It just so happened in Rus' that people cannot do without a bathhouse. The tradition of floating the body has come to us since ancient times. And therefore, every owner of a plot of land, after building a house, thinks about his own bathhouse.

A real Russian bathhouse is a wooden frame. But what kind of rock to build it from is up to the owner.

The most popular are pine and aspen. And which material is still better suited for these purposes can be found out by comparing them with each other.

Choosing what is best for a bath...

To understand what you are dealing with, it is correct to compare different options. We have already written about the popular dilemma of choosing between linden and aspen, now we will consider two other pairs that are compared a little less often.

Pine or aspen

Be prepared for the fact that there will be no clear answer. Because first of all you need to look at the quality of the same pine and the same aspen - there are regions where one is better than the other.

By the way! According to tradition, pine was usually used to build a house, and aspen was used for baths.

But it is always difficult to obtain good, functional aspen without rot inside ; there is a lot of defects at the selection stage. Here, by the way, is a big piece of advice for the owner of a future bathhouse - check each log yourself when purchasing - so that the core is intact, it suffers primarily from rot.

You need logs - 15-20 centimeters or more, so be careful - trees of this thickness most often have a problematic core.

ON A NOTE! Rotting aspen is accompanied by the smell of vanilla - if you smell it, put the log aside from healthy ones.

In this regard, pine is less susceptible to rot and pests, but it swells greatly from water. And resin is a problem in a steam room.

pure pine without interior decoration of a steam room , so there is no need to say which is better: a bathhouse made of aspen or pine - the choice lies between a pine bathhouse with aspen lining inside the steam room or an aspen bathhouse without lining trim.

If you prefer a log house in its pure form , if there is no need for additional insulation, then make it from aspen - everything will be fine, it will only become harder later, water “hardens” it.

If there are problems with a good aspen, if you know that a poplar in instead of it (they are relatives, the wood is very similar, but its quality is different, aspen grows in a swamp, hence its resistance to water, poplar does not have it), then take a good construction pine , build a log house from it, and protect yourself from resin with a clapboard made of aspen or linden (or other hardwood). See more information about pine here.

Alder or aspen

But here it’s more interesting - both are deciduous, both are suitable for finishing a paired room. As for a log house, aspen is definitely suitable for its construction, and alder is considered a good interior(!) material - its characteristics are similar to linden.

Therefore, we would risk recommending the following: focus here on the quality of the material. Since there is little good aspen, and specifically in your region there is good alder, you can build from it, but on condition that the lower crowns are made of oak or larch (contact with water and soil for alder leads to rotting).

BY THE WAY! The rule of the lower crowns, that is, making them from more durable and rot-resistant species, can be applied to aspen - only you will make it better.

In addition, the areas under the windows - this is a reason to take care of additional protection of these areas or to abandon windows as much as possible, leaving only the necessary ones.

In general, in the question of what is better for a bathhouse: alder or aspen, we place our bet on aspen, relying in this, as you already understand, on tradition.

What types of wood panels are there?

When you go shopping, please note that these planks come in several varieties. Namely:

- “Extra” class products. This includes perfectly smooth and clean products. Such panels do not have natural defects or knots. The wood itself is white and smooth. The tone of the product is uniform along the entire length of the bar. This group is characterized by the highest cost.

- Finish category A. Small knots are occasionally found on such products. There may be slight differences in the shade of the panels. The products are characterized by high strength, but are no longer as smooth as the previous version. This material costs a little less than “Extra” aspen lining. It can be used for finishing any surfaces.

- Grade B panels. Such materials are characterized by the presence of a small number of nicks, scratches and knots. The boards differ in the color of the wood and may fail earlier due to fallen knots.

There is another option - class C products. This group includes low-grade materials.

They are characterized by a large number of falling knots, cracks and even rot. The cost of such products is minimal, but they can be used exclusively for rough work.

Service life of an aspen bath

Of course, no one can predict the service life of an aspen bathhouse specifically in your case. Wood is different everywhere, and aspen is capricious - it is advisable to cut it down in the spring, and select the trunks so that there is no rot even in the initial stage.

During operation , you can also extend or shorten the service life - it depends on whether you have provided all the conditions for drying or not.

From the outside, the structure is exposed to atmospheric precipitation, so it is advisable to treat the log house with antiseptics and water-repellent impregnations - this will also have a positive effect on its service life. We wrote about processing logs for log houses here, and about processing timber here.

And you shouldn’t believe those who say that antiseptics on the outside will affect the atmosphere inside - even industrial processing does not penetrate the log deeply, and independent impregnation goes no more than 3-5 mm . Therefore, it requires renewal every few years.

Inside, as already mentioned, there is thoughtful ventilation , plus, possibly, water-repellent, harmless impregnation with oil or oil wax. This is essential for the steam room and washing room; in other rooms you can varnish, paint – whatever you like.

Well, if you need at least some numbers, we found these on one of the forums: the builders themselves give the average log bathhouse made of aspen 20 years , but if the wood is selected well and the conditions are provided, then the bathhouse can last for half a century .

Properties and characteristics

Aspen belongs to the extensive genus of poplars, the willow family. According to the structure of the trunk, this is a coreless, diffusely woody tree species. In Russia, this tree is found everywhere in the European and Asian parts of the country, from deciduous forests of mid-latitudes to tundra zones.

This tree grows up to 150 years, but the cause of its death is often not age, but rot that affects the core of the trunk, so trees between 30 and 50 years old are usually chosen for industrial felling. During this time, the tree reaches a height of 35-40 meters.

Aspen wood is dense, with poorly visible growth rings, and uniform in structure. The moisture content of the wood in the central part is lower than in the peripheral areas of the trunk. The color of the wood is white, grayish-white, sometimes greenish. In the cut, it is impossible to notice the rays emanating from the center. For some decorative work, such wood is valuable precisely because of its uniformity. After staining or painting, the structure of the wood remains uniform and does not reveal any structural elements.

The moisture content of a freshly cut tree is about 82%, while the maximum moisture content of this wood (when soaked) reaches 185%. With high atmospheric humidity, aspen quickly absorbs water, but also quickly loses it when drying, which is a positive quality.

In terms of resistance to biological factors, wood belongs to the lowest, fifth class (according to the ISO EN 350-3:1994 standard).

There are a total of five classes in the above standard. The first class of resistance includes, for example, Indian teak and Australian eucalyptus. Larch and oak are classified as class 2 in terms of wood stability. In Russia, the resistance of a tree to the effects of fungi and mold is determined in dimensionless conventional units. According to the Russian classification, resistance to fungi is 1.2 units for mature wood, and 1 for aspen sapwood.

Chopped sauna

Since both a round log and timber ( or rectangular in cross-section) can be used as a building material for a chopped bathhouse, we decided to talk about both separately.

From timber

You need to understand: a log with a diameter of 15 and a beam with a side of 15 cm are different source materials in thickness, because to make a beam with a side of 15 cm you need a log a little more than 20 cm in diameter. Remember the Pythagorean theorem and calculate how thick a tree is needed for a 20 cm beam.

What is this for? Moreover, aspen timber will be more expensive than logs - because its production requires older, thicker trunks, and they are most often rotten inside. Yes, and you still need to look for straight aspen. As a result, we get material that required more careful selection than a log of the same diameter.

is no different from a log house in terms of choosing the material and caring for it The only difference is the greater likelihood of core rot, which must be discarded, but otherwise everything is the same. Protect from moisture, dry and it will last a long time.

Here is another video in which you can see how unevenly the aspen frame has shrunk:

Log house: pros and cons, reviews

If we compare the pros and cons of a log bathhouse made of aspen, the reader himself will be able to come to the conclusion whether he wants to build such a bathhouse for himself or not.

But it’s probably worth starting with the fact that it is not true that aspen used to be used for firewood, but is now sold at exorbitant prices for bathhouses. The aspen tree is full of parts unsuitable for construction, which are used for firewood and matches, and this can be a part, or maybe the whole trunk.

The part suitable for construction is usually small and located high above the ground . The yield of timber is usually small, and there is still drying ahead, during which the tree may warp, so aspen that is not rotten or warped is a rare and good material, and it can also be expensive.

And if we talk about the advantages and disadvantages, then only high-quality material.

Let's call the disadvantage of an aspen bathhouse that it is less resistant than other species to the action of fungi that cause rotting. But coating with antiseptics and other impregnations solves this problem.

The second disadvantage is that wood for construction must undergo a long drying period or it is accelerated drying using modern technologies. Otherwise, the under-dried wood will greatly change its dimensions during drying.

IMPORTANT! However, they try to cut and process aspen while it is not yet dry, because the ease of processing depends on the presence of juices inside. It is known that the drying wood of this tree becomes more hard and dulls the instrument.

The advantage of aspen baths is that hardwood is used, which does not emit resin. It is perfect for a couple's room.

Aspen is a little better than linden in terms of technical characteristics and a little cheaper than linden. Among deciduous trees, ash has excellent characteristics, but we take the most common options from the species of this category.

Reviews about aspen baths, as expected, are ambiguous; there are both ardent supporters and opponents of this wood, based on their own experience of interacting with it.

What can we say? That a lot depends on the handling of this wood. The advice given above was not given out of the blue - you can rot a bathhouse in three years before major repairs. And the original quality also affects a lot - if the core is rotten, then you can’t expect anything good.

On the other hand, there are many people who have observed the durability of an aspen bathhouse in their own homes or in their neighbors, relatives, and acquaintances. But then we had a question: what were these long-lasting baths like? To put it bluntly, this is a completely different system, it has a lot of ventilation and a layer of soot on the surface acts as an antiseptic, so you can’t rely on such a bathhouse today. Wood harvesting also matters - if everything is according to the rules, then you can count on durability.

There are many nuances, and reviews depend on them. If you decide to build from aspen, be sure to protect and ventilate it.

Installation

Sheathing a steam room with your own hands is quite simple if you do everything according to the rules and do not deviate from the installation instructions for this particular finishing material. You should not violate installation technology, since the profile, if installed incorrectly, will quickly become unusable.

Although the aspen profile has a high level of moisture resistance and has a considerable margin of safety, this will not save the panels, if installed poorly, from rapid wear of the material. To avoid negative consequences, a number of necessary requirements must be met:

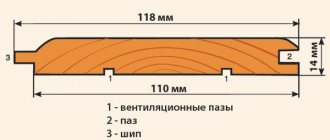

- Mandatory gap between the profile and the wall to ensure ventilation;

- If the wall is subject to moisture or is itself damp, then it is necessary to treat such a wall with a moisture-proof solution;

- Impregnate the wooden planks of the sheathing generously with primer to prevent the appearance of rot and bark beetles. Also, the sheathing should be impregnated with a fire retardant compound;

- The profile is also treated with protective solutions, after which it must be dried in the yard or on the balcony, and then the panels are put into a steam room - a day before the start of work. During this time, the lining adapts to room temperature and, in general, to the atmosphere of the steam room. This condition must be met to avoid deformation of the panels after installation due to significant temperature differences.

The lining can be installed in three ways: horizontally, vertically and diagonally. The preparation of the walls will depend on which installation method you choose.

Another thing is important: no matter how you install your panels, the sheathing should be positioned perpendicular to your profile.

Laths for sheathing are selected based on the quality of the walls; as a rule, a lath with a cross-section of 40x20 mm or specialized metal profiles are used. If it makes sense to increase insulation by adding a layer of insulation, the slats can be thicker. A distance of at least 400-500 mm must be maintained between the guides. The length of the guide must correspond to the height or width of the walls, it depends on the installation method (horizontal or vertical). If the guide is shorter, the length is increased with an additional beam, the main thing is that the beam is in line with the butt rail.

The sheathing is fixed to the wooden wall with self-tapping screws, but if you have a brick or stone wall, then you need to use dowels. Additional bars are attached around window and door openings, to which platbands and wooden panels are mounted. Holes for sockets and other decorative inserts, as well as for various fasteners, are drilled using a drill attachment - a crown.

After installing the sheathing in your steam room, it is highly recommended to coat the decorative areas of the surface with wood varnish. This procedure will not only significantly improve the appearance of your steam room, but will also significantly increase the service life of the material you have chosen.

Some people use paint instead of varnish, but in this case the unique texture of the wood itself is hidden. The panels should be varnished every year, or at least once every three years. In this case, your profile will be in excellent condition for a long time.

It is important to understand that varnish is a flammable material, so after you have applied varnish to all panels, you need to cover the surface with a special fire retardant solution. Apply the solution to the surface with a roller or brush and then allow it to soak in.

The initial and final aspen panels are fixed at a distance of about 5 mm from the ceiling and walls. This is done to increase ventilation between the panels and the wall. After installing the initial and final panels, minor defects may be revealed, including hidden nail heads or screws; such defects are perfectly masked by baseboards or decorative inserts.

This cladding will serve you faithfully for many more decades; aspen reacts remarkably well to aggressive influences and will not crack, especially with proper use and proper care. Aspen lining for a bathhouse leaves only positive reviews from craftsmen who have dealt with this material, and this material is also widely in demand among modern consumers.

Finishing with aspen lining

A good alternative to building an aspen log house is finishing it with clapboards made from this type of wood. In this case, you can choose more resistant wood for the log house or even build a bathhouse from less traditional materials - frame, brick, foam blocks.

Aspen sauna lining is intended primarily for steam rooms . For the rest, you can use any other breed. Which, by the way, is very convenient, because we haven’t heard about logs made of different types of wood for rooms, and there are no such problems with finishing - you can choose any characteristics to suit your taste.

So what we're saying is that outside of the steam room, you don't need to clap the walls with aspen unless it's part of the design plan. After all, everything has its advantages and disadvantages

Aspen lining: pros and cons

Light-colored, fine-fiber lining, its hardness varies significantly depending on the degree of shrinkage - from soft, like linden, to such that the tool bounces off. However, the latter is more about logs, and thin lining in any condition can be cut.

The main disadvantage of aspen lining for a bathhouse is that it darkens over time. This happens with all wood that is regularly moistened, but in aspen it is more pronounced. If you compare it with linden, for example.

Aspen darkens from water

But this is a decorative flaw inherent in this particular wood. By the way, you can always get rid of it using chlorine bleach - special for baths or regular “Whiteness”, which is a solution of sodium hypochlorite.

with water-repellent impregnations based on linseed oil or beeswax can protect against darkening It is possible to use other oils, but not sunflower oil, of course. We wrote about wood bleaching here.

The advantages of aspen lining in a steam room are that it does not emit resin, is available at the lowest price among other species, rooms decorated with it look more spacious because it is light (at least at first