It’s hard to imagine a traditional bath without hot steam, a fragrant broom and a warm shower after bath procedures. To organize hot water supply in a bathhouse, the main heat source is often used - an electric or wood-burning stove.

An alternative option is a water tank for a bathhouse, which is mounted on a heating boiler or stove. Read more about how to wisely choose a device of suitable volume and configuration for a private sauna or bathhouse.

How to choose a water tank

The water tank is a special welded structure, which is made from modern materials, equipped with an inlet for cold water and shut-off valves for hot water.

To choose the right tank for your bath, you should decide on the main parameters of the heater:

- type;

- material of manufacture;

- volume;

- installation method.

First, you need to provide for the principle of water intake, choose the appropriate size and installation method of the tank, so that in the future you do not spend an additional amount on re-equipping the equipment. The thickness of the walls of the structure depends on the size of the tank, which can range from 1 to 1.5 mm.

Next, you need to choose a method of heating the water - a stove or a built-in heating element. To decide which container will be more profitable to install, you need to take into account the total number of visitors for whom the bathhouse is designed.

If the bathhouse can accommodate no more than 2 people, then a device with a capacity of 50 liters is sufficient. For large companies, it is preferable to choose a tank with a capacity of 100 liters or more.

The material of manufacture and design features of the device should be taken into account when purchasing.

How to protect a tank from corrosion using improvised methods

Before starting the fight against corrosion, it is recommended to comprehensively analyze the cause of the problem. First of all, it is worth getting your water tested. However, if you place water from a well or borehole in a clean transparent glass container and observe it, it is not so difficult to determine the increased iron content - an orange precipitate will form at the bottom on the second day. In this case, you will not only have to protect the tank from iron oxide, but also install a water purification station.

The second point is to choose the right rust removal strategy. If the sinks are deep and entire layers are peeling off on the walls, a major cleaning will be required using a full range of methods, including mechanical and chemical cleaning.

If the rust is simply washed off or wiped off with a rag, then you can get by with the use of chemicals.

Types of water tanks for baths

There are three types of water tank - built-in, remote or on a pipe. Moreover, each has positive and negative sides.

Built-in structures

A built-in tank is a classic version of the design, installed on the bottom of a heating stove and combined at the top with the combustion chamber.

This ensures accelerated heating and maintenance of optimal water temperature for a long time.

In this case, the bottom of the tank is in direct contact with an open fire, and liquid is drawn from the tank from above or through a built-in tap.

Remote structures

A remote tank is provided for a furnace equipped with a heat exchanger. Such a device is connected to a heat exchanger using copper pipes, so it can be installed in any room of the bathhouse - washing room or dressing room.

Among the advantages of a remote-type water tank are maintaining a high water heating temperature, reliability and practicality.

The principle of operation of the device is quite simple: cold water enters the heat exchanger, and the heated liquid is supplied back to the tank.

Pipe structures

The design of the tank mounted on a pipe is quite relevant when the bathhouse is used throughout the day.

Such a device provides rapid heating of water to a comfortable temperature thanks to the thermal energy released through the chimney pipe.

The tank on a bath pipe is distinguished by its significant dimensions, high thermal capacity and efficiency. In addition, it is able to prevent carbon monoxide leakage during frequent firing of the sauna stove.

The most common version of the device is a samovar-type tank, equipped with a single or double fitting. These tanks vary in volume, size and design.

Where does rust come from in a water tank?

The appearance of rust in the tank of a sauna stove is common for containers with an open volume. This is especially true for homemade containers, which are created using steel or metal sheets or large diameter pipe sections.

Upon contact with water, and even more so when the temperature rises due to a chemical reaction, the walls are first covered with a small layer of oxide, and over time the corrosion process becomes widespread. The containers most susceptible to these processes are in bathhouses, which are used occasionally, and especially in cold times, when the room remains unheated and after the procedure is completed, the water is drained from the tank.

Corrosion does not bypass tanks in heated rooms; this process takes a little more slowly, but there is no escape from it. The process lasts slowest in tanks that are constantly filled with water, but here, too, over time, rust is deposited on the walls.

There are several reasons for the occurrence of rust - contact of water with unprotected metal, the presence of iron oxide in the water itself, saturation with chemically active substances that promote corrosion.

Materials for making tanks

The type of material used to make the sauna tank determines the durability and reliability of the structure, the speed of heating and cooling of the liquid. Water heating devices are made of stainless steel, cast iron and metal.

Stainless steel

The most popular material for the manufacture of tanks for heating water in a bathhouse is stainless steel. It is resistant to corrosion, fire, high humidity, deformation and damage.

In addition, stainless steel products have high thermal conductivity, hygiene and resistance to temperature changes.

The stainless steel tank can be presented in cylindrical and rectangular shape.

Proper care of stainless steel products guarantees efficient operation and a long service life.

Made of cast iron

Cast iron remains the traditional material for making water tanks. It has good performance characteristics - low thermal conductivity, resistance to corrosion, deformation, mold and overheating.

The disadvantages of cast iron products include their impressive weight and complexity of installation.

In cast iron tanks, water heats up slowly, but also cools down over a long period of time. Therefore, one volume is enough to satisfy hot water needs for the whole day.

Made of metal

The cheapest option is metal tanks, which are susceptible to corrosion, rotting and deformation. Such characteristics can negatively affect the quality of water and the durability of the product.

It is strictly forbidden to paint metal devices with moisture-resistant paint, which can release toxic substances when heated.

Less popular are enameled tanks, which are sensitive to mechanical damage. If there are chips in the enamel, such devices are not recommended. To protect the heaters from possible corrosion, their surface is treated with a special heat-resistant compound.

Stainless steel tanks of the remote type are considered the most practical and reliable. Such designs are distinguished by their attractive appearance and safe operation.

Preparation and painting of the product

Before painting the inside of the barrel, its surface must be properly prepared. This rule especially applies to old containers that have already been in use. The tank or barrel must be cleaned using abrasive equipment.

The surface must be degreased to ensure adhesion of the metal to the soil or enamel. Used containers always contain residual dirt and corrosion. If there is rust in the barrel, it must be removed using a metal brush or an electric drill with an attachment. Next, treat the inside of the barrel with a rust converter, which will help stop the corrosion process.

If anti-corrosion work is performed incorrectly, the adhesion of paint materials to the metal surface will not occur. You can paint the inside of containers provided that you have provided adequate ventilation.

To prevent water from penetrating into the pores contained in the paint, painting should be done in two or even three layers. The container ready for painting must be completely dry. Priming is also carried out in two layers. For protection, you must have rubber gloves, goggles and a respirator. Each successive layer is applied only when the previous one is completely dry.

As a painting tool, you can use a brush or a compressor sprayer.

You only need to paint on a flat surface. If the container contains non-potable water, then you can use the simplest method of corrosion protection.

Painting the inside of a metal container should be done at an air temperature of -15 to +40 degrees.

On video: how to protect a barrel from rust.

Selecting the optimal tank volume

An equally important task is to determine the appropriate tank volume. The calculation of this parameter should be carried out taking into account the rate of water consumption per adult for bathing procedures, which ranges from 18 to 26 liters of water.

For a family of 2 people, it is enough to purchase a 50-liter tank, for a holiday with a group of 4 to 6 people - a 100-liter tank.

Factory models of water heating devices are presented in a wide range of volumes - from 20 to 200 liters. Electric boilers also have different volumes - from 30 to 100 liters.

TOP 5 best water tanks for baths

| Photo | Name | Rating | Price | |

| #1 | Teplodar Parus | ⭐ 99 / 1002 — votes | Find out the price | |

| #2 | Ferrum | ⭐ 98 / 100 | Find out the price | |

| #3 | MetalStroy | ⭐ 97 / 1004 — votes | Find out the price | |

| #4 | Volcano | ⭐ 96 / 1001 - voice | Find out the price | |

| #5 | Horizontal | ⭐ 95 / 1004 — votes | Find out the price |

Which water tank would you choose or recommend?

Take the survey

Methods for installing a water tank

Having decided on the type and material of manufacture, you can consider the available methods of installing devices that provide fast and efficient heating of water.

You can install a hot water tank with your own hands in the firebox, above the heater and next to the stove.

Installation in the combustion chamber

The method involves the use of a sauna stove with a large combustion chamber for internal installation of a water tank.

The following requirements are imposed on the device for heating water: minimum wall thickness - 0.8 mm, resistance to temperature changes and deformation.

The structure is heated over an open fire, so it can capture its base and end elements. This method is often recommended for installing stainless steel tanks.

Installation above the heater

An equally popular option, which involves installing a heater above the compartment for heating bath stones and generating steam.

If a cast iron device is used, it must be suspended from the ceiling structure using a metal cable and hooks. The best option is a lightweight stainless steel tank.

It is economical to install a water heater above the stove around the chimney pipe, which can provide accelerated heating of water from the stones and pipe.

Installation near the stove

This method involves installing the tank near heating equipment. As a rule, it is used in saunas with high air temperatures and low humidity.

In this case, the hot water tank is mounted at a distance of at least 250 cm from the direct heat source, and the water is heated using a double-circuit heat exchanger with cold water supply and hot water output.

Cold water is supplied to the heat exchanger and heated, then discharged into the heater, after which the heating cycle is repeated.

Use of improvised means

Folk remedies can partly help temporarily solve the problem. The set of measures includes all stages of metal processing - cleaning, installation of a protective layer and its fixation on the inner surface.

To combat rust, acid-containing substances are most often used. Upon contact with metal, the acid reacts and forms a stable oxide layer on the surface. Experienced bathhouse attendants recommend pouring 50-100 grams of citric acid into 20 liters of water and boiling the tank. The oxide film will protect the surface for one to one and a half years.

A more modern option suggests treating the walls with a special anti-rust agent. This is a more effective method, but after it it is necessary not only to rinse the container, but also to apply a protective coating.

The following can be used as a coating using available materials:

- Aluminum powder mixed with liquid glass (silicate office glue) - the composition forms a heat-resistant coating that can withstand 2-3 years of active use;

- Red lead is a filler or the main primer for compositions used to paint metal surfaces (the bottom of sea vessels is painted with red lead);

- The lime-cement coating is prepared in a 1:1 ratio. Apply to a dried surface. For best results, it is recommended to apply 3-4 layers of treatment.

From the video you can learn how to paint a container with red lead.

The disadvantage of these methods is the complexity of the coating application and the relatively short duration of the protection. On the other hand, these methods allow you to quickly and effectively provide rust protection with truly affordable means.

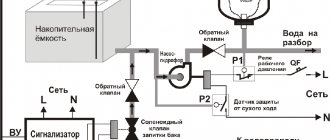

How does the system work?

Heat from the stove is transferred to the register or water jacket of the heat exchanger, which leads to an increase in the temperature of the coolant. Since the water in the tank has a lower temperature, pressure is created that promotes gravity flow of the liquid. Thus, hot water enters the tank, and cold water enters the heat exchanger through a pipeline, where it is heated (from the bottom point of the tank, water should be supplied to the bottom point of the heat exchanger, and from the top point of the heat exchanger, water should accordingly go to the top point of the tank). The minimum pipe diameter is 3/4 inch. The process continues until the temperature in the oven drops.

How to connect the water tank

Important! The tank must be higher than the heat exchanger, otherwise water circulation will not be ensured.

Without installing a pump, the total length of the pipes between the heat exchanger and the remote tank should not be more than 3 m. There is also a nuance in the principle of the pipeline design. It is necessary to create a slope to ensure natural circulation of the coolant: the pipes connecting the heat exchanger to the tank must have a slope of at least 25...30 degrees, and those delivering water from the heat exchanger to the tank must have a slope of at least 250 degrees.

Installing a heat exchanger allows you not only to do without a water heater in the tank, but also to transfer heat to all rooms.

DIY sauna tank

The heat exchanger must be chosen wisely. It should not reduce the performance of the heater by taking away a significant amount of heat from it. The maximum that it can take is 10% of the generated thermal energy.

If it is not possible to organize the movement of water by gravity, you can supplement the system with a circulation pump. This will increase its effectiveness. It will be possible to increase the length of the pipeline and reduce the slope. But the operation of this equipment is only possible from a 220 V electrical network.

Circulation pump pressure calculator

Go to calculations

Important! When operating water supply systems, remember that it is forbidden to heat the heater if the tank is empty. Otherwise, the welds may come apart. We also must not forget that in winter, water must be removed from the system (if the bathhouse is not heated), since when it freezes it can break the structure.

You cannot heat a stove with an empty tank.

Since when installing a water supply in a bathhouse, you often cannot do without a circulation pump, which ensures the movement of liquid in a closed circuit, the 5 best models are offered.

Types of bath paints

We have already said more than once that, with the exception of the steam room in the bathhouse, all other rooms are quite comparable to similar rooms in a residential building. Therefore, everything that is applicable in a residential building can also be used in a bathhouse.

Recreation room with wood varnish

IMPORTANT! Do not use only exterior paint compounds on interiors and vice versa.

The chemistry of paints is a complex thing. Nowadays, manufacturers are fighting to ensure that their products are better, which means they last longer, do not lose color, and are ready for various loads. hybrids appear - for example, the addition of polyurethane makes the composition more durable and wear-resistant, which is important for the same sex.

The main directions still exist, but their boundaries are significantly blurred by “hybrids”.

INTERESTING! Paints based on organic solvents are gradually becoming obsolete. But this is not just a tribute to fashion; they are outdated due to their toxicity to humans and the environment.

Alkyd enamels and their subtypes, nitro enamels, as well as oil paints - all this can be called “last century”. However, they are still produced by the paint industry and are in demand, but the main reason to purchase them is budget constraints.

Because with sufficient financial freedom, water-based paints - they are the most environmentally friendly, have a low odor that is not comparable to previous dyes, they are convenient to use and the result is decent.

However, today you can find the following types of water-based paints:

- acrylic;

- mineral (with the addition of cement or slaked lime);

- silicate (based on liquid glass);

- silicone.

Here we will go over the most optimal dyes for baths. Mineral ones, for example, last too long and are therefore doomed to lose demand.

Acrylic

It is successfully used to create coatings both inside and outside of various buildings. As a paint for baths and saunas, it can be used to cover any surface, including floors. Only in this case you need a special, wear-resistant variety, because walking on the floor erases the paint.

BY THE WAY! An important advantage of acrylic paints is their fire safety. This is compared to the “outdated” ones, which are completely flammable.

Acrylic bath paint can be successfully used for painting both wood and concrete surfaces. However, all this is stated on the labels. There are varieties suitable for painting walls and ceilings, there are special types for floors, and there are facade paints. In general, acrylic is applicable everywhere.

Acrylic varnish for baths, manufacturer “Yaroslavl paints”

If you are interested in specific details regarding paints for walls or floors, or façade or interior paints in general, or you have decided to paint a stove and are choosing the appropriate enamel, just follow the appropriate link. We touch on these issues here very superficially. Here is a link to the entire relevant section of our website.

Silicate

Silicon based dyes

They are used mainly outside, for facade work on brick or concrete. This creates a coating that will last 20 years - good news, right?

But brick baths are less common than wooden or wood-clad ones, so we’ll be brief here. Of course, it is suitable if it matches the type of surface.

Silicone

An expensive option, but suitable for finishing the same shower. Silicone dyes “breathe”; in addition, they are elastic, therefore the wood underneath will also “breathe”, and the elasticity will not allow the coating to suffer when the volume of the wood changes.

Silicone, for Elcon lining

Both silicone and acrylic dyes have a lot of advantages They are durable, heat-resistant, fireproof, environmentally friendly and so on. However, they are not cheap yet . Nevertheless, we recommend them. Latex ones are no less good - this is a type of acrylic with the addition of latex).

Latex paint Dali

Silicone enamel

Paint for an iron stove in a bathhouse

First of all, it is a durable coating that is least afraid of temperatures. That is, the pigments may turn out to be unstable and change color, say, at 150 degrees, but the coating will not lose its shape or change at all.

Actually, when we mentioned silicate paints above, this was silicone paint for facades. But now it is separated into a separate category, because there is a reason to use heat-resistant enamels in the bathhouse - this is painting a homemade metal stove.

For those who are wondering “what paint to paint an iron stove in a bathhouse with,” we answer that the best option is organosilicon or silicate paint with increased heat resistance that allow it to withstand the temperatures of a hot stove. Read more about paints for stoves in metal baths in this article.

Acrylate varnish

An alternative to covering wooden walls and ceilings in bath rooms, with the exception of the steam room, can be a water-based varnish that contains acrylates.

However, those who want to varnish wood floors of this type should take into account the fact that without special additives, scuba tanks are prone to abrasion.

Of the additives that will increase its wear resistance, polyurethane should be mentioned first .

Small heating stove

If there is a need, then in the bathhouse, along with the main stove, a small one is additionally installed. This significantly increases the flow of hot air and heating of the bath room.

Stages of work:

- A metal water container in the shape of a cylinder - 75x45 cm - is mounted on the side of the stove.

- The interior walls are lined with bricks.

- Pipes are connected for supplying cold water, as well as for discharging hot water. A faucet is installed (read: “What types of bath faucets are there - a reliable water supply device”).