313

Regular visits to the sauna are a great way to relax, support your immune system and improve your overall health. That is why many of us dream of building a compact bathhouse complex on our own plot. And the “heart” of the wooden structure is the stove, the performance characteristics of which determine the quality of the steam in the steam room and the effectiveness of the bath procedure. For decades now, the Troika sauna stove has held the palm among similar designs. What is the secret of its popularity?

Troika is one of the most reliable oven equipment on the market

general description

Troika units have a simple appearance at first glance, but they have high power, and also allow you to additionally cover the surface with brick. The latter circumstance allows the unit to fit into almost any interior. Another advantage of such stoves is that they are manufactured at a factory in Russia, this indicates their adaptability to harsh climates, which cannot be said about some foreign-made heating devices. Most often, in the manufacturing process of the described furnaces, low-alloy steel is used, which is a feature of Troika products.

Positive and negative feedback

If you are interested in Troika stoves, then you should read the reviews in more detail, from them you can understand that in winter these models take about 3 hours to heat up, in summer this time will be reduced. As buyers emphasize, a large amount of fuel is not required for bathing procedures, while the heat is retained in the room for about 10 hours during operation of the device. This equipment is inexpensive, but it does the job for two.

Users also note some disadvantages, including the enormous weight, which sometimes reaches 380 kg. This sometimes leads to difficulties during transportation and installation. Thus, in order to lift the unit, the strength of 4 people will be required. Some owners of country houses and country houses also note that they do not really like the need to cover the front surface of the stove with bricks. But the manufacturer counted on exactly this when designing the products. Finally, the walls are thick, which results in later heat transfer. In this regard, these designs cannot be compared with bare thin-walled products that are common today.

Feedback on design features

Troika stoves have certain characteristics; a distinctive feature of the model range is the thick walls of the firebox. The top element is 10 mm thick, while the side walls are 8 mm thick. Thanks to the use of low-alloy steel in the production process, the device has a long service life. Users really like that the fuel channel is of a remote type, which is why the firebox can be taken out of the dressing room. In this case, the thickness of the walls will not play any role.

If you were looking at Troika stoves and thought that some designs from other manufacturers are very limited in the volume of loaded stones, then you should know that this has nothing to do with these models. The described equipment may involve heating stones whose mass reaches 250 kilograms. For comparison, in models from other manufacturers this figure varies from 50 to 80 kilograms.

Bath stove "Troika 02" with water tank

Price on request

Order

Ask a Question

Features and Benefits:

The design of the TROIKA 02 stove allows the stove to be fired from the washing compartment and is guaranteed to warm up two rooms of the bathhouse, creating different temperature conditions in them. In this case, the firebox, tank lid and water tap are located in the washing room, and the heater is in the steam room. A voluminous, non-ventilated stove allows you to produce a large amount of steam; the thick metal of the firebox and smoke channels will ensure a long service life of the stove (more than 10 years). Supplying water to the lower hot zone of the heater produces a large amount of light, invisible steam. The oven is designed for brick lining. Brick is the material most suitable for lining stoves and creating the mildest climate in a steam room; it gives thermal radiation close to our body, like solar heat.

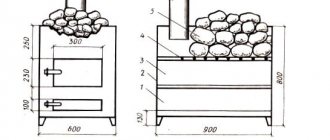

Furnace material: low-alloy steel, heat plate -14mm, top of the firebox - 10mm, sides - 8mm.

Specifications:

| Model | Steam room volume, m3 | Size, mm | Weight, kg | Weight of stones, kg | power, kWt | Log length, mm | Guarantee | Tank | Fire door |

| Troika 02 | from 10 to 18 | 900*400*900 | 130 | 100 | 20 | 850 | 3 years | front 72 l | cast iron door without glass |

Reviews about tank volume and chimney pipe

Troika sauna stoves can have a tank with different volumes, which depends on the specific model. If we consider options number 1 and 5, then they are equipped with a 72-liter tank, while oven number 2 has an 80-liter tank. The location of these elements is quite convenient; they are located on the front side, which facilitates maintenance. This is especially true for those baths that do not have running water. In addition, according to users, these devices can be installed in steam rooms, which have low ceilings. Where it is impossible to install models in which the tank is located on the chimney pipe.

Owners of country houses note that, if necessary, the tank can be removed and washed at any time, which cannot but be called a positive feature. Troika stoves, reviews of which are mostly positive, have large-diameter chimney pipes. Therefore, there will be no problems with traction, no matter what the weather is like outside. Cleaning such elements is quite simple; anyone can do it. For this purpose, the heat generator is equipped with a cleaning device, which is located in the side part. The doors are made of cast iron, which, as users emphasize, makes them resistant to high temperatures.

Bath stove "Troika 01" with water tank

Price on request

Order

Ask a Question

Features and Benefits:

The design of the TROIKA 01 stove allows for guaranteed heating of three sauna rooms, creating different temperature conditions in them. A voluminous, non-ventilated stove allows you to produce a large amount of steam; the thick metal of the firebox and smoke channels will ensure a long service life of the stove (more than 15 years). Supplying water to the lower hot zone of the heater produces a large amount of light, invisible steam. The oven is designed for brick lining. Brick is the material most suitable for lining stoves and creating the mildest climate in a steam room; it gives thermal radiation close to our body, like solar heat.

Furnace material: low-alloy steel, heat plate -14mm, top of the firebox - 10mm, sides - 8mm.

Specifications:

| Model | Steam room volume, m3 | Size, mm | Weight, kg | Weight of stones, kg | power, kWt | Log length, mm | Guarantee | Tank | Fire door |

| Troika 01 | from 10 to 18 | 620*600*1100 | 130 | 120 | 20 | 570 | 3 years | right/left 72l | cast iron solid / metal with glass |

Solutions for special conditions

Troika stoves, photos of which you can see in the article, are sometimes equipped with a heat exchanger. Such devices allow you to heat not only the steam room, but also adjacent rooms such as a sink, as well as a dressing room. If you are on a limited budget and the steam room has a small area, then on sale you can find models that are small in size and equipped with a convector. We are talking about model number 7, the size of which is 50x50 centimeters. This option is installed in small steam rooms, for which the manufacturer abandoned the remote firebox, adding a 60-liter water tank to the device, which is located on the pipe.

Reviews of Troika brand stoves for brickwork

The Troika stove for a bathhouse, as mentioned above, can be intended for lining the front surface with brick. Users choose such designs most often when compared with other models from the manufacturer. They are offered for sale in 6 configurations, one of them has a power of 20 kilowatts and weighs 210 kilograms. We are talking about model number No. 6M2. The permissible volume of a steam room for such equipment can vary from 8 to 16 cubic meters, while the dimensions of the device are 70x31x135 centimeters. Consumers like this model because its cost is low and amounts to 30,900 rubles.

The more serious model number 6 has a power of 35 kilowatts, its weight is 330 kilograms, and the permissible volume of the steam room can vary from 20 to 30 cubic meters. The cost of this model is average and amounts to 40,000 rubles. It is preferred by those users who do not want to purchase models at a higher price, while low-power options are not suitable for them.

The maximum power of this line is model No. 5R. Its weight is 380 kilograms, the permissible volume of the steam room can vary from 30 to 40 cubic meters. According to users, the high cost is 68,500 rubles. fully justifies itself with its quality characteristics and attractive design.

Furnace lining

In addition to laying the foundation, direct installation of the stove structure and its connection to the chimney, installation work in most cases includes lining with refractory bricks.

At the first stage, a clay solution is prepared, which is used to make spherical samples, which are shaped into a cake and left to dry for 10 days. Samples are made in different ratios of clay and fine-grained sand, preferably mountain sand and carefully sifted from debris. The proportions are as follows:

- 1 sample: clay;

- 2 sample: 9 parts clay and 1 sand;

- 3 sample: sand and clay in a ratio of 1 to 3;

- 4 sample: 3 parts sand, 1 part clay.

Dried samples are tested for strength. To do this, each cake is raised 1 meter above a hard surface and released. An unbroken sample is the optimal mixing option for brickwork. The solution is mixed, filled with water and left for 3 days to impart the necessary elasticity.

You can also use a ready-made mixture, sold at any hardware store. The clay-sand composition is convenient to use, but it has a significant drawback - the ratio of components is not always stable. In this case, the composition is brought to the ideal level by adding pure clay (if the solution turns out to be “lean”) or sand (if the solution turns out to be greasy). To increase the strength of the masonry, you can add cement to the solution - 400 grams per bucket. The average consumption of the finished mixture is 1 bag per 80 bricks.

- Before starting work, the material is moistened with water. This will improve the quality of adhesion between clay and sand and brick.

- The solution is applied on top of the previous level.

- The first level of quality refractory bricks is made from whole bricks. They start from the far corner. At the next level, use ¾ of the block, subsequently observing this order. This makes it possible to connect the rows with the highest quality possible.

- During the finishing work, all additional furnace elements are installed.

- An opening necessary for further maintenance of the stove is left in the sash area.

- The masonry is carried out up to the upper level of the stove structure, but it is necessary to leave a small gap between the brick wall and the metal structure (8-10 cm). The gap is necessary for uniform heating of the brick screen and proper air circulation.

The stove is started after installing the chimney, starting at low temperatures for 20-30 minutes

Important! At the 2-3 level of masonry, it is necessary to leave several gaps of half a brick, necessary for ventilation and additional heating of the room.

Instructions for lining a sauna stove are presented in the video:

Reviews of stoves with mesh

Troika sauna stoves, reviews of which will allow you to make the right choice, are also offered for sale in the form of models with mesh. It is covered with stones and acts as a screen that protects a person from the hard infrared radiation of the metal. According to users, stoves in this category are presented in two models. They are distinguished by the possibility of quick installation and do not require maintenance during operation. This is especially attractive to the modern buyer. Both models, according to consumers, look aesthetically pleasing, are characterized by high heat capacity, cool down slowly, but warm up quite quickly.

Bath stove "Troika 05" with water tank

Price on request

Order

Ask a Question

Features and Benefits:

The configuration of the TROIKA 05 stove is optimized for small steam rooms. The beveled top of the heater makes it easy and convenient to supply water to the stones. The steam produced on the stones goes up, without the risk of burning anyone (relevant for small steam rooms). A voluminous, non-ventilated stove allows you to produce a large amount of steam; the thick metal of the firebox and smoke channels will ensure a long service life of the stove (more than 15 years). Supplying water to the lower hot zone of the heater produces a large amount of light, invisible steam. The oven is designed for brick lining. Brick is the material most suitable for lining stoves and creating the mildest climate in a steam room; it gives thermal radiation close to our body, like solar heat.

Furnace material: low-alloy steel, heat plate -14mm, top of the firebox - 10mm, sides - 8mm.

Specifications:

| Model | Steam room volume, m3 | Size, mm | Weight, kg | Weight of stones, kg | power, kWt | Log length, mm | Guarantee | Tank | Fire door |

| Troika 05 | from 10 to 18 | 900*600*1100 | 150 | 120 | 20 | 850 | 3 years | right/left 72l | cast iron door without glass/metal door with glass |