For most people, now building a bathhouse on their own site is simply a necessity, because it’s so nice to relax after a hard week of work or invite your friends and take a steam bath, as they say, warm the bones and breathe in the spirit of the bathhouse.

Of course, building a bathhouse is a serious matter, and often requires the help of specialists. But if you have a little experience in construction, carpenter skills, as well as free time and, most importantly, a great desire, then you can start this process yourself.

So, a few simple tips for building a bathhouse with your own skillful hands.

First you need to get organized and determine the main stages of construction and the sequence of actions. You need to choose the most suitable place to build a bathhouse, decide on the type of construction, the future interior, but most importantly, before starting construction you should evaluate your financial capabilities.

In order not to bother yourself with the long development of a bathhouse project, you can order a ready-made project. It is important to have an experienced carpenter nearby during construction.

The size of the future bathhouse depends both on the financial capabilities of the owners and on the size of your site. But do not forget, the bathhouse should consist of such main premises as a steam room, a dressing room and a washing room, and everything else is at your discretion.

The best material for constructing a bathhouse is undoubtedly beams or logs, because natural wood can “breathe,” retain heat for a long time and give a pleasant woody smell.

The method of constructing a bathhouse is in many ways similar to the construction of a conventional residential building, but still, there are some peculiarities in the process of building with your own hands.

What is a bathhouse made of?

The choice of building materials is an important part of the work. It is recommended to use one of the following types:

- Profiled timber has low thermal conductivity and an attractive appearance. The specificity of use is the need to wait time for the structure to shrink and properly caulking. A timber measuring 15x15 cm is used;

- Glued laminated timber is characterized by a smooth surface, durability, and effective heat retention. Expensive, high quality material;

- Planed timber is an excellent construction raw material that provides heat and sound insulation;

- Logs are a traditional material that requires appropriate technologies. It is necessary to take into account the direction of the fibers, and also carefully seal all cracks and cracks;

- Rounded logs are an externally aesthetic material that ensures structural strength. The condition of use is to wait for the shrinkage period for a year. Only after this time can finishing work be carried out;

- Frame elements - construction from panels on a frame - a cheap, simple option. Such structures retain heat well and do not require a massive foundation;

- Brick, a fire-resistant and durable material, unconventional for our country, is becoming increasingly popular;

- Cinder blocks - bathhouses made from them are cheap to build. Feature – short construction time;

- Aerated concrete is a moisture-resistant raw material, like sleepers. Provides durability of the structure, excellent heat retention;

" Important. Wood is considered the most suitable material - its advantages: thermal insulation properties, aesthetic appearance and pleasant smell of wood.

Construction from logs or timber, you can use different technologies for laying elements (in a “bowl”, in a “paw”). The optimal height of the log house walls is 2.5 m. It is recommended to assemble the lower crowns from hard wood. When purchasing construction wood, inspect it carefully. Cracks may increase over time; the presence of blue spots indicates possible rotting inside the logs.

How to make a steam room in a bathhouse correctly

The main part of the bathhouse is the steam room, it is needed to take a steam bath, so making the steam room in the bathhouse correctly should be the main goal of the builder. The most common area of a steam room is 2X2.4 m, height – 2.2 m. As a rule, there are no windows in it; heat escapes through them. It is necessary to provide effective ventilation in the steam room and the entire bathhouse, otherwise fungus and mold will firmly establish themselves on the wooden elements of the interior, and you will have to fight it, and this is just improper ventilation.

Insulation is carried out by covering the ceiling, walls and floor with boards 40 cm thick. It is advisable to use good, thick insulation with foil.

Features of the steam room design include the use of ceramic floor tiles, since there are constant high temperatures and humidity. It is better to make furniture from aspen, which does not release resin at high temperatures. To save space, the benches are fixed against the walls.

The main element is the stove. Brick, metal and electric are used. They are usually installed in the corner closest to the door. The door itself should have a high threshold and a low frame. This protects against drafts and heat loss.

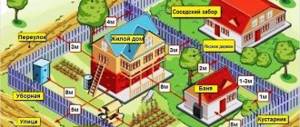

Selecting a location

It is better to choose a flat area for construction so that you do not have to make a solid foundation. The place should not be too damp, otherwise the bottom of the building and the floor will begin to rot.

If there is a body of water nearby, it is better to build a bathhouse closer to it, in this case you can plunge into cool water after the steam room. The entrance to the dressing room is usually made from the south side so that snow does not accumulate in front of the door.

How to properly make a foundation for a bathhouse

Every building needs a foundation. Its filling depends on the weight of the walls of the structure. The foundation is a construction stage that requires large expenses. Cement, sand, gravels and labor are expensive. It is important to make the foundation for a bathhouse correctly, since it is like the root of a flower or a tree, everything stands on it and holds on. Saving on it can weaken the reliability and strength of the entire bath structure.

Experts recommend pouring a strip foundation designed for clay soil. In the case of hard soil, a base height of 60 cm is sufficient. In this case, the freezing depth should be taken into account. It should not be greater than the height of the base. The tape type allows you to build a cellar, retains heat well, and is durable. For air circulation, it is advisable to raise the foundation approximately 50 cm above ground level.

Foundation pouring progress

- Preparing the construction site - marking is carried out using reinforcement pegs and fishing line.

- Digging a pit - based on the deepest point, the depth of the entire trench is calculated. Its width is 10 cm larger than the proposed walls, and it digs 50 cm deep.

- Laying a sand or gravel cushion is necessary to reduce the load; the top layer is carefully compacted and leveled using a level. It is poured to a height of 15–20 cm. Polyethylene waterproofing is spread over it.

- The construction of wooden formwork is a labor-intensive task that provides the shape of the poured concrete. Usually a smooth, durable, cheap edged board is used. The boards are fixed with nails and screws. Must be tightly connected to each other.

- Preparation of reinforcement - provides high strength to concrete. The reinforcement grid should be 5 cm from the edge of the foundation. It is advisable to use a rod with a cross-section of 12 mm.

- Ventilation arrangement - made from plastic pipes 10 cm wide, placed in the foundation. Before pouring, the holes are sealed to prevent them from being filled with mortar.

- Filling - it is advisable to use an automixer. Preparing a solution with your own hands is a labor-intensive process. Recommended cement grades: M-200, M-300, M-400.

" Important. It is necessary to add crushed stone to concrete

Proportions:

- 3 parts stones;

- 1 part cement;

- 3 parts sand.

Water provides the required consistency, and crushed stone provides sufficient strength for the foundation. Filling occurs gradually, it must be monolithic, without gaps. Tapping the reinforcement while filling allows the concrete mass to be placed more densely. After pouring, you must wait a month before starting the next construction stage. During this time, you can cover the concrete with a film and periodically wet it to increase strength.

In addition to the strip foundation, a columnar foundation is popular, suitable for wet soil and having a lower cost. It consists of brick or concrete supports located 1.5 m from each other, placed at corners and walls.

The foundation must be protected from moisture by filling it with hot bitumen and covering it with roofing felt in several layers.

Error at the initial stage of construction

When starting any construction on his site, the owner must first make a conclusion about the presence or absence of heaving soils on his territory. If such a conclusion has not been made, this can lead to dire consequences that will lead to the integrity of the bath structure. First of all, with the choice of foundation, there are two main technologies:

- Pile-strip type of foundation, installed on uneven surfaces or heaving soils.

- A strip type foundation structure is mounted on all relatively flat surfaces where there is no heaving soil.

An error in choosing a foundation design can lead to subsidence of the building and its gradual destruction.

After the bathhouse begins to settle, numerous cracks will begin to appear on the walls and ceiling, both outside and inside the building. In the future, if the problem is not eliminated, the structure may partially or completely collapse.

How to properly drain a bathhouse

The condition of the structure depends on the removal of accumulated water. The drain in the bath removes dirty water from it. The decision on the future type of drainage is made at the initial stage of construction. It is important to properly drain the bathhouse; this will help cope with troubles in the form of an unpleasant odor and other nuances. You should not arrange it directly under the bathhouse, as this causes:

- mold growth;

- the appearance of an unpleasant odor;

- destruction of lower building elements.

This can be avoided by installing a septic tank next to the structure, or connecting to a central sewer system. Many people arrange round pits at a distance of five meters from the building. For a bathhouse designed for 4–5 people, a well 1.5 m wide and 2.5 m deep is sufficient. It should have a filter bottom made of crushed stone, sand and crushed brick, reinforced walls from well rings, bricks, metal tanks, car tires .

The water is drained through metal or plastic pipes located at an angle at a depth of at least 50 cm. To simplify the exit of water, the floor in the bathhouse is made at a slight angle towards the drain.

How to properly make a chimney in a bathhouse

It is a common belief that a steam room should be heated with a wood stove. This necessitates the removal of combustion products outside. Making a chimney correctly in a bathhouse is very important, because it is fire safety that cannot be neglected. Good draft and safety are the main criteria for a quality chimney. There are three types of chimneys that can be made in a bathhouse:

- stainless steel pipe;

- pipe with a double wall of fire-resistant insulation;

- chimney made of bricks.

The pipe material must match the raw material from which the oven is made. Recently, the desire for safety has promoted the use of fire-resistant materials. The problem is that a significant part of the chimney is located indoors, in contact with wooden elements.

" Important. A hot pipe can cause a fire. The need for a setback from combustible structures should be taken into account.

There are two installation options:

- interior

- outer:

In the first installation option, the chimney goes straight through the floors and roof;

External installation involves first placing a part of the pipe horizontally up to the wall of the building (no longer than one meter), and then lifting it vertically.

In total, it is permissible to arrange no more than three turns of the pipe. It is important to ensure that the chimney does not come into contact with the supporting structures of the roof. Provision should be made for cleaning the vertical pipe. Treating it with fireproof insulation, for example, basalt fiber, will prevent condensation and protect against fire.

When assembling a brick chimney, the thickness of its wall should be one to one and a half bricks. Steel pipes are several sections nested inside each other. Be sure to insert the lower section into the upper one so that the condensate flows outside and not inside the pipe.

Where the pipe passes through the ceiling, it is necessary to make a steel box filled with fireproof insulation. On the external walls of the bathhouse, the pipes are secured with brackets. One fastener must secure each section. The top of the chimney is covered with a visor.

Features of arranging a steam room

In a steam room, the most important structural elements are the stove and shelves. Shelves for sitting should be about 60 centimeters long, and full shelves for lying should be 1.9 meters long. You can choose between different types of shelves: bench, flat shelf, or with additional head support.

You can warm up the bathhouse using a conventional pipe heating system on water or gas, electric heaters or a conventional stove-heater. The stove should be placed in the far corner of the steam room. If the work is carried out without the help of a specialist, then it is best to buy the stove rather than assemble it yourself, as this will significantly complicate the task.

At the last stage, electricity and water supplies are supplied, and a sewer drain is installed.

How to properly ventilate a steam room in a bathhouse

Ventilation in the steam room is a necessity, because high humidity and high temperatures require balanced air exchange. If organized ventilation is not provided, a harmful microclimate will arise in the steam room of the bathhouse, caused by mold, unpleasant odors, and heavy air.

The natural ventilation device provides for the circulation of warm and cold flows. At the same time, there are supply openings for cold air at the bottom, and exhaust openings for steam are made at the top.

Vents are installed during the construction of the building on opposite walls, preferably diagonally relative to each other. They must be equipped with protective grilles and shutters. This system works subject to a difference in air temperature inside and outside the steam room. Often window hoods, doorways, and chimneys serve as hoods.

It is useful to periodically ventilate the room between bath procedures so that the air is renewed and the wooden paneling dries out. If necessary, forced ventilation devices can be installed.

Frame construction

The most inexpensive and simplest option is a self-built frame bathhouse. Even a person with no construction experience can assemble it. This method of construction is the fastest, since in this case there is no need to wait for shrinkage, but to immediately begin interior decoration and installation of windows and doors.

But it should be remembered that the walls of the frame structure require additional insulation.

How to properly make a roof and ceiling in a bathhouse

The roof should not protrude beyond the perimeter of the walls by more than 0.5 meters. It is a frame of rafters located about a meter from each other. Its hydro- and thermal insulation is required, since temperature changes have an aggressive effect on the material. The covering is made of slate, tiles, wood, metal. Don't forget about the galvanized iron ridge.

Proper roof installation is one of the main priorities in the construction of a country house or bathhouse; this issue cannot be taken carelessly, because the reliability and durability of the roofing are the main postulates of construction.

To properly make a ceiling in a bathhouse, you need to decide on its type, and there are only two of them.

There are two types of ceiling:

- Hemmed from the bottom, from boards. It must be protected with thermal insulation materials so that steam does not leave the room;

- Ceiling-flooring, arranged under the roof. You can use unedged boards in the bathhouse. On the side of the room, a film is strengthened, completely covering the openings between the beams and the upper part of the wall. In this case, it is necessary to leave two-centimeter holes around the perimeter of the walls under the ceiling for ventilation. Foil or clay is used to preserve steam.

Ceiling insulation is carried out using felt, polystyrene foam, penoizol, polyurethane foam.

How to make a bath floor correctly

The floor in the bathhouse is arranged on a frame made of lags 5 cm thick. It is important to treat them with waterproofing solutions and antiseptics. The logs are placed directly on a concrete foundation, previously covered with a layer of roofing felt. Planed boards are laid correctly (with a gap) on them. A small gap of up to 5 mm needs to be made to drain the water.

The boards are fastened with iron screws and nails. New logs are placed on top, between which insulation is placed (basalt wool, polystyrene foam, expanded clay). The insulation is covered with polyethylene with a thickness of at least 3 mm. A flooring made of planks (only hardwood is suitable), cork slabs or fiber mats is laid on this frame. It should be raised approximately 5 cm to ensure continuous drying. After laying them, the floor should be sanded.

Along with wood, concrete floors are common, which have a structure of several layers:

- compacted crushed stone;

- cement mortar;

- vapor barrier layer;

- polystyrene foam insulation;

- polyethylene film;

- another level of cement mortar;

- reinforcement mesh filled with concrete.

Bathhouses made of wood are considered classics of the genre in Russia - we can say that wood has been the national building material for centuries. Certain architectural and aesthetic traditions have developed that characterize wood as the best raw material for construction.

The bathhouse is rightfully considered an integral part of Slavic culture and an indispensable attribute of its history. Moreover, the concept of “Russian bath” is perceived not so much as a process of ordinary washing, but as a certain custom of bodily and spiritual cleansing. This process of visiting a bathhouse has developed and improved over several centuries.