Twenty years ago it was impossible to find a private bathhouse built from any materials other than wood. However, with the advent of such material as foam concrete on the market, baths and saunas made from it began to appear in many Russian yards. The owners are captivated by the low cost of this finishing material and the high speed of construction of wall structures. However, during operation, the owners of such structures face a number of problems: destruction of walls, the appearance of mold and mildew on the walls and a number of other problems. Thus, a bathhouse made of foam blocks, reviews of which were previously extremely positive, began to be of significantly less interest.

This article provides information on how to build a bathhouse from cellular concrete correctly. At the end of the article there is an overview of some reviews about foam concrete baths.

The feasibility of using foam blocks

Baths made from this material are actually usually very inexpensive. In addition, foam blocks have almost all the same advantages as wood: they allow air to pass through (“breathe”), are very easy to cut, and are not too heavy. Their advantage, compared to timber and logs, is that they do not burn at all and do not rot. The disadvantages of walls made of this material include the fact that it is capable of absorbing moisture, while gradually collapsing. Therefore, projects for bathhouses made of foam blocks must be developed taking into account the characteristics of this material, in particular its hygroscopicity.

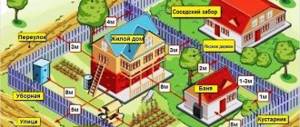

According to SNiP standards, it is prohibited to build baths from foamed cement. However, these rules were invented quite a long time ago. Since then, a huge number of new, modern materials with truly unique properties have appeared on the market. Foam concrete also belongs to them. In addition, SNiP standards were developed mainly in relation to public baths. Of course, in this case the rules must be very strict. A small country bathhouse made of foam blocks can become a very convenient and quite durable structure. But of course, only if all rules and construction technologies are observed.

The use of twin blocks in construction and the features of their masonry

A very big advantage of this building material is its lightness. One block of material weighs about 23 kilograms (which is much lighter than similar-sized blocks made of brick, reinforced concrete or ordinary concrete), but it is very durable and strong, and also has excellent thermal insulation. The twin block structure is filled with air bubbles, making it lightweight. Twin blocks have low shrinkage - this gives them additional durability and layer integrity.

First of all, the waterproofing layer is laid. The laying of twin blocks itself must begin from the corner. A solution approximately one centimeter thick is applied to the waterproofing and corner blocks are installed. After the corners of the load-bearing walls are completely completed, the first row of twin blocks is laid.

After laying the first two rows of twin blocks, it is necessary to wait until they dry completely. It is important that the first rows rest exclusively on cement, while subsequent rows can be mounted on glue, the consumption of which will be minimal if the parameters of its use are correctly observed.

If we take the totality of such characteristics as appearance, practicality, environmental friendliness, labor intensity of operations and the price of material, then we can safely call twin blocks the leaders of the construction market. Low cost combined with excellent characteristics, reliability and durability make twin blocks indispensable in the construction of building structures.

People's reviews of buildings made from twin blocks, such as bathhouses or houses, are also positive, since the material is quite easy to use and is widely available for sale.

How to place twin blocks correctly is shown in the video:

Advantages of a foam block bath

In addition to being cheap and having a rather pleasant microclimate, the advantages of such structures include environmental safety. When heated, foam blocks do not emit any harmful substances. In addition, they retain heat very well, meaning you will have to heat the bathhouse no more than once on a wash day. Since the foam block is not flammable, you do not have to comply with any special standards when installing the heater.

And of course, the undoubted advantage of this material is its ease of installation. Assembling a bathhouse from a log or timber is a rather labor-intensive task and at the same time technologically complex. Not everyone has experience in constructing such structures in our time. Probably any owner of a suburban area can lay out block walls.

Bathhouse designs made from foam blocks can be anything, that is, the owners of the site have the opportunity to choose the layout of this structure at their discretion. The material is easy to cut even with a regular hacksaw.

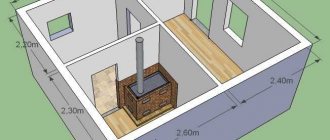

Drawing up a bathhouse project

When drawing up a design plan, it is necessary to take into account the technical parameters of gas blocks. The accompanying documents that come with the products have clear instructions on how to solve the issues of vapor and waterproofing of buildings made from such products. In such buildings it is recommended to install dry steam rooms.

You should be very careful about sealing the door and window openings of the bathhouse. If you correctly design a bathhouse made of aerated concrete, there will be no difficulties during the work process. It is important to install special membranes that will allow evaporation to pass in only one direction. In addition, the project must include a ventilated façade.

If the bathhouse is developed independently, it is necessary to take into account some features:

- Where the rest room, vestibule, bathroom and steam room will be located.

- How communications to the bathhouse will be installed and protected.

- What kind of foundation to build?

- Will there be a swimming pool installed in the bathhouse?

- What type of heating is better to choose?

To understand the projects of bathhouses made of gas silicate blocks, you should look at photos of already completed buildings.

Disadvantages of foam block baths

The disadvantages of a bathhouse made of foam blocks are, first of all, dampness and destruction of the walls; in particular, saturating the blocks with water is dangerous in the winter. In a heated bath, vapors easily penetrate into the porous material. After the steam room cools, the water freezes and, expanding, simply breaks the concrete. Therefore, when building a bathhouse from foam blocks, special measures should be taken to waterproof the walls. In addition, the building will also have to be insulated. In this case, the walls will take longer to cool, and therefore, even if water gets into the material, it may have time to dry before freezing. In addition, much less condensation collects on insulated walls.

Experienced owners of suburban areas also recommend installing ventilation in such bathhouses. This will prevent stagnation of damp air, therefore extending the life of the walls.

Of course, all these tricks: waterproofing, insulation, ventilation - will cost the owner of the bathhouse a pretty penny. Therefore, structures for this purpose made of foam blocks are usually built only in steppe regions, that is, where it is difficult to obtain wood or it is very expensive. In forested areas of the country, it may be more advisable to build a wooden bathhouse. Most likely, it will not cost much more than paving stones.

Characteristics of aerated concrete

Many experienced specialists are increasingly turning their attention to aerated concrete blocks, preferring it to wood when building a bathhouse. Why do they like to use it? The secret lies in a large list of positive properties of aerated concrete:

- It is quite easy to use it to carry out serious constructions without any construction experience. To build a bathhouse, you do not need to hire a team of professionals.

- The cost of gas blocks is much lower than high-quality lumber. Moreover, such products have the best performance characteristics.

- A bathhouse built from aerated concrete blocks can last much longer than a wooden one.

Among other characteristics of the material, it is worth highlighting a significant degree of moisture absorption. It is this property that stops many developers from choosing aerated concrete as the main material for the construction of buildings like baths. Aerated concrete absorbs moisture very quickly.

This problem can be eliminated - it is enough to perform good internal waterproofing of the bathhouse. Outside, special compounds must be applied to such walls. Various impregnations can protect the walls of the bathhouse from excessive moisture absorption.

Important! Experts do not recommend painting or plastering the outside of aerated concrete buildings.

Aerated concrete has the ability to retain heat in a bathhouse. The walls do not require additional insulation. In the construction of baths, insulating blocks are used that are capable of perfectly maintaining their technical parameters even in unfavorable conditions.

Aerated concrete blocks are not capable of mold. They do not attract rodents. It is important that when building baths from such material, the fire resistance of the structure increases significantly.

The blocks are light in weight and do not require installation of a solid foundation under the bathhouse. This allows you to spend much less money and effort on its device. Baths made of aerated concrete blocks do not shrink over time. The bathhouse can be used for its intended purpose immediately after construction.

Bathhouse made of foam blocks: price

The cost of such a structure will depend, of course, primarily on the layout and size. A wall foam block 60x30x20 costs about 2,500 rubles per cubic meter. A small bathhouse measuring 3x4 meters with one partition and a ceiling height of 2 m will require a little more than 6 m3. That is, the construction of the actual walls will cost about 16-20 thousand rubles. This will require about 5 m3 of mineral wool. It will cost about another 8 thousand rubles. About 2000 rubles will be spent on the glue solution. Thus, the walls of a small bathhouse made of foam blocks, at a rough estimate, will cost about 30 thousand rubles. Of course, to this amount you will need to add the cost of the foundation, lumber for the floor, ceiling and roof, waterproofing and lining.

A large 6x4 bathhouse made of foam block will, of course, cost more. It has recently become very fashionable to build attics on such structures. This is, of course, very convenient and allows you to save space on the site, but of course, it will additionally increase the cost of the structure. The walls and partitions of a standard 6x4 m bathhouse will require about 11 m3 of blocks.

Construction of foundation and walls

Building a bathhouse from foam blocks is a simple procedure. Such a structure is erected in approximately the same way as a brick one. The difference is that the seams in the masonry of foam blocks are very thin, and special glue is used as a solution to hold the blocks together. When building even a small bathhouse from this material, it is advisable to reinforce the walls. To do this, in every fourth row, metal rods are placed in gutters cut out with a grinder. An armored belt must also be placed on top of the masonry.

It is recommended to make the foundation for a bathhouse made of foam blocks strip and quite powerful. All foam materials are fragile. And therefore, even with small movements of the soil, walls made of them can crack. For the same reason, blocks should be laid as evenly as possible, using piers, plumb lines and a level.

Walling

After waterproofing has been laid on the foundation, they begin to build foam concrete walls. Using a building level, the highest angle of the building is calculated and walls begin to be built from there.

Foam blocks are laid on edge, and thin seams are made between the blocks. This eliminates heat loss through them.

The most important point when building a bathhouse with your own hands is considered to be the laying of the first row. The blocks are held together using a mortar of cement and sand. After finishing installation, the surface should be carefully leveled. All subsequent work depends on how the first row is laid. For ease of work, pull the cord between the corners of the future bath.

When laying the second and subsequent rows, special glue is used . It is sold in bags as a dry mixture and diluted with water right at the construction site. It only takes 10 minutes to prepare it. Minimum glue consumption. The baths, in the construction of which this glue was used, have dense walls without joints.

For structural strength, experts recommend erecting foam blocks in three rows, and laying a reinforcing layer of metal mesh between them.

Foam blocks for the first masonry should be of the highest density ; a cement mixture is used as a connection. For the next rows, adhesive mixtures are used.

To use the glue, you do not need to wait for it to harden. It is applied along the entire perimeter of the block, and foam blocks are laid on top. Level them using a hammer with a rubber tip.

Bathhouse floors made of foam block

To prevent the walls from being saturated with water from below from the ground, it is worth installing special floors in such a structure. They need to be made concrete and slightly inclined towards the center. In this case, a receiving tray and a plastic drain are installed in the middle of the bath. The pipes should be laid underground below the freezing level and extended to the septic tank.

In order to extend the service life of concrete floors, they should be covered with tiled rough tiles. The base itself should be treated with penetrating waterproofing before laying it. In the future, special wooden gratings are usually installed on top of the tiles. After taking water procedures, they can be taken outside and dried.

Foundation waterproofing

This operation must be performed. In this case, you will get a durable bathhouse made of foam blocks. Reviews from owners about such buildings are not bad, but only if they are waterproofed according to all the rules. For the foundation of a bathhouse, both vertical and horizontal waterproofing are usually used. When installing the tape at the bottom of the pit, be sure to pour a sufficiently thick layer of sand. After the foundation concrete has gained sufficient strength, its top is glued with two layers of roofing material.

The walls of the base of the bathhouse must be protected from moisture both outside and inside. In this case, you can also use roofing felt. Penetrating agents are also considered a very good solution for waterproofing the foundation of a bathhouse. Sometimes the base walls are coated with bitumen mastic in two layers.

Construction of the foundation

When building a bathhouse with your own hands, the most important thing is to have a properly laid foundation. They dig a pit for him. Its dimensions are: width - 30 centimeters, depth - 60 centimeters. Pins are driven into the corners of the dug pit , a rope is pulled, and then additional ones are driven along the entire length of the foundation with a distance of 1.9 meters.

Then a frame is made from reinforcement, 12 millimeters thick. Next, the formwork is assembled from boards with a width of 25 millimeters. After this, the foundation is poured with concrete. As a result, it should be 70–75 centimeters high. After the concrete has hardened, sewer pipes are laid where the shower will be.

Then the foundation is waterproofed. It consists of the following stages:

- A layer of molten bitumen is applied to the foundation, and then roofing felt is placed on it.

- After everything has hardened, repeat with a second layer.

Waterproofing walls

To protect the enclosing structures of the bathhouse from moisture, it is best to use foil vapor barriers. You can take special isospan or penofol. Today on the market there are foil materials designed specifically for baths. The waterproofing is secured to the wall with beams. The joints should be additionally nailed and taped on top with metallized tape. The lining is subsequently attached to the beams.

The ceiling of the bathhouse is usually made of boards. You can protect it from moisture by using impregnating waterproofing designed specifically for wood. A bathhouse with a foam block attic is very comfortable. However, when choosing just such a project, you should keep in mind that in this case, most likely, the roof will also have to be waterproofed from the inside. In the attics of baths, the microclimate is usually quite humid.

Twinblock calculator

To calculate the required amount of material, you must first calculate the perimeter of the building, which will be equal to the sum of its double length and double width. To calculate the area of the walls, the calculated perimeter must be multiplied by the height.

The most important operation in calculating twin blocks is determining the wall thickness. To match it with the area of the building, it is necessary to convert all obtained values into meters. The amount of material is calculated as the area of the building walls divided by the thickness of the twin block (in meters). In addition, you can use online calculators that allow you to calculate the required number of twin blocks, for example, for building a house.

Ready-made projects of houses built from twin blocks

house No. 1 house No. 2 house No. 3 house No. 4

Bath insulation

Next, let's look at how to insulate a bathhouse made of foam blocks. A structure made of this material can be insulated from the cold using both expanded polystyrene and mineral wool. The latter material is considered more preferable. The fact is that polystyrene foam does not allow air to pass through very well. When using it, the walls of the bathhouse will not “breathe”. Insulation should be carried out exclusively from the outside. The fact is that when sheathing from the inside, the so-called dew point moves inside the walls, and they begin to become damp.

How is a bathhouse made of foam blocks insulated? Reviews from owners about such structures are only good if this operation is carried out correctly. Foam block wall insulation technology usually includes the following steps:

- The walls are covered with timber lathing.

- Insulation is installed between its elements. Cotton wool can be installed simply by surprise. Expanded polystyrene should be additionally secured with mushroom dowels.

- The frame with insulation is covered with waterproofing material.

- External cladding is being installed. It can be a lining, a block house, etc. Foam block baths covered with façade vinyl siding that imitates stone look very nice.

You can also cover the walls of the bathhouse with very dense mineral wool with additional fastenings - “fungi”, and then finish it using decorative plaster.

How to build correctly

A foam block bathhouse places special demands on technological and geometric accuracy during construction. Therefore, it is worth briefly going over the important points.

Foundation

Since foam blocks weigh little, and bathhouses are not multi-story (maximum 2 floors), the load on the foundation will not be large. Therefore, lightweight options are made with a pit only 60 cm deep.

IMPORTANT! In this case, special attention should be paid to leveling - it is worth taking measurements more often and using a laser or other level.

The strip foundation is 70-75 cm high. The space inside is filled first with crushed stone and then with expanded clay. Before the construction of walls begins, the foundation is waterproofed with bitumen and roofing felt (two layers of each alternately), more details here.

We select and build a foundation for a bathhouse made of foam blocks: depth, types. How not to collapse a building

Wall insulation

This is a necessary procedure that will not only keep the rooms warm, but also protect the wall material from moisture. Wall insulation is carried out inside and outside. Internal insulation can be done with your own hands.

The exterior is done using the ventilated façade method, using the following wall insulation materials:

- mineral wool;

- glass wool;

- jute felt, which is used for insulation between crowns ;

- Styrofoam.

IMPORTANT ! Foam plastic is not used for internal insulation.

The same insulation materials can be used inside, with the mentioned exception. In the steam room and washing room, foil is installed as a vapor barrier. Insulation for a steam room should be chosen especially carefully. In order for the walls to dry, vents are made in them. Instead of ordinary films, it is better to use a membrane as a waterproofing agent. Which insulation is better depends on the tasks at hand.

When thermally insulating baths, an integrated approach is important, i.e. insulation of all parts of the structure: floor, walls, ceiling and roof. Various materials are used to insulate the ceiling; clay and its mixtures are actively used. It is recommended to pay special attention to the issue of the need for thermal insulation of baths with an attic.

Internal and external finishing

It is permissible to use a variety of materials both inside and outside the bath:

- lining;

- block house;

- imitation timber;

- siding;

- plastic;

- artificial and natural stone;

- tile;

- plaster (outside only).

Most of the above is suitable for finishing on any side. The fact that the walls of the bathhouse are made of foam blocks does not make any changes to the finishing technology. Most often, finishing work is carried out on insulation.

Useful video

Watch the video where the owner shares how well he finished a foam block bathhouse with clapboard and tiles:

Is it possible to build it yourself?

Yes it is possible. Many people do this, especially since you can work even alone - the blocks are light and large. You just need to make every effort to ensure that the masonry is even. In addition to low cost, simplicity and speed of construction, as well as the ability not to resort to the help of professionals, are the factors that made foam block baths so popular.

Is it possible to build a bathhouse from foam blocks? We will not deny: building such a bathhouse looks tempting. Although it is far from the perfection of the classic Russian wooden bathhouse, its availability solves the problems of those who would otherwise wait for years.

Clients who have not yet decided on the material for their future bath should familiarize themselves with the list of proposals:

- timber baths;

- frame baths;

- mobile frame baths;

- frame-panel baths.

- brick baths;

Many clients are thinking about the choice: timber or log house; familiarizing yourself with the list of advantages and disadvantages will allow you to make the best choice.

How to arrange ventilation in a bathhouse

Thus, you now know how to build a bathhouse from foam blocks, as well as insulate and waterproof it. Next, let's figure out how to make ventilation in this structure. The foam block bathhouse must be ventilated. Ventilation in the bathhouse is arranged as follows:

- In the immediate vicinity of the stove, at a height of no more than 30 cm from the floor, a supply hole is made in the wall. Sometimes it is also done in the foundation of a bathhouse. In the latter case, a hole (with a valve) should be made in the floor.

- An exhaust hole is hollowed out in the opposite wall at the top. A valve is installed on it. If the opposite wall does not face the street, the exhaust hole should be made in the same wall as the supply hole, but on top and in the opposite corner. In the latter case, an exhaust fan should be used to ensure good air flow.

Stages of bath construction

When building a bathhouse from aerated concrete, it must be taken into account that the work always begins with laying the foundation. According to the design data, it is necessary to dig a foundation pit in advance. For aerated concrete, a non-buried strip structure is suitable. It will be enough, because aerated concrete blocks weigh very little. Such a foundation is installed when constructing a bathhouse on any type of soil.

Important! When pouring the base, it is necessary to determine in advance the exit points of the communication networks.

Before laying the first row of blocks on the foundation of the bathhouse, you should lay two layers of roofing material. It is necessary to install aerated concrete from the corner of the bathhouse, which is located higher than the rest. The first blocks are laid in the corners. Then they are leveled in height using a string and a level. The blocks are mounted on a cement composition.

Important! To increase the strength and reliability of aerated concrete baths, special attention should be paid to the first row of blocks. If you lay it correctly, all unevenness in the base will be easily leveled out.

The remaining rows must be laid in strict accordance with the horizontal line of the first row. Every fourth row should be reinforced with reinforcing mesh. This will make the masonry of the bathhouse walls much stronger. A reinforced concrete belt is made above the door and window openings.

In this belt it is necessary to place twisted wires into which the anchors are placed. This is necessary for the correct installation of the mauerlat beam. The construction of a bathhouse made of aerated concrete blocks ends when the rafter system is constructed. When installing a roof for a bathhouse made of aerated concrete, almost any material can be used.

Bathhouse made of foam blocks: reviews from owners

The owners of suburban areas have a very good opinion about buildings of this type. The owners of bathhouses made of foam blocks note, first of all, that they retain heat very well. In addition, such buildings do not require any special care: treatment with anti-rot compounds, caulking, etc.

Of course, foam block baths have earned good reviews due to their low cost. Almost anyone can build such a structure on their site. If you line the inside of a foam block bathhouse with linden clapboard, it will smell like a real wooden one. The same applies to the benefits of taking water procedures. In addition, in a bathhouse made of foam blocks, judging by the reviews of the owners, the smell of dampness never appears. The outside of such a bathhouse can be covered with a block house, and then it will look quite traditional.

As you can see, if all the required technologies are strictly followed, a very good bathhouse can be built from foam blocks. Reviews from owners about such structures are mostly good. But only if ventilation is provided in the bathhouse, and its walls are well insulated and waterproofed.

External and internal finishing

No matter how high-quality foam blocks are, they are still afraid of moisture. Waterproofing the walls of the bathhouse consists of impregnating them with water-repellent compounds, and from the inside they are supplemented with the laying of special films .

The appearance of the bathhouse should be aesthetic. The method of modern external cladding is a ventilated curtain-type façade, due to which excess moisture from the blocks escapes into the external environment. The most popular materials are base and vinyl sidings, they are mounted on frames.

The inside of the bathhouse is lined with wood, painted with polymer paints or finished with ceramic tiles. very popular today due to the smell of pine needles and wood. The best tree species for a bathhouse are coniferous.

The steam room is decorated with aspen or linden due to their properties of not heating up when heated. Before covering the wood, the outer layer, which is easily exposed to moisture, is removed and treated with a special protective waterproofing substance.