Distinctive features

Cast iron heats up more slowly than steel, but its properties are superior to all materials . During the operation of the furnace, burnout occurs more slowly. The case retains heat for up to seven hours. Cast iron is an alloy of iron and carbon, making it resistant to corrosion and resistant to high temperatures.

Silicon and manganese in the composition make cast iron more durable and ductile.

The structural elements of the furnace are combined into a single structure by welding . All joints are treated with sealant. The operating principle of cast iron stoves is the same. It comes down to heat transfer indicators and heat retention time. This is what distinguishes cast iron from other materials.

The stones are placed on top, and the water tank goes around the pipe and the stones. This ensures minimal heat loss.

Firewood is thrown into the firebox. When they burn, a hall is formed. It pours into a special compartment. Next, the hot air rises, and the stones are heated by the stove and pipe. The temperature in the pipe reaches 250 degrees Celsius . The stones give off heat to the room, thereby creating a comfortable environment.

Main design features

When purchasing such equipment, you need to be especially careful when choosing cast iron fireboxes. This is where the firewood smolders, generously releasing its heat into the room. In many ways, issues of safety and effectiveness depend on the correct choice of this element. There are two types of models on sale:

- Closed. The design is equipped with a glass door, which allows you to protect you from flames. The efficiency is approximately 80%. With this option, the consumption of firewood is significantly reduced.

- Open. This type of fireplace insert is less efficient, but also costs less.

In addition to some design features, the products have an individual design, so you need to select them not only based on the characteristics of the model itself, but also on the interior of the room in which the device will be located.

Advantages and disadvantages

Cast iron stoves are considered the standard. They are much more practical than stone, steel and other units. This is due to the optimal composition, design features and build quality.

Advantages:

- simple installation;

- cheap fuel (firewood);

- compact dimensions - usually the stoves are small, so they can be installed even in a small room;

- installation does not need to be coordinated with interested organizations, unlike gas boilers;

- the oven reaches the desired temperature much faster compared to electric and gas appliances;

- the housing is highly sealed;

- products are resistant to high temperatures (steel deforms over time);

- the water in the tank remains hot for up to 4 hours;

- service life is more than 30 years, which is not typical for stoves made of other materials.

Flaws:

- you need a stronger foundation than when installing a steel stove;

- unlike an electric boiler, it is necessary to make a chimney;

- despite the massiveness, the material is fragile, so you need to be careful when installing;

- the price of cast iron stoves is higher compared to steel and other units;

- Sudden cooling is not allowed, otherwise the cast iron will crack.

Cast iron or steel? Choosing a sauna stove

The vast majority of bathhouse lovers today still prefer iron stoves. The number of their supporters is growing in direct proportion to the growth of the urban population. Brick kilns are still being built and used in villages out of habit. Otherwise, this is already perceived as obstinacy in observing old traditions or, to some extent, luxury.

And manufacturers of compact stoves are not asleep; they know how to lure doubting buyers to their side. Want a traditional oven? - please, options with a brick lining, lined with ceramic or stone casings - that's what you wanted - a brick oven, or almost like that.

In general, there are no problems with the choice; you will find whatever you want. Questions arise elsewhere - to choose it most accurately for yourself.

In general, the characteristic design features of metal wood-burning stoves are simple and straightforward. Many more questions arise when choosing the type of heater - open or closed; a separate article is devoted to this, which you can read here.

Another stumbling block is the type of material - steel or cast iron. It would seem that there is something so special here, but at this simple, at first glance, moment, oh, so many copies have been broken.

Let's try to understand the features of cast iron stoves (c/p), note their advantages and disadvantages.

A little science

Let's start by noting the key features of each type of alloy; this is necessary to better understand the essence of the issue. As you know, both materials fundamentally contain iron and carbon; the difference lies only in their percentage of each other and additional components.

Steel, having in its composition from 1.5 to 2% carbon and at least 50% iron, acquires hardness and strength. Cast iron is characterized by a carbon content in the alloy of more than 2%. As a result, it also becomes hard, heat-resistant, but at the same time fragile.

The ratio of the number and amount of binding components in each type of alloy determines their physical and chemical properties, thanks to which they can be endowed with special parameters that increase their strength characteristics

The main differences between cast iron and steel are as follows:

- steel is stronger and harder than cast iron, - steel can be cut, welded, forged, cast iron can only be cast, - cast iron has lower thermal conductivity, but higher heat capacity, - cast iron, due to its porous structure, has less weight, - it is easier to give steel a beautiful appearance, than cast iron.

Various components and additives can to some extent approximate or even acquire a number of properties inherent in a particular type of alloy, but this is very expensive technologically and is used only in special industries. For this reason, it is advisable to make sauna stoves only from special, but typical steels and cast iron, which have all the above differences.

We’ve sorted this out, now let’s look at the experience of using black and white, what attracts or, on the contrary, scares potential buyers.

Advantages of cast iron stoves

Stoves made of cast iron have a large wall thickness of 10 mm and above, while steel stoves are most often smaller (regular 6-10 mm, heat-resistant - 4-6 mm). The difference in this leads to the fact that such bath appliances accumulate heat much better, retain it longer and release it longer. Ultimately, this affects the saving of firewood and a smoother and more gradual heating of the steam room.

1

Steel heats up a little faster than cast iron and, accordingly, begins to release heat into the bathhouse earlier, but this difference is not significant.

Thick walls, plus the heat resistance of cast iron, affect durability. Stoves cast from this alloy do not suffer from the same disease as steel ones, firebox deformation from extreme temperatures and do not burn out over time. Manufacturers of iron stoves unanimously repeat, do not overheat them, but, firstly, how to set this limit by eye, and secondly, even with gentle use, this still happens sooner or later. Cast iron has no such problems.

The corrosion resistance of this material has long been known; unlike steel, it does not rust even under severe conditions of temperature and humidity changes, thereby again ultimately increasing its durability.

They are also endowed with good heat resistance, i.e. under prolonged exposure to fire they do not form scale, which cannot be said about steel.

All parts are made by casting, their assembly is carried out either according to the tenon-groove principle or using special sealants. The absence of welds is another plus for these devices, because... Often, if the technology is not followed, they turn out to be the weakest point in conventional products.

This alloy has another important feature - it is chemically neutral, as a result of which the process of oxygen burnout does not occur.

2

Flaws

As you know, the prices for such stoves are not low, but this is not the only thing that scares off potential buyers. What worries them most is the fragility of cast iron. This alloy is resistant to sudden temperature changes; cold water that gets on the walls of the furnace can crack its body. It is not possible to weld this section, it can only be replaced or it will have to be scrapped.

Despite the fact that cast iron is lighter than steel, the former is ultimately heavier due to its thick walls. For this reason, for variants of such stoves with a closed heater and a large bowl volume, it is necessary to build a foundation for laying stones.

And finally, let's compare prices. In the economy class segment, only steel stoves are presented. Those made of cast iron belong to the medium or high price category.

Many manufacturers, trying to acquire successful and durable stoves, began to design combined ones. In them, the combustion part is made of cast iron, which in turn is protected by a stainless steel casing. Such options, in general, are not bad, but those who prefer wet or so-called. “broom” steam still gives preference to brick or black-and-white with stone panels or covered with brick.

Manufacturers of cast iron stoves

Hephaestus – cast iron SCh20-25 ChH10, wall thickness from 10 mm to 60 mm, bath volume from 25 to 45 cubic meters. Models come with the letters PB.

Svarozhich - made of gray cast iron SCh-15, wall thickness 6 mm-15 mm, steam room volume up to 35 cubic meters. Models are “Fire Bird” and “Slavyanka”, the latest model has all the options: economy, standard, classic and luxury have a combined design – the firebox is cast iron, the heater is stainless steel.

Izhkomtsentr VVD - cast iron GJL200, wall thickness - 10 mm, volume - 18 - 40 cubic meters. Models – “Kalita” and “Sudarushka”. Construction - firebox and body made of cast iron, lined with stone. Sudarushka M and MK are combined, the firebox is cast iron, and the heater is stainless steel or ferrous metal.

PetrazovodskMash - gray cast iron, walls - from 10 mm to 20 mm, steam room volume up to 20 cubic meters. Models – the letters ATB or “Karelia” are used in the name.

What to choose and which one is better?

Stoves for baths and saunas are made of cast iron, heat-resistant steel or alloyed stainless steel . Materials differ in carbon content. The ductility and strength of steel and cast iron is due to the low carbon content (2%). Each option has its own characteristics and disadvantages.

The main advantages of a cast iron stove:

- Thermal conductivity . The indicator is much better than that of structures made of brick and steel, which deform due to temperature changes. The efficiency of a cast iron stove is 82%. After one load of firewood it works up to 7-9 hours. The weight is up to 300 kg, which eliminates the need to install a foundation on it.

- Easy care . If you install a cast iron stove, you don't have to spend a lot of time maintaining it. The product does not rust and does not require special paint. Due to the absence of cladding, the unit is easy to install and, if necessary, dismantled for transfer to another location. Steel products need to be treated with heat-resistant paint, and this should be done once a year.

- Design . For this reason, both steel and cast iron stoves attract buyers. The range is represented by a variety of models, which allows you to find the right option. The ovens are equipped with doors made of heat-resistant glass. Various forged elements give the stoves a sophisticated look.

- Safety in operation . Compared to brick stoves, cast iron products are safer to use, as they are less likely to cause fire.

- Lifetime . One of the main features of cast iron stoves. With proper use, the service life exceeds 35 years.

The only disadvantage of a cast iron stove is the high price . But products from domestic manufacturers are cheaper. At this quality, it is no worse than that of Swedish and other manufacturers.

Steel sauna stove

Sauna stoves can be made of black heat-resistant steel or stainless steel. Recently, there are fewer and fewer stoves made of heat-resistant steel. Although they are cheaper, their service life is very short: at high temperatures, which are inevitable when preparing a bath, oxidation processes occur very intensively and the metal is destroyed after some time. They say that the firebox “burns out.” An unpleasant point is also the large amount of thermal expansion: when heated, the stove begins to change its size, which can cause the welds to burst. However, they also have advantages: with their small size and low weight, steel sauna stoves have high heat transfer and quickly heat the room. But at the same time they cool down quickly, making it impossible to dry the steam room. These stoves are good if you need an inexpensive stove for a short period of time.

Stainless steel sauna stove. Heats up quickly, but also cools down quickly

Sauna stoves made of stainless steel (alloying metal content of at least 12%) have their pros and cons. The advantages include greater durability. In addition, stainless steel does not oxidize even when heated. But this does not apply to places where welding was carried out. In the seams, the alloying materials have evaporated, and the metal oxidizes very actively when heated. There is another problem with stainless steel seams: with a rapid change in temperature, tension arises due to a large difference in heating, which can lead to destruction. Therefore, in stainless steel stoves the weak point is the seams. Manufacturers are aware of this problem and are trying as best they can to correct the situation: they use special equipment for welding. The structure to be welded is placed in a chamber with a special oxygen-free atmosphere, where welding occurs. Under such conditions, the alloyed materials almost do not evaporate, and the seam, even when heated, practically does not oxidize.

Stainless steel sauna stoves are not without one more drawback: thermal expansion is still high. And when heated, the walls of the stove and, especially the firebox, begin to “walk”. To eliminate this effect or reduce its size, additional stiffening ribs are welded onto the walls, which prevent a critical change in the geometry of the chambers. This problem is partially solved by increasing the thickness of the metal used, but this, firstly, leads to an increase in cost, and secondly, to greater mass. But light weight is one of the advantages of metal stoves.

Important! Stainless steel is not necessarily shiny. There are blued steel grades that have a deep black color.

How to choose a cast iron stove and what to look for?

The range is represented by a huge selection of models . The buyer decides which one to choose based on individual needs and financial capabilities. To find a suitable option, you should read the recommendations.

Stove selection criteria:

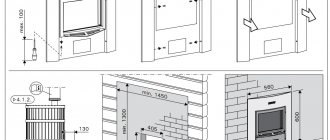

- Placement of the firebox . It can be regular or extended. The latter is installed in the wall opening. This allows you to heat the stove not from the steam room or from the rest room.

- Tank type . The design can be built-in or wall-mounted. When choosing, you need to focus on the specifics of the bath.

- Productivity . This indicator is indicated in the product passport. It determines how quickly the room warms up.

- Door type . Models with a tempered glass door are more expensive, but simpler products are not inferior to them in quality.

- Material . Some manufacturers replace some of the elements with steel ones to reduce the cost of their products. The disadvantage is that the service life of the oven is significantly reduced.

- Heated volume . The indicator is indicated in the product characteristics. It is worth focusing on the area of the room.

- Ash box . Most modern models have a built-in box where combustion waste is collected.

Popular furnaces with heat exchangers

Cast iron stoves are deservedly popular among lovers of Russian baths, but how are they combined with heat exchangers? As it turns out, they combine perfectly.

Cast iron stove

To get started, we recommend visiting the website of the Petrozavodsk stove manufacturer Karelia. Among the products offered to visitors are components, among which there is a disk-shaped heat exchanger, apparently attached to one of the walls of the furnace. Thus, you can purchase both a stove and an exchanger at once. As an option, they also sell mounted tanks for the chimney.

Cast iron stove with heat exchanger for a bath. Photo source

Vesuvius stove

Vesuvius stove with heat exchanger for a bath

The stove manufacturer Vesuvius also provides the opportunity to simultaneously purchase a stove (and in its catalog you will find both steel and cast iron stoves) and a heat exchanger . The buyer is given a choice of three models - two “samovars” for the chimney, differing in capacity, and one rectangular heat exchanger, which takes heat from the stove wall.

photo of heat exchangers on the Vesuvius website

Stoves for baths "Termofor"

There is a message on the Termofor website that the manufacturer took into account customer preferences and produces the most popular models - Tunguska 16 and Tunguska 24 - with already installed heat exchangers , which require an external location of the storage tank. The material of the exchangers is high-quality food grade stainless steel, 2 mm thick . Depending on the buyer’s choice, the placement can be varied by installing it either on the right or on the left wall of the stove.

Useful video

Termofor sauna stoves with a heat exchanger may be built well, but there are negative reviews. Watch the video and see what it looks like:

TOP 7 best cast iron stoves for baths and saunas

When choosing a product, you should take time to study the characteristics of different models. When comparing, it is easier to understand which oven will be most suitable. The rating includes seven stoves from different manufacturers. Each of them has its own characteristics, advantages and disadvantages.

Hephaestus PB-04 MS

The products are made of alloy cast iron. The thickness of the parts is 40 mm. Due to its unique shape, the oven heats up to 500 ⁰C in a short time. Convection fins on the side mounts increase heat transfer. Despite the thickness, the unit quickly distributes steam.

Characteristics:

- dimensions - 39.40x56x64.50 cm;

- weight - 130 kg;

- heated volume - 15 m³;

- power - 8 kW;

- type - closed;

- Efficiency - 87%;

- secondary afterburning - yes;

- ash box - yes;

- chimney diameter - 11.5 cm.

Advantages:

- completely made of cast iron;

- spacious ash drawer;

- glass door;

- optimal size;

- convenient connection to the chimney;

- holds up to 180 kg of stones.

Flaws:

- high price;

- complex installation.

Hephaestus PB-04

High-quality stove made of alloy cast iron . Due to its unique design, it quickly warms up to the desired temperature, which ensures fast steam distribution. The side walls are equipped with convection fins, which increase heat transfer from burning wood.

Characteristics:

- dimensions - 39.40x56x64.50 cm;

- weight - 130 kg;

- heated volume - 15 m³;

- power - 8 kW;

- type - closed;

- Efficiency - 87%;

- secondary afterburning - yes;

- ash box - yes;

- chimney diameter - 11.5 cm.

Advantages:

- spacious compartment for stones and firewood;

- environmental friendliness;

- long service life;

- attractive appearance;

- high-quality case;

- built-in ash drawer.

Flaws:

- difficulties with installation (formation of a reinforced base);

- high price.

Vesuvius LEGEND STANDARD 16 (DT-4S)

The stove from the Russian manufacturer is extremely popular . The manufacturer uses high-quality materials to manufacture products. The stove heats a large room in a short time.

Characteristics:

- dimensions - 56x70x69 cm;

- weight - 117 kg;

- heated volume - 18 m³;

- power - 16 kW;

- type - closed;

- secondary afterburning - yes;

- ash box - yes;

- chimney diameter - 12 cm.

Advantages:

- weight of stones up to 120 kg;

- stylish design;

- glass door;

- high efficiency;

- fast heat transfer;

- easy care;

- glass self-cleaning system.

Flaws:

- some elements are made of steel;

- a protective coating must be applied.

Vesuvius LEGEND FORGING 16 (270)

When manufacturing furnaces, the manufacturer controls every stage: from the extraction of raw materials to packaging of products . Due to this, the stoves are of high quality. Model LEGEND FORGING 16 (270) has an attractive appearance.

It is characterized by high heat transfer. The thickness of the firebox walls is 1.2 cm.

Characteristics:

- dimensions - 56x70x69 cm;

- weight - 98 kg;

- heated volume - 18 m³;

- power - 16 kW;

- type - closed;

- secondary afterburning - yes;

- ash box - yes;

- chimney diameter - 12 cm.

Advantages:

- all-welded construction;

- spacious ash drawer;

- high efficiency;

- heat-resistant glass door;

- remote firebox.

Flaws:

- corrosion;

- the need for treatment with a special compound.

Vesuvius Sensation 16 Anthracite (270)

The manufacturer is constantly improving models. Cast iron stove Vesuvius Sensation 16 Anthracite (270) has optimal characteristics. Quickly warms up the room due to the dense walls.

Characteristics:

- dimensions - 41x64x69 cm;

- weight - 99 kg;

- heated volume - 18 m³;

- power - 16 kW;

- type - closed;

- secondary afterburning - yes;

- ash box - yes;

- chimney diameter - 12 cm.

Advantages:

- Beautiful design;

- capacity up to 60 kg of stones;

- convenient ash drawer;

- high efficiency;

- heat-resistant door;

- minimal load of stones on the collector;

- self-cooling and self-cleaning system;

- high quality coating.

Flaws:

- overcharge;

- installation difficulties.

Vesuvius RUSICH ANTHRACITE 22 (DT-4) 2016

High-quality model that meets European quality standards . A closed stove equipped with a chimney. The wall thickness is 0.8 cm, which ensures rapid distribution of heat and steam.

Characteristics:

- dimensions - 56x73x69.50 cm;

- weight - 99 kg;

- heated volume - 14 m³;

- power - 16 kW;

- type - closed;

- secondary afterburning - yes;

- ash box - yes;

- chimney diameter - 11.5 cm.

Advantages:

- quality material;

- durable cast iron door;

- optimal size;

- convenient connection to the chimney;

- it is heated from the next room;

- colorful appearance.

Flaws:

- holds 40 kg of stones;

- complex installation.

KASTOR Karhu-16 JK

Finnish stove made of alloy cast iron . Durable product. It warms up the room perfectly and maintains a high temperature for a long time.

It has a simple design, making it suitable for any room style.

Characteristics:

- dimensions - 43.50x71x49 cm;

- weight - 59 kg;

- heated volume - 16 m³;

- power - 16 kW;

- type - closed;

- secondary afterburning - yes;

- ash box - yes;

- chimney diameter - 10.4 cm.

Advantages:

- quality material;

- high level of productivity;

- compact size;

- beautiful design;

- high power;

- easy cleaning.

Flaws:

- high price;

- glass door.