Making a bathhouse from sleepers with your own hands - step-by-step instructions

Bathhouse construction from sleepers has always been the subject of a lot of controversy and discussion. On the one hand, massive beams made of treated wood are ideal as a building material. On the other hand, the use of toxic chemicals for preserving and processing wood can negatively affect the health of bathhouse owners.

You can build bathhouses from sleepers with your own hands in a short time.

We evaluate negative and positive qualities

A competent owner, before building a bathhouse from sleepers, will try to obtain as much information as possible from available sources. First of all, find out how seriously a bathhouse made of sleepers affects your health, whether it is harmful or not.

The positive aspects of the option of building a bathhouse from sleepers with your own hands include the following:

- Extremely low price for the material; used sleepers can be purchased for 12-15% of the cost of a new product. On average, the price for model A-1, with a cross-section of 25x18 cm, ranges from $2 per piece;

- Long service life, a ten-year sleeper in a bathhouse box will easily last another 15-20 years. They practically do not rot, are not affected by microorganisms and pathogenic microflora, insects, and rodents.

The durability of the bathhouse box largely depends on how to make a bathhouse from sleepers, what kind of foundation and finishing design is planned to be used when arranging the room.

The second condition is the quality of the material. Therefore, the design of a bathhouse made of sleepers, the method of constructing any sleeper buildings, is chosen based on the actual conditions on the ground and the quality of the purchased material.

Advice! You should not completely trust reviews of bathhouses made from sleepers published by the owners of buildings. Only a few percent of respondents give an objective assessment of the emerging problems.

Negatives of building a sleeper bath from ten-year-old sleepers:

- Possibility of poisoning by vapors of creosote, phenol. Under the influence of heat, flying sleeper structures intensively release carcinogenic substances that provoke the development of oncology;

- High flammability of the sleeper box of the bathhouse. It is no longer possible to saturate the sleeper with fire retardants; the surface layer of flammable creosote interferes. And sleeper baths burn several times more often.

It is quite possible to cope with both problems, but their solution involves the use of additional sanitizing finishes and insulating materials, which can lead to a significant increase in the cost of building a bathhouse.

Final Steps

How to caulk a bathhouse from sleepers

At the final stage of construction, lay boards with a thickness of 55 cm on the beams, and then lay slate or roofing felt on the structure. Leave the bath for 6 months without touching it for the necessary shrinkage.

We suggest you familiarize yourself with How to calculate how many boards you need for the floor: board calculation

As soon as the structure has given the necessary shrinkage, you can begin to caulk it. To do this, stock up on a hammer and caulk made of wood or metal. If you are unable to find this tool in the store, make it yourself using an electric jigsaw.

The bathhouse is caulked as follows: the insulation is twisted into a tight bundle and pushed between the sleepers of the crowns. The result should be a perfectly even and dense insulating seam. This step does not need to be carried out when initially using jute fibers as an insulating material, since this insulation itself is quite dense.

To give the building an external appeal, you can cover it with siding or other material of your choice.

At this point, the construction of a bathhouse from sleepers is considered complete, and if you carefully study the technology, it should not present you with insurmountable difficulties in the process. The main thing is to be patient, which will pay off in the end.

Decision-making

It is clear that the best option would be to build from new raw materials. A massive sleeper beam made of larch or fir is ideal, since the wood is still clean, and good quality industrial wood is used for products - larch, fir, and sometimes pine. Thanks to the pure wood, a new, self-built bathhouse made from sleepers, photo, is practically no different in appearance from a house made of timber.

But before planning how to build a bathhouse from such sleepers with your own hands, it is worth asking about their selling price; it is only slightly less than the price tag for timber and logs. But such a sleeper bathhouse is not inferior to classic timber log houses either in appearance, or in safety and comfort.

If, for certain reasons, it is necessary to build a bathhouse from treated sleepers, then you need to pay special attention to the process of choosing the material:

- For construction, solid beams are used, no older than ten years, without cracks, chips and traces of putrefactive wood;

- When tapped with a hammer, the sleeper wood should produce a sharp, almost high-pitched sound, without dull tones indicating internal defects;

- To build a bathhouse, you need to look for larch or fir; it doesn’t make sense to take pine or fir for a wooden building; such material is suitable for building a shed or fencing a site.

Birch or pine sleepers are often treated with a phenol-creosote mixture in high-pressure chambers. Impregnation penetrates very deeply into the wood. Such a sleeper will disappear from toxic compounds in twenty years, not earlier. In sleeper arrays made of larch and fir, due to the dense structure, the mixture penetrates into the thickness by a maximum of 5-7 mm, so this type of sleeper, like no other, is suitable for building a bathhouse with your own hands.

To build a bathhouse from medium-sized sleepers, you will need at least a hundred full-size sleeper beams. In total, a set of sleepers to build a bathhouse box will cost $300-350.

What kind of building material is this?

Sleepers are lumber.

It can be treated with creosote. Sleepers are used for the external walls of a building. Therefore, they are susceptible to the influence of external factors such as rain, snow, and sun. Therefore, the main indicator of this material will be a long service life. That is why the wood is treated with a poisonous antiseptic, which helps prevent the sleepers from rotting. Sleepers are used in the railway industry. Because they have a lifespan, they are eventually written off. And to build bathhouses with your own hands, you need exactly discarded materials.

Anyone who plans to use sleepers in construction should have an idea of what they will be working with and what their features are in installation and use in the future.

There will be many advantages here. The main thing can be called the low cost of materials. The durability of such baths exceeds twenty years or more. The construction of bathhouses from sleepers will be very fast. And most importantly, installation here will be simple.

Of course, there are also disadvantages. Such baths will have an ugly appearance. Therefore, owners often line the walls. To understand the picture of what awaits you, just type into a search engine: do-it-yourself bathhouse photo. And of course, an unpleasant aroma will disrupt comfort.

At the same time, such buildings are still in demand and craftsmen have been building them for many decades.

How to properly build a bathhouse from sleeper scraps

There are quite a lot of options for constructing sleeper buildings. Most often, untreated sleepers are laid out on a strip concrete foundation, with a reinforced waterproofing layer of mastic or roofing felt. The further process of erecting the walls of the bathhouse completely depends on the budget.

The simplest version of a black bath made from untreated sleepers

As a rule, to the average individual developer, sleeper factories offer at a reasonable price only scraps - short pieces, the remains of unprocessed sleepers, 120-200 cm long. The weight of one piece instead of the standard 70 kg is only 35 kg, which is very convenient, especially if the room is being built with your own hands , and even alone.

The material undergoes factory drying and primary impregnation, with the help of which soluble compounds are washed out of the wood. This type of sleeper does not shrink, so the gaps for drying out are minimal.

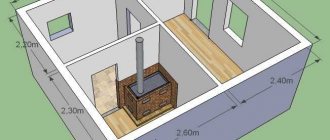

In the simplest case, you can simply build a bathhouse from sleepers on a concrete strip with your own hands. The steam room is very small, so in order not to bother with laying insulation on the walls, it is enough to cover the inner and outer surfaces of the walls with clapboard on the sheathing. Due to the two air gaps and the characteristics of sleeper walls and partitions, an acceptable level of thermal insulation is achieved.

Of course, it is not easy to heat such a bathhouse from sleepers, especially in winter, so two powerful wood-burning stoves are used in the tiny space of the sleeper steam room and dressing room. Thermal power of 20 kW is enough to quickly and deeply heat the walls of the bathhouse and the lining of the steam room. It will not be possible to sit comfortably for several hours in such a bathhouse, but it will be very possible to thoroughly steam and wash yourself in the country after work.

The advantage of this design of a bathhouse made of sleepers is its simplicity and reliability. Such a building will not rot, since there are no insulation materials, and, accordingly, no places for condensation to accumulate. A concrete strip foundation must be equipped with vents. As a result, after completing the bath procedures, due to the huge amount of heat stored by the walls of the furnace, the sleeper bath is evenly dried and gets rid of residual moisture.

Installation of subsequent crowns

- First of all, you will need to lay slats on the foundation that will prevent the sleepers from touching it. This is also necessary to provide additional ventilation.

- After this, proceed to laying the first crown, which should be positioned strictly horizontally. This can be achieved using a level.

- Connect the sleepers together, filling the space between them and the foundation with foam. The first crown does not need to be secured to the foundation, since the finished weight of the structure will provide the necessary stability.

- A layer of heat insulator (tow, jute or moss) is placed on the crown and secured with a construction stapler.

Bath crowns made of sleepers

Subsequent crowns are laid strictly horizontally with further fixation to each other. The sleepers should be fastened with dowels or metal pins, having previously made holes for unloading. In this case, the diameter of the fasteners and holes must be completely identical.

Note! All crowns are mounted and processed in the same way as the first. This is necessary to give strength and reliability to the sleeper bath. However, the last two crowns do not need to be connected, since in the future they will be removed when installing beams for the ceiling.

Project of a full-fledged bathhouse made from sleepers

Based on unprocessed sleeper blanks, you can build a fairly convenient and inexpensive bathhouse with a high level of comfort, and most importantly, high durability of the box. Sometimes, instead of blanks, you can use black sleepers.

If it was not possible to buy sleeping material inexpensively, then the problem can be solved by special preparation of material that has already been used. For example, “fresh” 5-7 year old sleepers with shallow impregnation will cost 25% more than ten-year-old material, but it is this sleeper block that is of particular interest:

- The structure of the wood differs practically little from a new clean piece, there are no cracks or damage;

- Creosote impregnation is concentrated on the surface of the sleeper and does not penetrate deep into the wood.

This material looks quite presentable, so often bathhouses made from five-year-old beams are not even subjected to additional external finishing. The main problem is how to get rid of creosote impregnation. To do this, the sleeper at the ends and three of the four side faces is simply cut on a powerful circular saw to a “living” tree. The remaining fourth side, after laying the sleepers in the walls of the bathhouse, will face the street, and over time will lose up to 80-90% of the impregnating creosote.

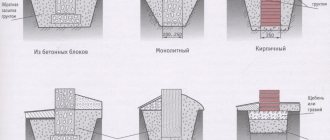

Features of the foundation for the sleeper walls of the bathhouse

For a full-size standard bathhouse made of sleepers, the best option remains a strip shallow foundation. The main problem that plagues all wooden baths is how to effectively waterproof the base of the lower crowns of the walls of the building.

Therefore, when arranging the foundation and base of a bathhouse made of sleepers, additional measures are taken:

- Mandatory installation of vents - holes in the concrete foundation strip, through which it is possible to “remove” the bulk of the moisture from the underground space;

- Laying the first crown with full treatment with special waterproofing mastic;

- The next two crowns are laid from uncut impregnated sleepers.

When compared with conventional timber baths, a sleeper bath lasts 15 years even on waterlogged soil, while timber begins to rot already in the fifth year of service.

Using treated sleepers to strengthen the foundation and basement of bathhouse walls can have unpleasant consequences. Creosote and phenol are easily washed away by moisture and transferred to the soil, through which fumes can enter the room. To block toxic and unpleasantly smelling substances, waterproofing made of thick polyethylene film is laid on the ground in the underground, then the first layer of insulation made of polystyrene foam sheets.

Insulation with a thickness of at least 70 mm is sealed at the joints with tape and filled with concrete screed. Next comes a layer of waterproofing, which is necessarily separated by an air gap from the subfloor laid above. The gap cannot be filled with expanded clay or any other bulk insulation. If water leaks into the cavity, be it groundwater with phenol from sleepers, or from the bathhouse premises, the expanded clay will soak in groundwater and creosote, and the bathhouse will have to be dismantled, the floors removed and the backfill replaced.

Wall decoration from sleepers

All products made from sleeper wood, especially the cutting planes, must be re-treated with an antiseptic, fire retardant and water-repellent impregnation. This will reduce the release of odor and protect the walls of the bathhouse from fire.

Insulation of bathhouse walls is carried out according to the standard scheme:

- The first layer of glassine or vapor barrier is laid directly on the crowns of sleepers, glued with tape and covered with foil;

- The second layer consists of mineral wool laid on the sheathing;

- The third layer is filled with linden lining;

- The walls in the steam room are simply sanded; in other rooms they are impregnated with hydrophobic compounds.

Sometimes owners use a trick and heat the bathhouse several times before installing the insulation. In this way, it is possible to warm up the sleeper walls, thereby forcing most of the fumes with an unpleasant odor to be released into the dry, hot air.

Nuances of finishing work

The use of additional external and internal materials helps extend the life of the structure and minimize the spread of toxic chemicals.

Exterior finishing

Despite the fact that the workpieces are coated with creosote, many treat them with an antiseptic and also use a fire-fighting solution. The facade can be covered with drying oil, stain, or varnish to prevent the material from swelling under the influence of moisture. If desired, the bathhouse is lined with a house block, siding, or clapboard.

How to build a bathhouse from black sleepers

First of all, the material purchased for the construction of a bathhouse must be sorted and the cleanest and most even sleepers selected. They will be used to lay the walls on the facade. Part of the sleeper beams will be dismantled into facing material - a homemade tongue-and-groove board, ordinary beams will be used for laying the walls, the most impregnated with phenol will be used for arranging the foundation and base of the bathhouse.

Walls and foundation made of sleepers for a bathhouse

If in the area allocated for the construction of a bathhouse, the soil is too saturated with water, or the area is periodically flooded with melt or rainwater, it is best to place the room on a pile foundation. One of these options is shown in the photo.

The main difference is the use of sleepers to make piles. The frame of a sleeper bath weighs at least 8000 kg, this is much heavier than in the case of a frame or panel construction, so the pile support is made from one or two sleepers, sawn in half.

A pit is dug under the future support, into which a layer of crushed stone and sand is poured. The halves tied together with wire are re-treated with resin or bitumen, placed in a hole and covered with the same mixture of sand and screenings.

The next step is laying out the strapping. To build the frame, sleepers are spliced into one massive beam along the entire length of the bathhouse wall. After laying and driving in the metal dowels, the strapping beam is sealed with roofing felt, and only after that the first crown is laid.

The technology for assembling bathhouse walls from sleepers is practically no different from laying timber, the only difference being that the crowns are tied together every 3-4 rows with steel brackets made of thick reinforcement. In the process of laying the next crown, the surfaces are laid with jute, flax, but more often with dried moss.

The corners of the bathhouse are cut from two sleepers with a lock “in half a tree”, while the direction of the cut changes to the opposite with each subsequent crown.

Roof and ceiling

For a small bathhouse, the last two crowns are laid simultaneously with the ceiling beams. The material used is the best sleepers split in two from the available remainder. The resulting pairs are spliced into a long beam, which covers the ceiling. At the same time, the ceiling is hammered with a board.

The rafters for the roof of the bathhouse are cut and joined on the ground, then raised in pairs to the ceiling and cut into the last crown of the walls. The sheathing is immediately filled and covered with roofing felt. In this condition, the bathhouse should overwinter, the walls will gain weight, and the structure will shrink.

Wall and box decoration

At the stage of finishing work, the crowns are packed and embossed with jute tow, the floors are cut out and laid inside the paired dressing room and rest room. All that remains is to cut out the window and door opening, install the frames, hang the doors and move on to finishing work inside the room.

The ceiling is hemmed from the inside of the steam room and dressing room, a waterproofing film is laid and filled with expanded clay backfill. All elements inside the bathhouse are assembled to their final dimensions, without any gaps for shrinkage or sagging.

If you plan to decorate the walls with siding or clapboard, the wood must be re-treated with fire-retardant solutions. A bathhouse made from sleepers burns faster than usual, video

Therefore, the outer surface of the walls is thoroughly cleaned, treated and dried before the sheathing and lining are installed.

Waterproofing device

It is better to leave openings for doors and windows right away. And you also need to pay attention to the fact that the walls inside are even, because it will be very difficult to level them later. After the walls are ready, saturate them with a fireproof solution to reduce the risk of fire, and after that with varnish or drying oil. The roof and floor are installed in the same way as when building from other materials.

Bathhouse doors and windows made from sleepers

Foundation waterproofing device

The gap between the equipped foundation and the laid sleepers must be insulated from

moisture. This is achieved by pouring molten bitumen onto the foundation base and then laying roofing felt. Another layer is laid in a similar way after the bitumen has completely hardened.

Construction of bathhouse windows and doors from sleepers

Doorways can be made both during the construction of a building and after its completion. Due to lower labor costs, you should give preference to the second method: you just need to cut out the necessary holes in the finished log house using a chainsaw.

When deciding to install door frames during construction, prepare for a complex process and take into account possible shrinkage of the finished structure. At the same time, built-in boxes can cause its unevenness, and this in turn may require additional repairs.

The effect of creosote on human health

The smell of creosote (this is the composition that is used to impregnate sleepers) cannot be removed by anything. The fact is that the impregnating composition does not lose its properties for more than fifty years. Sleepers that are laid under the railroad bed continue to emit a fetid odor even after 20 years of lying in the open air (I just haven’t seen sleepers that are even older).

You don’t have many options; if you tightly cover the sleepers with some polyethylene-based material, you won’t feel the smell of creosote, but the smell of mold will come (the sleepers will stop “breathing”, or rather the wall made of them). This is the method I used. It was first obtained by Karl von Reichenbach in 1830 from the distillation of beech tar. Wood creosote is used for tuberculosis and as an antiseptic.

A bathhouse is a wonderful addition to every country house. Construction of a bathhouse takes a lot of time, effort and money. Traditionally, bathhouses are built from logs, but the cost of this material is not at all pleasing to thrifty owners. In search of an alternative building material, many have found a solution in the construction of a bathhouse from sleepers. How to build a durable, reliable and, most importantly, inexpensive bathhouse from sleepers?

Firstly, this is the 4th hazard class versus the 2nd, and secondly, the wood after impregnation does not have a sharp pungent odor. But impregnation is 10–20% more expensive due to the higher cost of the antiseptic. The Ryazan sleeper plant, in particular, uses a 50/50 mixture (coal oil and fatty acid) when impregnating sleeper products. Why is creosote dangerous? Popular answers Creosote is a colorless (sometimes yellowish or yellow-green), flammable, poorly soluble in water oily liquid with the smell of wood tar or phenol, obtained by pyrolysis of wood or from fractions of distillation of coal tar. It consists of phenols and their esters, as well as naphthalene and anthracene.

Strip foundation

- Before laying the sleepers, we prepare a trench for the foundation, at least 60 cm deep.

- A two-layer cushion is poured into the bottom of the trench: the first layer is river sand, the second layer is fine crushed stone, the cushion is moistened and compacted well. The layer thickness is at least 15 cm.

- Work is underway to install waterproofing, for which conventional rolled roofing felt is used. Example of foundation waterproofing

- Next, sleepers are laid, similar to brickwork. The joints must be overlapped by sawing out 50% of the thickness from each joining end of the sleeper. The sleepers need to be well interlocked with each other; for this purpose, wooden dowels are mounted between the rows, using a dowel gun or a brace, and the ends of the structure using steel brackets. The process of laying sleepers in the foundation

- Then comes the work of insulating the base and backfilling.

The number of rows in the sleeper foundation depends on the characteristics of the soil and the presence of a basement under the house.

Any strip foundation requires excavation work - clearing the construction site, which includes removing the turf layer of soil and markings for arranging the future foundation.

Layout of the strip foundation

As soon as the site is prepared and marked, it is worth starting to arrange trenches, the depth of which should be 80 - 100 centimeters. Important! For a more durable base, at least three rows of sleepers should be made. So, the trench is ready, now you can start arranging the pillow using several types of material:

- small crushed stone;

- river sand;

- fine gravel.

The height of the pillow for this type of foundation should be at least 30 cm.

Step-by-step instructions for making a strip foundation

Do not forget about waterproofing, which is constructed from roofing felt or polyethylene film in two layers - depending on the construction budget.

It is desirable that the length of the ditch corresponds to the length of the sleepers, since sawing off part of the reinforced concrete sleepers is very difficult, although possible. The sleepers are fastened using construction brackets made of hardened metal.

The principle of laying base elements from reinforced concrete sleepers

As soon as the masonry is ready, you need to install a reinforcement frame along the entire perimeter of the base, both inside the future building and outside. Then put together the formwork from boards or ready-made panels. Pour concrete. On the third day, you can dismantle the shields and leave the foundation to dry; this can take up to two weeks.

The process of concreting railway sleepers

The next stage will be the arrangement of waterproofing, since any base must be insulated from moisture, for this they use bitumen mastic and any roll insulating material. After waterproofing is completed, backfilling work is carried out. The foundation for the house is ready.

Foundation waterproofing process

The construction of a strip foundation is implemented in two options:

- Shallow foundation;

- Deep foundation made of sleepers for a wooden bathhouse.

The first type is an ideal choice for building a garage, barn, greenhouse, and other outbuildings. The second option is for more permanent buildings, such as a bathhouse. Before laying the sleepers, preparatory work should be carried out.

Remove the plant ball of soil and fill the ditch with gravel about 10 cm thick, then compact it. Lay the sleepers. They should be laid in the ground, connecting to each other and fixing to the ground. The sleepers are connected with a strapping beam, and they are nailed to the ground using special crutches.

The deep foundation is made by analogy with any other prefabricated foundation. Its construction begins with preparation - earthworks. They clear the area of vegetation and dig trenches around the perimeter. Their depth depends on the soil. If it has heaving properties, then it is recommended to dig trenches to a freezing depth of more than one and a half meters. Sand and crushed stone are poured inside the trench, moistening the mixture and then compacting it.

The walls and bottom are covered with waterproofing, protecting the sleepers from moisture. Then the material itself is laid. The fastening is carried out between each other and with the ground, similar to that for the shallowly buried version. The sleepers are fastened at the ends with construction staples. A support beam is placed on the frame so that the bathhouse can be built on it.

Columnar foundation

When making a foundation from sleepers for a concrete bathhouse, they often use a vertical arrangement of beams. The depth of the insert inside the soil is determined by its properties. The part of the sleeper protruding above the ground is tied with a grillage (its role can be played by a wooden beam).

In this situation, the sleepers are in a vertical position. The distance between the pillars should be equal to the length of the sleepers, since the grillage will be built from them. First, the racks are installed in the corners, then under the load-bearing walls and at the intersection of additional walls that will serve as partitions of the structure.

An example of a mounted columnar foundation made of sleepers

For insulation, you can use polyethylene film of 200 microns, in two folds. Once the sleepers are installed vertically and well secured, it is advisable to fill the holes with concrete to increase strength, you can begin installing the grillage.

The grillage is equipped with mandatory strapping, which consists of wooden dowels between the rows and iron brackets - the grillage is insulated like any type of base. You should not rely on creosote impregnation and leave the base without insulation, this can lead to irreversible consequences - rotting of the material in a short time.

An example of a grillage made from railway sleepers

If you make good insulation and carry out all the work according to the technology, then such a foundation will serve you for many years.