Description of buildings made of hand-cut planed material

A log house is the main load-bearing part of a wooden structure without a roof, ceilings or floors .

The comfort of living in the house entirely depends on its quality. Therefore, after the work is completed, they allow 6-12 months for the structure to shrink, depending on the quality of materials, work and local climate.

After shrinkage, finishing work is carried out, which includes: finishing, installation of the roof and foundation, installation of windows and doors, installation and connection of communications.

To construct a log house, planed logs are used, which are firmly fastened together during the construction process . Such a building is a true work of carpenter’s handiwork, which displays the best traditions of wooden architecture.

Houses are called log houses, the material for the construction of which is chopped, and not cut or sawed, therefore the ax is the main tool with which the construction process is carried out.

It is when chopping with an ax that a high quality of processing is achieved, which cannot be achieved using other tools. For example, when cutting, a saw “shags” the wood, which becomes more permeable to moisture. The ax, on the contrary, crushes the fibers, reducing its porosity.

Houses made from chopped logs are solid, warm and durable.

Construction from rounded logs.

Rounded logs are a fairly modern material, produced on machines, the workpiece is clamped in the centers. Therefore, there is no warping effect. This material absorbs the advantages of hewn logs, losing its disadvantages. Namely, the customer pays for a cube of the finished product, not raw materials, receiving logs of the same diameter already adjusted to each other. Today, the cost of a cube of a house kit of 220 logs is 8,000 rubles. A house made from OCB does not require long shrinkage periods. In three months, up to 80% of the total shrinkage of the house will occur. There is an opinion that during the production of OCB, the densest or protected layer of sapwood is removed. We will not dwell on this in detail, we will only mention that sapwood is a less dense, young layer of the tree through which sap flows in the trunk, and it is protected only as long as the tree grows. Therefore, by removing the sapwood, we did not spoil the log; the material only gets better. The house is quite easy to install and does not require control assembly procedures. It is possible to immediately install windows and doors in the house, leaving a compensation gap for shrinkage, covering it with soft insulation. The OCB has a lunar groove - a kind of thermal lock that protects the wall from through inter-crown freezing, as is the case with timber.

Log houses made from OCB still remain 100% environmentally friendly, and also do not require expensive finishing. Therefore, such houses will suit the widest range of customers. Able to understand the benefits of one-time costs for structural materials and further savings on finishing and operation.

Pros and cons of such structures

Among the many positive qualities, the main advantages of such buildings should be highlighted:

- Massiveness, reliability and strength of the log house.

- The natural aesthetic appeal of the material does not require additional external and internal expensive finishing.

- The material is environmentally friendly and safe, creating a comfortable indoor microclimate - there is always excellent air and steam exchange.

- Exclusivity of design. Natural wood has always been in fashion and now remains a decoration for any interior. Log surfaces both outside and inside create harmony, warmth and comfort in the house. In addition, it becomes possible to create any desired architectural project.

- Low thermal conductivity of walls and their ability to retain heat inside the house, due to which it becomes possible to significantly reduce and optimize energy and coolant costs.

- Manual processing preserves the protective layer of wood, which increases resistance to moisture, insects and ultraviolet radiation.

- The durability of raw materials due to the latest methods of processing allows us to compare construction wood with brick structures. With proper care, a wooden house becomes a home for several generations of a family (its service life is at least a century).

Before starting construction, you should consider the disadvantages of this structure:

- High degree of fire hazard. In the event of a fire, a wooden house can burn completely. The problem is solved with the help of special fire-retardant impregnations, which are used to treat hewn logs during their harvesting or construction.

- It will take time to shrink. The log can shrink significantly - up to 20% during the first year. If the material procurement technology is not followed, this process can last up to 3 years.

- Large expenditures of money both for the purchase of material and for the assembly of the log house, for which professional craftsmen will have to be involved. Although, if you have carpentry skills and knowledge of assembly technology, you can save money by doing the work yourself.

- The need for a monolithic, strip foundation due to the large weight of the log house.

- Difficulty in installation due to different diameters of logs and uneven surface.

- Logs of different diameters create cracks, so careful sealing of the seams and caulking of the log house will be required.

Basic operations for cutting timber from a log

First, mark the central axis (diameter).

Then the ends of the log are marked as described above. After this, chamfering lines are marked along the ends of the log marked with a chalked cord.

To do this, the cord is secured along the edges of the log in pinches made with an ax, so that the cord is taut. After this, the cord is pulled back a little, like a bow string, and released. When the cord hits the log, it leaves a line. The cutting will be done along this line.

First, along the side to be hewn, cuts are made with an ax every 20-40 centimeters, not reaching the hew-off line a few millimeters.

After this, a rough cut is made with an ax, removing the main layer of wood, moving from cut to cut. When the main layer of wood being removed has been removed, the surface to be hewn is cleaned either with careful clearing blows of an ax or with a sherhebel.

Today, beams are rarely hewn from logs with an ax. For this purpose, there are milling-canter lines that produce timber on an industrial scale. However, when building a bathhouse, you may have a situation where you need to hew out a flat surface on one or more sides of the log. Therefore, you need to know the basic techniques for cutting a beam out of a log or cutting a log by 1-2 edges. In the construction of bathhouses, hand-held electric and gas-powered tools are currently widely used. If you make a plane with a chainsaw, then the sequence of operations will be the same - marking, making cuts along the side to be cut, rough removal of a layer of wood, and only then finishing to the cutting line using an ax or electric plane. Now you know how to hew a log, how to hew a beam from a log . In other articles we will talk about how to properly make a groove in a beam or log, how to saw wood correctly, how to plan boards and beams.

See also:

Preparing logs for a log house

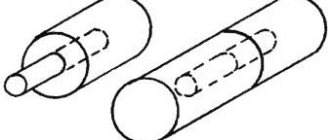

How to splice logs end-to-end, straight and oblique

How to make a rectangular or oval groove in a log?

How to plan boards and beams correctly?

How to cut boards and bars correctly?

Which wood is better?

For the construction of log houses, it is better to use those logs that were harvested in winter.

During this period, there is no sap flow in the trees, therefore the wood contains a minimal amount of moisture, which will help avoid rotting, drying out and warping of the material.

Wood grown in the northern regions is considered to be of the highest quality for such construction . Trees grow much more slowly in harsh weather conditions, so their wood is hardier, more uniform and dense.

For log houses, coniferous wood is most suitable, especially Baltic pine and Canadian spruce, as well as cedar and larch. But if there are no desired options on the market, you can use oak, ash, aspen and other hardwoods.

Pine is easy to process, has good characteristics and an affordable price, so houses are built from this wood.

Types of lumber and their grades

Processing technology allows materials to be delivered ready-made to the construction site in the form of bars, slats, and boards obtained directly from cutting tree trunks.

According to the processing method, lumber is divided into edged and unedged . Edged ones are characterized by the same width and length, the presence of smooth edges, the height of which is in the range of 13–100 mm. The surface of such materials can be planed. Unedged lumber, on the other hand, has a raw edge and quite different widths.

Wooden buildings for seasonal and year-round use

The following buildings are made from unrounded chopped logs:

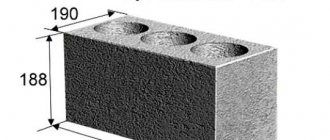

- For seasonal use (cold house) . Such houses are usually built on summer cottages for living with the onset of warm weather and before the first frost, so a high level of thermal insulation is not required. A suitable material would be sanded logs with a cross-section of 20-22 cm. The standard area of the building itself does not exceed 50 square meters. m.

- For year-round use . This option imposes higher requirements, since such a residential building must withstand sudden temperature changes and various weather conditions. In order for a log house to meet all the requirements, it is necessary to perform the following steps: skillfully select the diameter of the log, carry out high-quality wall insulation, and install an efficient heating system. As a rule, such buildings have a large area - at least 150 square meters. m, so logs are taken with a cross-section of 28 cm or more.

This is a rather expensive solution, but purchasing logs at a high price will allow you to save on purchasing fuel for heating in the future.

Projects of houses made of hewn logs

This building material has received particularly positive responses among consumers. Like debarked houses, houses made of hewn logs are made by hand, so the procedure for processing and laying a log frame is far from the fastest process, but it is worthwhile.

Why is the material so in demand? A cottage from such a forest is unique; it is impossible to find an identical structure. This feature brings such buildings closer to the traditions of Russian architecture.

Even though it is difficult to build such housing, hewn logs, due to their properties, are more durable and less susceptible to negative environmental influences. Manual cutting increases the wear resistance of the material due to the fact that during processing the protective layer of resin is not completely removed. And additional antiseptic impregnations can further extend the service life of the log house.

However, prices for houses made of hewn logs are quite high. But the investment is worth it.

DIY construction stages

When choosing a particular material for building a log house, it is necessary to inspect it for darkening, destruction and signs of rotting, and also take into account the required diameter.

Preparation

After acquiring the necessary material, they begin to build a log house:

- Such work begins with a thorough drafting of the building (at the design stage it is advisable to contact specialists). In addition, they obtain technical specifications from the authorities servicing communication systems, as well as a construction permit.

- If there is no electricity and water on the purchased site, these issues are resolved at the preparation stage. To ensure water supply, they drill a well, and in the absence of electricity, they stock up on at least an electric generator.

- The site is fenced to prevent the entry of strangers and to preserve valuable building materials.

- A small utility block is being built where tools will be stored and where it will be possible to shelter from bad weather.

- Next, clear the area of stumps, roots and debris.

Before building a log house with your own hands, all the material is carefully prepared. The logs are sanded, leveled and knots removed.

Then it is sorted in ascending order of diameter, since the lower crowns of the log house will require timber of a larger diameter than the upper ones.

Assembly of crowns

Before starting to lay the prepared logs into crowns, it is necessary to treat the longitudinal grooves and corner locks with an antiseptic . This is a mandatory condition that is met to extend the life of the house. Planed logs should be processed as a whole.

Also, after finishing the construction of the walls, it is advisable to cover the ends of the logs with wax. This will partially protect them from cracking.

A crown is a series of beams or logs that are laid at an angle of 90 degrees relative to each other and fastened together at the corners. The walls of the house are made from crowns. There are first, second, window sill, window and over-window rows.

The construction of the house begins with the frame crown (the first) . The logs must be edged so that they adhere as closely as possible to the foundation.

But before that, a backing board is laid on the foundation. Linden is usually used.

The thickness of the timber should be 50-100 mm . Minimum width - 150 mm. After laying the first crown, you can proceed to the construction of walls.

Now the second crown is being laid. For it, it is advisable to select the thickest logs, since they will later be the basis for installing the floor joists. To improve the fit, a longitudinal groove is made in the upper beam.

The groove should be ⅓ of the section of the previous beam. To delineate boundaries, a carpenter's tool is used - a line. The groove should be made in a semicircular shape for a better fit.

After laying the second row, the crowns are fastened together. For these purposes use:

- Square dowels.

- Round wooden dowels.

It is recommended to use wooden dowels, as they are sold already prepared. It is enough just to make holes of the required diameter.

Holes are made in increments of 1-1.5 meters. The two upper crowns are completely stitched, and the third from the top is half stitched.

If 4 crowns have already been laid, it is necessary to completely sew the third and fourth, and the second - not completely . And so from row to row. The dowels have to be recessed into the crown so that the structure does not warp during assembly.

During the process of laying logs, it is necessary to ensure that the thickened ends are located on opposite sides in adjacent rows. The horizontal and vertical of each crown must also be controlled.

Floors

The beams should be cut out with a secret frying pan.

Accuracy of fit is extremely necessary here , since it affects the rigidity of not only the ceiling, but also the walls.

The quality of cutting the groove must be checked before placing the next crown.

Nowadays, many builders prefer not to cut out the frying pan, but to use metal brackets to fasten the floors . This decision is completely justified, since such installation is much simpler and ensures durability and strength.

But it is important to use stainless or galvanized steel, the minimum thickness of which is 3 mm. But this method is only suitable for beams with a rectangular cross-section. It is not suitable for round logs.

Installation of window and door blocks

Door and window openings are arranged in two ways:

- Manufactured after completion of construction work. After installing all the crowns, all that remains is to cut the holes.

- Provided during the construction of walls. This option is much more complicated. You will have to cut the ends off the top and bottom logs. It is also necessary to provide ridges on the side walls of the opening for casing and a gap for shrinkage.

Most specialists make openings after completion of construction work. There are no particular difficulties with this procedure.

But in any case, a ridge is made in the openings. Also, between the casing and the upper overlapping crown, you need to leave a shrinkage gap of about 50 mm.

Grinding

Sanding improves the appearance of the log house and reduces the amount of paint and varnish materials consumed . You can start sanding without waiting for complete shrinkage. It is best to use a grinder.

A special disc with sanding paper is installed on it. To clean the log house in the corners, use small discs, hand brushes or a vibrating sander equipped with a special working platform that resembles an iron.

Caulk

Caulking a house is a separate important stage in its construction .

It is important to choose materials that will reliably protect the house from blowing and heat loss. In addition, the insulating material must absorb and release moisture, be environmentally friendly, resistant to the development of various microorganisms and durable. Typically, moss, tow, felt, and linen are used to perform this type of work.

Caulking is done immediately after the installation of the roof is completed . It is advisable to use tape type insulation. One edge of it is applied to the seam of the lower crown and, using some flat tool, is pushed into the slot along the entire length of the row.

The hanging edge, about 5 cm wide, is folded up and a roll is formed, which is again hammered into the seam. Having caulked one row, move on to the next row.

It is important to process the entire crown around the perimeter at once. You cannot insulate one wall first and then move on to another. The procedure is also carried out from the outside so that the structure does not warp.

The second time caulking is carried out after 1-2 years . In some cases, the process is repeated a third time 5-6 years after the construction of the house. By this time, complete shrinkage will occur, causing new gaps to appear.

Nowadays, for insulation, they use a material based on jute or flax-jute, impregnated with an antiseptic. The material is windproof and retains heat well.

Inter-crown insulation looks like tapes, which are laid in an even layer along the entire length of the log, as well as on the plane of the notch and secured with a stapler. At the same time, there is practically no gap between the logs

treated with a special compound, which increases its volume by 3-5 times, is considered effective as inter-crown insulation This way all the voids are filled.