A combination stove is quite practical equipment for bathhouses. Thanks to its advanced configuration, it combines the functions of heating a room and heating water for bathing.

A distinctive feature of such a device is the ability to work on both solid fuel (wood) and gas (natural and liquefied).

This device is quite versatile due to the presence of elements for different types of heating. There are separate devices for burning gas and solid combustible substances.

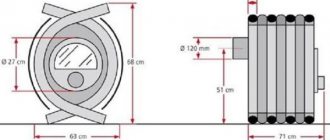

In order to install such a stove in a bathhouse, even at the design stage it is necessary to take into account the large size of the equipment. In addition, there are different models of universal stoves that differ in functionality. Some are designed with an emphasis on heating large volumes of liquid, while others are characterized by ease of use. These features also need to be taken into account during construction.

Operating principle and differences of gas equipment

You cannot objectively judge the quality of the purchased injector. Do not disassemble the finished product in search of possible defects. So there is a chance to damage rather than check an expensive device.

By assembling each element of the burner yourself, you will receive not only pleasant satisfaction from the work done, but also savings. At the same time, the operation and repair of gas bath equipment will become safe and conscious.

The heating gas unit is a sauna stove body with a gas supply device located in it. Here are the main elements of the control mechanism with which the fuel supply is regulated.

The burner heats the air in the firebox. The thermal energy of the nozzle is transferred through the body to the tray with stones

A heating stove with a gas nozzle requires special attention to the chimney, which must be cleaned periodically.

The advantages of heating water and sauna stones with a gas burner include:

- Simplicity of the workflow. To heat up, just turn the valve and ignite the gas in the burner. In an hour, the steam room of the bathhouse will be sufficiently heated.

- Environmental friendliness. During operation of a gas device, harmful emissions during gas combustion have the smallest volume compared to other types of fuel.

- Ease of maintenance of the burner and the stove itself. There is no need to deal with soot from walls and remove waste, as with coal or firewood.

You can equip the oven with special sensors that are triggered at a critically low exhaust speed. In this case, the gas supply is automatically turned off.

Inexpensive fuel from a gasified stove allows you to not limit the number of bath procedures. Even with daily heating of the bathhouse, maintaining cleanliness becomes very easy

Such a disadvantage of a homemade burner, such as additional registration of technical permits, pays off due to high productivity. Using a gas injector will save 30% costs compared to solid fuels. Heating a sauna with gas is two times cheaper than using an electric boiler.

Requirements for installation of furnace equipment

To connect the heating device to the chimney, you need to choose the right pipes: one product must slide into the other in the direction of combustion by at least 0.5 diameters. It is recommended to use pipes made of stainless or roofing steel.

It is important to avoid laying rolled metal products through residential premises: this can be dangerous!

Places where the pipe passes through wooden floors must be thermally insulated. Over time, the wood dries out so much that one day it may burst into flames due to high temperatures. Therefore, the attic must also always be kept clean and tidy.

The section of the pipe above the ceiling must be insulated to avoid condensation. If this is not done, the temperature difference on the inner and outer walls of the pipe will cause water droplets to appear inside the product. In the future, this will cause destruction of the masonry and a decrease in the level of traction. In addition, the condensed liquid dissolves the flue gas, thereby creating acids that corrode the pipe.

Try to use only dry firewood. Burning plastic or glued objects in the firebox can also lead to condensation.

This problem is especially obvious in winter during severe frosts. It is also possible that ice plugs may freeze in the upper part of the chimney. However, insulating the entire pipe will help avoid these troubles.

During installation of the equipment, it is necessary to provide an outlet for cleaning the channel in the smoke system, since over time it can become clogged. To do this, an easily removable section can be made at the junction of the main part of the chimney with the pipe.

An opening 35-45 cm wide is made in the wall between the dressing room and the steam room at a height of 47-55 cm from the base of the stove for the exit of the burner and the front part of the heating device.

The thickness of this wall should not exceed 30 cm, so as not to complicate the maintenance of the equipment during its operation.

It is prohibited to attach the unit to walls or floors and install additional brick structures nearby that may interfere with heat exchange.

There are also some requirements for the waiting room. Among them the following are noted:

- it must be 2.2 m high and have a hood, as well as a window with ventilation;

- it is important that the door opens outward;

- it is desirable that the chimney is located at a level of 5 m above the burner;

- the joints between the duct and the furnace must be sealed, and all pipes in the room must be carefully insulated.

Design features and types of burners

Important parameters of a homemade gas burner are safety, ease of manufacture, suitability for use in specific conditions, and efficiency. There are quite a lot of options for choosing modifications of the device supplying the gas mixture. They are used for heating a house, heating water boilers, even for hiking.

It is necessary to navigate this variety of types of devices in order to make a high-quality sauna burner with your own hands.

Based on the method of air entering the burner, they are conventionally divided into two types:

- Atmospheric , with natural air supply to the combustion zone.

- Fan type , with forced air supply carried out by a built-in fan. They are blown and supercharged.

For DIY production, atmospheric burners are more popular among craftsmen. The simple nozzle design can be improved with additional options. For example, equip the burner with a thermostat, draft sensors, flame control, and gas shut-off valve.

The physical parameters of both the sauna stove and the selected nozzle model should be taken into account. Before you start making the burner, decide on the dimensions

All these functions will increase the reliability and safety of operation, but at the same time they will increase the cost of your product. You will decide for yourself how appropriate the additional equipment is, based on your financial capabilities and the frequency of operation of the burner.

Atmospheric devices

Such burners are one or more hollow metal tubes through which gas fuel is supplied under pressure. Ignition is carried out using a piezo lighter. Atmospheric nozzles are the cheapest and easiest to manufacture.

Usually they make atmospheric gas burners with their own hands. Their advantages are independence from electricity and pressure drop in the gas main

The main disadvantage of atmospheric gas burners is considered to be the need for a constant high-quality air flow. It will have to be equipped additionally in the bathhouse. Typically, an ash pan or an air duct connected to it is used for this purpose.

A ventilation pipe with air intake from an adjacent room is effective. At a low draft level, most of the poorly burned fuel goes into the chimney. This poses a risk of gas leakage if there are microcracks in the brick mass.

Therefore, a brick stove with such a burner requires constant inspection and monitoring of the condition of both the stove mass itself with smoke circulation and the chimney.

Complete set of blowing devices

Fan burners are a unit with a fan, sensors and controllers. Air intake and injection from the street is carried out automatically, the operation of the equipment is controlled automatically. The combustion power in the blowing device can be adjusted according to needs.

Forced uninterrupted supply of air allows you to increase the efficiency of the heating device due to high-quality gas combustion. Accordingly, fuel consumption for heating the sauna stove is reduced.

A fan burner is more difficult to install, but easier to operate. The intensity of the nozzle in such a scheme is easier to regulate using automation

The cost of the equipment is affected by connecting the burner to electricity. In case of possible power outages, it is necessary to have an alternative source, for example, a diesel generator or battery.

Both types of gas burners can be converted from liquefied gas to main gas and vice versa. To transfer, the nozzles are replaced, due to which the volume of the gas mixture pumped into the combustion chamber changes. Replacement nozzles are selected in accordance with the manufacturer’s recommendations, or more precisely with the dimensions indicated by him.

Criteria for choosing a design option

Each type of burner has its own power and gas consumption parameters. An energy-dependent inflatable burner with more expensive components is used for heating boilers in large-volume baths.

To heat small and rarely used rooms, it is recommended to install an atmospheric burner. For a modest-sized bathhouse, a model with a flow rate of 1.5-4.5 m3 per hour is sufficient.

To maintain a comfortable temperature in the bathhouse, you need a burner with an even flame distribution. This problem is solved by all kinds of distribution tubes or flame dividers. They are usually round holes. But sometimes the format is changed to narrow slots; such nozzles are called slot nozzles.

A slot gas burner demonstrates the difference in the physical parameters of the fire when the external shape of the holes changes. This small difference in burner design significantly affects the overall flame pattern.

For any selected type of burner, it is preferable to make a long, elongated outlet. This will speed up the heating of the firebox by increasing the flame area. After all, gas heating is allowed only from the room adjacent to the steam room.

Kinds

Depending on the location of the water reservoir in the design, there are three types of gas-wood stoves:

- Units with built-in heating tank. This equipment is easy to use and low maintenance. The container is made of stainless steel and is installed above the fuel chamber on the side of the heater. This structure of the furnace allows you to heat the stones and water in the tank at the same time. The main advantage of the equipment is that there is no need to drain the liquid. As for the disadvantages, these include the fact that the stove is designed for a small volume of water. In one session you can heat up to 20 liters, and this amount is quite enough for several people.

- Stoves with a tank mounted on a chimney. This design is more practical, as it is aimed at saving heat generated from smoldering firewood. Due to the fact that the tank is installed directly on the chimney, combustion products do not enter the environment, but pass through the water, giving off their heat and thereby warming it up. This system is capable of heating large volumes of liquid for several hours, so you can safely fill a storage tank of 50-75 liters.

- Ovens with a separate remote container. The water in the tank is heated using a coil mounted in the combustion chamber. The storage device can be placed in any corner of the bathhouse, even in the dressing room. Another important point is that it contributes to additional heating of the room. In addition, you need to be very careful when operating the tank, because there is a high probability of getting burned if you accidentally touch it.

As a safety measure, do not forget to periodically release heated water to avoid large accumulations of steam in the room.

It is advisable to use combined sauna stoves only if there is a need to heat water.

To choose the most suitable and efficient unit for a bath, you need to consider the following factors:

- Tank capacity. A large capacity of 50 liters is a good solution for a large family or for installation in an industrial bath. If the room is designed for several people and there is no need for so much water, it is better to choose a built-in storage tank with a capacity of 20-25 liters. It saves space indoors and requires virtually no maintenance.

- Technical conditions. For the main or additional heating of a bath room or dressing room, a stove with a remote tank is well suited. The coil in this case serves as a regular radiator. However, this device has its drawbacks. The first is the mandatory use of the water circuit, and the second is the constant repair, and sometimes the complete replacement of the coil, which tends to clog frequently.

- Terms of Use. The gas-wood stove has a device that allows it to be used for both a Russian bath and a Finnish sauna. The main difference between these rooms is the temperature and humidity of the heated space.

Preparing for the manufacturing process

Having understood the structure of the gas burner and decided on the model, you can move on to the next preparatory step. Make a list of the necessary materials and tools.

The following list can be taken as a basis:

- steel tube 100 mm long and with walls 2 mm thick;

- fuel control valve;

- steel cap, piezoelectric element, rubber for handle;

- welding machine, grinder.

Don't forget about little things like connecting elements. For example, for a valve type VK-74 you need to stock up on a cap with a conical thread.

Description of work stages

Before you begin assembling the burner parts, it is better to have a drawn diagram on hand for convenience.

Self-production technology provides for the following sequence:

- the base of the device, the nozzle, is made using a grinder;

- the fuel dispenser is assembled from a valve and a steel cap screwed onto it;

- a cap is welded to the nozzle, then a piezoelectric element is installed.

When installing a burner assembled and tested by specialists, you must comply with the distance restrictions. It should be no more than 5 meters from the gas nozzle to the end of the chimney pipe.

Modernization of heating equipment

Any home craftsman can install a homemade atmospheric gas burner for a sauna stove. So, without any special costs, a solid fuel boiler can be converted into a gas one.

Equipping an existing solid fuel stove in a sauna with a factory-made gas burner unit will require some adjustment. You will be faced with the need to modify the dimensions of both the burner and the combustion chamber of the wood-burning stove.

Converting a solid fuel sauna stove into a combined gas and wood stove is within your power, but it will require precision and some effort. Do not allow the flame to come into contact with the walls of the firebox

To heat the combustion chamber evenly, the burner should be positioned closer to the bottom of the stove and strictly in the center. It is unacceptable to place the source high and offset in any direction. In this case, the camera will not warm up completely. And the flame from the burner can touch metal parts or the heater of the sauna stove.

Materials used to make a gas oven

There are quite a few options for arranging gas furnaces, and sometimes it is difficult to understand the complexities of installation work. To make the process easier, let’s look at what a gas stove can be made from.

Models made of brick or stone material are practically no different from conventional wood-burning stoves. In principle, these are the same devices, only converted to run on gas. With the help of such stoves, the classicism of the Russian bath is preserved, but at the same time there are significant differences - thermal energy is well retained, the steam room warms up evenly, gas today is a more affordable type of fuel. True, heating occurs slowly, so preference should be given to stone. It is not recommended to build stoves from such materials yourself - it is better to use the services of professional specialists.

Today the manufacturer offers a large number of metal furnaces that run on gas. They are much cheaper than their stone or brick counterparts, and installation work is easier to carry out. Metal stoves are compact, can be installed in small spaces, and quickly heat up a steam room. In addition, it is possible to select a model with the most suitable power, which will allow efficient use of fuel. Installing a metal gas stove in a bathhouse necessarily involves thermal insulation. It is made from the floor with brickwork and sheet steel, arranged along the walls and along the passage of the chimney duct through the ceiling and roof.

Automatic protection system

Unburned fuel in a sauna stove sometimes causes an explosion of the gas-air mixture. Therefore, monitoring the flame of a working nozzle is necessary for your safety. This can be done visually or using automation with modern photocells sensitive to light.

The burner protection system automatically provides the following functions:

- power regulation;

- fuel and air supply;

- completeness of gas combustion.

It is necessary to take into account the increase in dimensions of the modernized design. Especially with small bathhouse sizes. If device size is an important criterion for you, then all automation can be placed outside for compactness.

You can add automatic schemes for working with simple elements. Compact placement will save usable space in a small bathhouse

To control the combustion process, you can use an automatic factory-made installation such as SABK-8-50S. It provides a high level of security thanks to four levels of protection. The operation of furnace gas equipment with such a device will automatically stop in the event of a dangerous emergency mode.

Installation principles

It is better to entrust the installation work to professionals, but if a person is confident in his abilities and does not want to spend money on the work of specialists, he can do the installation himself. In this case, you need to take into account a number of rules:

- The gas pipeline that will pass through the bathhouses must be assembled from copper or steel pipes.

- Hide the pipeline so that it cannot be damaged.

- Flexible connecting sleeves must be solid. You cannot assemble them from individual elements.

- Maintain the distance between the stove surfaces and walls. The minimum is 5 cm, the optimal is 15 cm. Additionally, you need to protect the walls with metal screens that will reflect thermal radiation.

- Flexible connecting units must be resistant to temperature and pressure changes.

- Consider the ventilation system inside the bathhouse.

After installing gas equipment, you need to perform a test run. This will allow you to see possible gas leaks and eliminate them.

Supplying gas to the bath

Sauna stoves with gas nozzles have become a technological breakthrough for people living far from forested areas. Considering the low cost of gas fuel compared to firewood, the cost of heating with a burner becomes completely negligible.

Steam room lovers do not have to limit themselves and use such a bathhouse every day. Only, of course, if health allows.

An uninterrupted supply of gas fuel to a sauna stove can be ensured from:

- Trunk network laid to a suburban area and connected to the bathhouse.

- Gas cylinders that require periodic refilling.

- Gas tank installed on the site either permanently or in a mobile version, suitable for periodic refueling.

The most time-consuming procedure will be the connection to the general gas system of a city or rural settlement. It requires the purchase, installation and registration of gas meters. You will also need to obtain permits, technical and payment documentation.

The gas pipeline in the area with the bathhouse facilitates the task of supplying fuel. Solving technical issues with connecting a reliable gas burner will not be difficult

Connecting a regular gas cylinder will also require inviting a representative of the gas service and preparing technical documentation. Tanks have special placement requirements.

For example, gas cylinders cannot be installed in a bathhouse. They should be located outside in an easily accessible, ventilated place. There must be fire-fighting protective equipment nearby - a fire extinguisher, sand.

Regulatory requirements

A homemade sauna stove burner must have a certificate of suitability from Rostechnadzor. In addition, a special permit is required for operation. When using mains gas as fuel, you must obtain such a document from the gas supply organization.

The following requirements apply to installing an atmospheric model in a bathhouse:

- minimum bath volume 12 m3;

- availability of proper ventilation;

- compliance with fire safety measures;

- the top of the pipe is equipped with a spark arrester;

- good adjustable traction;

- the pipe is insulated from the ceiling and roof.

Cylinders can be placed in a special metal cabinet separate from the bathhouse. Gas tanks are located in an underground container at a distance of more than 5 meters from the bathhouse. The connecting pipes must be checked by a specialist for leaks. They are made of steel, copper and other non-combustible materials.

Fire inspectors have special requirements for the pipeline to the furnace and places where cylinders are installed. Those who ignore the rules are likely to get fined, which will reduce all savings to a minus

As practice shows, it is better not to install a homemade burner without permission from the authorized bodies. It's too risky in terms of security.

Having received permission to operate and all instructions, you should ensure that measures are taken to maintain the normal operation of the homemade sauna stove burner. It is necessary to periodically check the joints of the burner and the pipeline for leaks. If necessary, clean the chimney and strengthen the insulation.

Inspecting the condition of the equipment is not limited to the gas burner. It is important to monitor the insulation of the chimney from the ceiling and roof.

To track the dynamics of changes in the state of equipment, keep a special log. Write down in it the dates and operations performed to service the elements of the gas unit. When heating a sauna using a homemade nozzle, follow the usual fire safety rules.

The following article will introduce you to the intricacies of making a gas burner from a regular blowtorch, which is worth reading for skilled home craftsmen.