How does the Buleryan stove work?

The Buleryan stove is often compared to a potbelly stove and a regular long-burning wood stove. We can say that the device took elements from both.

The operation of the oven is based on the principle of convection. Pipes for heat exchange are connected to the volumetric secondary chamber, in which the process of burning wood occurs. The principle of their operation is very simple. Cold air enters the pipe at the base of the Buleryan stove, and then comes out already heated at the top of the structure.

The furnace body can be of two shapes. For small rooms, cylindrical Buleryan stoves are most often made. For a large heating area, the stove takes on a teardrop shape. Pipes are placed on the outside of the structure. To ensure maximum heat transfer, they are soldered into the structure and protrude by only one third.

Operating principle of the Buleryan stove

The furnace firebox consists of three parts. A grate or fire-resistant mesh is placed at the bottom of the firebox. They can be made of cast iron or steel with a thickness of at least 4 millimeters. There is a special compartment at the top of the firebox. It is obtained thanks to a partition, for the manufacture of which a steel sheet is used. This compartment is also called the secondary chamber. In it, the combustion of gases occurs, which are released during the burning of wood. Combustion of fuel in the furnace itself is not complete. The released combustion products pass into the chimney. The length of the chimney is about 1 meter. Due to this part of the furnace, the combustion process becomes slower, and the combustion products cool down. The chimney is made curved and contains an economizer. Thanks to this device, secondary combustion of gases occurs. This stove structure increases heat transfer by 20% compared to other stoves.

The combustion process of wood is regulated using a damper. The damper is a damper near the exit from the firebox that regulates the intensity of the draft. It is attached to the pipe using a special metal rod. On the door, by changing the position of the gate, you can regulate the intensity of the oven.

Scheme of the Buleryan furnace

The Buleryan stove is enough to heat a room of 100 m3. This will take no more than 3 hours. Large designs of the Buleryan stove are suitable even for heating large rooms, up to 400 m3. Not every oven can cope with such a task.

Keeping warm is also easy. Buleryan is an economical stove that requires adding firewood only twice a day.

Tips for use

The Buleryan long-burning stove is used as follows:

- It is heated to high temperatures using wood chips, finely chopped firewood, paper, cardboard and other flammable materials. The fire ignites when the throttle and damper are open, but the door is closed;

- After the first portion of fuel turns into hot coals, large firewood and even whole logs of wood are placed in the firebox. The throttle moves to the extreme position, the gate closes;

- The fuel smolders slowly, and warm air (60-70°C) comes out of the stove pipes. After 8-12 hours, the firewood finally burns out. But if you replace them in a timely manner, the device will continue to operate as usual.

We remind you that before heating the Buleryan stove, you need to open the throttle and damper.

Buleryan device with a water circuit

The Buleryan wood-burning boiler with a water circuit has a simple and effective design. The equipment is equipped with levers to control the combustion process, a power regulator, a gasifier, and a large combustion chamber. Afterburner injectors are located in the front pipes.

Setting up the stove is easy, it is done using levers, the combustion chamber is sufficient for a large volume of fuel, but it is recommended not to fill it completely. To increase efficiency, ash is also left in the firebox during operation.

An example of a buleryan with a water circuit

Buleryan device with a water circuit

The Buleryan wood-burning boiler with a water circuit has a simple and effective design. The equipment is equipped with levers to control the combustion process, a power regulator, a gasifier, and a large combustion chamber. Afterburner injectors are located in the front pipes.

Setting up the stove is easy, it is done using levers, the combustion chamber is sufficient for a large volume of fuel, but it is recommended not to fill it completely. To increase efficiency, ash is also left in the firebox during operation.

An example of a buleryan with a water circuit

Operating principle

General operating principle of the furnace:

- a manifold is placed on the convection pipes to connect the return and supply;

- during heating, pressure is created, the liquid can rise to a height of up to eight meters without using a pump;

- when pressure is created, the coolant flows to the radiators of individual rooms (a slight slope of the pipes is used for natural circulation);

- From the radiators, cooled water flows to the boiler for heating.

The principle of operation of a buleryan with a water circuit

Advantages and disadvantages

Buleryan has the following advantages:

- standard radiators are used for heating;

- the stove can be used for buildings without basements;

- connection to any heating system is available;

- the structure is assembled from heat-resistant steel that can withstand negative operating factors;

- installation of the structure is quick and does not require special knowledge.

Among the disadvantages, it is necessary to note the strict requirements for the arrangement of the chimney and the impossibility of operating the structure without a water jacket

Characteristics and selection criteria

The characteristics are, first of all, determined by the parameters of the room where they are going to install it.

For production, steel and cast iron are mainly used. Buleryans made of cast iron have great reliability and durability. At the same time, they are more massive and difficult to use in small rooms. Steel heaters are well suited for small spaces, but at the same time, they have less efficiency compared to cast iron ones.

The second important parameter is the number of water circuits of the heating system. A single-circuit system is designed for space heating only. In addition to heating, the dual-circuit system heats water for domestic needs.

The third parameter is the manufacturer of the solid fuel boiler. In this choice, you can rely on the reviews of people who have already become happy owners of a boiler from this manufacturer.

The remaining selection criteria do not depend on the parameters of the room and the boiler itself. This is the volume of the room, the material of the walls and ceilings, and the height of the chimney.

Choice

In order to choose the most optimal oven option, you need to pay attention to a number of indicators:

- power;

- availability of auxiliary functionality;

- manufacturer;

- price.

All technical and operational characteristics of the Buleryan heating stove can be found in the instructions that are included with purchase. It also clearly states how much room a particular model can successfully heat.

An excellent variety is the Buleryan stove with a hob, which not only successfully supplies the room with heat, but also allows you to cook food.

There is a wide variety of models on the market that can be installed in a garage, bathhouse, or country house. All of them are distinguished by high performance characteristics, great efficiency, and attractive appearance. Therefore, everyone can choose a model that will satisfy all their needs.

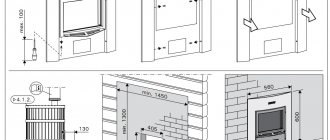

Installation of the Buleryan stove

The oven is mobile. Installation and dismantling of the product is not difficult. Installation does not require specialized education.

A person with minimal technical knowledge can perform the work.

Fire safety standards for installation

Buleryan is a furnace, some surfaces of which can heat up to high temperatures. This should be taken into account and fire safety standards must be observed during installation.

The stove is installed:

- on a non-combustible base. If the floor in a room is susceptible to fire when exposed to high temperatures, it is necessary to arrange a specialized area on which the product will be installed;

- distance to walls. Before installing Buleryan, you need to choose the right installation location. The stove heats the room by heating air masses. When choosing a location, you need to take into account the distance from the stove surfaces to the walls.

This parameter depends on the material from which the vertical surfaces are made. For wooden, unplastered walls, a minimum distance of 1 m is required. for concrete surfaces this figure is reduced.

Is a foundation needed for Buleryan

The location and method of installing the boiler differs depending on the preferences of the owner of the room and the materials from which the surfaces are made.

At the installation site, it is necessary to equip a specialized platform made of non-combustible material. Typically, a sheet of metal is used or a foundation is fabricated.

Some experts mount the stove on a stand made of a profile pipe.

The foundation is made with a height of 10–30 cm. The material for arranging the site can be brick, cinder block, concrete, etc.

The overall dimensions of the foundation must exceed the dimensions of the boiler. The protrusion located under the fuel loading hatch should protect the floor covering from sparks and heat.

Possible mistakes

When installing the Buleryan stove with your own hands, it is important to maintain all the necessary distances to vertical surfaces. This will ensure fire safety and free access to the boiler for maintenance.

Installation

When installing the Buleryan heating stove, it is necessary to maintain a distance from the walls, which are provided for by fire safety requirements. This gap is determined based on the material of the walls:

- between the stove and unplastered wooden walls a distance of at least 1000 mm must be maintained;

- the gap between a 25 mm layer of non-combustible plaster and ceramic tiles is 700 mm;

- single brickwork - 500 mm;

- double brickwork - 300 mm.

One of the most important conditions for installing Buleryan is the base (stand under the stove). It is important that it is non-flammable. For example, you can use 4 rows of bricks that are laid flat. The solution is a clay mixture.

Buleryan stove mounted on a stand

The dimensions of the base should be 30 cm larger than the dimensions of the stove. Also, a metal stand for the Buleryan made of pipes can act as a non-combustible base. Its height is 150-300 mm. Regardless of the method, in front of the furnace itself you need to place a sheet of metal with dimensions: w*d, 500*700 mm.

Particular attention should be paid to the installation of the chimney of the Buleryan stove. The procedure must be carried out according to standard requirements (the only exception is that it must all be well insulated).

The chimney pipe can be made from:

- brick, wall thickness 120 mm;

- concrete with a wall of 60 mm;

- metal

The parameters of the chimney depend on the specific model.

DIY installation of a heating stove "Buleryan" with a water circuit

Many people wonder whether it is realistic to do such an installation themselves and whether it will save money.

It is not difficult to build such a stove, because no special skills are required. To do this, you need to stock up on certain materials and tools. If you do not have any equipment, you can rent it at any repair shop.

Materials required to make the stove:

- pipes with a diameter of 5-6 mm;

- sheet metal with a thickness of 2.5 mm and more;

- gas cylinder;

- welding machine;

- angle grinder;

- Bulgarian;

- pipe bender;

- metal scissors, electrodes.

The furnace is built according to previously prepared drawing. As a basis, you can take the plan of a small stove for a utility unit and adjust it to the required dimensions.

Before work, it is important to practice welding seams: they must be strong. The safety of the entire system depends on their tightness.

Next, you need to prepare the parts of the furnace. To do this, you will need eight pieces of pipes (air ducts) of different lengths - from 1 to 1.5 m. Wide strips with semicircular ends must be cut from sheets of metal. All these parts bend at an angle of approximately 80 degrees.

The front and rear walls of the structure are made similarly to each other. First, a template is drawn, then a part is cut out of sheet metal using it. A loading window is cut out on the front wall, shifted slightly lower in the center. After this, strips of metal are welded along the entire diameter of the window, and from the outside. As for the rear wall, a hole is cut in the upper part in accordance with the dimensions of the pipe. A T-shaped pipe with a valve is mounted into the resulting opening, which is then welded to the body.

The air ducts are installed in a staggered pattern, starting from the rear wall. The outlet part of the rolled metal product must go outside. This design must be accurately calibrated and installed. Additionally, wooden blocks are used. Next, the seams are sealed at the joints.

The bottom wall is welded on the inside of the structure. To prevent the sheet from moving, it is first fixed pointwise, then along the entire perimeter. Ready-made metal strips are welded between the pipes.

The door for the Breneran stove with a water circuit is like a short cylinder. It must be designed to fit perfectly into the collar of the loading window. To increase the reliability of sealing, asbestos rope is used.

The next step is to cut out a hole for blowing, where you need to weld a pipe with a throttle valve. This element is quite simple to make. To do this, the pipe is cut along the axes and a flat disk with a pin is inserted. In addition, it is necessary to install a heat-reflecting screen on the inside. The fire door is hung on hinges and equipped with a lock. Similar parts can be made from leftover sheet metal or purchased ready-made.

Buleryan long-burning stove from a gas cylinder

Buleryan from a gas cylinder

A simple configuration of a Buleryan stove for self-production, the basis will be a used old gas cylinder. This will be a combustion chamber and will help avoid the additional work of welding the base. This configuration of the Buleryan stove is the most accessible for making at home, without special equipment.

Scheme drawings dimensions

Buleryan’s DIY diagram below provides complete information on the size and complexity of this design.

Material

- The metal is no thinner than 3 mm for the ash pan.

- Cast iron door purchased or prepared in advance.

- Reinforcement or pieces for legs and grate.

- Used gas cylinder.

- For a chimney (pipe blank).

Tools

- Welding + electrodes.

- Grinder or grinder.

- Metal brush.

- For markings, chalk, marker.

- Roulette or ruler.

- Electric drill with drills of the required diameter.

- Pliers, hammer, chisel, metal file.

Step-by-step instruction

Step-by-step diagram for assembling a Buleryan stove

Before starting work, we first prepare the cylinder. To avoid the cylinder exploding, you need to make sure that there is no gas (residues) in it. A simple method is to fill the container with water to the brim, then drain the water and drain the container.

Drawing for buleryan from a gas cylinder

We mark the holes we need on the cylinder: square for the door, round for the chimney. To make a round hole you need either a cutter, or holes are drilled in a circle and then knocked out with a chisel and hammer. Clean it thoroughly with a file.

The simplest method for making a grate, if you don’t have one ready-made in size. We drill holes of the required diameter in the bottom of the oven, i.e. the cylinder.

Holes for ash pan

We weld a box for ash from the bottom of a sheet of metal, weld a door to this box and this box will act as a blower.

Blower for Buleryans

The doors are purchased, or we make them ourselves.

Doors for the Buleryan oven

We attach a pipe from a piece of pipe of the required diameter to the top of the cylinder. And finally, the last step is to secure the boiler to the legs or stand. The DIY Buleryan stove is ready for use.

How to install Buleryan

The main stages of installing a Buleryan heater

- When choosing a place to install the stove, the main thing is to ensure free air convection for better heating of the room.

- The boiler gets very hot during operation, you need to provide a fireproof place for it.

- Under the boiler and in front of the firebox, it is necessary to place a metal sheet on the floor to prevent fire.

- It is recommended to install the stove no closer than 30 cm to the wall and with a distance of at least 60 cm from furniture and other objects.

- if the boiler is located in the corner of the room, then it is advisable to protect the walls with fireproof materials (metal, stone, brick).

- We put the Buleryan stove 20 cm from the floor for natural air convection, for this we mount a stand.

Boiler stand Buleryan

Chimney device

Types of chimney installation: one of them is classic (or traditional). This installation method is used at the initial stage of building a room. The chimney pipe is located vertically and passes through all ceilings.

Types of chimney devices

This method excludes the horizontal arrangement of any nodes. The second method is used at any time, at any stage of the construction of the premises, even after the construction is completely completed. This method is called coaxial; it works more efficiently than the traditional one, as it ensures high-quality removal of combustion products and is less fire hazardous.

Distributing heat throughout the rooms of the house

For the most effective use of the Buleryan stove, in order to heat not one room, but several or the entire house, corrugated pipes can be connected to the heat exchange pipes coming from the stove.

Corrugated pipes are distributed in rooms

The pipes are routed accordingly through the walls of the premises, if necessary through the ceiling. Decorative grilles are installed in the rooms to receive warm air.

Heat distribution between rooms in a large house

However, it should be taken into account that the air leaving the furnace has a fairly high temperature; when passing pipes through partitions and ceilings, the conditions that are provided for the installation of chimneys must be observed. The photo below shows several wiring options.

Heat distribution from a common box

Galvanized or corrugated pipes are used for wiring.

Efficient heat distribution between rooms

Improving the stove design

Buleryan stone finishing

Very often, buleryan is a design element, especially when it comes to a country house or a chalet-style house.

Brick screen for Buleryan stove

But if we are talking about a homemade device, its aesthetic parameters are of course inferior to products made in production.

Buleryan in the interior of a country house

The most successful way of decoration is to use brick or decorative stone.

Buleryan in the interior

To do this, it is not at all necessary to completely cover the stove with bricks; it will be enough to decorate the walls around the boiler or make a background wall-screen behind which the stove itself will be.

Decoration of the Buleryan stove

The photographs show interesting design options for our heater.

Buleryan boiler in a country house

What is the efficiency and can it be increased?

The efficiency of Buleryan, depending on the size and power, as well as the correctness of the settings, is 70-90%. These figures can be increased by 3-5% by installing no more than 6 pipes per unit. Important: Efficiency may decrease if the furnace power is less than the maximum permissible area of the house or other building for the selected model. The Buleryan stove has the following disadvantages that can negatively affect this indicator:

- The use of coal reduces the heat output.

- The efficiency is as promised only when using dry firewood.

- 60% of gases go into the chimney.

- It is necessary to correctly regulate the process of adding and limiting air access.

If all the disadvantages of buleryan are taken into account, the efficiency will increase. Installing glass for the Buleryan stove (in the door of the combustion chamber) will create the effect of a fireplace in the house

Common Mistakes

In order to extend the life of the Buleryan stove, you must adhere to the following recommendations:

- Do not use the device's maximum power for long periods of time. This contributes to rapid wear of the firebox, chimney, and other parts of the system;

- Give up coal. It forms a large amount of condensation and creates too high temperatures. Once again: heating with wood is correct, heating with coal is not;

- Adjust the throttle and damper. They determine the power of the device, fuel consumption, and temperature in the house.

The lineup

It is worth noting that such stoves do not have a large range of models, but this will not prevent you from choosing the most suitable option.

For example, the Breneran-Aqua model.

It allows heating of significant volumes of water, so it is most often used for water heating. Its efficiency is 70%, but with just one tab it can work for almost 12 hours straight.

Another model is a gas generator. It is designed to quickly heat indoor air and can heat 4.5 cubic meters of air in one minute.

Good to know: Breneran stoves, unlike conventional potbelly stoves, can operate without even getting hot. In general, any Breneran model can quickly increase the temperature in the desired room. This allows you to start bathing procedures after just half an hour. But the most important thing is the enormous savings in firewood, with an excellent rate of injection of thermal air.

Advantages and disadvantages of the Canadian stove

Essentially being the same “potbelly stove,” Buleryan has a special charm and charm, doesn’t it?

The specifics of using the Buleryan stove initially required compliance with several mandatory requirements, which subsequently made the unit famous throughout the world. The design of the heating device had to ensure:

- Mobility. Since cutting down trees involves constant movement through the forest, the logger’s stove is constantly transported from one place to another, and from transport to room is carried by hand.

- Compactness. The unit must have a configuration and dimensions that make it possible to install the device in small temporary buildings.

- Safety. Since the operation of a buleryan involves installing a heating device directly in a residential area, its design must exclude the possibility of carbon monoxide leakage. This was made possible due to the sealed working chamber and the decision in favor of a single-door design. Another important plus is that the configuration of the body prevents the body of the furnace from accidentally touching the hot metal.

- Performance. Using forced convection makes it possible to warm up a room in record time. This condition is met thanks to a system of channels that accelerate air exchange.

- Possibility of long-term work. The configuration of the working area and the design of the blower allows the Buleryan to work for several hours from one load of fuel, and firewood, bark, chips, shavings, etc. can be used as fuel. It is not recommended to heat the stove with coal, since due to the high combustion temperature of this fuel, metal the housing overheats and becomes deformed. As a result, the geometry of the device is distorted, the combustion door does not close, and cracks in the places of welded joints.

It is quite easy to circumvent the manufacturers' ban on the use of high-temperature fuel. To do this, it is enough to equip the lower part of the heat exchangers with a manifold and supply air using any blower. Accelerating heat transfer will reduce the temperature of the buleryan to a safe level.

- Simplicity and reliability. When developing the design of the solid fuel unit, engineers took into account that it would be operated in places remote from civilization. To manufacture or repair a Canadian potbelly stove, no special equipment or expensive materials are required, and for a beginner to operate the stove, a little instruction is sufficient.

As you can see, the advantages of Buleryan were incorporated into the design at the design stage. Perhaps the developers had no idea that their brainchild would become so popular and would be used both in everyday life and in production. Of course, like any other design, a convection oven of this type is not without some disadvantages. First of all, the unit achieves its declared performance only when using absolutely dry firewood. When the fuel humidity is more than 10%, the released water vapor prevents the flow of air and reduces the combustion intensity, which leads to a decrease in efficiency. In addition, like any potbelly stove, the Buleryan does not retain heat at all - as soon as the fuel burns out, the temperature in the room begins to drop.

The model range of Buleryan type furnaces contains many types, differing in power and configuration

The disadvantages of the design include the fact that the operation of the stove assumes a gas-generating mode of operation, in which the wood smolders more than it burns. This process is accompanied by increased smoke formation, which leads to the release of harmful substances and tar deposits in the smoke channel. Often the outer part of the chimney and nearby areas of the roof are covered with an oily substance, which does not add any attractiveness to the picture. It is also important that when installing a stove, additional requirements are put forward for thermal insulation and the height of the chimney, otherwise the efficiency of its operation will be reduced.

As you can see, the unit is not without its shortcomings, which both the developers and the owners honestly point out. Nevertheless, the numerous advantages of Buleryan have made this heater one of the most popular units on the market of compact solid fuel equipment.

Brick lining

To increase heat distribution in the steam room, as well as to increase the service life of the stove, a specialist is recommended to create a “protective casing”.

It is not difficult to understand how Brenaren is covered with bricks.

Laying must be done in a checkerboard pattern. To do this, the brick must be soaked in advance. After this, it is shaken, freeing it from excess water, and placed on the cement solution, leveling it with a wooden hammer.

When the installation is completed, the brick walls will need to be dried, leaving the mortar to set for several days. After this, the surface can be finished. At the same time, the first fire must be carried out extremely carefully so as not to overheat the furnace and thereby allow the solution to finally thicken.

Watch the video in which a specialist reveals the secrets of installing a stove and a chimney for it:

Conclusion

Canadian technology, which is used to manufacture heating boilers and their analogues in other countries, is an effective source of heat with low consumption of solid fuel. Correctly configured system will allow you to maintain optimal temperature in rooms of any size. It is important to adhere to the rule: the ratio of the power of the unit and the size of the premises so that the efficiency is optimal. To heat several rooms and/or water for domestic needs at once, it is recommended to choose special systems that use a liquid heat exchanger and gas generation process for their operation. Additionally, the Buleryan stove for a greenhouse or house with a water heating circuit uses the principle of pyrolysis in its operation.

Sources

- https://pechiexpert.ru/osobennosti-ustrojstva-pechi-buleryan-02/

- https://otopleniehouse.ru/pech-buleryan/

- https://pechnoy.guru/pechi/otopitelnye/buleryan/buleryan-s-vodyanym-konturom-otopleniya.html

- https://lucheeotoplenie.ru/teplovoe-oborudovanie/pechi/buleryan-s-vodyanym-konturom.html

- https://househill.ru/kommunikacii/otoplenie/kotel/tverdotoplivnye/osobennosti-pechej-buleryan-s-vodyanym-konturom.html

- https://kotle.ru/otoplenie/pech-buleryan

- https://PechnoeDelo.com/otopitelnie-pechi/buleryan-s-vodyanym-konturom.html

- https://SdelaiKamin.ru/pechi/kak-sdelat-pech-buleryan-svoimi-rukami-opisanie-i-chertezhi

- https://pechnoy.guru/pechi/otopitelnye/buleryan/ustrojstvo-buleryana.html

- https://teplo.guru/pechi/piroliznye/ustanovka-breneran.html

[collapse]