustion of fuel depends more on the chimney and traction force. And only specialists know how important it is to install a high-quality passage through the roof.

When building a furnace, the main attention is paid to the temperature stability of the materials. But the fire-resistant brick of the chimney and the mineral insulation of the sandwich pipe are defenseless against systematic moisture.

Poor design of the pipe outlet to the roof entails serious consequences affecting the operation of the chimney. Violation of the standards for thermal insulation of pipes from flammable roofing materials and attic floors can lead to:

- to fire in places where the pipe and combustible materials of the house structure come into contact;

- to the formation of a large amount of condensate in the pipe, which will lead to its rapid destruction;

- to the formation of a thick soot deposit on the inner wall of the chimney and a decrease in its working clearance;

- to a decrease in stove draft and the formation of carbon monoxide, which is dangerous to human life.

Poor quality waterproofing of a roof penetration assembly threatens:

- penetration of atmospheric moisture into the attic, which provokes the formation of fungus and mold;

- getting the rafters wet leads to the initiation of wood rotting processes, no matter how well it is treated with an antiseptic;

- destruction of the brickwork of the chimney;

- increased corrosion of the metal pipe;

- by getting the thermal insulation (mineral wool) wet, after which this material becomes completely unusable and loses its thermal insulation properties.

We recommend that you read: How to perform installation when using polypropylene pipes?

Note! Even minor flaws during the installation of a roof penetration of a chimney over a couple of years can cause an unexpected fire, destruction of the heating system, and carbon monoxide poisoning of residents.

Drywall box

In this case, the instructions for installing the ceiling-passage unit look the same as with a metal box, with the exception that other materials are used. The procedure itself looks like this:

- It is necessary to make a square hole in the ceiling. In this case, the distance from the walls of the ceiling to the surface of the pipe must be at least 200-250 mm.

- Using heat-resistant plasterboard, make a high box. It will cover the pipe from blocking.

- On the ceiling side, a metal sheet with a circle in the middle (in accordance with the diameter of the chimney) is also fixed to the hole made.

- A metal pipe is pushed through the sheet.

- In the interfloor ceiling, a heat insulator is laid around the entire perimeter and along the entire height of the box.

As noted earlier, when installing a ceiling-passage assembly, expanded clay and other materials can be used instead of mineral wool.

Carrying out penetration depending on different types of roofing

The roof penetration will vary depending on the shape of the chimney and the material that covers the roof. Thus, to install a sandwich pipe, installation of a heat-insulating box is not required, since the insulation here is laid during manufacture. To penetrate the roof of a brick or ceramic chimney, it is necessary to construct a thermal insulation box to protect the building from fire.

Elastic penetration for round pipe

The simplest but most universal penetration exists for a sandwich pipe. It is a rubber or silicone pyramid that is put on the pipe and fixed to the roof. Moreover, the smoothness of the roof covering in this case does not matter much - the elastic insulating apron is equally hermetically attached to the ribbed surface of the profile, wavy tiles, and soft ondulin. Manufacturers offer ready-made flexible penetrations for sandwich chimneys of any cross-section.

Installation of elastic penetration is carried out as follows:

- A hole is cut in the roof for the pipe outlet so that at least 38 cm remains from the pipe wall to the combustible roofing materials.

- A galvanized metal sheet with a hole for the chimney is fixed to the inside of the roof. The distance from the outer wall of the pipe to the edge of the sheet hole is at least 14 cm.

- Remove the pipe and secure it in the desired position.

- The elastic penetration pyramid is cut to a level corresponding to the diameter of the pipe and put it on the pipe through the top.

- The protective apron of the penetration is applied to the chimney passage, having previously coated the edges with fire-resistant sealant.

- A metal mounting ring (flange) with holes is placed on top and secured with self-tapping screws.

For roofs with a steep slope angle, manufacturers produce special elastic penetrations, where the slope of the pyramid and apron is more pronounced.

Note! The elastic penetration material is designed to withstand significant changes in external temperature and is resistant to sunlight and moisture.

Metal penetration for round pipe and smooth roof

A metal feedthrough for a round pipe can also be purchased ready-made. It is a metal cone, the upper hole of which corresponds to the diameter of the chimney pipe. When choosing a metal penetration, you need to know the angle of inclination of your roof.

We recommend that you read: Furnace chimney installation - types and how to do it yourself

Installation diagram for metal penetration:

- the hole in the roof and the inside of the protective structure are designed as for elastic penetration;

- a passage pipe is put on the chimney, the edges of the lower part are coated with fire-resistant sealant;

- secure the protection with self-tapping screws with rubber caps to seal the mounting holes.

Note! A steel passage pipe is used to design the chimney penetration only for smooth roofs.

Exiting the chimney to the street

If the outer walls of a house or bathhouse are made of brick or other non-combustible material, then bringing a chimney through them is not so difficult. To do this, a round through hole is made, and subsequently a metal sleeve is installed there.

But in the case when the opening is made perfectly round in exact accordance with the dimensions of the sandwich, you can do without this element. It will also be impossible to insert the sleeve if the chimney passes through the wall at an angle other than a straight one.

When installing a gas outlet pipe, one should not forget that its joints should not be located in the thickness of the ceiling. Existing gaps must be filled with the selected fireproof sealant. By and large, installation of a ceiling-passage assembly for a bathhouse or home comes down to installing a pipe in the wall and connecting it to a vertical chimney.

At the same time, if the house is built of wood or using frame technology, then you should be guided by the same rules as arranging a chimney through the ceiling. In other words, you should also make an opening here, but in the wall and install a ready-made box or make it yourself. Then fill the internal cavity with a heat insulator and cover both sides with metal sheets (made of galvanized iron).

Construction norms and rules SNiP for polyurethane foam

Standards for installing a chimney and ceiling units, as well as recommendations for operation, are in SNiP 41-01-2003. The document provides safe temperature conditions for various buildings and structures, and lists the sizes of chimneys and ceiling units. If you purchased a factory ceiling assembly, then you do not need to look at SNiP; the manufacturers did this for you. All you have to do is install the product and read the instructions, which are necessarily included with the ceiling unit.

For those who are curious, I will still give the key dimensions and recommendations:

- Sleeves for ceiling passage units must be made of non-combustible materials.

- The cross-section of the sleeve must be wider than the diameter of the chimney to ensure convenient installation.

- The cutting (pipe passage devices) in the roof must be made of fire-resistant materials.

- The cutting is carried out at least 50 cm when the chimney channel passes through areas with combustible structures. For fire-resistant materials - 38 cm.

- You should not use a rigid connection between the groove and the ceiling to prevent curvature of the chimney.

- Retreat, i.e. the distance between the chimney and the nearby enclosing structure (wall, etc.), for combustible materials - from 26 to 50 cm, for non-combustible materials - from 20 to 38 cm.

When calculating the offset or groove width, the insulation of the chimney itself is taken into account. For example, if the chimney is made of a pipe with 5 cm insulation, then the minimum setback in a brick house will be: 20 – 5 = 15 cm. But it’s better to do more!

A number of rules for fastening the passage

To correctly install a metal chimney to a wall, you must follow simple rules:

- For a pipe with a tee and a condensate drain in its lower part, it is best to use a special bracket.

- When installing sections one into another, the chimney should be secured to the wall using clamps every meter.

- It is necessary to ensure that the fastenings do not coincide with the joints of the sections.

- When going around the roof overhang, it is necessary to use elbows whose angle is only 30° or 45°.

If the installation of the drainage system has not yet been completed, then you should leave space for laying the gutter using fasteners of a suitable length.