It’s getting cold, you want warmth, even heat, and again a sauna made of a sandwich panel pops up in construction plans; the price is what’s very attractive about it.

We all know that a real bathhouse should be made of wood, preferably a log house, and all that. But let's face it - there are many saunas made of the wrong materials, where you can also take a very good steam bath. And in general, the best one is the one in your yard!

A sauna made from sandwich panels can be quite compact, even 4 by 4

Let's proceed from parameters such as:

- safety;

- availability;

- practicality;

- pleasure.

Features of the material

Sandwich panel is a ready-made construct that solves the problem of standard frame buildings. It is both easy to install and immediately contains insulation. Bathhouses made from sandwich panels and their projects are also not complicated. In fact, they can be assembled independently by anyone who has the skills for simple measurements and using power tools.

The sandwich panel is durable, can act as an element of structural rigidity, can withstand heavy loads, weighs little and is easy to process. It consists of several layers:

- outer covering. It can be a board of OSB, magnesite, metal, cement particle composition;

- internal insulation. Its role can be polystyrene foam (expanded polystyrene), mineral wool, high-density basalt wool;

- another layer of outer covering.

All layers of the composite are firmly connected to each other with a special polymer glue, during the hardening of which a pressure of several tons is applied to the slab. A bathhouse made of sandwich panels, if you choose the right materials and do not try to pay as little price as possible for them, will become a building that will serve for decades.

What are sandwich panels

The basis of the material most often includes chipboard sheets (if it is SIP) or steel sheets. The panel consists of several plates, between which insulation material is placed.

Sandwich panel composition

There can be several fillers for slabs:

- Styrofoam;

- mineral wool;

- polyurethane foam.

When building a bathhouse yourself, any of the proposed options can be used, however, based on such an indicator as environmental friendliness, mineral wool . Polystyrene foam and polyurethane foam are considered less environmentally friendly. However, such materials have excellent thermal insulation and sound insulation properties, and also have a very insignificant weight. However, when using these two materials, you should be prepared for the fact that the chimney will have to be completely insulated.

For the production of SIP panels, only high-tech equipment is used, which allows connecting individual elements to each other using an adhesive composition.

Manufacturing of sandwich panels

In this way, it is possible to achieve a high-quality, inexpensive and at the same time durable material that can withstand significant loads on a par with rounded logs. Based on its thermal insulation properties, the material can be compared to timber (kiln-drying) with dimensions of 20x20 cm or brickwork consisting of two bricks.

Comparison of material thicknesses to achieve the same thermal insulation value

Panels with a length of 7 m and a width of 2.4 m are considered standard. But the thickness can vary between 12-22 cm.

What panels are needed for a bath

It is worth noting that a bathhouse made of metal sandwich panels will seem like an unexpected idea to many people. However, it is precisely this material that shows the best ratio of price, speed of building assembly, and durability. The following dangerous factors are always present in the bathhouse:

- heat;

- non-zero danger of emission of coals and sparks where the bathhouse is heated with a wood-burning stove;

- high humidity.

Special metal sandwich panels with basalt or mineral wool are an excellent choice. They are designed not just to withstand moisture. The composite is designed to withstand even aggressive chemicals at high temperatures. In addition, this material is guaranteed non-flammable, which is important for any type of bathhouse.

Preparatory work

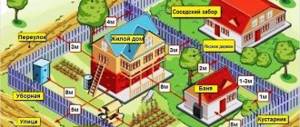

If it has been decided to build a bathhouse using sandwich panels without outside help, then first you should select the most optimal project for the future construction.

Bathhouse project example

Once the project is ready, you should begin purchasing all the necessary materials. For a bathhouse, you should purchase panels with a thickness of partitions of 10 cm and external ones of 20 cm, which will be more than enough. Oriented strand boards will act as barriers. For their production, compressed sawdust is used, which are glued together with synthetic wax and resins.

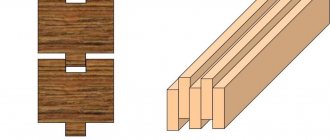

Oriented Strand Boards

To increase the strength indicator, the outer panels are made longitudinal, while inside they will be placed transversely. Such materials have their own classification, which fully complies with all declared standards. The special additives contained in the material must be at a minimum level and be completely safe for human health. Otherwise, during the heating process, specific substances may be released that will negatively affect the general condition of visitors.

Advantages

There are many advantages to a self-built bathhouse made from sandwich panels. A short list of obvious advantages is as follows:

- warms up quickly, even from a small stove;

- retains heat well;

- assembles quickly;

- in most cases, the construction of a complex foundation is not required;

- In addition to sandwich panels, a summer cottage-type steam room being built near a country house will require simple materials (beams, self-tapping screws).

You can build a bathhouse with the help of a couple of people. This does not require complex tools and devices.

Pleasure

Sandwich panels have a very low heat capacity and very good thermal insulation properties. This means that the sauna will warm up very quickly, which saves time and energy.

If you still think that there should only be wood in the bathhouse, cover the steam room with boards.

A bathhouse made from a sandwich panel is a small building, but the development of the project must be carried out very carefully. There are many nuances. You need to move the hottest objects away from the walls. The sandwich panels are connected almost hermetically, so ventilation should work well. It is better to use the same pipe from the oven not an ordinary pipe, but a sandwich pipe.

Pipe sandwich - design

The entrance to the bathhouse must be made with a vestibule, otherwise every opening of the front door will be accompanied by a cold draft. The penetration of cold air into the bathhouse in winter is especially unpleasant. In general, it is better to make a vestibule right away than to build on it later.

The bathhouse not only needs to be built correctly, even the stones need to be laid in a special way

A bathhouse is usually built on a hill or a slight slope. This is necessary to avoid dirt. An ideal addition to the bathhouse would be a swimming pool. And it is not at all necessary to make the pool stationary. You can buy an inflatable one, or better yet, a frame one. But you should think in advance about a flat, sand-filled area of at least 2 by 3 meters. Well, in winter, when you close the pool, after a bathhouse on the same site you can fall face down in the snow.

The floor in the bathhouse is another part of the structure that requires a special approach

Late autumn, winter and early spring are the best times to build a bathhouse. Materials are becoming cheaper, and if you build from sandwich panels, then low temperatures will not affect the quality of construction. The main thing is not to put off building a bathhouse until later, otherwise you will never build it. The bathhouse is an excellent means of treating and preventing winter colds!

Flaws

Bathhouses made from sandwich panels also have disadvantages. They are clearly visible if you build a structure with your own hands.

- When working with standard sheets, cutting the necessary parts, a lot of garbage is generated.

- Calculating the optimal number of sheets needed for purchasing is quite difficult; losing money is almost inevitable.

Even when ordering a ready-made kit for assembly, extreme care and certain qualifications of those performing the work are required. If you have doubts about your own abilities, you should carefully search and buy a turnkey bathhouse made of sandwich panels, with construction on site.

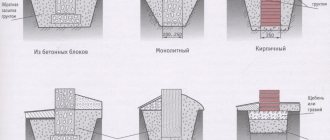

Foundation

A sauna made from sandwich composites is an easy construction. It does not require a complex foundation. However, the specific type of design should be chosen extremely carefully.

- The classic strip foundation is chosen only for soils that do not freeze in winter. It is not suitable for loose soil. The foundation is deepened to the ice level to avoid splitting of the structure.

- A concrete pad is created on sandy and loose soils. Such a foundation is simple, but a lot of material is spent on its creation.

- A columnar foundation is the simplest for soils of medium and high hardness that do not freeze in winter. To place the bathhouse on the base points, a timber frame is created.

All of the above types of foundations are inconvenient if the terrain is uneven. To make a good foundation for construction, you cannot do without earthworks. A pile foundation allows you to get rid of this. By placing the upper ends of the pillars at different heights, it is easy to level out any differences in height on the site.

Companies offering turnkey construction of bathhouses most often use piles. They can become clogged or screwed into soft ground. This can also be a convenient option for self-construction. A modern pile can be screwed by one or two people using simple clamping devices and a lever.

Site preparation and foundation pouring

Before you begin building a frame-type bathhouse using SIP panels, you need to prepare a work site designated for construction. The area must be cleared of stones, construction debris, grass, trees, bushes and other vegetation.

If the site is inclined or there are significant unevenness, then the site is leveled using an auxiliary layer of soil, or the top layer is cut off until the optimal result is obtained.

Construction of a building on a slope

A cord and wooden pegs will be needed to apply the necessary markings for the future foundation for the bathhouse. Each angle must be carefully measured and be 90°.

If the bathhouse is small, then installation is allowed without constructing a solid foundation. However, if the soil on the site is clayey, then it is still recommended to install a strip foundation. A small ditch, no more than half a meter deep, is dug under the foundation. But a width of 40 cm will be more than enough.

Strip foundation for a bathhouse

The formwork is being installed. The resulting molds are filled with cement-based mortar and pins are inserted into the still wet foundation, which will subsequently participate in fixing the strapping.

Pouring the foundation of the bathhouse

Immediately after the foundation has completely dried, you can begin laying a layer of waterproofing (2 layers of roofing material) and installing strapping type timber on it.

Installation of strapping beam

Before proceeding with the actual assembly of the structure, you should make sure that the cement is completely dry and mature. Drying should take about a week to be more convincing. Afterwards, the layer is opened and kept in the sun for several more days.

Walls

The walls of the bathhouse are erected by attaching sandwich panels to the timber of the load-bearing structure. If we are talking about independent construction, parts of the required size are pre-cut, door and window openings, and ventilation holes are made.

For external walls, a panel with a thickness of 125 to 250 mm is used. Internal partitions are constructed from thinner material. To save money while maintaining strength, it is wise to use panels with a thickness of 75 mm. Upon completion of construction, a beam is attached to the top of the walls, forming a common frame.

General information

Even a person ignorant of construction can voice the basic requirements for bathhouses of various designs:

- high thermal insulation;

- Fire safety;

- environmental cleanliness.

A sauna is not just a steam room. Traditional projects, depending on the type of bathhouse, may include a small dressing room, a separate room with a small pool, a room for gatherings at a table, etc. But it is the steam room that is the “heart” for which construction is started.

Roof

If you order a turnkey bathhouse, you can get any roof configuration. The most popular is the gable roof. It is simple and allows, in some cases, to get a comfortable attic.

If you build a bathhouse yourself, a simple, sloping, flat pitched roof will simplify the work and reduce material consumption. Even a beginner can assemble such a structure.

Exterior of the bathhouse

The external decoration of the bath can be anything. For those who used magnesite board panels for walls, there will be no problems. The material is called artificial stone; walls made of it look neat and stylish even without finishing. The only thing you need to do is seal the joints.

Otherwise, there are no restrictions on exterior finishing. The choice of a specific option depends only on the wall material. For metal sandwich panels, you can resort to decorative stone finishing or build a ventilated façade.

Magnesite board, cement-bonded particleboard, OSB have a sufficiently high adhesive ability that allows the application of plaster. But vinyl and acrylic sidings are an ideal option for all composites. They look stylish, are durable, and are easy to install.

Interior and exterior works

Everyone will have their own preferences regarding the interior decoration of a bathhouse made from SIP panels. From the influence of external factors, such as weather conditions, additional protection should be provided for the panels themselves. Only in this way can its service life be significantly increased. The waterproofing layer must be covered with more plastic materials. Afterwards, you should arrange the sheathing, to the surface of which the selected type of sheathing will be nailed. It can be siding. However, lining made of natural wood is still preferable.

It will also need to be protected from moisture using one of the many impregnations. Internal surfaces can be covered with waterproofing mastic, securing aluminum foil to it. Afterwards you will need to nail another sheathing on which the lining will be located. A ventilation gap is required. The interior decoration will depend on the personal preferences of the owner and his budget. In the steam room itself, the walls can be additionally lined with brick, while natural wood of inexpensive species can be used to cover the surfaces in other rooms.

Bathhouse projects

Bathhouse designs can be very diverse. It all depends on the depth of the future owner’s wallet and the available space on the site. For example, standard projects are represented by buildings 4x6, 6x6, 6x9 meters. However, it will not be a problem to order a bathhouse of large dimensions, one or two floors.

The choice of sizes when building with your own hands is done purely utilitarianly. The bath should have:

- indoor steam room;

- bathroom-shower;

- restroom;

- entrance vestibule-locker room.

All areas of the premises are selected according to the personal preferences of the future owner and the planned number of people who will use the bathhouse at the same time. The project can be roughly estimated even on a notebook sheet. Or - get acquainted with the offers of contracting companies, which always provide a turnkey price list with detailed construction plans.

Bathroom flooring installation

In order for the structure to be durable and incredibly strong, all wooden elements should first be treated with special fireproof and antifungal impregnations several times with an interval of several days.

Sequence of upcoming installation work:

- A beam with a cross section of 10 cm is attached to the foundation pillars. Galvanized fasteners will help with fixation. However, first they need to be concreted into the thickness of the base.

- The bottom harness is done completely. Boards 5 cm thick are nailed around the inside perimeter.

- The logs are installed on the base of the floor, which are screwed using self-tapping screws. The step will be about half a meter.

- OSB on both sides is treated with a composition based on a bitumen primer, after which they are laid along the joists. Jumpers are installed between the lags, but only in those places where the individual sheets will be joined.

- After completing the installation work of the first layer of flooring, you should immediately begin the second. The order will be the same, but the material will spread across the joists.

Bathroom floor installation

Prices for finished projects and installation

For those who have made the final decision and will build a bathhouse from sandwich panels with their own hands, it will not be difficult to buy the necessary materials. Other people will be interested in getting acquainted with the average market offers. Turnkey baths with installation on the buyer's site differ in cost from different companies. The reason is in the materials used, foundations, type of finishing.

- The SIPbud company will offer a turnkey bathhouse made from panels with OSB. The design uses fire-resistant timber, special connectors, metal or bitumen shingles. The company produces plastering, installs electricity and sewerage, and installs interior doors. The foundation is strip-pile, insulated. The minimum cost of the project is 300 USD.

- Viva Haus approaches its work more thoroughly. Her bathhouse, measuring 6x6 m, has a decorated entrance with a porch, stairs and veranda, windows, a gable roof, and looks extremely stylish and modern. The cost of the project in a configuration with installation, for interior finishing “all inclusive” is 694,000 rubles.

- The Samara company, whose representative is the individual entrepreneur, “RiMar”, offers a variety of baths in compact format. From a house with an area of only 4 sq.m. to comfortable buildings of 35 sq.m. for any season, insulated, with an attic. Prices in the maximum version range from 189,000 to 716,000 rubles.

Without exception, all companies present on the market provide thorough insulation for all-season use of baths in any climate zone. Therefore, to specify the construction parameters (to obtain the necessary designs for a bathhouse made from sandwich panels), it is recommended to contact the managers. In addition to saving money, this step can help you get your new bathhouse much faster.

Features of building a bathhouse using Canadian technology

The technology of building a bathhouse using SIP panels is called Canadian and has been successfully used in the construction industry of Canada and the USA for more than 50 years.

First you need to figure out what this material is. SIP is a structural insulated panel. To put it simply, it is a kind of sandwich of two enclosing surfaces filled with insulation. Expanded polystyrene usually plays the role of a heat insulator between two slabs. It is practically hydrophobic and has very low thermal conductivity.

SIP panels have many advantages:

- Light weight

. To build a steam room, you do not have to pour a powerful foundation. - Efficiency of installation

. 1 m2 of wall can be installed in a few hours, and therefore the construction of a bathhouse as usual will take several weeks. In addition, construction can be carried out even in the cold season. - Reliable thermal insulation

. The material has very low thermal conductivity, so it allows you to save on heating costs. - Absence of cold bridges

. Correct installation will ensure the desired temperature in the steam room. - Moisture resistance

. The SIP panel is not affected by mold and mildew at high humidity. - Thorough sound insulation

. The noise from outside will not interfere with your time in the steam room. - Seismic stability

. A properly installed structure can withstand tremors of up to 6-7 points.

But even with so many advantages, SIP panels have some disadvantages:

- Difficult installation

. Installation requires strict adherence to technology. Otherwise, the structure will be short-lived. - Small operating temperature range

. Expanded polystyrene, which is used as insulation, can withstand a maximum temperature of +120 degrees, after which it begins to deform. - Short service life

. With proper installation and operation, this design will last up to ten years.

The disadvantages also include the unaesthetic appearance of the steam room. It doesn't look as impressive as a log house. In addition, there is no wood smell characteristic of a bathhouse.