In any house where stove heating is present, it is very important to create good draft in the chimney. A significant element in the gas exhaust system is a device that increases the rate of removal of combustion products. This design is called a deflector; it not only increases traction, but also protects the channel from debris or precipitation. The design of this product is quite simple, which allows you to make a chimney deflector with your own hands - the drawings from which you can make the design are clear and simple.

Important points in preparation for assembly ↑

There are many types of devices that increase chimney draft. There are quite easy-to-manufacture options that are popular - TsAGI, Grigorovich deflectors, chimneys mounted on brick pipes. Although such complex structures as weather vane deflectors have an advantage due to which they are also successful - these devices provide decent traction in any wind direction.

Chimney deflector

What is needed from materials and tools ↑

When creating any of these pipe nozzles to remove combustion products, you can use materials and tools that do not require such special skills as, say, the ability to work with a welding machine. To make a chimney deflector with your own hands, just use:

- a wooden or rubber mallet;

- metal scissors;

- roulette;

- ruler;

- special chalk for metal;

- electric drill;

- manual riveter;

- metal drills;

- hacksaw for metal;

- regular scissors;

- simple pencil.

Types of deflectors

It’s easy to make a device if you have:

- sheet metal, for example, galvanized iron;

- a metal strip or a small steel corner;

- aluminum rivets (drills are selected according to the diameter of the rivets);

- for fastening the product to the chimney, bolts and nuts;

- cardboard for preparing patterns.

Deflector diagram

The first stage of work is drawing up drawings and patterns ↑

Before you start making a chimney deflector with your own hands, prepare drawings on plain paper. For each option, there is a certain ratio that affects the efficiency of the device when removing gases. Therefore, a product diagram is created indicating the dimensions, according to which the required amount of materials will be calculated and patterns will be created for cutting sheet metal.

After preparing the drawings, patterns are made that are subsequently used to construct the elements of a particular device. Having made the necessary patterns, we begin to create a metal structure.

Grigorovich deflector

How deflectors work

A deflector is an ingenious structural device that is attached to the top outlet of a chimney. The name comes from the Latin deflecto - to deflect, and the action is based on Bernoulli's law: air flows flow around the complex surface of the deflector and create a rarefied area above the pipe opening. The stronger the wind outside, the greater the draft inside. The deflector is used for solid fuel boilers, stoves and fireplaces and performs several functions at once:

- increases traction force;

- increases the efficiency of a furnace or boiler (up to 20%);

- prevents reverse draft during gusts of wind;

- protects the chimney from precipitation, debris, insects and birds entering it.

Regardless of the shape and design, deflectors protect the chimney from debris and precipitation and help improve draft

All deflectors perform the above functions in approximately the same way. Let's figure out how the designs of deflectors differ from each other.

Ball-shaped rotating deflector or rotary turbine

This design (brands - “Turbomax”, Rotowent, Turbovent) is attached to the pipe from above, rotates and creates an air vacuum. It looks like a dome and protects the pipe from rain and contamination. Designed for boilers and conventional ventilation. Minuses:

- will work well only in windy weather;

- can be used at exhaust gas temperatures of no more than 200 degrees;

- not recommended for use with solid fuel heating appliances;

- difficult to do on your own, since you have to work with many complex-shaped parts;

- the spherical deflector can spontaneously create draft when the heating device is not working.

It is quite difficult to make a rotary deflector yourself

Deflector-vane

Unlike all other mechanisms, it rotates around the chimney and is the most ingenious and efficient design. Reacting to the direction of the wind, the deflector-weather vane takes the desired position. The grates trap the wind and create a strong vacuum in the chimney. Its use allows you to reduce the length of the pipe above the roof and increases the efficiency of the heating device by more than 20%. When used with a gas boiler, it prevents its spontaneous extinguishing. But making it yourself is quite difficult: the design is also quite whimsical.

The weather vane deflector perfectly compensates for the insufficient length of the chimney

Dynamic deflector Astato (France)

Powerful and modern deflector. Suitable for fireplaces and wood-burning stoves. It consists of conical disks connected to each other by stands with a protective mesh attached to them. The steel body is protected by a polymer coating, so the deflector is able to work in an environment with aggressive combustion products. The grille protects the air duct from debris. The device has a fan driven by a single-phase electric motor, removed from the zone of hot air movement, and temperature and air flow sensors, which themselves regulate the speed of its rotation, creating the draft required at the moment. The work is fully optimized and automated. The big drawback is the very high cost, up to 4 thousand euros. It is impossible to do it yourself.

Astato deflectors operate automatically, but are very expensive

H-shaped deflector

Used for chimneys of industrial facilities and powerful boiler houses in areas with gusty winds. A pipe of equal diameter to the chimney is attached to the chimney. Two more pipes together form a structure similar to the letter “H”. The wind blows into the vertical pipes of the deflector and pulls air from the horizontal jumper, creating a vacuum there and thereby increasing the draft in the chimney. Pros:

- creates a uniform vacuum in any wind direction;

- there is no need for protective caps, because the chimney is structurally closed with a jumper, and sediment and debris pass through the through side pipes without entering the pipe;

- compensates for thermal expansion of the chimney using a thermal compensation system.

Disadvantage: difficult to do on your own.

The H-shaped deflector does not allow water or debris to enter the pipe even without a cover.

Spark arrestor

There is another “stove” problem: stoves and fireplaces emit a certain amount of sparks from the chimneys. This is dangerous for the roof and surrounding buildings. Therefore, spark arrestor devices are installed on chimneys, in which sparks strike a material with high thermal conductivity, lose their thermal potential and go out. A simple spark arrester can only perform this function - be a piece of pipe with holes, for example. But often the designs of the spark arrester and deflector are combined, just as the useful qualities of each device are combined.

The spark arrester acts as a deflector and prevents hot sparks from flying out of the chimney pipe

TsAGI deflector

A simple and effective development of the Zhukovsky Central Aerohydrodynamic Institute. Created in 1944 by V.I. Khanzhonkov. It has an open flow part and works for heating and ventilation. This deflector can be installed inside the pipe, which allows it to be used in ventilation systems. Pros:

- completely prevents the possibility of reverse thrust;

- protects against the penetration of precipitation into the chimney;

- simply made by hand;

- requires the use of the simplest materials such as galvanized iron.

Cons: difficult to clean from resins and combustion products.

The TsAGI deflector is very easy to make with your own hands from available materials

Grigorovich deflector

This further structural development of the TsAGI deflector has a so-called reverse cone. Works better in areas with prevailing upward air currents. Works even in the absence of wind.

Unlike the TsAGI deflector, this device does not have a cylindrical wall

Round deflector "Volper"

The design is fundamentally identical to the TsAGI deflector, only the cover for protection from debris and precipitation is located above the diffuser.

The Volper deflector is structurally almost identical to the model invented at TsAGI

Disc deflector

The deflector is very simple in design and does not have a cylinder. Reminds me of a flying saucer. This deflector works best where low winds prevail.

The tall dish deflector device is best suited for areas with a predominance of low winds

Grigorovich deflector - manufacturing stages ↑

The simplest product is the Grigorovich device, which is easy for most people to make.

Calculations and preparation of drawings ↑

When drawing drawings and sizing this product, the following ratio applies:

- the height of the structure is approximately 1.7d;

- the cap must be made with a width of 2d;

- The diffuser width should be about 1.3d.

Grigorovich's homemade deflector

The symbol d refers to the diameter of the smoke channel. If a different size ratio is used during manufacturing, this will negatively affect the efficiency of the created device.

Based on the drawn drawings, patterns are prepared that are used when cutting galvanized iron into elements, from which the product is then assembled. To do this, transfer the outline of the elements in expanded form and in full size onto the cardboard, using a ruler, tape measure and pencil. When making a deflector for a chimney pipe designed by Grigorovich, prepare patterns for the outer cylinder, diffuser and cap.

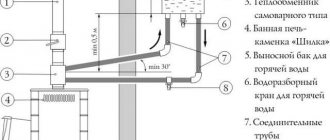

Diffuser calculation

Stages and nuances of making a deflector ↑

Next, the following work with metal is performed:

- Using prepared patterns, outlines of the necessary parts are applied to sheets of metal, outlining cardboard figures with special chalk. If special chalk is not available, you can use a simple pencil. Add 20 mm to the contour of the parts in places where they overlap, which will allow you to maintain the required configuration of the finished elements during assembly.

- Using metal shears, the elements necessary for assembly are cut out of galvanized metal, thereby preparing the expanded outer cylinder, diffuser, and both parts of the cap - the umbrella cap along with the reverse cone.

- Then, using a hacksaw, metal strips or a corner are cut into pieces of the required length, through which all the elements will be connected into the finished product.

- The parts are given the required shape by folding and bending them in a certain way.

- The next operation is assembling the product. The elements are placed on top of each other and, using an electric drill, the necessary holes are drilled. Using rivets placed in prepared holes, the parts are fastened together.

- To install the Grigorovich device on a chimney, you can use two options - in the first case, through holes are drilled at the mounting location, through which the structure is fixed with fasteners on the chimney, and in the second option, a clamp is made from a strip, through which the deflector is fixed to the pipe.

TsAGI chimney nozzle

What is a deflector and why is it needed?

Regardless of the design solution, the deflector is designed to enhance traction

It is known that the most common ventilation system is natural. It has an influx of fresh air and exhaust of exhaust air using different temperature and atmospheric values inside and outside the room. But, unfortunately, for the ventilation system, such a difference in modes is relevant only in the cold season. In the summer months, there is practically no draft in the hood. But during this period it can be “forced” to work. The efficiency of the ventilation system is favorably influenced by a natural phenomenon such as wind.

And in order to enhance this effect, a special device is used in the exhaust part of the ventilation system - a Volpert-Grigorovich deflector. Installed on the top of the exhaust pipe or duct. The work is based on physical laws, namely Bernoulli’s law.

Important! Wind flows flowing around the walls of the deflector from the outside create rarefied air along almost the entire perimeter of the device. This process makes it possible to “suck” exhaust air out of the hood with a fairly large force. To put it simply, additional thrust is created by the wind blowing across the deflector, and it arises even from a small breeze.

Manufacturing procedure for the TsAGI deflector ↑

No less common is the device developed at the Central Aerohydrodynamic Institute (TsAGI). Thanks to its simple design, it will not be difficult to make such a deflector with your own hands.

Preparation of drawings and patterns ↑

Initially, drawings are prepared, during the preparation of which the dimensions of the product are calculated. The diameter of the chimney, indicated by the symbol d, is taken as a basis. When designing a product, use the following size ratio:

- the size of the wide part of the diffuser is 1.25d;

- ring diameter – 2d;

- ring height – 1.2d;

- distance from the lower edge of the ring to the narrow part of the diffuser – d/2;

- diffuser height – d/2 + 1.2d;

- umbrella width – 1.7d.

TsAGI nozzle size ratio

The ease of assembling the product from elements created using such templates depends on how correctly the patterns are made, and in the future this will affect the efficiency of the design. It is necessary to prepare patterns for the following parts:

- diffuser;

- inlet pipe;

- ring;

- umbrella.

Features of creating diffuser and umbrella templates ↑

To make a diffuser pattern, it is necessary to make the correct calculation, which will result in a figure with the required contour. To do this, you need to use the option of creating a truncated cone. The following is taken as the data on which the calculation will be based:

- chimney diameter – d1;

- diameter of the circle by the amount by which the diffuser increases in the wide part – d2;

- diffuser height – H.

Preparing the Umbrella Template

It’s easier with an umbrella pattern. It is necessary to draw a circle whose diameter will be equal to 1.7d. Next - two radius lines so that the angle between them is 30°. Then cut out a pattern from cardboard, not forgetting to cut out the area located between the two radius lines.

The templates for the outer ring and inlet pipe are rectangular in shape, so making them will not be difficult.

Procedure for manufacturing the TsAGI deflector ↑

After preparing the templates, work with metal begins. When making a deflector for a pipe with your own hands, do the following:

- Using patterns, the necessary contours of parts are drawn on the metal. At the same time, 20 mm are added in places of overlap. The lines are drawn with special chalk or a simple pencil.

- Using metal scissors, cut out the parts along the drawn contour in expanded form.

- Using a hacksaw, metal strips or a metal corner are cut into pieces of the required length - these pieces will be used to fasten structural parts made of galvanized iron.

- The cut out elements are bent properly, holes are made in the overlapping areas, and the edges are fixed with rivets.

- Next, the product is assembled - the elements are drilled in places where they overlap each other, and through the resulting holes the parts are secured relative to each other with rivets.

- The structure can be attached to the chimney in two ways: make holes for fastening in the inlet pipe, or additionally make a clamp from a metal strip, for which you will need a bolt and nut.

Adapter option for rectangular chimney

Fan - advantages and disadvantages

An exhaust fan can speed up the air flow 3-7 times. At the same time, the volume of gases removed per unit of time increases by the same amount.

Besides:

- the active system allows you to increase traction simply and at minimal cost;

- The hood parameters do not depend on the weather. Does not affect the hood and indoor temperature;

- conditions for reverse thrust are excluded;

- it becomes possible to regulate the rate of smoke removal depending on the operating mode of gas and furnace equipment. When the heater power decreases, the fan speed is reduced.

To remove smoke, a smaller cross-section of air ducts is required due to rapid air movement. This means that an active chimney requires less material during manufacture.

A modern chimney fan is protected from rain and leaves. It is installed on the pipe using special fasteners

But there are also disadvantages:

- the fan consumes energy. Due to this, the operating costs of the heating system increase;

- You need to run a cable to the motor. This is not so easy to do. The active hood is placed on a pipe, and it is not advisable to make holes for the wire in the roof;

- It is necessary to provide measures to protect the impellers from precipitation and icing.

The listed disadvantages must be taken into account when moving to active smoke removal. Then the disadvantages can be neutralized.

Taking into account the positive properties of active exhaust hood, the smoke exhauster is installed on the chimneys of modern cottages, in houses, when installing fireplaces using wood or briquettes.

Requirements for the exhaust device

Not every engine with an impeller is suitable for working with carbon monoxide.

The smoke exhauster must be:

- Heat resistant. It must be taken into account that when a stove or fireplace is operating, the smoke heats up much more than in the column. The temperature of gases from the fireplace at the outlet of the chimney can reach 300 °C or more.

- Resistant to aggressive gases.

- Economical. When there is wind, the electric motor turns off. The impeller spins as in a rotary turbine.

- Water resistant. Weather conditions should not interfere with smoke removal.

- Effective. The fan must ensure rapid removal of furnace gases at any indoor and outdoor temperatures.

A duct fan for removing smoke is built into the air duct. But more often they use a smoke exhauster installed on a pipe.

The high-temperature duct fan must operate in an aggressive environment. Therefore, it is made from smoke-resistant materials

Do not confuse a chimney fan with a forced draft fan in a fireplace. The latter is designed to ignite and maintain combustion in the firebox. While the boost fan is cut into the chimney, or a smoke exhauster is installed on the pipe. Modern devices for active removal of furnace gases can withstand temperatures up to 600 °C.

An active smoke removal device monitors the temperature of gases and their speed using sensors. The data is used to control the engine and ensure the safe operation of the fireplace, stove and gas equipment.

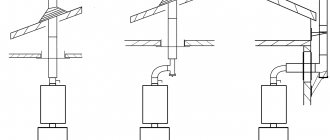

Installation of a fan in a chimney

Before installing the fan on the pipe, you need to carry out a number of preparatory work. The first step is to ensure safe working at height.

To do this, a special ladder is installed on the roof next to the pipe with the possibility of attaching safety elements

Next, mark the places on the pipe for attaching the smoke exhauster, and run a cable to power the engine. Lay signal wires from gas equipment controllers and other energy devices.

At the following stages:

- Mount the fan assembly, eliminate the gaps, and check the tightness of the connections.

- Connect the power cable, connect the sensors to the wires.

- Apply power voltage and start the smoke exhauster.

- Using measuring instruments, check the parameters of the carbon monoxide removal system.

- The installation work is completed and the fixtures are removed from the roof.

- Sensors are connected to power plant control systems.

- They turn on gas equipment, stoves, fireplaces and check the effectiveness of smoke removal again.

To operate a top-mounted smoke exhauster, cables and wires are routed through the roof. This is not always convenient. If you do not need to install a product with the function of a rotary turbine, buy a high-temperature duct fan to remove furnace gases.

Install the device as far as possible from the place where the exhaust air is heated. The installation algorithm for a duct smoke exhauster does not differ from that discussed above.

Making a chimney nozzle with a square or rectangular cross-section ↑

When creating a chimney deflector with a square or rectangular cross-section, you can use two design options.

Use of an adapter in the design ↑

Initially, a drawing and a template are prepared, according to which the adapter will be cut out of galvanized steel in expanded form.

Drawing of an adapter for a deflector on a chimney with a rectangular cross-section

After preparing the patterns, they move on to working with metal:

- Using a pattern, apply the outline of the adapter to galvanized metal. It is necessary not to forget about the overlap area, adding 20 mm to the contour.

- Use metal scissors to cut out the product.

- Then the flat element is bent in such a way as to obtain a product of the desired shape.

- In the place of overlap, holes for rivets are made using an electric drill.

- Use a hand riveter to secure the overlapping edges of the adapter.

- To attach to the chimney, holes are made through which the adapter will be fixed to the pipe using fasteners.

- At the junction of the device and the adapter, holes are also made for the coupling bolts.

Chimney for a rectangular chimney

Technology for creating a simple chimney ↑

The second option is to make a canopy attached to a rectangular chimney. Anyone can figure out the task of how to make a chimney on a pipe with their own hands, since the design is extremely simple and the calculations are simple.

The drawing is prepared on the basis of calculations, thanks to which the required dimensions of the product are determined. Then, based on the drawing, patterns are created that are used to draw the contours of parts onto a sheet of galvanized iron.

Drawing of a chimney for a rectangular chimney

After preparing the template, we begin to manufacture the product itself:

- Using patterns, with special chalk the contours of an unfolded smoke umbrella are applied to a sheet of galvanized iron. It is necessary not to forget about the overlap areas, adding 20 mm to the connection of the edges of the part.

- Using metal scissors, cut out the parts according to the drawn outline.

- Using a hacksaw, cut a metal strip or corner into pieces of the required length. To fix the deflector on the chimney, it is most convenient to use a corner.

- The parts cut from the sheet are bent so that the smoke umbrella takes the required shape.

- Next, the product is assembled by drilling holes in the right places and fixing the parts with rivets.

Option for manufacturing a weather vane deflector

The design of the smoke channel deflector and the principle of its operation

All chimney deflectors have the same design and consist of four elements:

- cylinder;

- diffuser;

- ring rebounds;

- protective cap.

Devices may differ in design, size and number of additional elements, but they all work on the same principle.

The deflector is mounted above the chimney and, in the event of a side wind, creates a vacuum in the chimney. Thus, draft increases and combustion products are removed more efficiently.

Since the structure does not create resistance to the internal air flow, smoke does not flow back into the room and is effectively removed outside the building. In addition, the device protects the channel from dirt and debris and looks aesthetically pleasing.

Research shows that installing a deflector on a chimney increases the efficiency of heating appliances by 15–20%. However, this value depends not only on the deflector, but also on the characteristics of the location and cross-sectional diameter of the chimney.

Self-production of a weather vane deflector ↑

The weather vane allows you to reduce the height of the pipe by increasing traction, since it is always in the right relationship with respect to the wind, prevents precipitation from entering the pipe and decorates the roof.

Tools and consumables for work ↑

To make one of the options for a weather vane on a chimney pipe with your own hands, you need to add to the above tools and materials:

- set of wrenches;

- pipe section;

- a metal (preferably stainless steel) rod or a ready-made pin;

- die for cutting threads on the rod;

- tap for cutting threads for fixing bolts;

- bolts for fixing bearings in the pipe;

- 8 nuts that will need to be screwed onto the rod to secure the bearings and secure the deflector housing.

- two bearings, the size of which is selected according to the diameter of the rod and the internal diameter of the pipe.

Drawing of a deflector in the form of a weather vane