Today we will touch on a very interesting topic - the construction of a turnkey bathhouse. Let's figure out what this concept can mean, how much it costs and how to talk with builders in the same language.

People approach the construction of a bathhouse very differently. Some people take a thorough approach: they draw up estimates, plan placement on the site down to the centimeter, review hundreds of sites in search of the best deals - they try to thoroughly understand all the details. For others, purchasing a sauna may be spontaneous. Seriously, clients often tell us that they were driving past your exhibition and didn’t seem to be planning to buy a bathhouse, but they saw it, liked it and were hooked! We believe that it doesn’t matter how the client came to order and how much money he could potentially have - business needs to be conducted with everyone equally transparently. Therefore, it is better to immediately tell them what awaits them during the construction of a bathhouse and how much it can cost.

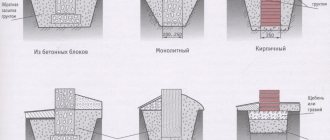

Construction principles

First of all, it is necessary to determine the location of the log house and where to build it: indoors, or perhaps it will be an autonomous building. The location of the structure has its pros and cons.

If it is inside the house or in a utility room, then there is no need for external insulation of the walls and ceiling, there is no need for a roof, but at the same time the likelihood of a fire increases significantly. If you build it separately from the premises, then more materials will be required for cladding and insulation, and it will cost more.

A suburban area or in the private sector is an excellent place to build; log baths are especially valued. Their greatest value lies in the fact that wood is an environmentally friendly material. Also, wood looks much more beautiful in appearance than other materials. Log cabins for baths can be purchased ready-made or made with your own hands. If you cut them out with your own hands and in a small volume, it will be much cheaper than ordering a ready-made log house.

Communications

Sewerage diagram for a bathhouse.

An important stage in the construction of a bathhouse is the installation of communications, which is also expensive. There are no problems with electricity now, since it is available even in the most run-down villages, but connecting to a central sewerage system and heating is a question.

As for the drains, they can be drained into a cesspool and periodically, as necessary, pumped out. In this case, you need to prepare yourself for the fact that you will have to dig trenches, spend money on pipes and periodically hire a machine to clean the sewage pit.

If it is possible to pump out the pit through ditches, then you need to stock up on a powerful pump.

It is possible to organize an autonomous sewage system for a bathhouse on the site by installing a septic tank.

It will also have to be cleaned, but much less frequently than the pit. However, the cost of such a station is considerable - about 3-4 thousand dollars.

As for heating, there are hardly any alternatives, and it is best to install a boiler that will heat the steam room. The best option is a solid fuel boiler, since it is relatively economical and does not require frequent maintenance. Having firewood or coal, you can heat the bathhouse very well - so that there will be heat not only in the steam room, but also in the washing room and in the relaxation room.

When calculating how much it costs to build a bathhouse, you should also take into account the materials needed to insulate the room. The quality of thermal insulation largely depends on the materials chosen, so you should not skimp on them.

Scheme of a stove for a bath.

Otherwise, you will have to spend more on fuel and heating the bathhouse.

When starting work on insulating a bathhouse, you need to install electrical wiring and thoroughly waterproof it. To avoid the harmful effects of high temperatures and moisture on the wiring, it is advisable to hide it in a high-quality metal sleeve.

It is relatively inexpensive, but will be a good guarantee of the reliability of the local electrical network.

In principle, installing electrical wiring is not very difficult, however, it is better if it is done by an electrician. Also, you should not skimp on installing ventilation, since its installation requires special skills. And it will cost only 10-15% of the price of the equipment itself.

Cost estimate required for construction

When constructing yourself, first of all, you need to draw up a plan of work and expenses . It may include the following items:

- drawing and construction project;

- pouring the foundation;

- construction of a log house;

- carrying out plumbing, heating and furnace, drainage;

- insulation;

- Finishing work;

- construction materials and tools;

- additional costs (what else may be needed during the construction of the bathhouse and what was not taken into account in advance).

A bathhouse measuring 6 by 6 with a shower and a vestibule will cost much less without installing a swimming pool , since additional materials will be needed for its construction and special means for its operation.

Cost of construction of wooden houses and baths

| № | NAME | UNITS MEAS. | PRICE, RUB |

| 1 | Removal of axles, planning for foundations up to 100 m2 | m2 | 100 |

| 2 | Excavation, installation/dismantling of formwork, reinforcement, acceptance of ready-mixed concrete | m3 | 4000 |

| 3 | Gravel-sand preparation device (with thrombus) | m3 | 800 |

| 4 | Performing coating side insulation | m2 | 100 |

| 5 | Installation of brick columns (0.25x0.25x0.6) | PC | 400 |

| 6 | Production of a blind area (excavation of soil, filling of ASG with compaction with a vibrating plate, reinforcement, installation of formwork, receiving concrete) | m3 | 3500 |

| 7 | Installation of roofing felt on the side surfaces of the formwork | m2 | 50 |

| 8 | Installation of “vents” in the formwork | PC | 150 |

| 9 | Installation of foundation blocks 30x30 (without base) | PC | 220 |

| 10 | Manual soil development | m3 | 500 |

| 11 | Laying concrete mix by hand | m3 | 3500 |

| 12 | backfilling | m3 | 800 |

| Log work | |||

| 13 | Installation and dismantling of scaffolding | m2 | 100 |

| 14 | Production and installation of a log house, timber 100x150 | m3 | 3500 |

| 15 | Production and installation of a log house, timber 150x150 | m3 | 3700 |

| 16 | Production and installation of a log house, timber 180x180 | m3 | 4000 |

| 17 | Production and installation of a log house, timber 200x200 | m3 | 4200 |

| 18 | Planing of timber on both sides with phase | m3 | 1200 |

| 19 | Antiseptic coating of wooden products for 2 times | m2 | 140 |

| 20 | Varnishing wooden products 2 times | m2 | from 300 |

| 21 | Caulking of interventional seams | p.m. | 60 |

| 22 | Installation of subfloor | m2 | 200 |

| 23 | Installation of a rough ceiling | m2 | 250 |

| 24 | Hemming the cornices | m2 | from 400 |

| 25 | Installation of doors without platbands | PC | 1800 |

| 26 | Installation of windows (without platbands) | PC | 1200 |

| 27 | Sanding walls | m2 | 350 |

| 28 | Rough brickwork | m2 | from 600 |

| 29 | Installation of logs | m2 | 110 |

| Roof installation | |||

| 30 | Construction of a gable roof (rafters) | m2 | from 350 |

| 31 | Sheathing device | m2 | from 100 |

| 32 | Installation of metal tiles | m2 | from 250 |

| 33 | Installation of corrugated sheets | m2 | from 200 |

| 34 | Installation of roof moldings (ridge, strips, etc.) | p.m. | from 150 |

| 35 | Viewing window device | PC | from 1500 |

| 36 | Covering the roof with roofing felt in 1 layer | m2 | 150 |

| 37 | Installation of a drainage system (at a height of up to 6m) | p.m. | from 300 |

| Finishing | |||

| 38 | Installation of platbands | p.m. | 110 |

| 39 | Antiseptic coating of wooden products for 2 times | m2 | 140 |

| 40 | Varnishing wooden products 2 times | m2 | 300 |

| 41 | Insulation of wall floors with steam/waterproofing | m2 | 30 |

| 42 | Insulation of wall floors with mineral wool, thickness 50mm | m2 | 100 |

| 43 | Construction of a frame for a partition | m2 | 300 |

| 44 | Painting (antiseptic) windows | m2 | 600 |

| 45 | Painting (antiseptic) doors | m2 | 150 |

| 46 | Installation of window sills | p.m. | 200 |

| 47 | Manufacturing and installation of slopes | p.m. | 300 |

| 48 | Installation of fiberboard on an existing floor | m2 | from 90 |

| 49 | Linoleum flooring (without plinth, adjustment) | m2 | from 100 |

| 50 | Installation of blockhouse and imitation timber (without cutting corners) | m2 | 350 |

| 51 | Installation of locks (internal) | PC | 300 |

| 52 | Installation of handles | PC | 50 |

| 53 | Installation of logs (after 50-60cm) | p.m. | 110 |

| 54 | Sanding the lining | m2 | 300 |

| 55 | Floor sanding | m2 | 250 |

| 56 | Wall cladding, plinth with tiles) | m2 | 1300 |

| 57 | Siding installation | m2 | from 400 |

| 58 | Drywall installation | m2 | from 300 |

| 59 | Installation of baseboards and corners | p.m. | from 60 |

| 60 | Installation of bath shelves | PC. | from 3000 |

| 61 | Installation of accessories | PC. | 200 |

| 62 | Installation of floorboards | m2 | 400 |

| 63 | Installation of a sauna stove | PC | from 3500 |

| 64 | Chimney installation | p.m. | from 900 |

| Transport, loading and unloading costs | |||

| 65 | Cargo handling | 5% | from the cost of mat. |

| 66 | Fare | 10% | cost mat. |

| SIZE (M) | PRICE OF A HOUSE MADE FROM STRONG BEAM (RUB) | PRICE OF A HOUSE MADE FROM STRONG BOOMS (RUB) | NUMBER OF PARTITIONS IN THE HOUSE |

| 4 x 6 | 410 000 | 425 000 | |

| 6 x 6 | 490 000 | 510 000 | |

| 6 x 7 | 566 000 | 588 000 | 1 |

| 6 x 9 | 606 000 | 630 000 | 1 |

| 7 x 8 | 685 000 | 711 000 | 2 |

| 7 x 9 | 758 000 | 788 000 | 2 |

| 8 x 8 | 762 000 | 795 000 | 2 |

| 8 x 9 | 784 000 | 880 000 | 2-3 |

| 9 x 9 | 930 000 | 970 000 | 2-3 |

| 9 x 10 | 1 035 000 | 1 080 000 | 2-3 |

| 10x10 | 1 110 000 | 1 160 000 | 3 |

| 10x11 | 1 198 000 | 1 253 000 | 3 |

Read more about basic timber houses here.

Wood selection

The construction project is drawn up by an architect; if you contact a government agency rather than a private company, it will be much cheaper. Then you need to decide on the purchase of wood.

Deciduous trees are the best option, as coniferous trees usually have a lot of knots. Deciduous trees differ greatly in their characteristics. How much will a log bathhouse cost? First of all, the price depends on the type of wood and the thickness of the timber. The most commonly used tree species are:

- Pine.

- Linden.

- Aspen.

- Abacus.

Abaca has the most durable wood , it is very resistant to high temperatures and high humidity, and costs $3,500–$4,000. It is believed that aspen absorbs bad energy and that is why, when a person takes a steam bath, he is cured of many diseases ($2,000).

Linden, on the contrary, transfers positive energy to a person; after steaming, in such a steam room you get a boost of energy, and linden also has a very pleasant smell ($2,500–3,000). It is very difficult to determine which wood is best suited for construction; it all depends on personal preferences and financial capabilities.

Conducting communications is a very expensive expense. If electricity and plumbing are not a problem, then sewerage may have its own difficulties. The fact is that many villages do not have sewerage. In this case, you can make a drain and a drainage hole . It is worth considering that it will also be necessary to dig trenches and dig a drainage hole. At least once a year it will need to be cleaned using a special machine.

Calculation of the cost of a strip foundation

To calculate the cost of a strip foundation, you need to calculate all the volumes of work and materials:

- First you need to calculate the volume of excavation work. If the cross-section of the foundation is 400x500 mm, and the length of the foundation along the perimeter is 14 m, then add another 100-300 mm to the height of the foundation, depending on what preparation you have. If you plan a sand preparation with a thickness of 100mm and a cushion of ASG with a thickness of 200mm, then the total height of the preparation will be 300mm. This means that the depth of the trench is taken to be equal to the value consisting of the thickness of the preparation and the height of the foundation, which will be in the ground. Let your foundation protrude 200 mm above the ground level, then below the ground level you will need to monolith 300 mm. The total depth of the trench will be 600mm. The total volume of excavation work to construct a trench for the foundation will be: 14 * 0.6 * 0.4 = 3.36 m3

- Construction sand for preparation will be required in the following volume: 14 * 0.4 * 0.1 m = 0.56 m3, where 0.1 m is the thickness of the sand layer, 0.4 m is the width of the trench, 14 m is the length of the trench. The cost of 0.56 m3 of sand for your foundation will be approximately (depending on the cost of m3 of sand in your region) 210 rubles.

- The sand and gravel mixture (SGM) for preparation for the foundation will be required in the amount of: 14 * 0.4 * 0.2 m = 1.12 m3. The cost of the SGM will be 500 rubles

- The volume of concrete is calculated by multiplying the length of the foundation by its width and height: 14 * 0.5 * 0.4 = 2.8 m3. The cost of imported concrete in a mixer will cost 9,000 thousand. Read more in the article about calculating concrete and choosing the grade of concrete for a strip foundation.

- Calculating the required amount of reinforcement for the foundation is a little more complicated. For longitudinal reinforcement and with a monolithic foundation height of up to 500 mm, four rods with a length equal to the perimeter of the foundation with a diameter of 12-14 mm are sufficient, which will be: 14 * 4 = 56 m. Transverse rods with a diameter of 8 mm are installed in increments of 600-700 mm. If the height of the rods is 480 mm (20 mm less than the height of the foundation section), you will need 4 pieces each (to tie the longitudinal rods into a spatial frame) to install them in 24 places, that is, a total of 96 pieces, which will be 46 m. On sale you will buy them by the meter, based on the fact that the reinforcement is supplied in 6m or 12m lengths. And at the moment it is necessary to calculate their cost based on tonnage. Therefore, convert to tonnage using the table for calculating the weight of reinforcement and then multiply by the cost of a ton of reinforcement. Longitudinal reinforcement will cost: 56m*0.888kg/m*28000rub/t= 1392rub. Transverse reinforcement will cost: 46m*0.395 kg/m*28,000 rub/t=509 rub. In total, you will need 1901 rubles for fittings

- The formwork of the above-ground part can be made from available residual material, such as unnecessary boards, leftover plywood, etc. Or you can buy edged boards t = 50 mm, which can then be reused, for example, as rafter boards when installing a roof. Let there be a new material: boards t=50mm. The formwork area will be: 14*2*0.2=5.6m2. You will also need bars for the formwork frame: 0.1 m3. Total: 0.38m3. This means that to purchase boards you will need 0.38 m3 * 6000 rubles = 2280 rubles

- Let's sum up the costs only for materials, in rubles: 210+500+9000+1901+2280=13891 rubles.

- The cost of work on laying the foundation should not exceed the amount of materials excluding VAT. You also need to deduct the cost of the boards, because the formwork material is a returnable material that is used by the contractor many times. Therefore, it usually does not participate in calculations. Therefore, no more than 9840 rubles

- In the cost part, it is also necessary to take into account transportation costs. Since delivery is included in the cost of such materials as sand, ASG, concrete, it remains to take into account only the fee for bringing two types of materials to the construction site: boards and reinforcement. Within the city, delivery costs 500 rubles. This means ordering a car from two different places will cost 1000 rubles.

- The total cost of the strip foundation, taking into account all of the above, will be 24,731 rubles

- For ease of data correction, it is best to summarize the entire calculation in an Excel spreadsheet.

Calculation of costs when constructing a foundation

So, the calculation of the cost of the foundation consists of the following costs:

- Cost of materials

- cost of work

- fare

Usually, if you call any organization and ask: “How much will it cost to install a foundation,” then they answer you that 1 m3 of a monolithic foundation costs 8 thousand rubles. This means that they bear all costs, including the purchase and delivery of materials.

The cost of a bathhouse made from a log of the smallest area

Consider, for example, the smallest room , measuring 2 by 2 square meters, with all the necessary communications, a chimney, heaters and finishing work, and the necessary accessories. A steam room and the room itself will cost $2,000 made from aspen, $2,300 from linden, and $4,000 from abaca.

The cost of a bathhouse also depends on the cost of building materials and the price of their delivery, the size, and floors of the log house. In a log structure, the thicker the tree trunk, the more expensive the log house itself will be. Such a bath does not need finishing, as it looks very good on its own. The service life is longer than that of baths made from other materials.

How much does a log bathhouse cost and the cost of a bathhouse made of other materials, which type will be cheaper, this is the question asked by those who want to build this wonderful structure.

Pricing for materials, tools, wood and other special accessories depends on the region of residence and seasonal price changes.

Your own bathhouse cannot be very expensive, because by steaming, a person gains health. Here they rest and harden, even the years of life are extended. No money can compare with health!

Turnkey sauna: expectation VS reality

As with building a house, the rule applies here - you need to divide your wishes by 2 times, and increase your budget by 2 times. And all because on most websites of construction companies, the prices indicated for turnkey construction do not in fact meet the expectations of the client for this turnkey project.

What does the customer understand by a turnkey bathhouse? Most likely something like this, right?

While for a builder a turnkey bathhouse is essentially a box with windows, doors and a roof:

“Uh, wait! - you say, - how can you use this? Turnkey means when you bring in the furniture, the basin is there, and that’s it, you can light the stove!” Yes, but only here we meet the reinforced concrete reality - in the cheap and medium price segment of timber baths, no one will offer you a turnkey construction service in such a volume. Prices on websites are very often taken from the ceiling - anything to create the illusion of cheapness and hook the client. Then it’s up to the seller, who will most likely convince you to buy the service.

Here, again, there is a double-edged sword. Here the builder says: “This bathhouse costs 100 thousand rubles.” By this he means that it is just a box with windows on bare ground. But the client likes the price and places an order. And when the team has finished construction and asks to accept the object, the client rolls his eyes and begins to be indignant, saying, that’s all? Or another situation - here I am, Dima Glushakov, putting on my website the price for a bathhouse at 380 thousand. I strongly doubt that a person who is not familiar with my company, seeing such numbers, will linger on my site for at least a few more seconds. But in this cost I include the foundation, complete finishing outside and inside, furniture, stove equipment, shower, and electrics. At the same time, I give a real, I emphasize - an absolutely real guarantee for all materials, work and equipment.

Therefore, when you see an offer on the website for the construction of a turnkey bathhouse, take an interest in the package. Don’t be afraid to ask whether exterior and interior finishing is included in the price. What about the stove? Shower? Maybe a foundation?

So, my friends, the price on the website is only half of the upcoming costs

. Let's figure out what awaits you next.