The specifics of the bathhouse presuppose the high-quality organization of the ventilation system. A large amount of moisture, high temperature, hot water steam, residues in the air of burning particles, smoke, solid fuel combustion products, etc. - all these factors require constant ventilation. Moreover, this process should be carried out not only after the completion of the procedures, but also directly during their implementation. Ventilation in the dressing room is as important as for other bath sections and is connected to the general ventilation system.

Bathhouse projects

Number of projects 687

- 1 room

- 2 bathrooms

Bath Slavyanka project

- To favorites

- 53.5² Total area

- 8 x 7m Construction area

from RUB 722,250

Construction period 35 days

- 1 room

- 1 bathroom

Project of log bathhouse 4x6 m

- To favorites

- 4 x 6m Building area

from 190,000 rub.

Construction time individually

- 1 room

- 1 bathroom

Bathhouse project BBm-6

- To favorites

- 38² Total area

- 4 x 6m Building area

from 513,000 rub.

Construction time individually

- 1 room

- 2 bathrooms

Bathhouse project BD-63, Kozino

- To favorites

- 63.4² Total area

- 9 x 9m Construction area

from 977,000 rub.

Construction time individually

- 1 room

- 2 bathrooms

Project Banya Orange 8.5*10.9

- To favorites

- 83² Total area

- 9 x 11m Construction area

from RUB 964,813

Construction time individually

- 1 room

- 2 bathrooms

Sangria Baths Project

- To favorites

- 75.5² Total area

- 11 x 10m Construction area

from RUR 1,019,250

Construction period 40 days

- 1 room

Sanduny Baths Project

- To favorites

- 17² Total area

- 4 x 6m Building area

from 320,000 rub.

Construction time individually

Available at the exhibition

Barrel sauna project “Super-Lux”

- To favorites

- 2 x 5m Building area

from 184,900 rub.

Construction time 1 day

- 2 rooms

- 1 bathroom

Clementine Baths Project

- To favorites

- 120.04² Total area

- 12 x 7m Construction area

from RUR 1,620,540

Construction period 64 days

Log bathhouse project AR-027

- To favorites

- 17² Total area

- 5 x 4m Building area

from 229,500 rub.

Construction period 90 days

- 2 rooms

- 1 bathroom

Acapella Baths Project

- To favorites

- 70.62² Total area

- 6 x 7m Construction area

from 953,370 rub.

Construction period 35 days

- 3 rooms

- 1 bathroom

Bani Sloboda project

- To favorites

- 75² Total area

- 9 x 10m Construction area

from 1,040,000 rub.

Construction period 30 days

- 1 room

- 1 bathroom

Project AS-2000-6

- To favorites

- 48.4² Total area

from 653,400 rub.

Construction time individually

- 1 room

- 2 bathrooms

Bani Khvoynaya project

- To favorites

- 66² Total area

- 9 x 9m Construction area

from 891,000 rub.

Construction period 35 days

- 1 bathroom

Log bathhouse project BO-028

- To favorites

- 36² Total area

- 6 x 8m Construction area

from 486,000 rub.

Construction period 90 days

- 1 room

- 1 bathroom

Olympia Baths Project

- To favorites

- 32² Total area

- 6 x 8m Construction area

from 550,000 rub.

Construction time individually

- 1 room

- 2 bathrooms

Bani Frog Project

- To favorites

- 64² Total area

- 8 x 8m Construction area

from 1,140,300 rub.

Construction time individually

Project Baths Anastasia

- To favorites

- 25.5² Total area

- 5 x 4m Building area

from 355,000 rub.

Construction time individually

- 1 room

- 1 bathroom

Bathhouse project No. 15006

- To favorites

- 43² Total area

- 5 x 11m Construction area

from RUR 1,806,313

Construction time individually

- 1 room

- 1 bathroom

Project AS-2002-14

- To favorites

- 76² Total area

from 1,026,000 rub.

Construction time individually

View all projects

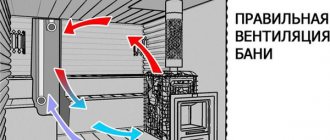

Air exchange is needed in any room, and especially in a bathhouse with its special microclimate. It is he who dictates how to make ventilation in the bathhouse, so that the influx of fresh air does not drive out the heat, but forces the air heated by the stove to circulate in the right direction. Without thinking through the design, you can get problems such as cold floors, a rapid decrease in temperature in the steam room, dampness with all its consequences, and the accumulation of carbon monoxide. You don’t have to invent anything: methods for ventilating baths have long been known, you just need to choose the most effective one in your case.

It’s easy to breathe in a properly equipped steam room Source i1.wp.com

Forced ventilation of the bath

The ventilation system is somewhat complicated and installation of electrical equipment is required. Another problem is related to the microclimate in the steam room. There, high temperature and air humidity are the main enemies of any electrical equipment. Fans must have reliable protection of the housing from moisture; during connection, the recommendations of the PUE must be strictly followed. And in order to comply, you need to know them.

Forced ventilation of the bath

Forced ventilation - elements

The advantages of forced ventilation are that the rate of air change in the room is significantly accelerated and the control parameters are expanded. Natural ventilation is very dependent on weather conditions, and in some cases it can become ineffective. Especially if the wind is directed at right angles to the exhaust vent. Forced ventilation works with the same effectiveness in any weather and regardless of the direction and strength of the wind.

How to calculate forced ventilation in a bathhouse and what type of ventilation it is? How to choose fans? We answered all these questions in the article “ Do-it-yourself forced ventilation in a bathhouse . There are also detailed step-by-step instructions for installing ventilation and advice from professionals.

Is ventilation necessary in a traditional Russian bath?

In the old days, Russian baths were not specially equipped with a ventilation system, and served well for many years. Air exchange in them occurred naturally. This was facilitated by log walls without insulation or cladding, between the crowns of which air leaked. As well as brick wood stoves with a blower, fired directly from the steam room, the chimney of which served as an exhaust hood.

Nobody thought about how to do ventilation in the bathhouse, and there was no need for it, since the bathhouses were small and consisted of a maximum of two rooms - a dressing room and a steam room, in which they steamed and washed. For such small buildings, the burst air exchange that occurs when the door is opened when entering and exiting the steam room was sufficient. And at the end of the procedures, it and the stove door were left ajar until the room was completely dry. Damp warm air was drawn into the chimney.

In the Russian bathhouse there was no special air exchange system Source dveribani.by

The possibility of burst ventilation can be provided in modern baths if you make an opening window on the wall opposite the door to the steam room, and diagonally from it. They are opened briefly before the next batch of steamers enter, only to freshen the air, but not to chill the room.

If you are building a Russian bathhouse without any frills, many separate rooms, with a traditional stove, you don’t have to think too much about how to make a hood in the bathhouse so that there is no dampness. A door, a small window, a good stove draft and mandatory ventilation after everyone has washed are enough.

Ventilation tips

The most effective of many schemes is bastu. It is quite simple to do in both a new and an existing bathhouse.

We offer two videos that describe in detail the structure of the Swedish system.

Here the author installed a damper on the exhaust, but not on the supply. It’s not difficult to make: it can just be a metal plate.

Full review, interesting scheme for warming up the waiting room.

The authors of these materials described and showed in sufficient detail the stages of creating a ventilation system. In both videos there are interesting comments on where you can find rational grain for your existing or under construction bathhouse.

The distance from the bottom edge of the hood to the floor causes a lot of controversy. There are general recommendations, but since each bathhouse and climate are individual, the distance indicated by someone cannot be a dogma. The ideal interval is determined experimentally. To do this, a movable tube is placed on the lower edge of the exhaust pipe.

Proper ventilation in a bathhouse is a simple scheme with natural air movement. Fans in conditions of high humidity and temperature changes can fail at any time. A complex system with many air ducts is also unreliable.

The need for ventilation in modern baths

Modern baths have become completely different over the last century. Today they are built from different materials, not just logs. They are clad on the outside, insulated and clapboarded on the inside, literally sealing the building. They make several isolated rooms - a steam room, a washing room, a locker room, a relaxation room, a bathroom, and sometimes a swimming pool and a kitchen.

Plan of a modern bath complex Source remoo.ru

The principles of heating have also changed: stoves are often made with a firebox from a dressing room, and many people prefer electric heating devices, which do not require a chimney, to work with wood. And in order not to go outside in bad weather, such complexes are often attached to the house or placed directly in it.

The desire for convenience, comfort and beauty can lead to undesirable consequences and even harm your health if you do not think about how to properly ventilate a bathhouse. The most common consequences are carbon monoxide poisoning, rotting of wooden structures and the appearance of mold, the spores of which are not at all harmless.

Waiting room - recommendations for arrangement

The construction of a bathhouse is not complete without a set of basic premises: a steam room, a washing room, a dressing room, a relaxation room. It is this set that helps you get complete rest and enjoyment from it. In order to save space, the dressing room is often used as a locker room or rest room. Since vacationers will spend the maximum time in this room, the microclimate in it must meet the following requirements:

- Optimal temperature conditions. The walls, floor, and ceiling must be insulated; a heating system is provided. During operation, baths have gained particular popularity, where heat in the dressing room is obtained due to the proper placement of the stove. When its back wall opens into the rest room;

- Ventilation in the bathhouse. The influx of fresh air and the outflow of exhaust air must be equal in volume;

- The lighting is bright. Natural is often used. For this purpose, the bathhouse is built so that the windows face south. Thus, the sun's rays will not only be a natural source of light, but also heat;

- The area of the dressing room is calculated based on 1.3 square meters. m. per vacationer.

According to the above list, a direct dependence of the microclimate on heating and ventilation is visible.

Methods of natural ventilation

Dense and heavy cold air always sinks down, and heated air is displaced by it and rises. This is how moving air currents arise in rooms with any heating device. But without an influx of fresh air, it is not renewed, but simply moves.

If you make a hole in the lower part of the wall, air from the street will flow through it if its temperature there is lower than in the room. And through the hole at the top it will be pulled out. This is natural ventilation.

Scheme of the movement of air masses in a heated room Source e-derslik.edu.az

This elementary law of physics is used when thinking about how to make ventilation in a bathhouse with your own hands without using any mechanisms. As a rule, natural ventilation without forced air intake is quite enough for a small bathhouse. Unlike residential premises, where in summer it can be as hot as outside, the temperature in the bathhouse is always higher.

But it is necessary to maintain a comfortable temperature for receiving procedures, and in such a way that drafts do not form and there is no sharp change from heat on the shelf to cold on the floor. To do this, air flows must move along a certain trajectory, which is set by placing supply and exhaust openings in specific locations.

Ventilation through the chimney

The easiest way to solve the problem is how to make ventilation in a steam room if it contains a furnace firebox with a blower. It will serve to remove exhaust air through the chimney, in which draft occurs during fuel combustion. But this scheme will only work if there is an influx of air from outside.

Ajar door to the steam room Source prodverivdome.ru

Inflow can be ensured in the following ways:

- from time to time slightly open the door to the steam room;

- make a small gap of 1 cm in the door or leave the same gap between the door and the floor;

- if the log house of the bathhouse is not sheathed, such a gap can be left between the first crowns located below the floor level, provided that the boards are not laid tightly;

- make a special opening in the wall opposite the stove at a height of 20-30 cm from the floor.

In any of these cases, the cold flow penetrating into the room moves towards the heat source and displaces the air already heated by it upward. As it moves, it warms up the entire room, gradually cooling down and descending. Here it is drawn into the ash pit and discharged through the chimney to the street.

Air movement pattern Source i.ibb.co

Note! This scheme only works if there is draft in the chimney, which occurs when wood burns. In the absence of combustion, air exchange practically stops.

This method of making ventilation in a steam room is not the most reliable and effective, since most of the fresh air is immediately drawn into the stove. Therefore, even during the construction of the bathhouse, it is advisable to think through other options for installing vents in the walls.

See also: Catalog of projects of houses with a bathhouse made of timber

Ventilation through vents

To ensure that air exchange does not depend on the operation of the stove, special openings are installed in the walls for air inflow and outlet. It is guaranteed to work subject to the following conditions:

- the exhaust hole is placed under the ceiling of the bathhouse - where heated air accumulates;

- the supply opening should be located low above the floor on the opposite wall, the closer to the stove, the better, so that the cold currents drawn in do not hit the legs;

- the optimal vertical distance between the vents should be 150-200 cm;

- The cross-section of the exhaust opening must be larger.

Cold air immediately enters the heating zone Source ventilation-conditioning.ru

The ideal location of the supply air is behind the stove. Entering the room, it immediately begins to warm up, displacing the already hot air mass upward and towards the hood. Therefore, cold streams and levels with noticeably different temperatures do not form in the steam room.

If you want to know how to properly make ventilation in a bathhouse and steam room, provide this diagram at the design stage and before installing the stove. It is also important to make sure to make a difference in height between the ventilation holes. If they are located at approximately the same level, this will lead to a draft and rapid passage of fresh air in a straight line, without circulation in the room.

Advice! It is best to make an exhaust vent directly above the shelf to allow hot air to flow into it and quickly remove waste materials.

Natural ventilation hood Source stroyfora.ru

In order to be able to regulate ventilation or limit the access of too frosty air into the steam room, you need to provide covers or valves for the vents.

The benefits of natural ventilation are that it works without the need for devices that require mains power and can break down. Its installation and operation do not require large expenses.

Bastu ventilation in the bathhouse: diagram, device and principle of operation

“Bastu” is essentially the name of Swedish saunas, where the heating of the room occurs due to well-thought-out air convection. The ventilation was named after these saunas. The result of balanced and effective air exchange is as follows:

- • fresh and “light” air in the steam room,

- • easy to breathe and easy to perceive high temperature,

- • dry floors and other wooden finishing elements,

- • absence of fungus, mold and musty smell,

- • comfort and pleasant pastime in the bathhouse,

- • long period of operation of the steam room without repair.

The scheme and device are quite simple: under the stove in the floor or in the wall (at the very bottom) a supply hole is made for cold air. On the wall opposite from the stove, a vertical ventilation duct is installed.

This box has 2 exhaust openings: bottom and top. The lower one is for removing heavy wet steam, the upper one is for “relieving excess heat” and for drying the room. The “exhaust air” is discharged through an air duct through the attic to the roof.

Cold air passing near the stove heats up and moves upward. The top hole in the box should be closed during paired procedures (unless you are very hot). The moist air that has passed through the entire room and cooled slightly begins to fall down. Here it is sucked through the lower hole in the box and removed to the street.

In this case, the stove plays the role of a heat pump, and air exchange occurs naturally. No forced ventilation is needed here. The air flow constantly circulates due to the upward movement of hot air from the stove, so being in the steam room is very comfortable and easy.

Methods for installing forced ventilation

It is not always possible to provide natural air exchange of acceptable intensity. Such ventilation does not work well both in bathhouses with a large number of rooms, and in those that have a common wall with the house or are built into it.

In such cases, they resort to a device for forced injection and/or release of air, artificially creating flows or forcing them to move faster. To do this, fans are built into the system - exhaust or supply.

Supply fan installed in the corresponding hole Source engvent.ru

See also: Catalog of companies that specialize in the construction of baths, ventilation and air conditioning equipment

Depending on the type of object, one of the following types of forced ventilation is used:

- supply and exhaust when both types of fans are used. A rather rare option in private baths, since they do not require high ventilation intensity;

- supply , with mechanical suction of air through the supply opening and increasing the pressure in the room, due to which the exhaust air is squeezed out into the hood. Its main drawback is the too active supply of cold air masses;

- exhaust , the operating principle of which is the opposite: a fan in the exhaust hole forcibly removes polluted air outside, creating a vacuum inside, forcing clean air from the street to fill the vacated volume, entering the supply hole.

If you choose how to properly make a hood in a bathhouse, then preference should be given to the last option as the most optimal.

Fan on the exhaust vent Source stroi-remontirui.ru

Fan selection

Any mechanisms operating in a bathhouse must withstand difficult operating conditions: high humidity, heat, frequent temperature changes. Therefore, the fan is selected primarily based on these requirements.

Which ventilation scheme should you prefer?

Achieving proper ventilation in a bathhouse can be difficult. If you are just designing a bathhouse, take care of small windows, micro-openings between rooms, supply openings with access to the street and plugs. But do not place exhaust vents on the ceiling, so as not to overcool the dressing room.

Put the correct proportions into the bathhouse building. Optimal combinations of sizes of a dressing room (combined with a rest room), washing room and steam room:

- 2 : 1,5 : 1;

- 1,5 : 1 : 1;

- 2 : 1 : 1.

Make a separate dressing room approximately the same size as the sink and steam room. For the combined one, allocate half the length and the entire width of the building.

A separate dressing room is a locker room with a need for fresh air and an exhaust hood to remove steam, which can be placed in an external room or here if the size of the building is small

Follow the rules and recommendations:

- Achieve equality between the supply and exhaust flows.

- Buy mechanical fans only that are moisture resistant.

- The required ventilation intensity is more than 3 m³/hour per 1 m².

- It is worth adding combined ventilation with forced exhaust and natural inflow to the openings between rooms and wooden windows.

- It wouldn’t hurt to redirect some of the hot air from the steam room to the dressing room.

- Lay the air exchange paths between the supply and exhaust past the toilet.

Consider a universal steam room ventilation option. To do this, place the door to the steam room near the ash pan. Opposite the stove diagonally, make an exhaust opening 15-20 cm wide on the wall. Leave about 20 cm between this vent and the ceiling, aim for a height of 2 meters above the floor. Be sure to install an axial fan if the exhaust opening does not go directly to the street.

There is also an option with a ventilation pipe. Make it vertical, but then turn it and connect it at an angle to the straight channel above the steam room, if there is one. Make the pipe diameter larger above the joining point. Otherwise, lead her out of the dressing room exactly through the roof.

To prevent the performance of the axial exhaust fan from decreasing, wrap it with penofol or at least its narrow part

Place the inlet opening half a meter above the floor. Select a location approximately diagonal to the exhaust hood. Make the inlet opening the same size as the outlet (15-20 cm). Swipe to the street and add a cap too. Thanks to it, you can influence the speed at which the incoming air will push out the internal one. The inflow is enhanced by an additional hole next to the ash pan to supply air directly into it.

Insulate the exhaust pipe and the dressing room itself to minimize condensation. Thermal insulation will also make the air warmer, and after visiting the steam room it is better if the air temperature is comfortable. Make a circulation with a smooth temperature change along the height of the dressing room and on the way from the locker room, through the sink and to the steam room doors.

Be sure to insulate the floor. For a combined dressing room in the rest room, provide ventilation for the largest possible area per person and at least 1.3 m² per person.

Consider the tightness of the bath. A frame building requires increased air supply: it is better to install a supply fan in this type.

Make windows no more than 45 cm wide, preferably only made of wood. Install the entrance door with a size of approximately 180x80 cm. It is better to make interior doors a little smaller to reduce heat loss.

Scheme #1 - with open circulation

Let's consider a combined dressing room and a classic version of the setting.

At first, the moisture will not cause any inconvenience, but then the condition of the wooden ceiling will deteriorate - you won’t be able to relax normally in a dilapidated building

The first wall is narrow, with an entrance door. The second - with a doorway to a separate washing room or combined with a steam room. A stove is located a meter from the interior door, within the dressing room. The third wall is narrow, opposite the wall with the front door. The fourth is opposite the second, with seats for relaxation.

Make natural air exchange in the form of windows and also assemble combined ventilation.

Make an inlet hole on the third wall, always with a plug. Place the opening at a height of 50 cm from the floor, approximately in the middle of the wall, but with a slight offset towards the stove.

At the end of the fourth wall farthest from the inflow, organize an exhaust opening. Cut a hole in the top corner about 20cm below the ceiling. Insert an exhaust fan into the opening.

All that remains is to make the waiting room warmer. Together with this task, they solve the problem of removing air from the steam room. There it is collected under the floor, and through a pipe it will enter the dressing room. Do not just supply air, but also dispose of it at the same time.

There are three solutions:

- Direct the pipe from the steam room to the dressing room and place the outlet directly next to the ash pan.

- Bring the channel to the wall, and then air will flow through the hole.

- Lay the pipe lower and make a cut in the floor next to the ash pan.

The air coming from the steam room will be quite warm, and the stove will warm up more intensely due to the fact that it absorbs it.

Scheme #2 – with closed air circulation

In this case, you can organize a dressing room without supplying air from the steam room.

For natural ventilation, install a wooden window with a tilting mechanism and fix it with a small gap: even at the minimum mode, condensation will not form, and the temperature can be raised using steam from other rooms

At a height of 40-50 cm from the floor, cut a supply opening with a plug - on a narrow wall adjacent to the one where the stove is located. Make a hole not in the middle of the wall, but closer to the ash pan.

From the corner between the inlet and the stove, draw an imaginary diagonal and at the end of the long wall, at a level no higher than half a meter from the floor, organize an exhaust vent. Approximately at the same height as the influx, but it can be lower.

Do not make a hole in the wall; instead, install a vertical pipe. Above the ceiling, insert the channel into the exhaust pipe rising from the steam room, and if it is missing, lead it out through the roof. Install a deflector on the head of the pipe.

The air in the upper part of the room will already be warm, but first it will fall down and go into the exhaust vent not as quickly as with the first scheme. Such a hood will also protect against excess steam, so in the waiting room, where it is minimal, a closed circuit will be even more effective.

Scheme #3 – supply and exhaust on one wall

Useful for different stove placement options. Including if it is located in the very corner.

In this scheme, there is no need to strive for a diagonal arrangement, but do not place the hood exactly above the inflow either. Due to local ventilation, the waiting room will sooner or later become waterlogged.

Three main diagrams with a conditional display of air exchange when the main part of the stove is located behind the wall. Remember that you need to achieve the most diagonal arrangement of inflow and exhaust

The inflow is located directly opposite the ash pit or obliquely. In this case, you need to ensure that the cold incoming air does not blow on vacationers. The inflow will come in from the street and go straight to the ash pan of the stove, which will heat the room. Some of the air will go into circulation.

If it is located obliquely relative to the ash pan, this volume will be larger. Place the inlet half a meter above the floor or a little lower if furniture gets in the way.

Make an exhaust hole at the top of the same wall. Cut it obliquely relative to the inflow: as far as possible from it, and not lower than 25 cm from the ceiling.

Video description

It is easy to find units on sale that are specifically designed for baths and saunas - these are the ones shown in this video:

It is also necessary to determine the power of the device, since excess power is completely unnecessary and even contraindicated. This is easy to do if you know the volume of the ventilated room and the air exchange rate recommended for baths, which is 5.

For example, for a 2x3 m steam room with a height of 2.2 m, the fan power is calculated as follows:

2 x 3 x 2.2 x 5 = 66 m3/h

Advice! Buy a device with variable adjustable power and a timer that will periodically turn the device on and off. You can fully automate the system by including humidity and temperature sensors configured to certain values, upon reaching which they will start the fan.

If desired, you can assemble an automated system with remote control Source nevoton.ru

Such devices, depending on the design, can be installed directly in the exhaust vent (duct fans) or on the wall behind it.

Arrangement of ventilation in the dressing room

When building a bathhouse, you should understand that this is not only a steam room, but also a number of other rooms. Overall, it’s a complex. Therefore, a unified ventilation scheme is laid out at the time of design. To do this, you should consider a number of points:

- Determine the layout of the entire complex. Choose the location of the oven. Preferably as close to the doorway as possible. At a level of 500 mm from the floor in the immediate vicinity of the firebox, a through hole of the appropriate diameter or size is cut out (24 mm per 1 cubic meter of room). This cutout plus opening the door to the dressing room will provide an influx of warm air.

- On the opposite wall, diagonally at a height of 2 thousand mm, another hole is made with a size equal to the previous one. Exhaust air will flow out through it.

The hood is not installed in the ceiling, therefore, due to the increased humidity of the exhaust air, condensation will accumulate on the roof structure. - To supply fresh air, a window in the dressing room can be used, or another vent at a height of 500 mm from the floor.

Depending on the location of the rest room, the hood can be mounted on a wall behind which there is a wooden utility unit. Forced ventilation is often used to increase the efficiency of air movement.

When doing work on laying ventilation ducts with your own hands, do not forget about their heat and vapor barriers.

Video description

The following video shows an example of such a combination of ventilation and heating:

- If the floor in the steam room and washing room is made in the form of a flooring with slots on a concrete base, an exhaust duct can be made under it by combining the underground of the two rooms and equipping it with a fan. In this case, it is simply necessary, since the trajectory of the movement of air masses is complex, and natural ventilation is unlikely to cope with its task. A channel through a hole in the foundation removes moist exhaust air to the street. The supply opening should be located as close to the stove as possible so that the cold air begins to heat up immediately after entering the room. If openings are made in the walls between adjacent rooms, it will circulate throughout the entire volume, simultaneously warming both the washing room and the rest room.

Scheme of ventilation of a bathhouse through the underground Source youtube.com

Types of ventilation in the bath

Ventilation systems can be divided into several types. The exhaust can be natural, forced, and the systems themselves can be exhaust, supply or supply and exhaust. Ventilation can also be local or general.

With natural air exchange, fans or other devices that will circulate air are not used. This type of ventilation includes a regular window. Forced systems provide exhaust air to the street, and in return, fresh air with sufficient oxygen content is supplied to the room.

For natural burst ventilation in the bathhouse, one window is enough

Considering that the bathhouse always has a stove, natural ventilation can be easily installed here. The thing is that heating the air will provoke its accelerated movement, so it’s enough to simply make two types of holes, namely supply holes through which fresh air will flow, as well as exhaust holes to remove carbon dioxide. The first must be at the bottom, and the second at the top of the wall or in the ceiling.

Natural ventilation in the bathhouse works due to the difference in the location of the hoods and the air pressure in the bathhouse

But often natural ventilation is not enough. If the weather outside is absolutely windless, then the air circulation in the cooling bath will not be good enough. This will cause moisture to stagnate in the room and mold to appear.

For such cases, the bathhouse is equipped with forced ventilation. It differs from the previous version only by the presence of special fans in the holes. They can be turned on when you need to intensively extract carbon dioxide from the bathhouse or if you need to eliminate high humidity after using the steam room.

Forced ventilation in the bathhouse works by extraction due to the draft of fans

Regardless of what type of system will be used, the exhaust openings must be located above the supply openings.

In order to ensure high-quality ventilation of the bath room, you need to correctly calculate the number and size of exhaust openings. It is believed that a ventilation window of 20 centimeters should be installed per square meter of the room.

Arrangement of supply and exhaust openings

When designing a bathhouse, you must immediately provide for the location of vents in the walls or foundation. It will be easier to make them during the construction process, rather than punch them after completion. In the case of forced ventilation, their dimensions are not particularly important, since a fan of calculated power will provide the necessary air exchange.

It is easier to lay a piece of pipe when pouring it into the foundation than to drill a vent in hardened concrete Source readmehouse.ru

Another thing is how to properly make ventilation in the steam room of a bathhouse if the use of mechanisms is not provided. For good natural air exchange, the cross-section of the supply opening must be sufficient. It is calculated according to a standard that regulates the dependence of this section on the volume of the room. For each cubic meter of ventilated space it is necessary to install a vent with a cross-sectional area of 24 cm2.

If we take our example with a steam room 2x3x2.2 m, then its volume will be equal to 13.2 m3. Multiplying it by 24 we get 317 cm2. To determine the diameter of a round hole with such an area, use the converted formula for the area of a circle: divide it by Pi and take the square root from the resulting value. The radius of our hole is equal to 10 cm, so its diameter should be 20 cm.

The radius is found using the inverse formula for the area of a circle Source ds04.infourok.ru

It is even easier to find the length of the side of a square hole - it will be approximately 18 cm. The sides of the rectangle are also selected in accordance with the cross-sectional area - for example, 10x32 cm.

To arrange round vents, steel or plastic pipes of the appropriate diameter or slightly larger are used, and the channels in the rectangular wall are made in the form of wooden boxes made of boards.

The exhaust hole, as already mentioned, should be made larger than the supply hole. The gaps between the wall and the walls of the channel are filled with tow, other insulation, or foamed.

Another important point in such a matter as making an outlet in a bathhouse is protection from the outside from the penetration of insects, rodents, and debris into the channel. To do this, cover the hole from the outside with a mesh or lattice.

Ventilation grille with insect mesh Source www.video-sovety.ru

And inside, to regulate the intensity of the air flow, valves are installed, partially or completely blocking the holes when necessary. For example, in winter, the draft, due to the huge difference between the low temperature of the street air and the high temperature in the bathhouse, increases so much that the cold currents do not have time to heat up from the stove and quickly cool the room. It is reduced using a valve, leaving only a small gap or completely blocking the vent for the duration of the procedures.

How to make ventilation in a steam room

Among the ways to make a hood in a bathhouse with your own hands, we suggest considering the most suitable options for doing it at home, both natural and artificial ventilation.

Option 1

This is the most common method of ventilation, which provides one inlet and two outlets. An inlet hole is made in the wall 30 cm from the floor directly behind the stove. Exit windows are connected by a wooden box with a built-in corrugated tube 1 m long and are equipped with plugs. In addition, grilles are placed on the ventilation windows to prevent insects or rodents from entering the bathhouse.

This type of ventilation is most often used for small private baths.

Option 2

Ventilation ducts can be located at the same level. This ventilation option involves making an inlet hole 30 cm from the floor behind the stove. And the exhaust window must be equipped with a fan that draws carbon dioxide out.

Option 3

According to this scheme, two holes are cut in the steam room. The inlet hole is cut 0.5 m above the heater, and the outlet ventilation duct is located below, 20 cm from the floor. A fan is installed to force air out.

Option 4

If the design of the bathhouse provides only one wall facing directly onto the street, then the ventilation scheme involves the construction of two passages located on one wall opposite the stove. Fresh cool air enters the lower window 30 cm from the floor, which, hitting the stove and heating up, gradually rises up and exits through the exit window to the outside. The exhaust hole is located 30 cm from the ceiling and a fan is installed in it for good air circulation.

Option 5

The floor ventilation diagram in the bathhouse will be useful if the steam room has a plank floor with holes between the boards and the underground. In this case, a window for air flow is installed behind the stove. As the air cools, it sinks down and exits through the cracks into the underground, and from there, out through a ventilation duct in the basement wall, connected to a pipe for air exhaust above the roof.

Option 6

Finally, a vent in the stove can serve as a ventilation duct to remove exhaust air if it is located in a steam room. The only thing that needs to be done is to ensure air flow by cutting a special gap in the wall opposite the stove.