Good devices used for heating baths and saunas are heater stoves called “Breneran”. This name was given to the unit by domestic manufacturers, who took similar Canadian devices “Bullerjan” as a basis. The design of such a furnace includes reservoirs for water, which, when heated, forms steam, and special compartments for stones. Hot cobblestones provide sufficient heating of the room in a short time. With the “Buleryan” (“Breneran”) stove you can create both a Russian bath and a Finnish sauna.

Convection oven Buleryan

In the photo of the Buleryan stove, the type of heating provided heats the room by convection type. It comes from Canada, which was invented by lumberjacks.

At this time, such stoves, as well as water stoves, are produced by Buleryan, a German company, the product is licensed.

In Russia they make analogues of this stove, and this is what they do.

Consumer reviews about furnace radiation protection

Buyers are advised to additionally use leather by making a unifying manifold. Only then can the pipes be opened. Such products are not offered in finished form on the market; they must be made manually or to order.

As a thermal insulation casing, you can use the material that is used to wrap the manifold on sports cars; it can be purchased at relevant stores. It doesn’t matter what model of stove you purchased, you should heat it by placing firewood in the entire volume of the firebox; this recommendation is perhaps the only one that should be followed when operating the stove.

Operating principle and efficiency

furnace device

Buleryan has a high efficiency: from 75 to 80%. In general, it is a cylinder located horizontally. The fuel combustion process takes place inside it.

The combustion of wood occurs in the primary chamber. Substances that have not been burned before rise into the secondary chamber, which is located in the upper part of Buleryan, and burn there to the ground. This combustion method makes it possible to burn fuel almost completely.

This is one of the factors that ensure the high efficiency of such furnaces. The ash pan is located in the lower part of the combustion chamber, but in some design options its presence is not provided. This is due to the fact that the degree of fuel burnout is very high and solid combustion products are almost completely absent.

Around the casing, the combustion chamber, there are rows of pipes.

If the oven uses a water circuit, then water vapor circulates through them. There are other options for such stoves in which air circulates through them to heat the house. Water vapor circulates according to this pattern: in the pipes it heats up and expands under the influence of high temperature.

For this reason, it rises up and enters directly into the heating system. In the process of heating residential premises, it gives off its heat and, as a result, cools and contracts. Then it goes down and again falls into the pipes that are adjacent to the boiler. There it warms up again and the described cycle repeats again.

Let's not forget that combustion produces gaseous waste. We are talking about carbon dioxide and a small amount of smoke. These combustion products must be vented outside through the chimney.

It joins at the top of it. Note that heat is also removed in this way. In order for it to be used for heating, the chimney is lined with mineral wool or a similar material. The use of this heat also contributes to increasing the efficiency of this heating system.

The casing here is usually made of two layers, which reduces the waste of heat when Buleryan operates.

The heating process can be divided into 2 main stages:

- Kindling. Firewood is added to the stove to create intense combustion.

- Maintaining the fire. At this stage, you need to regularly add a small amount of fuel. At this time, the combustion process occurs smoothly and with great force. Minimal effort is required to maintain it.

When using Buleryan, it can be designed (completed) so that it resembles a stylized Russian stove (or in some similar way).

Device

Construction of the Breneran furnace.

(Click to enlarge) These types of fireplace stoves consist of a massive outer casing, the thickness of which is 3 mm, as well as a heat-resistant firebox made of 5 mm steel. In addition, the package includes an additional water tank made of stainless steel.

The operation of such a device follows the same principle as that of a gas generator. After solid fuel burns, the resulting gases enter special ejectors for more complete combustion.

It is due to this that it is possible to achieve such high efficiency indicators, about 80%. In addition, such furnaces can operate in several modes. The first is fast heating, and the second is gasification. Accordingly, each of them performs its function, one allows you to quickly increase the temperature, and the second maintains it at the desired level.

It all happens as follows: special air ducts are put on pipes with a large diameter, which supply heated air to the required rooms. In addition, even cheap aluminum options that can withstand average temperatures can be used as these pipes. Due to this, even the smallest oven allows about 5 cubic meters of air to pass through it.

You may be interested in an article about pyrolysis stoves for home heating.

Read the article about the features of the furnace by Professor Butakov-Engineer here.

How to choose a Breneran boiler

The manufacturer of air-heating furnaces of the Breneran brand, JSC Laotherm, produces a whole range of heat generators that differ in power and design features. For ease of selection, all gas generating equipment is divided into the AOT series.

The line includes models for domestic and industrial operating conditions, operating on almost any type of solid fuel: firewood, pellets, wood and paper industry waste, with the exception of coking coal.

Model range of heating boilers Breneran

The model range of JSC Laotherm includes six basic modifications of the Breneran stove. When choosing a suitable heat generator, you should focus on the equipment characteristics specified by the manufacturer in the technical documentation:

- AOT 19 – the design contains 8 pairs of convection pipes. Furnace power 35 kW. The model copes with heating rooms with a volume of 1000 m³. The total weight of the structure without firewood is 240 kg. The firebox can be loaded with fuel up to 200 kg. The Breneran wood-fired gas-fired heating stove, long-burning AOT 19, is optimally suited for heating a residential building with several floors and rooms.

- AOT 16 is another productive stove, suitable for heating rooms up to 600 m³. The weight of the structure with an empty combustion chamber reaches 190 kg, which during installation will require the manufacture of a foundation. The model is optimally suited for industrial purposes. Based on the Breneran AOT 16 stove, air heating is installed for several rooms isolated from each other.

- AOT 14 – the series includes two types of equipment, differing in the presence of a glass door made of heat-resistant glass. The model with glass is designed for installation under brickwork, imitation under a fireplace or Russian stove. The maximum performance is 18 kW, which is more than enough to fully heat rooms with 180 m² or a volume of up to 400 m³.

- AOT 11 - starting with this series, the manufacturer Laotherm offers stoves that are more adapted for domestic rather than industrial conditions. The small dimensions of the boiler made it possible to reduce its weight to 100 kg, while maintaining high productivity of 11 kW. The stove can handle heating one large room or hall with a volume of 200 m³. By installing an air duct system for individual rooms, the AOT 11 boiler is capable of heating an entire house with an area of about 100 m².

- AOT 08 is a small, dimensional, but at the same time productive stove, optimally suitable for heating unheated premises: dachas, garages, greenhouses. The weight of the structure, with the combustion chamber empty, is only 70 kg. For improved circulation of heated air, there are 7 convection channels on the body. The series offers models with and without glass doors. Maximum productivity 8 kW, heated room volume 140 m³.

- AOT 06 – long-burning domestic solid fuel air-heating boilers using Breneran AOT 16 wood, designed for efficient and fast heating of rooms with a total volume of up to 100 m³. The model is successfully used for heating individual rooms. The stove's power is not enough to connect the air duct system. The series includes models with glass and all-metal doors.

For the convenience of consumers, the Laotherm company lists the standard sizes of furnaces in the full names of the models, from 01 to 04. This parameter affects the number of convection pipes and the dimensions of the structure.

Cost of Breneran stoves

Prices for Breneran solid fuel pyrolysis heating boilers make the purchase of such equipment affordable for almost any category of the population. What affects the cost of a boiler?

- Performance - the most powerful model AOT 19, will cost about 38 thousand rubles, a small household heat generator only 10,400 rubles.

- The presence of a fire door with a glass insert - this function is provided in models AOT 06, 08, 11 and 14. The presence of an insert increases the cost of the design by approximately 1000 - 1500 rubles.

The stove manufacturer specifically maintains the same price for stoves in all company stores to reduce the likelihood of purchasing a surrogate. According to representatives of Laotherm, the stove at a lower cost is a fake.

Furnace models

The variety of buleryan models is determined by variations in their functional features. The following models are available on the market today:

- AOT-8 (closed stove-heater).

Parameters: height 900 mm, width 750 mm, depth from 720 mm (steam room volume up to 17 m3) to 800 mm (steam room volume up to 22 m3); Its functionality does not require an extended coverage area and installation. AOT 8 - AOT-12 (open stove-heater). Parameters: height 800 mm, width 650 mm, depth 750 mm;

- Breneran Premium. The model has a protective coating - two special “casings”, one of which is located on the outside and is made of stainless steel, and the other is located in the inner surface of the stove and is made of durable steel metal sheets. For Premium class baths, it is necessary to expand the installation area.

Premium

Expert opinion

Nikolay Davydov

Stove maker with 15 years of experience

Before purchasing a stove for a Buleryan bathhouse, it is best to use common sense and rationally calculate the size of the stove according to the proportional features of the bathhouse and the size of the bathhouse itself. It is also better to choose an “open heater” type stove with a metal body made of heat-resistant stainless steel - this will allow you to maintain a good thermoregulatory balance in the bathhouse.

How to light a stove correctly

During intensive heating of the room, the active combustion mode is used. But for heating stability, smoldering is required. Pellets, wood chips and briquettes can be used as fuel.

The Buleryan wood-burning stove demonstrates excellent efficiency indicators. But the use of coal is not allowed.

It should also be taken into account that intense combustion during the entire operating time of the unit would cause the metal to burn out. Therefore it is not used.

At the first stage, it is necessary to ensure ignition using fuel, which is characterized by a high burning rate. For example, dry cardboard or wood chips will do. This fuel should be enough for 25-30 minutes. work so that coals are formed already at the moment of complete heating of the room.

The fire must be lit when the damper and throttle are open. Then the door should be closed. After coals have formed, you can begin to throw large logs or briquettes into the firebox.

- Storage water heater - installation methods and review of the most economical options (85 photos)

Circulation pump - 90 photos of popular models and their connection options

Electrode boiler - the best models from world manufacturers and DIY construction (110 photos)

The throttle is fixed at the desired mode, and the gate is placed in the closed position. Stepwise heating begins with air output at 60-70 degrees.

High-quality heating of the cottage can be guaranteed through the use of models with a water circuit. Heated water begins to move in the heat exchangers. This model is equipped with an ignition compartment - a firebox and a chamber for afterburning gases.

Buleryan water stoves provide rapid heating of water. Moreover, an increase in the temperature of a large volume of it is required. Almost all the energy of the unit is spent for these purposes.

No more than 7-10% of the energy reserve is spent on heating. The coolant is transferred to the heating system or storage chamber. It is recommended to add special antifreeze to the water.

How does such a stove work?

If we take an extremely general approach to considering the structure and design features of Breneran stoves, then, in fact, in their main characteristics they resemble the domestic “potbelly stoves” that have been used in the country since 1918. But upon closer examination of the issue, you begin to understand that this is far from the case, and apart from their outwardly similar appearance, there is simply nothing in common between them. Canadian Breneran stoves use a slightly different type of room heating. These stoves heat buildings not through natural air convection, but almost forcibly creating a fairly decent draft without the use of additional mechanical devices and electric motors. (See also: Do-it-yourself greenhouse stove)

Furnaces of this design consist of:

- housings;

- chimney;

- regulators of air supply to the furnace and the rate of exit of flue gases.

Additionally, various protective devices can be added to the furnace design to protect users and buildings from contact with the hot surface of the furnace. Or a natural stone stand at the top of the oven, which can be used in different ways - for example, for roasting meat on stones.

Features of the operation of chimney pipes

When using a stove, a number of questions may arise related to the operation of the chimney. Below are answers to the most common ones.

How long does a chimney last?

The operating time depends on the material of the chimney and the intensity of use. It also affects how often and with what the owner cleans his Bulleryan.

If you remove soot, remove condensation, and load the system correctly, then steel models will last 5-7 years, multilayer steel pipes - 12-17 years, ceramic chimneys - more than 40 years, brick ones - over half a century. Failure to comply with the rules for using the structure reduces the service life by three times.

Why does wind get into the chimney?

The wind blows into the chimney and interferes with the normal outflow of smoke when the rules for calculating and installing stove parts have been violated:

- The total height of the structure should be three meters.

- The chimney must rise above the roof by at least half a meter.

- All seams must be carefully treated with sealant.

If these rules are not followed, the wind will freely “walk” through the pipe.

Why does condensation appear, how to avoid it?

Water does not accumulate only in ceramic and multi-layer steel chimneys. In other cases, condensation cannot be avoided. It can be reduced by additional thermal insulation, which prevents temperature changes and the formation of “dew”.

If it is not possible to reduce the accumulation of water, then you need to wipe the outlet manually 1-2 times a month. Prolonged accumulation of water is dangerous for the chimney - the liquid mixes with substances from the smoke and corrodes the walls.

Why does soot accumulate, how to clean it?

When burning wood and other solid fuels, soot appears. There is no need to panic - this is a normal process, you just need annual cleaning (1-2 times a year).

Attention: mechanically cleaning the passage is prohibited, as scratches will appear, which will disrupt the operation of the chimney. It's safer to clean walls with chemicals

It’s bad if soot formation occurs too quickly (when cleaning is required after 2-3 months). The problem may be:

- violation of tightness,

- horizontal pipes are too long (should not exceed 2 meters),

- using low-quality fuel for the stove.

Oven operation and maintenance

Once a year you need to clean the chimney to prevent the stove from filling with smoke

In order for the Breneran stove to operate efficiently, it is necessary to comply with the operating conditions and properly maintain the heater.

Basic advice given by experts:

- You can only heat with dry, finely chopped wood. Place paper or cardboard under them.

- It is not recommended to preheat the oven for more than 30 minutes with the damper fully open. Breneran is designed for smoldering fuel, which can cause some of the thermal energy to escape.

- After the wood has completely burned out, the stove switches to gasification mode. To do this, you need to close the gate and throttle.

If the potbelly stove fills with smoke, one of the following errors can be judged:

- Low chimney height. Optimal performance is ensured by a pipe 5 meters high.

- The slide valve is closed.

- The smoke channel is clogged with soot. It needs to be cleaned. Preventive cleaning is carried out once a year.

Contamination of the furnace impairs its draft, which reduces heat transfer. For cleaning, you can seek help from specialists.

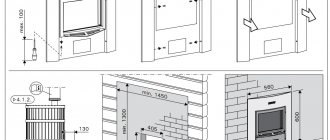

How to properly install a Breneran stove in a wooden house

Despite the fact that the manufacturer provides a complete and detailed manual for the installation and operation of gas generating equipment, during installation and combustion, the same mistakes are made again.

To ensure the functionality of the equipment, the “Canadian” Breneran convection wood heating boiler is installed in strict accordance with the instructions. There are rules affecting the requirements of fire safety regulations, the organization of direct and indirect heating of premises, as well as the installation of a smoke removal system. Only if all the instructions specified in the technical documentation are followed, the Breneran long-burning wood-burning gas-fired heating stove will operate at full capacity, with maximum heat transfer and efficiency.

Local heating

The easiest way is to install a heating system with natural circulation of air masses. To do this, you just need to take into account the operating features of the equipment and the manufacturer’s recommendations regarding installation.

The distance from the walls is at least 1 m.- The free distance in the direction of opening the combustion chamber door is at least 1.25 m.

- Furnaces models 11, 14, 16 and 19 are installed on a concrete base. For series 06 and 08, it is enough to lay a sheet of non-combustible solid material.

- All possible obstacles in the path of convection currents are eliminated. Optimal placement of the stove in the center of the room. Heating efficiency drops significantly when installed in a corner. You can increase productivity by installing a Breneran iron gas generator stove in a living room, in a place that is not fenced off from the rest: furniture, columns or interior partitions.

- Increased productivity is achieved by installing the stove at a distance of 30-40 cm from the floor level, on special metal legs.

Domestic long-burning wood heating boilers Breneran operate in two modes: conventional combustion and gasification. It is prohibited to heat the stove with the gasifier regulator fully open.

PPB requirements for installation of Breneran

Recommendations for the installation location in a wooden house are specified in PP N 390, SP 60.13330 (formerly SNiP 41-01-2003). In particular, the rules indicate the following features of furnace installation and air duct routing:

- The walls of the metal oven become very hot during operation; to avoid accidental fire, it is recommended to use a stand and a special fence. In the case of facing with ceramic bricks, the stove can be installed without metal legs, placing it on a prepared non-combustible base, rising 30-40 cm above the floor level.

- Fire safety requirements require the creation of fire breaks during the passage of the smoke exhaust system and air ducts in the floor slabs and roofing pie. Subject to insulation, there must be at least 50 mm to the surface of the pipe from flammable materials. The gap is filled with non-flammable insulation.

- A spark arrester must be installed on the pipe head.

- Heat distribution in a wooden house is carried out through pre-prepared channels made of non-flammable material with mandatory insulation of the pipeline.

Organization of a smoke removal system

The most common error leading to further operational problems. is incorrect installation of the smoke exhaust system. Any shortcomings will immediately affect performance and heat transfer, even if the Breneran potbelly stove is otherwise used correctly. Sufficient time should be devoted to selecting a suitable pipe and installing the chimney.

Breneran stove - an alternative to a potbelly stove, or a modern type of heating

It is known that energy sources such as electricity and gas are quite expensive, so the search for new types of heating devices becomes relevant. The Breneran device is a popular analogue of the Canadian Buleryan stove. It differs from other types in that it is surrounded by pipes in which air circulates.

The advantages of this device are beyond doubt. These include the fact that the design with circulating air, time-tested, guarantees long-term combustion and good heat transfer (80% efficiency) from one stack of firewood. Also, the advantages of the Breneran system are the ability to heat not only one room, but also neighboring rooms using air ducts. Almost any fuel is used for combustion, except coking coal. The advantages of Breneran are its autonomy - it heats rooms without the use of electricity, gas and other energy sources. The stove uses a device to control the heating and duration of fuel combustion.

About some disadvantages

this model:

- the need to regularly check the operation of the blower and gasifier;

- location of the smoke pipe at the back of the stove;

- there is no condensate receiver, which is often collected due to damp firewood

- if wiring is made to other rooms, then the stove will have to be heated more intensively

, but this is not a drawback, but rather a normal technological process.

If you wish, you can always choose your own model of the Breneran stove, depending on the purpose; To do this, you should read positive reviews about the Breneran stove;

“We installed Breneran at our dacha - since then we go there not only in the summer, but also on weekends in the winter. Beauty. It’s nice to sit in a warm hut and listen to the firewood crackling. The main thing is that they are dry. In the summer I will build a shed where I will put them. You can cook it and eat it. Now I’m thinking about installing such a miracle in the bathhouse, which is still in the project. We have a large family, and there are relatives who wouldn’t mind taking a steam bath on their day off.”

Zolotarev family. Ufa.

Operating principle and device

Outwardly, Breneran looks like a potbelly stove, but this is only in appearance. The furnace shell is a steel casing, the thickness of which is approximately 2-3 mm. The firebox is a compartment made of heat-resistant 5 mm steel. If we are talking about the technical characteristics of Breneran sauna stoves, then they also offer models with or without glass.

The principle of operation is based on the combustion of fuel, and the flow of the resulting gases into the ejector chambers, where they are completely exhausted, giving 80% efficiency. When heating with Breneran, you can increase the temperature in the room in the shortest possible time and maintain it stably for a long time.

“Nowadays it’s not so easy to find a real master stove maker, so we decided to buy a ready-made stove and settled on Breneran. A son from the city brought news that his friend has been working for 2 years and is fine. Bought and installed. What can we say about slow smoldering or the energy-saving factor - it’s warm, even hot, but at night you still need to add firewood at least once - especially in cold weather. And if there is a break in heating, then time passes until the beds warm up. Therefore, it is better to always maintain the temperature.”

Petrenko Ivan Stepanovich. Saint Petersburg.

How does the heating system work for other rooms and spaces?

Air ducts are installed on the pipes and branching to other rooms is installed - this can be a dressing room, a place to rest, a shower room, etc. Expensive devices are not necessary for this; it is enough to usually use aluminum ventilation hoses that can withstand a certain temperature. At the same time, even a small-sized Breneran processes and passes 4.5 cubic meters through pipes. air.

There are enough reviews about the Breneran stove to epyfnm about its advantages and disadvantages, and advantages over other types of heating:

“I have a metal processing shop - we make canopies, gates, fences. To heat his workshop, he purchased a Breneran stove. Now my guys don’t complain that their hands are cold. 100 square meters are easily heated. At the same time, you don’t need much firewood and it takes a lot. Work does not stop even in severe frosts, and a separate room for a stoker is not required.”

Pyotr Ivankovsky Ekaterinburg.

Different types of Breneran stoves

Breneran stoves are in great demand. They can be used in any premises: country houses, bathhouses, country cottages, workshops, garages, outbuildings, greenhouses. With their help, you can not only heat the room, but also cook dinner and heat water. There are units with a closed fire and with an open one, with and without glass.

Breneran is produced by a company with 20 years of experience in working with heating units. They produce devices:

- gas generators;

- with water heating;

- sauna stoves;

- with a stove for cooking;

- barbecue stoves, fireplaces, barbecues

Breneran gas generating devices operate on the principle of air convection. They were invented in Canada by lumberjacks for quick local heating of a room. At first, they did not provide for a connection to central heating. Subsequently, the heating unit was modified, and additions were made that allowed it to be used as a powerful heating system.

Breneran - a long-burning stove designed to heat a room with an area of 100 to 1000 square meters. meters. Cold air enters the lower pipes, which, when heated, rises, thereby releasing high temperature into the surrounding space.

“We are pensioners - we live most of the time in a holiday village. It's great and beautiful here. And when you come home and it’s warm there – what else can you dream of? For this we bought a Breneran stove. Our children chose it for us after reading reviews from other people. We flood it with wood chips, and then add firewood, after which we close the dampers as necessary and that’s it. There are two or three logs at night and the energy-saving mode does its job until the morning.”

Korolyov. Volgograd.

- Furnaces with a water circuit include Aqua Breneran:

- autonomous heating, independent of other energy sources (light, gas);

- universal water heater connected to the heating system;

- use of any type of fuel for heating;

- uniform heating of water;

- one bookmark in 6-8 hours;

- efficiency in work;

- heating of both residential and non-residential premises/

When heating: greenhouses, workshops, workshops, residential buildings, industrial premises, construction sheds, you can use a furnace with a Breneran water circuit. You can also use it to dry berries, mushrooms, grain, and wood.

The Aqua Breneran model is a stove with a water circuit. However, in the presence of a “cold core” due to stronger cooling of the flue gases, the draft in the pipe decreases. This causes more condensation to occur. Aqua-Breneran needs to be heated more intensively - one load of firewood may be enough for a shorter period of time.

For this stove, the recommended chimney height is at least 7 meters. The chimney should be cleaned at least 2 times a year.

Reviews about the Aqua-Breneran stove are varied, but they all agree on one thing - the stove is competitive and cost-effective compared to other types of heating.

Installation of Breneran stoves

It is recommended to install the stove at a distance of up to 1 meter from the walls. In front of the firebox there should be a platform measuring 1.25 m where the iron sheet is laid. The weight of a standard Breneran stove is about 105 kg. and you can install it yourself. A solid foundation will be superfluous; a platform 20 cm high is enough. The chimney pipe should be covered with asbestos cardboard and attached to an iron sheet adjacent to the chimney hatch cover. Thus, the ceiling boards are surrounded by a sheet of iron, which is secured with bolts, as a result of which the space around the chimney does not heat up and is safe.

“Before buying a device to heat my new home, I read reviews on the Internet. What attracted me to them is that the exhaust gas does not go into the pipe, but then works for heat transfer. Since we do not yet have gas supply in sight, we decided to get a Breneran. The interesting thing is that this stove is safe - it does not heat up red-hot, therefore, it can easily be installed in a room with furniture. And the name gas generator stove sounds solid, after all, we live in the 21st century. We bought a stove for 9600, well, with installation it cost more than 11 thousand. I’m happy – she justifies herself.”

Semyon Ivanovich Popov. Voronezh.

Conclusion

: Breneran wood heating stoves have both

advantages

and

disadvantages

.

In addition to the above advantages, the advantage of this type of stove is the price - it is relatively low, which is why this stove is considered a “budget option”

and is often used for heating domestic, warehouse, and industrial premises, while for a relatively low price the consumer receives a stove with good heating characteristics. To heat the living space of a country house or cottage, in the Furnace catalog you can select stoves of different price categories, including those similar in purpose, performance characteristics and prices to Breneran stoves.

Models with water circuit

Traditional Buleryan stoves, not equipped with water circuits, can be adapted to heat several rooms. To do this, thermal chambers are created around them with grilles for taking in cold air and air duct pipes for distributing heat to other rooms. This scheme is characterized by exceptional simplicity and makes it possible to easily organize full heating of a multi-room building.

The disadvantage of the presented scheme is that the air in the air duct pipes cools quickly, so their length is limited. It is also necessary to consider the installation location of the stove in order to minimize heat loss in the air ducts.

A water circuit is a more effective solution for organizing heating of multi-room houses and other buildings. Water cools much more slowly than air, which is due to its high heat capacity. A large number of radiators can be connected to the water circuit, and using circulation pumps, it is easy to implement a circuit with long pipelines. Let's see how Buleryan works with a water circuit and how it works.

Aqua Buleryan is a slightly modified version of a traditional air oven. We have already said that its combustion chamber is surrounded by curved pipes, forming a productive convector. By briefly working with a welding machine, these pipes are transformed into a giant heat exchanger. To do this, all the lower tubes are welded together, forming a manifold to which the supply (return) pipe is welded. The same is done with the upper pipes, from which the outlet pipe departs - here you have a heat exchange system.

The resulting Buleryan wood-burning boiler with a water circuit, according to user reviews, has many advantages:

This scheme provides the best smoke removal. In addition, to improve the draft characteristics, a deflector is installed on the chimney head.

- Effective heating of several rooms - these are country houses and multi-room cottages;

- High heating rate - this is ensured by an efficient water circuit with a large heat exchanger;

- There is no need to frequently add firewood - the long-burning system eliminates many tedious approaches.

Thus, Buleryan stoves with water circuits have good technical characteristics.

Main types

In addition to quickly warming up the air, the stove adds comfort to the room

There are several options for Buleryan stoves; some models include doors with heat-resistant glass. They are heating equipment that was invented in Canada. Due to the release of large amounts of heat as a result of fuel combustion, these stoves create powerful convection.

The Buleryan mini stove with a water circuit runs on natural fuel - birch wood. It is designed for heating any premises with a volume from 500 to 1000 cubic meters. One stack of firewood is enough for 12 hours of heating.

It can also be heated with peat briquettes, brown coal, and wood waste. When using coal, it must be mixed with other types of fuel.

Characteristics and selection criteria

The characteristics are, first of all, determined by the parameters of the room where they are going to install it.

For production, steel and cast iron are mainly used. Buleryans made of cast iron have great reliability and durability. At the same time, they are more massive and difficult to use in small rooms. Steel heaters are well suited for small spaces, but at the same time, they have less efficiency compared to cast iron ones.

The second important parameter is the number of water circuits of the heating system. A single-circuit system is designed for space heating only. In addition to heating, the dual-circuit system heats water for domestic needs.

The third parameter is the manufacturer of the solid fuel boiler. In this choice, you can rely on the reviews of people who have already become happy owners of a boiler from this manufacturer.

The remaining selection criteria do not depend on the parameters of the room and the boiler itself. This is the volume of the room, the material of the walls and ceilings, and the height of the chimney.

Advantages

The classic version of the Breneran stove is an all-metal structure that includes a large number of pipes that create forced convection.

Therefore, the heated air quickly heats up and spreads throughout the room.

And due to its clever design, the stove manages to take air from under the floor, warm it up in a matter of seconds, and then direct it upward, creating circulation. On average, the outlet temperature is up to 150 ˚С

It is worth noting that the burning time of one bookmark in such a stove will depend on many factors. So, it could be:

- firewood quality;

- total height of the chimney;

- in what mode the stove is operated;

- various nuances of the Breneran installation.

So, for example, some bathhouse attendants manage to provide heating for up to 12 hours in a row in one load. Although at the same time, it will not be possible to provide high-quality heating. It is most correct that with one load the furnace operation lasts an average of 7 hours. This will allow you to achieve maximum effect.

The main advantages of such furnaces are:

- high productivity (about 80%);

- greater efficiency;

- possibility of heating in a short period of time;

- versatility, allowing use both in the house and in the bathhouse;

- independence from stationary fuel sources (gas, electricity).

Considering the simplicity of the entire design of such a stove, in most cases it surpasses its main competitors in the form of gas boilers for private homes in many respects.

The most important thing is that it does not release any harmful substances into the air. In addition, an important point is that the design of such furnaces has been tested by time.

Price and reviews

Every year, long-burning Buleryan stoves are gaining popularity. This is due to their cost, which is less than the installation of similar gas equipment.

At the same time, you will not have to pay for the work of connecting to the gas main and the development of permits. The cost of such a heater, first of all, depends on its volume and, accordingly, power.

The price of the simplest and smallest ones starts from 7,500 rubles. Such a stove will heat a small room up to 100 cubic meters. For a room of 250 or more cubic meters, the price will start from 20,000 rubles.

It should be noted that many manufacturers decorate some of their products with various elements, including artistic forging. This also affects its cost.

Accommodation

Despite its excellent properties, installation of Breneran is very labor-intensive.

The reason is that the steam room must be protected from the harsh thermal radiation that comes from the metal parts of the stove. If this is not done, a fire may result.

The weight of the stationary version is only 105 kg. Although it is light in weight, allowing you to easily carry it, to install it, you need to make a special stand for the stove (a platform, approximately 20 cm in height). As for heating elements, they must be protected, since they will be hot metal.

For such furnaces, it is recommended to take pipes made of stainless steel, approximately 7 meters long. They must be made of sandwich material. As for the chimney, to organize it you need to take sheet steel and make holes in it for the pipe. You also need to make a hole for the chimney in the roof.

The pipe must be tightly wrapped with asbestos cardboard, and then secured to a metal sheet on the ceiling using corners. This will prevent the ceiling boards from heating up. Next, you need to put sandwich pipes on them, sealing the joints with sealant.

Please note: homemade chimneys connected to Breneran stoves make kindling somewhat more difficult, but the liquid that I use to light barbecues helps fix this. But the heat will be high, due to which the firewood will burn out more slowly.

DIY oven

To build such a furnace, you must be an experienced welder. To work, first of all, you will need a welding machine, a pipe bender, an angle grinder, metal scissors, as well as a set of drawings.

Scheme:

Then, do the work in a certain sequence:

- Cut the pipes to the required length.

- Use a pipe bending tool to give them the required shape.

- Make a contour of the required shape from sheet metal .

- Spot weld the pipes to the sheet of metal. The number of pipes must be in pairs. You will end up with a structure like a barrel with pipes welded on top.

- The next step is to install the back wall with a hole for the chimney. For the chimney you will need a pipe approximately 100 mm in diameter.

- Next, install the front part , with an opening door. At the bottom of the front part, install a pipe with a damper.

- Clean the seams and check the quality of the work done.

When choosing the size of the stove, focus primarily on the heating area of the room.

The most important thing is to choose the right installation location. It can be done anywhere in the room, but remember that the equipment should be no closer than 0.5 meters to the nearest wall.

The oven must stand firmly on the surface. Any vibrations of the body are unacceptable. After installation in the chosen location, it is connected to the heating system.

Wood burning stoves Breneran

Breneran long-burning stoves have many advantages. Including the fact that wood can be obtained almost everywhere. This option is indispensable for sauna heating, because logs are usually used for the firebox.

How to increase the efficiency of heating with wood?

Reviews from owners indicate that with a solid fuel model you can easily achieve the desired result of a wet Russian bath or a dry Finnish sauna. To do this, you either need to add water to the hot metal or not.

Installation of the Buleryan stove

The oven is mobile. Installation and dismantling of the product is not difficult. Installation does not require specialized education.

A person with minimal technical knowledge can perform the work.

Indoor boiler connection diagram. Radiator connection.

Fire safety standards for installation

Buleryan is a furnace, some surfaces of which can heat up to high temperatures. This should be taken into account and fire safety standards must be observed during installation.

The stove is installed:

- on a non-combustible base. If the floor in a room is susceptible to fire when exposed to high temperatures, it is necessary to arrange a specialized area on which the product will be installed;

- distance to walls. Before installing Buleryan, you need to choose the right installation location. The stove heats the room by heating air masses. When choosing a location, you need to take into account the distance from the stove surfaces to the walls.

This parameter depends on the material from which the vertical surfaces are made. For wooden, unplastered walls, a minimum distance of 1 m is required. for concrete surfaces this figure is reduced.

Is a foundation needed for Buleryan

The location and method of installing the boiler differs depending on the preferences of the owner of the room and the materials from which the surfaces are made.

At the installation site, it is necessary to equip a specialized platform made of non-combustible material. Typically, a sheet of metal is used or a foundation is fabricated.

Some experts mount the stove on a stand made of a profile pipe.

The foundation is made with a height of 10–30 cm. The material for arranging the site can be brick, cinder block, concrete, etc.

Furnace installation option.

The overall dimensions of the foundation must exceed the dimensions of the boiler. The protrusion located under the fuel loading hatch should protect the floor covering from sparks and heat.

Possible mistakes

When installing the Buleryan stove with your own hands, it is important to maintain all the necessary distances to vertical surfaces. This will ensure fire safety and free access to the boiler for maintenance.

Advantages and disadvantages of the unit

The Buleryan stove is capable of operating for a long time (5–7 hours) on one load of fuel, which provides its main advantage. Fuel consumption is quite economical, since it is burned as completely as possible, which brings the efficiency of the device to 80–82%. The stove is reliable and durable when used correctly. Its installation is carried out quickly.

When planning the use of this stove, one should also take into account such a disadvantage as the rather active deposition of soot in the chimney pipe, which requires frequent cleaning of the chimney. It can also accumulate condensation, which is pungent in smell and harmful in composition. When disposing of it, it is necessary to avoid environmental damage. The stove can only operate on wood and wood products, and the fuel is subject to increased humidity requirements (no more than 14–16%). Coal cannot be used. In addition, as a disadvantage, there is a large number of welds in the design, which makes independent production difficult and requires certain skills.

Ready-made installations can be selected in different types and performance. They are easy to install, but have a high cost. A DIY “Buleryan” stove for a bathhouse can significantly reduce costs, although you will have to purchase pipes of the required diameter.

Kindling technology

To use the stove, no specialized knowledge or skills are required. The boiler is easy to heat and maintain.

You can melt Buleryan as follows:

- Fuel is loaded into the firebox. First, firewood of small thickness is used. The fuel should be dry, this will minimize the amount of condensation that forms and allow the fire to start quickly.

- The wood is set on fire. The dampers that regulate the draft and the amount of air supplied are fully open.

- After hot coals have formed in the firebox, thicker firewood is loaded through the door. The dampers are installed in the desired position to ensure long-lasting combustion.

Operational moments

When starting the Breneran unit, you need to slightly open the vent and carefully burn a small amount of paper or wood chips in the firebox. After the flame burns, you can add firewood. Until the required temperature is established in the steam room, the oven will operate continuously. In just 45 minutes the room will warm up to 100 °C. Then you can cover all the holes through which oxygen enters the firebox. This reduces the intensity of the flame in the fuel combustion device, but the stove is already so hot that the heat emanating from it heats the water and stones. When the cobblestones are heated sufficiently, the steam room receives a high temperature that can last up to two hours.

Buleryan from a profile pipe

Do-it-yourself Buleryan from a profile pipe

A simple design of a Buleryan stove made from pipes. Buleryan can be made from round pipes or from profile pipes 60*40 mm. The photographs show step by step how to make a Buleryan cauldron with your own hands at home.

Schemes and drawing

Make a Buleryan stove with your own hands: the pipes can be bent or welded at the choice of the master.

The main task is to comply with the general principle of the boiler structure, its operation has not been disrupted, the diagram below shows a boiler made of round pipes, according to the same principle we use profile pipes.

Drawing for making a Buleryan stove

If you adhere to the diagram, then it is assumed that the pipes will be curved. Since not every craftsman can do this process, you can simplify this task and weld the pipes into the desired configuration.

Materials

- Metal sheet, thickness from 4 mm.

- Pipe profile (approximately 3-4 mm) size 6*4 cm - 7 pieces.

- A finished door or a piece of metal sheet.

- For the chimney outlet: pipe d-100-120 mm and a pipe for the damper.

- Door handle.

- Fittings for throttle and damper.

- The seal is heat-resistant in case of self-welding of the door.

- Hinges for doors.

Tools

- Welding + electrodes for it.

- Bulgarian and circles to it.

- Pipe bender (if the structure is curved)

- Electric drill and drills for it.

- Chalk or marker for marking.

- Roulette or ruler.

Step-by-step instruction

Without experience, it will not be easy to work; due to the non-standard shape, it is difficult to make a stove with your own hands, but it is possible. Be prepared to face difficulties, one of which is the number of welds, there will be a lot of them and they must be of high quality.

Profile pipes for assembling Buleryan

Bend 7 pieces of prepared pipes of the required length into the desired configuration according to the diagram and secure them with a welding seam.

Pipe blanks for frame

When you connect all 7 blanks together, you should get a structure of this type.

Buleryan step by step frame assembly

It is necessary to attach grate bars to the pipes from below (either ready-made, or make them yourself from metal blanks).

Frame made of seven blanks

After assembling the frame, we mark strips of metal and attach them pointwise between the pipes, or on top of the pipes, forming a casing.

Casing over pipes

Install the upper partition.

Partition in the Buleryan oven

The length of the partition should not reach the door by about 1/4. Approximately 7-10% of the total surface area will need to be carved out of the plate and welded. The main condition is the tightness of the welding seams! Next, we begin making the back wall. The easiest way is to make a pattern on cardboard or a sheet of thick paper, and then mark it on a sheet of metal.

Back wall of buleryan - blank

We mark the hole for the chimney pipe according to the size of the prepared pipe. Important: the chimney must start in the upper section, which is fenced off. Once ready, weld the wall at the back. Checking the tightness!

Now we come to one of the complex units - the front wall with the door. We cut out the wall itself in the same way as the back one, then we need to cut a hole in it for the door. This hole should be located closer to the grate, just above the grate.

Blank for the front wall

The diameter of the hole must match the size of the door. It is advisable to make it rather large; this will determine what kind of firewood will fit in the firebox. If you make the door yourself, then along the edge of the hole you need to weld a side from fittings curved to the shape of the hole, or a cut from a pipe of a suitable diameter (if the door is round). This side is needed for tightness. The door size will be slightly larger than the prepared hole.

Drawing for making a buleryan door

Along the edges of the door blank, you need to weld one strip of metal and, stepping back, weld a second one; the height of the side should be about 15 mm, so that the side on the front wall, when closing, is between these two plates on the door. To seal, an asbestos cord must be laid between these strips.

Prepared mechanism for the gate

We make a throttle. The damper is approximately 2-2.5 cm in diameter and about 10 cm long. A piece of pipe is best suited for this purpose. From the edge of the pipe, retreating 4-5 cm, we drill two holes, placing them radially. We pass a piece of reinforcement or a rod through the holes; one side will need to be bent - now this will be our throttle handle.

Throttle

Now you need to cut a round piece of metal slightly smaller than the pipe of the body itself - this will be our damper. Having inserted it into the body, we carefully weld it to the fittings. As a result, we get a damper that can be adjusted. The throttle itself now needs to be attached to the door. At the top we make a hole on a quarter of the surface and weld it.

Installation of hinges, shutter and damper for the chimney. The principle of its manufacture is similar to that of the regulator damper. We place the holes radially, pass metal reinforcement through them, then weld the damper and bend it at one edge to get a handle.

Handle to damper

Furnace design

Depending on the main purpose, you first need to select the optimal design of the stove. First of all, the power and size of the device are taken into account. Let's look at a drawing of the Buleryan stove for self-production. The first option is a typical Canadian design with a tubular outline that can be combined with a heater.

The second device does not provide numerous convection pipes, and the air flow is aimed at heating the steam stones.

The size of the proposed device is indicated in the drawing. The practice of using Buleryan stoves for baths indicates such optimal dimensions.

- Installations with a closed heater for servicing a steam room with an area of up to 16 m² - height 85 cm, width 68 cm, depth 75 cm. And for a steam room up to 26 m² it is better to choose a similar stove with a height of 90 cm.

- The opening stove-heater, capable of operating in a steam room with an area of up to 32 m², has standard dimensions: height 85 cm, width 57 cm, depth 66 cm.

The efficiency of the device is significantly affected by the diameter of the convection pipe. In principle, fairly common steel pipes with a diameter of 50 mm can be used, but the performance will improve significantly when using products with a diameter of 60–65 mm. Regular water pipes should not be installed.

Necessary materials

First of all, you should select the necessary consumables:

- a pipe with a wall of at least 4 mm with a diameter of 50–65 mm in sections of the required length (85–90 cm);

- steel sheet 3.5–4.5 mm thick;

- thin-walled steel pipe with a diameter of 32–36 mm for cutting rings for the door;

- pipe with a diameter of 11–15 cm for the chimney;

- steel corner with a shelf width of 25–30 mm;

- hinges for installing the door;

- handles - with a lock for the door, for the damper and the throttle lever;

- asbestos cord.

In self-production, the main equipment is considered to be a welding machine. There is a lot of work for him, and quite responsible. In addition, you should prepare the following tools in advance: a grinder, a hacksaw, an electric drill, metal scissors, a chisel, a hammer and sledgehammer, pliers, and devices for bending pipes.

To carry out the necessary measurements, you need a caliper, a metal ruler, and a square.

Technological features

When making the Buleryan stove, the following step-by-step instructions will be useful.

- Pipes for the convection circuit are bent according to the planned diameter, based on the selected project. A total of 7–8 segments are prepared in this way.

- Securing pipes. They are assembled into a column and secured with auxiliary elements made of metal strips or corners. You can immediately make a frame to which the pipes are welded. A frame made from a corner looks preferable, since a grate and a perforated partition can later be attached to it.

- The furnace body is formed from a thick-walled steel sheet, bent and welded to a pipe blank. The ends of the pipes exiting the housing should be no more than a third of their length.

- Making a grate. The grate can be purchased ready-made, but then difficulties will arise when adjusting it to the installation site. You can make a grate with your own hands from steel reinforcement with a diameter of 10–14 mm or steel strips. As a rule, it is formed in the shape of a triangle or trapezoid and is installed on a base made of a corner. It is better not to fasten it dead in order to be able to replace and clean it. The corners are welded, which make it possible to install the grate.

- Making a partition. It is made from steel sheet. For a tight installation, the partition must cover the pipes, and therefore a rather complex shape is drawn in it using a template. Then holes of arbitrary diameter are drilled in it, but so that their total area is 7% of the surface area of the workpiece. The partition is welded inside the furnace body.

- Installation of a rear wall made of sheet steel. A hole is cut in it for the chimney in the area where the afterburning chamber is located. The wall is welded to the pipe circuit.

- Installing the front wall. It is made in the same way as the back wall, but a window is cut out for the loading door. The window should be as close to the grate as possible, but slightly higher than it. The size should allow loading logs of decent size. Steel strips with a thickness of at least 10 mm are welded along the edge of the window to close the door tightly.

- Making the door. Its size is slightly larger than the dimensions of the prepared window in the front wall. On one side, on both edges, sides are formed from steel strips about 2–3 cm long. The distance between them is chosen so that they fit between the strips on the body. At the junction there is an asbestos cord.

- Making a throttle. The throttle valve is made from a piece of pipe 9–10 cm long and 23–26 mm in diameter. 2 holes are drilled in it, 5 cm away from the end, with the opposite arrangement. A metal rod is passed through these holes. One end of it is bent into the shape of a handle. A damper cut from a metal sheet is installed in the pipe on a rod. Its diameter is slightly smaller than the diameter of the throttle body. Next, this workpiece is fixed to the door, in which a hole is pre-drilled to remove the damper handle.

The door with the throttle is secured using hinges. Then the lock is installed on the door.

The final stage of production

A piece of pipe is welded to the hole for the chimney. The main chimney is then attached to it. A damper is installed on it, made similarly to a throttle valve.

The further course of action includes the following

| Steps | Subtleties |

| Fixing the chimney. | The initial section is performed horizontally. It is recommended to use an element made of pipes welded in a “T” shape. One end is secured to the outlet of the oven with a damper installed, and a door is attached to the opposite end. The remaining elements of the chimney are connected to the main pipe. |

| Making a stand. | The furnace body should be raised to a height of 26–35 cm. To do this, legs are welded to it. In some cases, the master refuses the stand in favor of a stationary brick pedestal. This option is also quite workable. |

After completing the last operation, the device is ready, but before putting it into operation, the entire circuit must be checked for the tightness of all welds. You should check the tightness of the doors and the operation of the dampers.

Buleryan long-burning stove from a gas cylinder

Buleryan from a gas cylinder

A simple configuration of a Buleryan stove for self-production, the basis will be a used old gas cylinder. This will be a combustion chamber and will help avoid the additional work of welding the base. This configuration of the Buleryan stove is the most accessible for making at home, without special equipment.

Scheme drawings dimensions

Buleryan’s DIY diagram below provides complete information on the size and complexity of this design.

Material

- The metal is no thinner than 3 mm for the ash pan.

- Cast iron door purchased or prepared in advance.

- Reinforcement or pieces for legs and grate.

- Used gas cylinder.

- For a chimney (pipe blank).

Tools

- Welding + electrodes.

- Grinder or grinder.

- Metal brush.

- For markings, chalk, marker.

- Roulette or ruler.

- Electric drill with drills of the required diameter.

- Pliers, hammer, chisel, metal file.

Step-by-step instruction

Step-by-step diagram for assembling a Buleryan stove

Before starting work, we first prepare the cylinder. To avoid the cylinder exploding, you need to make sure that there is no gas (residues) in it. A simple method is to fill the container with water to the brim, then drain the water and drain the container.

Drawing for buleryan from a gas cylinder

We mark the holes we need on the cylinder: square for the door, round for the chimney. To make a round hole you need either a cutter, or holes are drilled in a circle and then knocked out with a chisel and hammer. Clean it thoroughly with a file.

The simplest method for making a grate, if you don’t have one ready-made in size. We drill holes of the required diameter in the bottom of the oven, i.e. the cylinder.

Holes for ash pan

We weld a box for ash from the bottom of a sheet of metal, weld a door to this box and this box will act as a blower.

Blower for Buleryans

The doors are purchased, or we make them ourselves.

Doors for the Buleryan oven

We attach a pipe from a piece of pipe of the required diameter to the top of the cylinder. And finally, the last step is to secure the boiler to the legs or stand. The DIY Buleryan stove is ready for use.