Despite the Internet controversy that has flared up for a long time about the use of foil to retain heat in a bathhouse, the convictions of its supporters and opponents have not been shaken.

However, the subject of dispute was initially the physical properties of the material, and in our time there are enough means to make “selection” - to strengthen the necessary properties of the material and weaken the unnecessary ones.

Look at the bathhouse and the mode of its use as a set of factors, each of which can be “for” or “against” insulation with this material. With this approach, harm and benefit cease to be absolute categories, as they are usually presented in disputes.

We will tell you how to place the foil correctly to achieve optimal results, but this will be discussed in other articles.

This article is devoted to the consideration of materials available on the market; both foil and foil bath insulation will be considered here.

Bath foil: pros and cons of use

- A bathhouse, and even more so a steam room, are places with a very specific temperature regime and high humidity. Bath foil is ideal for this environment because it can easily withstand large temperature changes .

- Most insulation materials lose their properties when wet, so they are usually protected with a layer of waterproofing. Thin aluminum easily takes on this function, since the metal does not absorb moisture .

- Its high ability to reflect infrared rays ensures the preservation of heat inside the bathhouse and steam room.

- The ease of installation makes the installation of foil insulation feasible even for a non-professional. There is also no need for special equipment.

- The downside is that moisture that has not been absorbed by water accumulates on it in the form of condensation, which can cause rotting of the finishing coating or the growth of fungi on it , but this can be treated with a ventilation gap between the aluminum and the same lining.

- The high thermal conductivity of the aluminum from which it is made would also be a big disadvantage if it were not compensated for by a layer of insulation with low thermal conductivity that follows the metal.

- Another disadvantage is foil corrosion , that is, the formation of an oxide film on its surface. Of course, such a film worsens reflectivity. But the purity of the metal (the absence of impurities) significantly slows down the oxidation of aluminum.

- Well, temperature + water hammer , but more on that below

Foil layer for a bath: its functions and features

Would-be builders have always believed that foil is of no use when arranging a bathhouse. However, this opinion is wrong, and with the right approach to its installation, you can achieve a special effect.

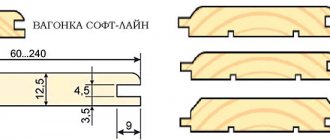

Foil material can have a different structure: smooth or ribbed PHOTO: bani.io.ua

In fact, foil is a thin layer of aluminum. When mounting it on the walls under wooden cladding, all the heat that the boiler produces reaches the surface and is reflected back. Thus, all thermal energy remains in the room. This layer is used together with insulation or separately. The corresponding material is capable of reflecting about 97% of the heat generated by the furnace.

When purchasing foil for a bath, you must ensure that the foil is intact, without perforation PHOTO: skif53.ru

Related article:

Finishing the bathhouse inside. Photos and examples. In a separate publication you will find interesting ideas for decorating steam rooms and relaxation rooms, and also learn the main stages of installation.

When is it needed and when is it not?

It is not needed by those bathhouse owners for whom neither fuel economy nor long-term heating are a problem.

It is also not needed by those who completely deny its ability to reflect infrared radiation through a layer of lining, but believe that the thermal conductivity of aluminum is a guarantee of rapid cooling of the bath precisely with the help of foil.

There is no need for it either if the bathhouse is sufficiently insulated using traditional methods, and its heating and cooling completely suits the owner.

It is wrong to assume that it will not find application in bathhouses made of logs or timber, since in wooden buildings only proper insulation of the crowns and high-quality sealing of all cracks is required. If desired, you can insulate any bathhouse. Let this be a repetition, but foil is needed where time and effort are valued.

It heats up faster and cools down slower.

Useful video

However, despite the above, there is an opinion that the absence of foil makes vaping softer, eliminating the sharp water hammer during paired procedures:

Which foil manufacturer can you trust?

There are a sufficient number of brands on the building materials market that specialize in the production of foil insulation. Among all, three manufacturers can be distinguished.

- Izolon . The concern is located in Izhevsk. Specializes in the production of foil and plastic. Special technologies are used to produce insulation. The material is available in stitched and unstitched form.

- Penofol . This manufacturer produces thin material with no backing. At the same time, the structure is quite strong and reliable.

- URSA . One of the leading manufacturers in Spain. It produces high-quality insulation materials of various thicknesses and structures. This insulator is also sold in Russia.

When choosing a brand, attention is paid to those brands that promise high quality and compliance with all GOSTs.

The remains of the foil sheet can be used in places where the thermal insulation is damaged PHOTO: klevo.net

Foil and insulation for baths with foil: types

| View | Release form | Peculiarities | Advantages | Flaws |

| Rolled foil | rolls: thickness 0.007-0.2 mm, width 1-1.5 m, length – 5-20 m | a roll can have from 3 to 5 breaks inside, so take it with a margin of 5-7%; any wall, but place foil on fireproof insulation | does not burn; does not release toxins; holds up to +650 degrees; reflects up to 97% of infrared radiation. | easily torn and wrinkled |

| Kraft foil | rolls reinforced with paper or paper and polyethylene. thickness – 0.03-1 mm | any surfaces, but you also need insulation | does not release toxins; holds up to +100 degrees; stronger than baseless; reflects up to 95% of heat. | flammable |

| Foil fabric | fabric rolls with one-sided foil reinforcement, width – 1 m, length 25 m | similar to the previous one | temperature range -50 +200; thermal reflection 97%; non-flammable; environmentally friendly material. | |

| Folar | rolls in three types of release: “A” - two layers of foil, between them - fiberglass in the form of a mesh with 4x4 cells; “B” – one layer of foil and the same fiberglass; “C” – foil, fiberglass, adhesive base. Roll width 1 m, length 50 m. | “A” temperature range -40 +300 "B" -40 +150 "C" -40 +80 very durable material; environmentally friendly - does not emit toxic substances when heated. | ||

| Folgoizolon | foamed polyethylene, foil-coated on one side. release form: sheets and rolls. sheet: length 120 cm, width 60 cm, thickness 2-11 cm. roll: length up to 30 m, width 1-1.2 m, thickness 0.2-1 cm. | for insulation of wooden walls and walls covered with clapboard | holds 100-150 degrees; self-extinguishes when burning; thick sheets can be independent insulation; light weight; high strength; low thermal conductivity. | flammable |

| Foil mineral wool | mats or rolls of mineral wool with one-sided foil; thickness varies from 0.5 to 10 cm, length and width depend on the manufacturer (there is no single one). | for insulation of walls made of concrete, brick, wood | temperature range -60 +300; reflectivity up to 97%; non-flammable; high thermal insulation properties (thanks to mineral wool). | |

| Foil basalt wool | insulation for baths with foil, a type of mineral wool, the same release forms. | similar to the previous one | properties - similar to the previous one, but basalt wool retains heat better; temperature range -200 +700 degrees. | |

| Foiled polystyrene foam | extruded polystyrene foam boards with one-sided foil coating. | operating temperatures -50 +75 degrees; with the addition of fire retardants - self-extinguishing in case of fire. | flammable; releases harmful substances; | |

| Bath insulation "Rockwool" with foil | stone wool slabs with foil on one side, dimensions 0.6x1 m, thickness 5 or 10 cm. Pack of 8 slabs. | holds up to +200 degrees; biostable; non-flammable; durable; eco-friendly. |

It is worth noting that all of the listed types, which is best for everyone to decide on their own, are excellent vapor barriers. They are not afraid of mold and mildew. But this is for them, and the tree needs an antiseptic.

Tips for installing foil

It is clear how to attach foil to the walls of the steam room. However, do not neglect the following tips.

- To install insulation, it is necessary to install a separate sheathing.

- Sufficiently thick foil sheets are best glued joint to joint using aluminum tape.

- Damaged canvases must be sealed with the same tape.

- Insulation and sheathing cannot be done closely. It is important to leave a distance between materials of at least 3 cm.

- The insulation near the windows must be measured closely, and after installation it must be covered with sealing tape around the perimeter of the frame.

For ceilings it is better to use super-strong foil material PHOTO: kakpotolok.ru

Soft material is installed on the prepared sheathing PHOTO: uteplix.com

Foil fixed with slats with insulation PHOTO: kubankrovmontag.ru

Follow the installation requirements and be guided by the performance characteristics of the material when using it. Also ask questions about the topic of publication and do not forget to rate the article.

Lining in the steam room: vertically or horizontally

There are two ways to solve the problem of how to line a bathhouse with clapboard quickly and efficiently:

- With horizontal planks;

- With vertical slats.

With the horizontal method, the lining is installed parallel to the floor surface. In a vertical position - perpendicular to the floor.

The horizontal position more effectively protects the lining from water penetration. This ensures good ventilation of the space between the wall and the panels.

The choice of method affects the technology of work and the final cost of repairs. For lining the inside of a bathhouse, they prefer the horizontal method. In this case, the wooden panels are installed with the tenon facing up.

Packaging properties of aluminum foil

Reliable barrier

The main property of aluminum foil is that it serves as a reliable barrier. Even the thinnest aluminum foil, just 6 micrometers thick - thinner than a human hair - provides reliable protection against light, oxygen, humidity, bacteria and unwanted odors. Therefore, products and medicines in aluminum packaging significantly increase their shelf life. Scientific research has shown that aluminum foil with a thickness of 6 micrometers (0.006 mm) can be considered an absolute barrier.

Quickly gains and releases heat

Aluminum foil conducts heat very quickly. This is a very important advantage, for example, when sterilizing milk, which then remains fresh for a long time even without a refrigerator. Rapid heat dissipation also reduces the process of cooling food for later storage.

Ideally plastic material

Aluminum foil is extremely lightweight and can easily be molded into different shapes and folded without any springback. This makes it an ideal packaging material for products such as oil.

Bright and attractive

Aluminum foil can be produced in different finishes - sparkling and matte. It can be painted with paints and varnishes, giving its silver surface a different texture - corrugated, ribbed or completely smooth. This foil is suitable for all printing methods and processes and therefore easily makes packaged products bright and attractive.

Boil, fry and bake

With aluminum foil you can cook, fry and bake both in the microwave and in a conventional oven.

Product packed in foil /1/

Why do you need foil film?

Foil film is used as a vapor barrier in rooms with elevated temperatures - in baths and saunas. This film does not melt and does not release hazardous substances even at a temperature of 120°C. Also, the reflective properties of the film are very important when installing modern steam rooms, because it is necessary to warm up the sauna in a short time and with a minimum of energy consumption.

But foil vapor barrier is justified not only in the sauna. If, when building a frame house, you replace the usual vapor barrier with foil, with the same heating power you can increase the temperature in the rooms by 2°C.

But reflective vapor barriers must be used wisely. Thus, it is not recommended for internal insulation of buildings made of heat-intensive materials (brick and concrete). Frozen walls will only worsen the microclimate. But in a wooden house made of logs or beams, foil film will be very useful for internal insulation.

Reflective vapor barrier is also suitable for an unheated loggia - a film laid under the floor covering will make it warmer. When glazing open balconies, when the entire perimeter is sheathed with sandwich panels that do not conduct heat, foil film will reduce heating costs.