Advantages of a home-made heating boiler

A do-it-yourself water boiler is simply indispensable for a country home, where heating costs are often too high. A DIY wood-fired water boiler for the stove is an excellent alternative to gas. and it will also significantly save hot water.

When it comes to a country house, not all houses are connected to gas heating, and connecting it is also not a cheap pleasure. Of course, the problem can be solved in another way by purchasing an electric model for heating in the store, but it is also very expensive, and the cost of electricity will also increase if it is installed.

A model created with one’s own hands may not be inferior to factory models in terms of power and efficiency, and sometimes even surpasses them many times over. If you work strictly according to the instructions and make all the calculations correctly, then you will definitely not be disappointed with the result.

When starting work, do not forget about the correct calculation of temperature, and also choose not too thin sheets of metal so that it does not burn out. In addition, as a material for work, you can take old used boilers or based on a finished wood-burning stove.

Key advantages of a hand-made water boiler for heating a furnace:

- environmental friendliness;

- good efficiency indicator;

- low cost of materials and fuel;

- safety;

- acceptable working conditions;

- standalone installation.

Indications and contraindications for use

Like any product, pork fat has a number of indications and contraindications that should be taken into account to exclude side effects and allergic reactions.

The consumption of internal pork fat has a number of indications in the treatment of the following diseases:

- Colds, especially those accompanied by cough.

- Pneumonia.

- Bronchitis.

- Skin diseases: eczema, burns, dermatitis, etc.

- Ulcers.

- Ear disease.

- Exhaustion of the body.

For injuries to the musculoskeletal system, ointment is used.

- Hepatitis.

- Cardiovascular.

- Atherosclerosis.

- Duodenitis.

- Cholecystitis.

- Pancreatitis.

- And also to people suffering.

The norm for an adult is 9-12 g of fat per day, 100 g per week.

Special indications

When consuming large amounts of pork fat, the following may occur:

- , so it contains histamines;

- pork products should be well processed thermally, as trichinella, echinococcus, and sarcocysts may appear;

- Since the product is high in calories, it is not recommended to consume it in large quantities during a diet.

Build process

The process of creating a boiler includes several stages. When manufacturing each element, it is worth taking into account the special operating conditions of the product being manufactured.

Air supply device

We cut a section from a thick-walled pipe with a diameter of 100 mm, the length of which will be equal to the height of the firebox. We weld a bolt to the bottom. From a steel sheet we cut out a circle with the same diameter as the pipe or larger. We drill a hole in the circle large enough to pass the bolt welded to the pipe. We connect the circle and the air duct pipe by tightening the nut onto the bolt.

As a result, we will get an air supply pipe, the lower part of which can be closed by a freely moving metal circle. During operation, this will allow you to regulate the intensity of firewood combustion and, consequently, the temperature in the room.

Using a grinder and a metal disc, we make vertical slits approximately 10 mm thick in the pipe. Through them, air will flow into the combustion chamber.

Housing (firebox)

The body will require a cylinder with a sealed bottom with a diameter of 400 mm and a length of 1000 mm. The dimensions may be different, depending on the available free space, but sufficient for laying firewood. You can use a ready-made barrel or weld the bottom to a thick-walled steel cylinder.

Sometimes heating boilers are made from gas cylinders for a longer service life.

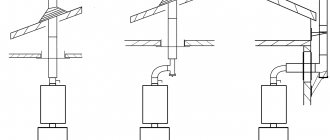

In the upper part of the body we form a hole for the removal of gases. Its diameter must be at least 100 mm. We weld a pipe to the hole through which the exhaust gases will be removed.

The length of the pipe is selected depending on design considerations.

Connecting the housing and the air supply device

We cut a hole in the bottom of the housing with a diameter equal to the diameter of the air supply pipe. We insert the pipe inside the body so that the air vent extends beyond the bottom.

The air supply pipe should end a few centimeters before the start of the chimney.

Heat Dissipation Disc

We cut out a circle from a metal sheet 10 mm thick, the size of which is slightly smaller than the diameter of the body. We weld a handle made of reinforcement or steel wire to it.

This will greatly simplify the subsequent operation of the boiler.

Convection hood

We make a cylinder from sheet steel or cut a piece of pipe, the diameter of which is several centimeters larger than the outer diameter of the firebox (body). You can use a pipe with a diameter of 500 mm. We connect the convection casing and firebox together.

This can be done using metal jumpers welded to the inner surface of the casing and the outer surface of the firebox, if the gap is large enough. With a smaller gap, you can weld the casing to the firebox around the entire perimeter.

From a steel sheet we cut out a circle with the same diameter as the firebox or a little larger. We weld the handles to it using electrodes, wire or other available means.

Considering that the handles can become very hot during operation of the boiler, it is worth providing special protection made of material with low thermal conductivity.

To ensure long burning, we weld the legs to the bottom. Their height should be sufficient to raise the wood-burning boiler at least 25 cm above the floor level. To do this, you can use various rolled products (channels, angles).

Congratulations, you have made your own wood-burning boiler. You can start heating your home. To do this, just load the wood and light it by opening the lid and heat dissipation disk.

How to buy and render lard into fat

One of the main factors is the right lard. The meat aisles offer a wide variety of choices, but to select a quality product you need to consider the following:

- The pig's skin should be soft and smell good. It’s good when the skin is ground with straw, but it can also be done with gasoline. This lard has a specific smell.

- The lard should be white and not have a sour, musty smell.

- To determine softness, it is recommended to pierce the product with a toothpick during the selection process. The stick should go in like butter.

- The thickness of the lard should be medium, plus if there are layers of meat, they should be grayish-red in color. This is an indication that the animal was well fed and was not starving.

If you are lucky at the market or you have a familiar hunter, then purchasing wild boar lard is optimal. This is due to the healthier natural diet and lifestyle of the boar. The fat is rendered according to the recipes below; it is also easy to salt it.

The price may even be lower than that of domestic pork - wild boar is a common hunting catch. The healing properties are enhanced. Meat with lard is a healthy and high-calorie food in cooking. The use of fat in cosmetology is also described.

This lard can be melted or prepared according to various recipes. To get the melted product you need:

- Wash and dry the lard with a paper towel.

- Cut into small pieces and place in a container.

- Heat the product over low heat until cracklings form, and then remove them.

- Cool the melted mass and put it in the refrigerator.

In order not to melt the lard excessively, it is necessary that the greaves have a flesh-colored or yellowish color.

You can also raise your own pig

, but for this the following factors should be taken into account:

- Decide on the breed of pig (for example, a bacon pig does not produce good lard).

- Provide piglets with optimal living conditions: a room with pens, a walking area with a canopy and a dug hole for swimming. The scale of construction depends on the chosen breed.

- Provide animals with high-quality food: boiled vegetables (carrots, beets,

- To ensure good quality lard, piglets should be fattened from three months of age. The animal should consume 6 kg of feed and 30 g of salt per day. From eight months of age - 7 kg of food and 40 g of salt. When a pig reaches 1 year of age, feed consumption is 8 kg.

Piglets can be given mashed root vegetables on the 20th day after birth, and porridge before this time.

What does a boiler consist of and how does it work?

The fuel in such boilers burns much longer than in conventional units. This is due to their operating principle, which involves burning wood in the firebox from top to bottom. The combustion chamber is cylindrical in shape and is completely loaded with wood through a door at the top of the housing. Ignition is carried out through the same door; the design of long-burning solid fuel boilers is such that air is also supplied to the combustion zone from above through a vertical pipe. A flat round weight made of thick metal (10-15 mm) is attached to the end of this pipe; arc-shaped air distributors made of strip metal are welded to it from below. A similar design can also be used to make a sawdust boiler.

Weight for a homemade boiler

The size of the load is 5 mm smaller than the internal diameter of the firebox cylinder, which allows the structure to move up and down. The other end of the pipe passes through the upper wall of the boiler; a damper is installed on it, with which the amount of air can be adjusted manually. The length of the pipe is 15-20 cm greater than the height of the combustion chamber. The latter can be arbitrary; home-made long-burning units work the longer, the larger the diameter and height of the firebox. At the same time, the volume of the unit’s water jacket and its thermal power increase.

Long burning boiler design

After ignition, the pipe with a load is lowered, pressing down the array of firewood. The air enters directly into the combustion zone; the design of the long-burning boiler provides for operation on natural draft created by a chimney of the required diameter and height. The generated heat heats the water in the jacket of the installation; it begins to flow into the heating system through the upper pipe. The principle of convection works here; the use of a circulation pump is not necessary. The water jacket in a homemade apparatus is located not only around the side walls of the firebox, but also in its top cover.

The grate of a homemade long-burning wood-burning boiler does not perform its usual function; air does not pass through it into the work area. The grate only serves as a support for the fuel mass, and through its cells, ash and ash fall into the lower section, from which they are freely removed with an iron scoop. As the fuel burns in the chamber, the load lowers and you can determine how much firewood is left at the upper end of the pipe. After the process is completed, the door of the ash compartment opens, combustion products are cleaned out of it, the load along with the pipe is raised and fixed in this position. You can make the next download.

Homemade long-burning wood-burning boiler

How to melt lamb fat, fat tail (based on 0.5 kg of fat tail fat)

6. It is best to immediately pour the fat into the jar in which you intend to store it, because... In a day the fat will thicken and turn white and it will no longer be possible to pour it out.

Now you know how to melt lamb fat. Before spreading the fat, you should warm it up a little.

Good luck and don't get sick!

Bear fat is considered a valuable product. It is used for nutrition and in the treatment of diseases. People ask the question: how to render bear fat? Pharmacies sell this product, but consumers are looking for natural lard without additives or flavors. It’s good to always have a healing potion on hand at home, and a natural one at that!

To obtain a healing product, they use subcutaneous fatty tissue and internal fat, which is located on the spine, heart, kidneys, and intestines of the bear. If you need lard for medicinal purposes, buy a product that hunters obtained in the fall. During the long winter, the animal consumes most of the beneficial substances from its fat stores, so spring is not the best time to purchase medicinal raw materials. You also cannot expect a useful product from a connecting rod killed in winter, except perhaps for food.

From one brown bear carcass they get from twenty to thirty kg of raw meat. The bear is gutted, the skin is removed, then the subcutaneous tissue is carefully cut off with a sharp knife and the internal fat is removed from the organs and intestines. Hunters do this immediately after slaughter so that the fat does not become saturated with the smell of decomposition. The fat base is washed with water, changing it several times until the liquid remains clear. After this, the water is drained and the fat is allowed to flow around.

Advantages of using a water boiler in a brick stove

One of the key advantages is efficient heat dissipation. It is also an important fact that the pipes can be connected to all rooms from the pipe.

A water-based boiler can be perfectly combined with different heat generators. When using antifreeze, the system will not defrost when the oven is turned off. Among other things, a water boiler in a brick stove can operate both in the presence of central heating and in autonomous mode.

It should also be noted that a water boiler in a brick is very reliable. like the brick oven itself, traditionally considered a reliable heat source. And when such a stove is combined with a water-based boiler, their mutual efficiency becomes many times stronger, and additional heat transfer appears. Together they are able to heat a room of up to one hundred square meters, without forcing you to spend a lot of money on such heating.

For a typical Russian winter, only two fireboxes per day will be enough to create a comfortable temperature in the room. In addition, the temperature can be regulated using modern automated systems.

We buy and melt

Melting internal pork fat is a delicate matter, but for those who are doing this not for the first time, it is quite ordinary.

First, it is important to understand how to choose the right product. Attention should be paid to the following characteristics:

- place of production (homemade fat from a familiar farmer or from your own farmstead is beyond competition);

- appearance (choose fat that is a uniform, soft cream or white shade);

- smell (pungent, specific – a sign of dubious quality).

To melt interior fat into lard in the amount of 3 liters and 1 liter of cracklings you will need: 3.5 kg of high-quality fat, a pan (aluminum), a fire divider.

- You need to take the fat and chop it finely.

- Then put it in a saucepan and put it on fire.

- Stir constantly and strain off the finished mixture.

- Heat until completely evaporated.

Lard can be stored in the refrigerator for up to one and a half years without losing its basic qualities.

Common foods in the human diet are products from domestic pigs and wild boars. Since ancient times, food has been one of the main sources of “fast” energy. Lard is not only a favorite delicacy in the human diet, but its fat is also popular in treatment.

Water heating with wood

This more complexly organized system is a pyrolysis boiler. consisting of two sections. In the lower one, wood is burned, and in the upper one, the gas generated due to combustion circulates. Thanks to the scheme in which gas does not immediately enter the chimney. its efficiency increases, and longer burning requires less wood.

Around the boiler there are thick pipes through which water flows, heated from it. Keep in mind that only dry firewood is suitable for a boiler of this type, so you should always have a good supply of it at home.

There are also systems that use hot air instead of water for heating. It passes through the circuit and is transmitted into the airspace of the house. The cold air, falling down, again enters the boiler for further heating.

Why does the fireplace fail to melt or smoke after a long period of inactivity?

First, let's look at the reasons why a heating device that has not been used for a long time does not heat well and smokes at the beginning of the season. The fact is that during the winter the chimney of a stove or fireplace becomes very cold and damp. The pipe can freeze so much that the air temperature inside it is lower than outside or in the house. Based on physical laws, cold oxygen in the smoke duct does not rise up the pipe. In other words, there is practically no draft in a cold pipe. To light a stove complete with a frozen chimney, you need to expel the cold air.

Peculiarities

Today, heating boilers have sufficient power to heat rooms for various purposes. They are economical. Their continuous operation time is almost the entire heating season.

These devices can operate on wood, coal, pellets (wood waste compressed and processed into granules), briquettes, peat, and wood gas.

Boiler types

Depending on the type of solid fuel, they are divided into the following types:

- wood-burning (heated not only with wood, but also with pellets);

- universal (they use different types of fuel and their combinations for work);

- gas generator boilers (they have increased efficiency and operate on wood and wood gas).

Models of the latter type are more convenient to use, since soot does not accumulate inside them, and a minimum of ash remains.

There are models of long-burning boilers, dependent on the electrical energy carrier and independent.

Such heating equipment operates on the principle of top combustion (the hearth burns from top to bottom). The combustion chamber, located at the top of the structure, is filled with fuel. The fan forces air through the duct, and the heat generated by combustion is sent to the heat exchanger. The volume of the combustion chamber is about 500 dm3, so such a heating device can operate without interruption for several days.

Advantages

Long-burning designs are heating devices that are very popular among the population. This is explained by their many advantages: not only the use of various types of fuel, but also their long combustion time, as well as the simplicity and environmental safety of their use.

A boiler of this type in its modern variation is a design equipped with automation and a fan to increase the pressure in the system. With a small amount of fuel consumed, such devices can maintain the temperature in large rooms.

The big disadvantage of the design is the high cost, more than 1000 USD. e.

What is important to do before warming up the chimney and pre-firing?

It is extremely important to remember that at the end and beginning of each heating season, regardless of the time of year, a preventive inspection and cleaning of the smoke duct should be carried out. During the period of non-use of the heating device, two things can happen to the chimney:

- Various debris from the street can get into the pipe - branches, bird or insect nests, leaves, pine needles, etc. The possibility of debris entering the pipe is especially high in cases where its head is not equipped with a deflector. Debris inside the smoke duct can clog it and prevent the free passage of smoke from the fireplace to the street, as well as stop the draft. The inability of flue gases to escape into the street will provoke their release into the premises, creating a situation dangerous to the health of residents. However, debris in the chimney can easily ignite and cause a fire in the chimney or, in the worst case, in the house.

- Build-ups of soot and condensation on the inner walls of the pipe can also hinder the free passage of smoke masses and draft. To eliminate risks when lighting a heating device after a long period of inactivity, experts recommend conducting a routine inspection of the pipe and, if necessary, cleaning the chimney. These actions can be carried out independently, but it is better with the help of professionals. A chimney cleaning service ordered from a specialized company will be performed efficiently and in compliance with all required, established fire and technical safety standards. At the same time, reliable quality guarantees are always provided for services of this type, ordered from trusted contractors.

What is pyrolysis combustion

As you know, it is not very convenient to heat a particular room with firewood, since this fuel burns quickly without releasing the required amount of energy. However, if the oxygen content in the firebox is low, the material will be consumed much more slowly. This is precisely what the principle of pyrolysis combustion is based on, due to which significantly less fuel is required and efficiency increases. The main products obtained in this case are coke, ash, and flammable gas, which also releases a large amount of heat.

This means that when constructing a homemade long-burning boiler, you need to take into account the following points:

- Initially, wood burning with a limited supply of oxygen releases flammable gas;

- then the resulting mixture is burned, in turn releasing heat.

Many home-made boilers operate on this principle, but it is important to remember that the equipment must be adjusted so that its operation does not damage the overall system for providing heat to the home

Cosmetic properties

- A valuable property of pork fat is its ability not to lose its biological value after heating.

- Used to prepare various ointments and creams that support and improve the beauty of the skin. The skin absorbs this product quite quickly, since in some biochemical properties it is similar to human fat.

- Another definite plus is the fast delivery of all the necessary components of cosmetics to their destination due to the high absorbing properties of health.

- The product does not clog the skin, allowing it to breathe as before, and is washed off without much difficulty.

- A huge number of skin care emulsions can be prepared on the basis of pork fat, since it is easily mixed with any other types of fats, as well as with aqueous solutions, alcohols, resins, glycerin and medications.

Useful additions

A home-made long-burning boiler assembled at home must be equipped with monitoring devices - a pressure gauge and a thermometer. If you decide to install an automation kit and a blower fan on your unit, then you will need to make a seat for it. The fan is placed in the top cover of the housing; it is better to make the electronic control unit remote by mounting it on the nearest wall inside the furnace room. Temperature and pressure sensors are embedded in the water jacket body. In this case, conventional indicating devices should not be ignored, because they will be able to operate when the power is turned off. Therefore, it is also better to install them, since not every electronic display displays coolant pressure.

After assembly, wood heating boilers must be checked for permeability of welds. Using a compressor, this is easy to do: fill the jacket of the device with water and create an excess pressure of 3 bar in it. Before testing, the seams must be cleaned of slag. Sinks and uncooked areas will make themselves known by leaking. When there is no compressor on the premises, the heating installation will need to be ignited and heated outside until a critical pressure of 3 bar is created in the jacket. Water pressure and temperature can be monitored using a thermometer and pressure gauge.

It is recommended to cover the casing of the water jacket and the inside of all doors of a home-made unit with heat-insulating material. As the latter, asbestos sheets and basalt wool are used, which are not afraid of high temperatures. For external cladding of insulation, you can use thin metal 0.3-0.5 mm with a polymer coating of the desired color.

Bread with lard and whey

Soft and fluffy homemade cakes are simply irresistible. To give it a special “fluffiness”, we suggest using lard. The dough recipes that we will offer in this article are simple, but guarantee excellent results.

Ingredients:

- Wheat flour - three glasses.

- Dry yeast - seven grams.

- Sugar - two tablespoons.

- Salt - two teaspoons.

- Powdered milk - one and a half tablespoons.

- Oatmeal - 120 grams.

- Lard - 30 grams.

- Serum - 300 ml.

- Warm the whey slightly and then dissolve the sugar and yeast in it. To do this, place the food in a warm place and wait until a lush “cap” appears on the surface.

- Sift the flour, add salt and milk to it.

- Grind the flakes in a blender.

- Combine the lard with the prepared products and knead the dough. When it rises, knead it with your hands again.

- Shape the dough into a loaf, make shaped cuts with a knife and leave the dough under a towel for one hour.

Bake the bread in a preheated oven until done.

Advantages of double-circuit heating

Double-circuit heating is the type of heating in which water is heated using a boiler specifically for use in the home and for heating the entire room. Thus, the entire need for hot water is provided by one double-circuit boiler. There are other reasons why it is gaining more and more popularity:

- Makes it possible not to depend on utilities and allows you to regulate the heating yourself, thereby creating comfort at home

- Possibility of installation in any part of the house. since no additional exhaust system is required, ventilation is also not required

- Apart from the boiler itself, you will not need anything, because everything necessary for heating and supplying the house with hot water for a long time will already be built in

- Favorable and affordable price

How a wood-burning stove with a water circuit works. Choosing fireplace stoves for a summer residence with a water circuit and a heat exchanger. Brick stove with a water circuit. A stove with a water circuit in development - how to do it yourself.

Lard in a slow cooker

The cracklings, prepared using the miracle of modern technology, turn out to be very soft and practically melt on the tongue. And lard can be added to any dish or made into a spread for sandwiches. If you want a richer taste, mix it with garlic, pepper or fresh herbs.

Ingredients:

- Lard - 1400 grams.

- Greens - to taste.

So, let’s cook lard in a slow cooker. The recipe is very simple:

- Chop the lard and place it in a bowl.

- Set the “Extinguishing” mode for four hours.

When the specified time has elapsed, remove the cracklings and pour the fat into jars.

Making a water circuit

You yourself can easily install and make a water boiler on a ready-made long-burning water stove, and if you don’t have one, then it won’t be too difficult to lay it out of brick yourself. For heating water. You can make a water circuit from old cast iron heating radiators, which you can easily find.

Their capacity is on average one and a half liters. You can connect several of these together and get a heater with a volume of 15 liters at the output, but due to its large dimensions it may not be suitable for use in all rooms. The most acceptable option is a Russian bathhouse.

First, disassemble it yourself. clean and rinse them with hydrochloric acid, or rather its solution. Before installing the entire structure, the gaskets separating the sections should be changed, since initially they are not adapted to high temperature changes. which can reach more than five hundred degrees. Since the old separator will not hold up and the radiator may leak, use impregnated asbestos cord for installation. After this you can start assembling. It must be assembled in such a way that the exit pipe is located above the entire structure, and the entrance pipe is located under it.

Place the circuit ready for use in the chimney as close to the firebox as possible. The hot air coming from there will heat the circuit and, accordingly, the water, making it suitable for heating the house. Subsequently, you will connect the entire water circuit system to the radiators that heat your home

Be sure to first check the entire system for any leaks, paying particular attention to the circuit. which you assembled with your own hands

If you have not found old cast iron batteries for its manufacture, then you can use ordinary pipes for the circuit, but with fairly thick walls.

The water circuit can be applied to absolutely any long-burning stove: from a fireplace to a potbelly stove. You can also make a boiler from fairly thick metal and place it directly under the firebox, which will make it heat up much faster.

Harm and contraindications

You can list the contraindications and possible harm from using Zdor on the fingers of one hand.

Pork fat is contraindicated for people who have recently suffered a serious illness or surgery, as a result of which the calorie content of their diet has been reduced and should be restored to normal values gradually.

Those who have liver problems should use the product with caution. The rest are advised not to abuse it.

As for external use, individual intolerance is possible. It can be easily identified if you perform a standard test on a small area of skin (wrist, elbow, etc.).

Self-production

It is quite difficult to construct a heating boiler with your own hands. The slightest inaccuracy and it will not work correctly, which can lead to tragedy. Therefore, it is necessary to carefully study the technology of their manufacture and carry out all activities very efficiently.

Shaft-type heating devices

You can create a mine or pyrolysis boiler yourself. The first operates not only on wood, but also on coal, peat or sawdust. You can immediately load up to 50 kg of firewood into its chamber.

When the chamber is fully loaded with fuel and high power, such a device will work continuously for up to 5 hours, at the lowest power (15-20 kW) - up to a day. Its efficiency is 75%. The power of such models can be adjusted automatically.

Pyrolysis model

Yellow or colorless wood gas, released under high temperature, is the heat source in the pyrolysis boiler. For such a heating device, you can only use completely dried firewood, otherwise it will not start. The pyrolysis design can also operate on pellets. Their automatic feeding into the furnace (using special augers) will be an additional advantage of the boiler. The operating time of a model of this type when fully loaded is 12 hours.

Disadvantages - high cost (you can reduce it if you make it yourself), energy dependence (the fan runs using electricity), large size. To make such a device you need:

- pipe and sheet of steel 4 mm thick;

- professional pipes, metal rods with a cross-section of 2 cm;

- electrodes;

- fan;

- fire bricks;

- automatic temperature controller;

- fasteners.

They first draw up a diagram of the future boiler with all the calculations. The most successful design of a homemade boiler in this regard, developed by engineer Belyaev, is taken as a basis. Adjustments are made to it according to the wishes of the home owner. For example, heating can be made more efficient by increasing the volume of the heat exchanger jacket.

Homemade pyrolysis devices must be installed on fireclay brick platforms specially equipped for them. After this, they are connected to the water circuit.

During the first test switch-on, they find out whether there were any errors in the boiler design. If everything was done correctly, the device can quickly switch to gas generator mode. The room will become much warmer within half an hour.

Tools and materials

A wood heating device is the safest design. Its autonomy, ease of operation, minimal risk of explosion, and the possibility of self-production are its main advantages. Its disadvantage is the regularity of adding fuel.

Homemade wood-burning boiler models can be made from the following materials and parts:

- metal barrel (volume – 200 l);

- steel sheet 3-5 mm thick (to create a firebox);

- metal pipe with a diameter of 20 mm and a wall thickness of 3 mm;

- L-shaped pipe (diameter – 20 mm);

- grate;

- doors for the vent and firebox.

Homemade models of wood-burning boilers are made using gas welding equipment and an angle grinder.

Sequence of work

Before starting work, you must carefully consider the design of the device, purchase all the necessary materials and tools.

Cut 3 circles (diameter of each 57 cm): this is the bottom, the top cover and the partition between the ash pit and the firebox. Make a hole with a diameter of 20 mm in two of them.

A strip 400 mm wide and 3600 mm long was cut from a sheet of steel, holes were cut in it for the firebox door, and below it for the ash pan. Weld the sheet together into a circle.

Weld a circle with a hole on top and without one on the bottom. Install a partition with a grate between them.

Weld the pipe and the barrel together according to the “one inside the other” principle. Install a firebox with a blower underneath. Connect all elements by welding.

Attach an L-shaped piece of pipe to the top of the barrel: it will connect the heating container and the chimney. When water heats up in a barrel, it forms steam, which will freely escape into the chimney, thereby preventing the pressure in the boiler from increasing.

Install pipes at the top and bottom for cold water inlet and hot water outlet.

Hang the doors on the firebox and vent.

Install the structure on a foundation made of refractory bricks.

Such a device heats using firewood, pellets or peat, tightly packed inside the firebox.

Even the simplest model of a wood-burning boiler requires care and attention when making it yourself

The use of fat for stomach diseases

Badger fat has successfully proven itself in the treatment of ulcers and other stomach diseases. In case of exacerbation, you need to drink it three times a day, 10 minutes before meals, half a teaspoon, or just as often, but one tablespoon an hour before meals. The course of treatment lasts one to two weeks. In the next two weeks, a break is taken, and then the treatment is repeated to consolidate the positive result.

For diseases of the liver, gall bladder and intestines, badger fat is contraindicated.

The use of fat in cosmetology

Unsaturated fatty acids of badger fat give exceptional results when used to create creams and masks. Thanks to these acids, any medicines and beneficial substances can be introduced into the skin, which is difficult to achieve when using other transport fats.

Here is one of the amazing face masks. A tablespoon of fat should be mixed with a dessert spoon of cocoa butter, add a few drops of some citrus essential oil and a little honey. Place all ingredients in a glass cup and heat to 40 degrees. While the mask has not hardened, it should be applied to the face and massaged in accordance with the massage lines. Then leave for 10-15 minutes, then blot your face with a soft cloth.

Principle of operation

Units with a water circuit are equipped with a heat exchanger built into the firebox or chimney duct. There are models that can operate in steam circulation mode.

A wood heating stove can be made of boiler steel or cast iron, designed to operate under high steam pressure. These devices are used both as additional equipment and as the main heat source.

A heat exchanger is installed inside the furnace unit. Heated gases move through the channels of the heating reservoir, transferring heat to the liquid. A furnace with a boiler in its design can have several tanks at the same time, which can significantly increase its efficiency. Water is heated in one tank, and with increased heating, the process of vaporization occurs in the second.

To heat a large building with traditional furnace heating, several furnaces will be required, and the consumption of coal or fuel will be quite high. Therefore, a more economical and alternative option would be a stove for water heating a house using wood, equipped with a special hot water boiler built into the firebox. Even in severe frosts, heating the stove twice a day is enough for such a heating system.

Such devices are capable of heating the building even during breaks between fireboxes. During the cooling process, the pipelines give up their heat for another 5-6 hours, thereby providing heating without consuming fuel. Water heating from a wood-burning stove has an efficiency of 80-85%.

Which firewood is better?

Heating a stove to heat a home or bathhouse with wood is the most economically efficient way. However, different types of wood produce different efficiency indicators. The duration of burning of logs depends on the density of the tree, therefore, the denser its structure, the longer the logs will burn and the more thermal energy they will release into the room. This is important to consider when choosing firewood.

Which tree species is the hottest?

Of course, oak is an ideal fuel in terms of efficiency, but this type of wood is very expensive and heating a stove with oak wood is an unforgivable luxury. That's why

In the middle zone and northern regions of the Russian Federation, it is most acceptable to use birch. Wood of this type optimally combines price and quality. In the southern regions, it is better to use white acacia to fire stoves.

At the same time, in order to heat buildings as efficiently as possible, you need to carefully prepare for the heating process.

Fat composition

Badger fat is valued for its high concentration of nutrients, which are 100% absorbed by the body without causing any negative effects.

In addition to vitamins A and E, it contains a group of vitamins B (2, 3, 5, 6, 9, 12), vitamins K, PP and R, tocopherols, carotenoids, folic acid, cytamines, micro- and macroelements and organic polyunsaturated oleic, linoleic and linolenic fatty acids (omega-3, -6 and -9).

The best cast iron stoves for saunas

Domestic manufacturers offer a wide selection of reliable and cheap devices. After reading the list of the best units, you will find out which cast iron stove is best for a bathhouse.

- "Hephaestus." Hephaestus stoves are rightfully considered the best on the market. Among their main advantages: high power, thick walls and safe operation. The design of the furnaces is monolithic, i.e. there are no fasteners or welding seams. The risk of damage to such a stove is reduced to zero. Convection fins located on both sides of the side walls provide rapid heating and high heat transfer. The efficiency of Hephaestus is the highest among its competitors: 90%. Hephaestus allows you to save on firewood and reduces soot levels. The cost of stoves starts from 25,000 rubles.

- "Vesuvius". Thanks to its one-piece design, it is highly durable and not prone to wear or damage due to temperature changes. Buyers note the good design of the stove, the presence of many modifications. The tank is located around the chimney. The walls of the firebox are thin, so the sauna quickly heats up to the required temperature. The oven capacity is up to 160 stones. The efficiency of Vesuvius is 70%. The assembly has a convenient compartment for ash, which helps in cleaning the stove. The average price for Vesuvius is 20,000 rubles.

- "ATB". Sauna stoves with a cast iron firebox "ATB" are prefabricated units - the design can be modified and faulty parts can be easily replaced. Some find this a drawback - cast iron is less durable compared to solid counterparts. Despite this, the ATB has thick walls and a convenient water tank with a capacity of 60 liters. The efficiency of the stove is 60%. "ATB" has a limitation on heating volume; the unit is not suitable for baths with an area of more than 20 cubic meters.

- "Magnum". These ovens have a high degree of safety. Thanks to the stone cladding, there is no chance of getting burned if used carelessly. The cast iron sauna stove “Magnum” is a conscious choice of buyers.

- AITO-AK. This stove is produced in Finland. They are not inferior in quality to domestic analogues and are highly valued by summer residents. The main advantage of the stove: clean steam. The stones are heated to a high temperature of 500 degrees and do not leave soot. Consumers note extremely fast heating and heat retention for up to 11-13 hours.

- "TORNADO". "Cast iron" produced. If desired, the buyer can independently do the stone or brick cladding. Prices are significantly lower than competitors. It is relatively light in weight and very large in size. Which means the walls are thinner than their analogues. It is known from the manufacturer that heat-resistant cast iron is used in smelting.

Integrating a stove into an existing heating system

If you already have a heating system that has previously been used with a different type of heating, you can connect a furnace to it. For example, it can become a replacement for a gas boiler.

Modern heating equipment usually does not contain a heating tank. But, it has a heat exchanger that performs a similar function.

The cost depends on a lot of factors - material, size, efficiency, maximum permissible heated area, etc. Moreover, there are models that allow not only to heat the house, but also to provide a full-fledged hot water supply system.

Factory stoves usually allow the use of both classic wood and coal, and pellets, which is a compressed wood material used as fuel.

General recommendations for rendering pork fat

Regardless of what you render the fat from, the most important thing at the initial stage is to clearly regulate the temperature. If the stove is heated too much, the lard may burn.

Until the first rendered fat appears, you need to monitor this process and stir the lard in a timely manner.

As soon as a certain amount of fat is rendered, the remaining pieces will boil in it, giving off fat.

You need to stir periodically. This will ensure that all the pieces of lard are rendered more evenly.

There is no need to render the fat until the cracklings are crispy. They should remain soft and light. They can then be further fried separately until they become brown and crispy. They can be used for stewing potatoes or other dishes. Fried cracklings can be sprinkled, for example, on potato salad.

Properly rendered fat in a glass jar should be pale yellow. When it hardens, it will turn white.

Before pouring it into jars, cool the fat so that the jars do not crack and your work is not in vain.

Fat should be stored in a cool place. Can be frozen.

Pork fat can be stored in such conditions for a long time, more than a year.

Positive and negative aspects of stove heating in a private house

In most cases, stove heating is installed if necessary, in the absence of main natural gas. But heating with a stove has its advantages and disadvantages, which it would also be nice to know about.

What are the disadvantages?

Negative points include:

- It takes quite a long time to heat up the stove, and therefore the premises. This occurs due to prolonged heating of the walls and coolant in the system.

- Not very high efficiency of a brick building. To increase it, you have to build a higher chimney, make it a labyrinth type, so that the heat remains inside the structure longer.

- A brick stove occupies a fairly large area, but only on such a scale is it capable of heating several rooms at the same time.

- Unlike heating with natural gas, the stove must be supervised throughout its entire combustion, since brick options require constant addition of fuel. Long-burning cast iron stoves are an exception, since firewood is added once per burning session.

Positive points

Stove heating also has many positive qualities, which are often decisive in choosing it for installation in a private home.

Storage

If stored properly, badger fat may not lose its beneficial properties for many years. What does proper storage mean? Firstly, it is a small glass jar - 150-300 grams, sealed hermetically, preferably with wax or paraffin. Secondly, minimal access to light. Thirdly, low temperature, no higher than +5 degrees. A regular refrigerator, vegetable compartment or freezer will do. Previously, badger fat was kept in glaciers and cellars. The main criterion is that it must remain white and hard. Frequent transitions from solid to liquid and vice versa deteriorate its quality.

Good fat has almost no odor. It is somewhat specific, but unobtrusive and not unpleasant. This is despite the fact that during heating the smell is sharp and quite persistent. The consistency of high-quality rendered fat is homogeneous, the color is white or with a slight creamy tint.

Now you know how to melt badger fat in a slow cooker, in an autoclave, in an oven and in a water bath, which means that you can make an excellent product yourself that will help you out in a variety of situations.

Special cases

The same rules must be followed if you use a coal-fired stove. The slight difference is that such a stove is pre-heated in the same way as a wood-burning stove, then a small amount of medium-sized logs is loaded, and only after they have burned well can coal be added. The first backfill should have a thickness of no more than 5-6 cm, and only after the first layer has flared up, you can fill in the second - up to 15 cm thick. This will ensure uniform combustion and economical fuel consumption.

Pellets are a type of solid fuel in the form of granules made from sawdust. You can use pellets to heat a regular wood stove, the only condition is that the distance between the grates should be less than the size of the pellets themselves. Sometimes for this purpose a metal basket with small cells is placed in the firebox. But it is better to pay attention to pellet stoves specially designed for this type of fuel. The owner here only needs to select the combustion temperature, and the device will load the fuel, adjust the air supply and draft itself, since all processes in it are automated and controlled electronically. Those who wish can program it manually if they have knowledge of how to light a stove and an understanding of how this device works. In all other cases, it would be better to use the automatic mode.

How to heat a kitchen stove that runs on solid fuel? The only difference is that such stoves have a “summer” and “winter” flow of flue gases, regulated by two valves. In the summer, when the stove is used only for cooking, both valves are opened so that the smoke leaves faster and the room does not heat up. In winter, only one, the top valve, is opened so that the hot smoke warms up the entire body of the stove.

If you are heating your stove for the first time after purchasing it, you need to make sure that there are no parts or stickers left in the firebox, ash pan or ash pan. You should not immediately fill the firebox with wood or coal completely - for the first time it is enough to fill approximately 1/3 of its volume. The fire during the first heating should be small, and during subsequent fires you can gradually increase both the amount of fuel and the intensity of its combustion.

In the cold season, when heating the room is constantly needed, you should not allow the stove to cool completely, since each time it is reheated, additional fuel is consumed. For economical operation, the furnace is fired twice a day - for stoves with a long-burning function, and more - for stoves of conventional design. At the end of the process, you must make sure that the fuel has burned completely, and only then can you close the valve. A sign of completion of combustion is the absence of blue lights above the coals and a coating of ash formed on their surface. If there are smoldering embers left in the firebox, you can be poisoned by carbon monoxide, which is difficult to detect because it has no odor. In order to quickly extinguish the coals in the firebox, they can be sprinkled with sand, but they should not be filled with water, as this will cause the stove to malfunction.

Cleaning the stove and chimney should be done twice a year, since soot deposits and contamination of the chimney will not allow the system to warm up quickly, which means more fuel will have to be spent. In addition, a clogged chimney can lead to a fire due to the highly flammable soot. You can clean the chimney and stove yourself, but to achieve better results and get rid of this troublesome task, it makes sense to invite specialists. We hope that theoretical knowledge of how to properly heat a stove, complemented by practical skills, will help consumers save fuel and avoid troubles such as stove repair or fire.