Installing a water tank in a bathhouse opens up a number of conveniences and advantages for the owner. Firstly, it becomes possible to prepare hot water while firing the furnace, which allows you to save energy resources and use them as efficiently as possible. Secondly, the use of such a unit in most cases makes it possible to refuse to install an electric water heater, which also benefits the budget allocated for the arrangement of the bathhouse.

How to make a stainless steel water tank for a bath

There are several basic requirements for water tanks: they must be spacious, durable, warm up in the shortest possible time and retain heat for as long as the needs of steam room visitors dictate. Among the options available to the average user, products made of stainless steel best meet the listed criteria.

Stove with a tank on a pipe

Sauna stove Varvara classic with a hanging water tank

Next, you are invited to familiarize yourself with the key features of water tanks made of stainless steel, as well as study the manuals for self-assembly and installation of such structures.

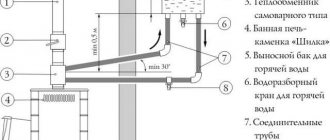

Diagram - example of installing a remote water tank

Why stainless steel: key advantages of the material

The modern market offers a wide range of water tanks made of cast iron, stainless steel and enameled material. As practice shows, stainless steel is the most popular among bathhouse owners, which is due to the competent and acceptable ratio of operational and technical characteristics and cost indicators.

Stainless steel is characterized by excellent thermal conductivity, withstands temperature changes and objectively lasts longer than various ferrous metals.

Examples of stainless steel tanks

Stainless Steel Oven Mounting Tank

Stainless steel tank

Stainless steel containers

A logical question arises here: which of the existing brands of stainless steel is better suited for the manufacture of the container in question, intended for use in a bathhouse? Firstly, this is brand 08Х17 (430), secondly, 8-12Х18Н10 (304). The mentioned materials, among other things, are used for the production of tableware and are characterized by high resistance to high temperatures, are completely hygienic, do not rust or deform during use. In addition, such materials are unpretentious and extremely easy to maintain.

Composition and mechanical properties of different grades of stainless steel

To summarize the above, we can highlight 3 main advantages of water tanks made of stainless steel:

- the products do not require additional protection from high air humidity and can easily withstand operation in conditions typical for a steam room;

- Stainless steel has high thermal conductivity, which makes it possible to obtain hot water in the shortest possible time;

- Stainless steel tanks do not deform due to sudden temperature changes, or these deformations are insignificant.

Prices for stainless steel sheets

stainless steel sheets

Tank on a pipe

On the pipe

This version of the sauna tank is mounted directly to the pipe that removes smoke from the stove. It plays the role of a heat exchanger and from it the water is heated.

This tank also has positive aspects:

- The heating area, given the height of the pipe, can be large, which helps to quickly heat the water and maintain its desired temperature.

- Another positive argument is security. The installation of tanks on a pipe protects the bathhouse from unwanted leakage of carbon monoxide.

Design options for water tanks for baths

Water tanks designed for use in a bathhouse can have different designs. There are 3 main options: a built-in tank, a remote container and a unit installed on a pipe. You can see the features of each type of design in the following table.

Table. Stainless steel water tank designs

| Construction type | Description |

Built-in water tank | Installation of representatives of this category is carried out during the construction of a sauna stove, as a result of which the stove and tank become a single structure. Heating of water in a built-in stainless steel tank is carried out by the forces of fire, due to which the efficiency of the water tank itself is kept at a fairly impressive level. The key disadvantage of this design is the fact that a significant part of the heat is spent on heating the water in the tank, as a result of which the heat transfer directly from the sauna stove noticeably drops. Helpful note! Much easier to manufacture and use is a mounted/mounted tank installed on top of the heater. |

Remote water tank | A more convenient and practical option compared to the previous model, especially if the tank is designed and installed for permanent use. If desired, a ready-made stainless steel water tank can be installed in the washing room of the bathhouse, connecting it with a pipe system to a furnace heat exchanger. The optimal material for making pipes is copper or brass. The only significant drawback of an external water tank is the likelihood of getting burned in case of careless handling - this situation is especially important if children go to the bathhouse. |

Pipe water tank | A pipe water tank can be installed either directly above a sauna stove or in the attic space. In such designs, water is heated in the shortest possible time. At the same time, the heat transfer rates of the furnace unit do not decrease. The undoubted advantage of installing a water tank in the attic is the ability to “unload” the steam room by eliminating the container from its surroundings and providing more free space. |

The table does not include another possible option for installing the tank - on the side of the stove.

Stove with side tank

Stove with a side tank - photo

This method has been neglected for the simple reason that it is the worst. The water in such a tank will boil very quickly. If the steaming process drags on, the constantly boiling water will make the atmosphere in the steam room simply unbearable. Yes, and servicing such a tank is a complete inconvenience: in order to save space, the container is made high, but very narrow.

How to install and connect correctly?

The main function of a sauna stove is to warm up the steam room. If wet steam is needed, then a heater is additionally equipped. Stones are heated in it, which produce hot steam after dousing with water. A separate room is made for bathing - a washing room. Here you need hot water so that you can wash off the sweat and swim in comfortable conditions.

Sauna stove

If the bathhouse is connected to the hot water supply of the house, a water tank is not required. But if it must be supplied separately, then a tank is very desirable, otherwise you will have to heat the water for bathing. These are additional fuel costs. They can be easily avoided by immediately installing a model with a tank.

Any stove can be equipped with a tank - gas, wood or electric. It can be made of steel, cast iron, brick or combined materials. The tank itself can be built-in, remote or mounted. For small baths, compact models with heaters and tanks are usually chosen or manufactured.

Homemade steel stove

Metal wood-burning stoves do not require such a massive foundation as brick ones, but it is still advisable to make a foundation for them, if possible. A small design of 0.5×1.2 m is sufficient.

For the foundation, make a hole about half a meter deep, compact the bottom and cover it with a layer of crushed stone 30 cm thick. A screed is made on top of the crushed stone cushion. When it dries, a waterproofing material is laid and concrete mortar is poured. After hardening, the foundation is covered with a sheet of metal and the installation of the furnace begins.

Foundation diagram for a sauna stove

When installing a stove, you should remember several important rules:

- For the structure, you need to allocate an area measuring 70x70 cm.

- The fire door should “look” towards the door. The heater door is on the contrary, in the direction opposite to the door.

- Where the chimney goes outside, the brickwork needs to be made 12 cm thicker.

- If the bathhouse ceilings are made of wood, they are protected with thermal insulation materials.

The technical documentation for each industrial model specifies the norms and rules that must be followed for safe installation of the structure. Strict adherence to the manufacturer’s recommendations is the key to normal operation of the stove throughout its entire service life.

Do not ignore the instructions and do not use the documentation included with other models.

Layout of the stove in the bathhouse

During the process of installing and connecting a tank in a bathhouse, one of the main priorities is deciding how the water in the tank will be heated. The water in the tank can be heated either from the heat of the stove in the steam room, or using a heating element. The main factor here is the number of people visiting the steam room and their need for hot water. The thickness of the tank will also affect the rate at which the water heats up.

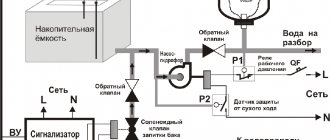

Connection diagrams for the water tank may vary. If there is running water in the premises, it is necessary to use a closed water supply system. For this purpose, it is most advisable to use a stove that has a coil, which, in turn, will be connected to a water reservoir and heat the liquid.

You need to connect according to the following instructions:

- The tank itself should be installed in the steam room and connected to the pipes using a coil.

- To achieve good circulation, it is worth connecting the upper part of the tank with the upper outlet of the coil, and the lower part of the tank, respectively, with the lower one. For this reason, cold water will enter from below, and hot water will be discharged from above.

- At the point where cold water will enter the tank, a safety and check valve is used.

- Then you need to set the threshold pressure for the valves at which they will operate. The drawings are presented below.

Thanks to this principle of operation, the liquid in the container will be heated using a coil. And after it is used, the tank will be filled with cold water again.

Recommendations for choosing the volume of the water tank

Having understood the features of stainless steel water tanks and choosing the most appropriate design option, all that remains is to determine the optimal volume of the container, after which you can proceed directly to the stage of its manufacture.

When choosing the required volume of a stainless steel water tank, you must, first of all, focus on the planned number of visitors who will simultaneously go to the bathhouse. For example, if the steam room, due to its physical dimensions, is not capable of accommodating more than 2-3 people, you can safely install a tank of 50-80 liters, at the rate of 25-30 liters of water for each bathhouse attendant.

Tanks come in different sizes - choose the one that suits you

Using the above recommendation, you can calculate the required volume of the water tank, taking into account the traffic of the bathhouse being equipped. For greater convenience, it is recommended to add at least 10-20 liters on top of the calculated value - each person’s needs and ideas about comfortable washing are different.

One of the possible water tank connection schemes

Step-by-step instructions for building a water storage tank

How are storage tanks used?

If your site has serious problems with regular water supply, it will be very difficult to do without a water storage tank. Both tap and rain water can be stored in such containers. Water supplies can be useful for organizing a summer shower, as well as in case of a possible fire. In addition, water from the reservoir is used for irrigation and for “bath needs”.

There are several common types of storage tank designs, most often they are rectangular or round.

In order to determine the optimal tank size in your case, you need to clearly understand the possible water needs of the site over a certain period of time. So, if you rarely use the container, there is a high probability that various harmful organisms will multiply inside it. This probability may be several times greater if the tank is not protected from sunlight. So, deciding in advance on the optimal tank volume is really very important.

Another important point: if we are dealing with a tank made of ferrous metal, then we cannot do without painting and priming, otherwise the structure will inevitably and quickly rust.

Making a stainless steel water tank with your own hands

Most factory models of water tanks are made of stainless steel 1 mm thick. For self-production, it is recommended to use thicker sheets - about 1.2-1.8 mm (the specific indicator is selected in accordance with the volume of the container). The costs of manufacturing the structure in this case will be higher, but for many years you will not have to think about the need for repairs, painting, coating with various special compounds and other similar maintenance of the tank.

As an example, you can use the following drawing - this is the easiest for self-assembly and one of the most popular design options.

Drawing of a simple water tank

You can change the dimensions proportionally in accordance with the required volume of the container. The volume is calculated using the standard formula, i.e. indicators of the length, width and height of the product are sequentially multiplied. For example, the volume of the container presented as an example will be about 25 liters.

Helpful advice! An even simpler version of a water tank is a product made from a piece of seamless stainless pipe. By choosing this solution, you get a number of advantages. Firstly, you won’t have to waste time and effort on cutting sheet metal, calculating allowances, reserves and other issues, i.e. the likelihood of errors is reduced to a minimum. Secondly, making a water tank from a pipe requires the use of welding in a minimal amount.

Stainless steel pipes with a diameter of up to 1020 mm and even more are available for sale, which allows you to purchase a product for making a container of the required volume without any problems. To determine the volume of the cylinder (namely, this is the final shape the storage tank will have), use the following formula.

Formula for determining the volume of a cylindrical tank

Helpful note! If you wish, no one will forbid you to make a tank from a profiled stainless pipe, and then the container will have a rectangular shape.

The further procedure for making a water tank yourself will be discussed using the example of using a piece of pipe as a workpiece.

Pipe - blank

Important! If you plan to install a pipe water tank, it is better to use a shorter but wider blank for its manufacture so that the smoke exhaust pipe can be passed through the internal cavity of the tank. It will look something like this.

Pipe mounted tanks

Samovar type tank

The procedure for making a water tank from a pipe is presented in the following table.

Table. Making a water tank for a bath

| Work stage | Description |

Cutting a piece of pipe | Previously, a formula was given to calculate the volume of a cylinder. With its help we find the required height of the water tank. For example, we want to get a tank with a volume of 30 liters and use a pipe with a diameter of 1020 mm to make it. Using simple arithmetic manipulations at the 5th grade level, we transform the formula into the following form: H = 30 / (3.14 * 0.512) = 37 cm - this is exactly the length that a pipe section should have to obtain a water tank of the specified volume. To cut a piece of pipe, we use a grinder. For working with stainless steel, discs with a thickness of 1 mm and a diameter of 11.5 or 12.5 cm are suitable. |

We process the cut areas | In order for the finished water tank to look beautiful, you need to properly treat the cut areas. In the future, similar actions will be performed when boring holes for connecting pipes with taps. The most convenient tool that allows you to quickly and efficiently solve the problems mentioned above is a hand drill. Such devices are equipped with a wide variety of abrasive attachments, which allow achieving maximum quality of processing of a particular material. In the absence of a hand drill, the seams will have to be tidied up using improvised means: a file, sandpaper, etc., which is definitely a more time-consuming and labor-intensive undertaking. |

Making the bottom and lid of the tank | At this stage we will need a sheet of stainless steel. It is recommended to make the lid and especially the bottom from a material that has a more impressive thickness compared to the walls of the pipe chosen for the manufacture of the body. The work is carried out in several stages: - a circle is drawn on a stainless steel sheet along the diameter of the holes that it will cover. You can simply place the pipe on a sheet of metal and draw a circle, tracing the contour of the product; - 2 blanks are cut out in accordance with the markings. For cutting and subsequent grinding of the edges, you can use the previously mentioned grinder and hand drill. If a pipe-based method of installing a water tank is intended, at the same stage, holes can be prepared in the bottom and lid according to the diameter of the chimney pipe (preferably 1 mm larger so that the chimney can pass through them; in the future, the gap will be leveled by welding). Also at this stage, you can prepare holes for further connection of pipes with taps, if they are mounted in the bottom (relevant for remote structures installed away from the furnace; in the case of over-fire/built-in and pipe-mounted tanks, it is more advisable to embed the pipes into the wall of the tank body). The nuances of drilling and welding stainless steel will be discussed in more detail in the relevant sections of the instructions. |

We connect the bottom and lid to the tank body | The photo shows a profiled pipe, but the welding process for this case and working with a round workpiece remains the same. Products made from the material in question can be connected in different ways: - by soldering using lead-free or high-temperature solders; — manual or automatic welding (in the case of stainless steel, work is carried out exclusively in a protective gas environment). The most preferable is the second option, the easiest to learn - manual arc welding. Argon is used as a shielding gas. Welding is carried out using a non-consumable electrode for working with stainless steel. In the international classification, devices intended for such welding are marked with the abbreviation TIG. When buying or renting a welding machine, do not forget to purchase/rent an argon cylinder and a reducer. The function of the latter is to reduce the pressure of the shielding gas at the outlet. The seams should be as neat and uniform as possible. It is recommended to clean them after completion. Recommendations regarding a suitable tool for this purpose have been provided previously. Helpful advice! If desired, the tank cover can not be welded, but attached using bolts and lugs, or simply made removable. This option is relevant for cases when water will be added manually by the user, and not supplied through the water supply. The container is ready. We begin to prepare the holes for further insertion of pipes. |

Preparing the holes | The structures under consideration are equipped with two pipes with taps. Cold water is traditionally supplied to the container through the upper pipe, and the heated liquid goes to the consumer through the lower pipe. The diameters of the plumbing pipes correspond to the diameters of the water pipes used in conjunction with them. The most commonly used pipes are ½ or 1 inch in diameter. An ordinary electric drill is suitable for drilling stainless steel. The main thing is that the work is performed at low speeds - no more than 100 rpm. In a drill with an electronic regulator, setting the required mode is not a problem. If there is no such regulator, you simply need to activate the start button with short presses - within a second the tool will not have time to accelerate to operating power. The holes are best made with a P18 drill. An even more convenient option is a special step drill (shown in the image). This tool does not lift up the edges of the hole, so it gets a perfectly round shape. Along with this, for drilling holes with a diameter of more than 14 mm, it is more convenient to use special attachments - the so-called. "crowns". |

Drilling bits | The presented diameters of such crowns correspond to both inch and metric gradations of plumbing pipes. Using appropriate drill bits, you can also prepare holes in the bottom and lid of the tank if it is intended to be installed in pipes. |

| Installation of pipes with taps | Branch pipes with taps to shut off the flow of water are available for sale. In combination with a stainless steel tank, it is preferable to use components made of the same material. In order not to waste extra time on arranging the threads, the pipes are simply welded to the previously prepared holes. Recommendations regarding tools and welding modes remain the same. After installing the water tank in accordance with the selected scheme (will be discussed later), water pipes (previously noted that it is best to use products made of copper or brass) of a suitable diameter are connected to the nozzles. The connection of the pipe to the pipe is made in any suitable way, for example, using a threaded adapter. |

So, the water tank is ready, and even the pipes for inserting pipes have already been installed. All that remains is to connect the finished device for its subsequent intended use.

Metal

Made of metal

In their own way, such tanks are good, but they still have more disadvantages. The main advantage in choosing such a material is its low cost. The thermal conductivity of the metal is good, so the water will warm up quickly.

If you decide to install a metal tank, then be prepared for constant maintenance. After each washing procedure, it must be completely drained and wiped dry to prevent corrosion, which will directly affect the purity of the water.

The procedure for connecting a stainless steel water tank

Important notes before you begin

It was previously noted that the most common options for mounting the tank are: inside the stove, away from it and on the chimney pipe. We propose to replace the first option with a method in which the tank is installed above the stove. This method is easier to implement, and you can resort to its use even if the stove has already been built - suddenly you first thought that you would not need such a heater, but after studying the material presented, you understood all the advantages of using it and wanted to install it in your bathhouse .

Important! The mentioned replacement will be possible only in the case of a collapsible chimney. The proposed method involves the combined installation of a tank - it will be simultaneously placed above the stones and around the chimney pipe, which will make the efficiency of heating water as high as possible. Otherwise, you will either have to give preference to the built-in tank model (if the stove is just being built), or install the unit at a distance from the stove.

If the stove is brick, preparing the space for the tank and its direct installation are carried out during the laying process (the specific stage depends on the chosen stove design and the size of the firebox, most often it is row 10). When laying a row, an opening is left to accommodate the tank. The size of the opening should be several millimeters larger than the dimensions of the structure being installed to compensate for thermal expansion.

The diagram shows an opening for installing a tank

Note! In the spaces between the marked quarters of the brick, pipes are laid, the presence of which will help to increase the heating efficiency - these are the design features of this particular furnace unit; these pipes may not be present in the project you have chosen.

The stove with the tank installed looks like this.

Oven with installed tank

A plumbing tap is embedded into the wall of the tank from below. It is assumed that the user will draw hot water directly from the steam room. If desired, the design can be improved by cutting in the previously mentioned pipe instead of a faucet, connecting a water pipe to it and leading it to the washing room.

When the masonry is brought to the upper edge of the tank, 2 metal strips are laid on it, the presence of which will allow you to safely cover the storage tank with bricks.

Tank overlap diagram

Next, the tank itself is covered and subsequent laying is carried out in accordance with the specifically selected furnace design.

Covering and further construction of the furnace

In the case of metal sauna stoves, the water tank is welded above the firebox (recommendations regarding welding were given earlier). As a result, the container is heated by flame forces, which ensures the fastest possible preparation of water. The design looks something like this.

Example of a sauna stove with a water tank

Important! If preference is given to a built-in tank design, for its manufacture you should use metal with a thickness of more than 1 mm and, at the same time, ensure that the quality of the welds is as high as possible. Otherwise, the tank will either quickly burn out or leak through poor-quality seams.

Helpful advice! In the case of a brick stove, you can take a simpler route by placing a water tank on the stove body above the firebox. The design looks something like this.

Water tank above the firebox

Installing a water tank above the heater

This method, as noted, involves combining options for installing the tank above the heater and on the chimney. The distance between the heater and the bottom of the tank is usually maintained in the range of 20-35 cm, with the possibility of changing in both directions: the smaller this indicator, the faster the water will heat up, but the tank will last less, and vice versa.

It makes no sense to provide detailed step-by-step instructions - you already have all the necessary knowledge. Previously, we described how to prepare holes in the bottom and lid of the tank for passing a smoke exhaust pipe through them. Do it.

Next, you need to pass the smoke exhaust system element through the internal cavity of the tank and connect the pipe to the tank at the inlet and outlet points (in the bottom and lid) by welding. You also know how to do this.

Stainless steel water tanks are relatively lightweight (for example, cast iron is much heavier and a tank made of it would require fixing to the ceiling using chains or other suitable means) and do not require additional fastening. Further installation of the chimney is carried out according to the standard scheme, depending on the selected type of structure.

Ideally, the finished system will look like this:

Tank installation example

Rectangular tank of samovar type

In the example image, the pipes and taps are not visible. The next design is not so beautiful in appearance, but the connection of the water outlet is clearly demonstrated here.

The photo shows the tap and water supply pipe

As for the supply of cold water, it can be organized in several ways, depending on the characteristics of the specific situation:

- The tank is filled manually;

- water is supplied from a well/well;

- Water is supplied from a centralized water supply system.

We will not consider each of the listed options in detail, because... These are topics for separate lengthy instructions.

Installing a remote water tank

The setup of such a system is also not overly complicated. The only thing is that the circuit is supplemented with a new device - a heat exchanger. It can be built-in or external. For self-production, it is better to choose the second option - it is more convenient and easier to implement.

A diagram of a system with a remote water tank is shown in the following image.

Diagram of a system with a remote water tank

Here we see that the external heat exchanger is installed on the chimney pipe. The water in the heat exchanger is heated by the heat of the flue gases transferred through the walls of the pipe. If there is an open heater under the heat exchanger, additional heating will be carried out by the heat of the hot stones.

Heated in the heat exchanger, the water goes into the external tank, from there, cooling, back into the heat exchanger. Water circulation will be ensured through the created slopes and pressure differences in the container with hot and cooled liquid.

Remote tank

Remote hot water tank 60 l

You can make a heat exchanger yourself. In essence, this is the same water tank, the manufacturing instructions for which you have already studied, only of a smaller volume (usually up to 5 liters). The heat exchanger is installed in the same way as the tank in the previous instructions (on the chimney pipe).

Tube heat exchanger

Register – heat exchanger for sauna stoves

Installing a built-in heat exchanger in a sauna stove

Prices for heat exchangers

heat exchanger

You already know how to make the necessary holes, install pipes, taps and pipes. Where to do this - see the diagram. All that remains is to prepare all the required elements and assemble them into a single system, maintaining the necessary distances and slopes in accordance with the above diagram.

In this example, a remote water tank is installed in the washing room and is equipped with a standard plumbing tap for draining water. The pipes, like the mentioned tap, are embedded in the bottom of the container. Holes for laying pipes through the partition can be made using a suitable tool, for example, a hammer drill.

In accordance with the current provisions of current standards, cold and hot water supply pipelines, if they are laid through a partition, must be laid through a sleeve. The diameter of the latter is selected so as to be 0.5-1 cm larger than the outer diameter of the pipe being installed. To seal the gap between the sleeve and the pipe, fireproof soft material is used to ultimately ensure the possibility of moving the pipe along the longitudinal axis in the event of thermal expansion. This is shown schematically in the following image.

Passage of water supply through the ceiling

The gaps in the partition can be masked in any suitable way, for example, by filling with the mentioned soft fireproof material and covering it with an external finishing element (lining, etc.).

All that remains is to figure out how to mount the water tank on the wall. The simplest option is installation on metal corners, the power of which would be sufficient to support the weight of the water tank.

Fastening is carried out as follows. Having attached the corners to the wall, you place marks on the surface, drill holes according to the marks and install dowels in them. Next, screw the corners to the wall using bolts 8-10 cm long and 1-1.2 cm in diameter.

Tank mount

You can install your water tank on the corners. The method is extremely simple to implement, but not the most reliable (we made a mistake when choosing the corners - they bent - the tank fell), and it is objectively suitable only for rectangular structures of small volume. The fastening method used when installing household water heaters is more reliable. To implement it, you will have to work with the welding machine again. You already have all the necessary knowledge, so no additional explanation is required. The procedure is as follows:

- a strip of metal is cut (the same stainless steel will do) with a thickness of 1.5-2 mm, a width of 5-10 cm and a length so that it protrudes beyond the side walls of the heater by several centimeters on each side;

- holes are drilled in the strip according to the diameter of the fastening bolts (you will understand by looking at the image below);

- the finished mounting strip is welded to the rear wall of the tank.

Further actions are similar to the previous instructions, with the only difference that the water tank is not installed on the corners, but is attached to the wall through them using a welded strip. It looks like this.

Fastening the tank through the bar

The tank is installed. You can test and, if everything is normal (no leaks, excessive heating and other unfavorable phenomena), accept the structure for permanent operation.

If desired, the system can be improved almost indefinitely, equipped with a variety of automation, measuring instruments, etc. The possibility of installing additional wiring to connect the tank to the shower stall in the washing room cannot be ruled out - this will allow you to wash with maximum comfort. An example of the implementation of such an idea is presented in the following image.

Connection diagram for a remote tank and a shower cabin to a sauna stove

Helpful advice! Install the tank in such a way that it is minimally distant both from the sauna stove and from the point of hot water intake.

Having sufficiently mastered the art of welding stainless steel, if you wish, you can make a tank not from a pipe, but from sheet material - this is a more responsible job compared to the considered option. An example of its implementation is covered in detail in the attached video.

Good luck!

Enameled

Enameled samovar type tank

Also a good option for making tanks. This material is also not susceptible to corrosion, provided proper handling is taken into account. If, due to an accidental impact, a layer of enamel breaks off from the surface, then rust may appear in this place. This can be corrected if you paint the area with heat-resistant paint in time.

The specifics of the material must be taken into account, and before making a tank for a bath, you should think about this method of arrangement so as not to accidentally damage it.

Final stage

Note!

- Forced;

- Natural.

The most preferable, according to the builders, is the second option, but you have to prepare in advance for additional time costs.

Remember that if you follow all the advice given to you by the builders, then without any difficulties you will be able to build a bathhouse quickly enough exclusively on your own.

Just remember to make sure in advance that you are prepared for the necessary financial costs.

Welding work

To begin with, you need to finally decide how the water will be heated - with a stove, or with electric heating elements that are mounted in the tank. An important factor such as the number of people may influence the decision-making process. If 50 liters of capacity is enough for one person, then for several people it needs to be made larger - at least 70 liters.

Now let's touch on the installation moment. If the tank is located on a chimney pipe, then it can be quite large and long - up to the ceiling, so the water in it will warm up quickly and evenly. If the water is heated by heating elements, you should not make the tank too large, since the water will take a long time to heat up, which in turn will lead to excessive consumption of electricity.

If you have chosen a cast iron or enamel tank, then these products are purchased ready-made. Let's talk about those that you can make yourself.

Depending on the chosen design, you need to purchase the required amount of material. To do this, you will have to sit with a pencil, drawing a tank and calculating its dimensions. For different shapes of the tank there are different formulas for calculating, just count not the total volume, but only the level to which the tank will be filled.

To work you will need tools and accessories:

- Welding machine (preferably DC).

- Electrodes Ø2.5–3 mm.

- Metal brush.

- Hammer.

- Pliers.

For those who are not professionals in welding, the easiest way is to weld a rectangular (or square) tank and weld elbows into it for supplying and discharging water.

If the tank is mounted on a pipe, then you will need the ability to make a ceiling seam, and not just any seam, but one so that water does not flow out through it. If you are not confident in your abilities, then entrust this matter to a specialist.

Boiler with heat exchanger and tank

The filled tank is heated by a coil, and when the hot water drops below the level, the valve will open and cold water will fill the required level.

If the hot water is not drained for some time, the safety valve will operate, causing the pressure in the tank to drop.

With the right choice of material and proper connection, the required level of hot water will be constantly maintained in your bath, and washing will be as comfortable as possible.

How to weld stainless steel: available methods of welding, the better, like at home, than thin

page » About welding » Welding stainless steel » How to cook stainless steel: choose a method according to your capabilities

Stainless steel is widely used in many areas due to its excellent technical characteristics:

- high resistance to oxidation;

- durability of stainless steel structures;

- strength;

- aesthetics of the finished product;

- ease of processing in various ways.

The most effective method of working with corrosion-resistant steels is welding.

How to cook stainless steel when solving certain problems will be analyzed in this article.

Peculiarities

Stainless steel has some features that can have a significant impact on the welding process:

- Linear expansion and shrinkage of the material . When heated, stainless steel products “expand,” and when cooled, they “contract.”

- The thermal conductivity of stainless steel is almost two times less than that of other materials. Therefore, when welding it, the current should be reduced by 15-20%.

- Corrosion-resistant steels have a fairly high electrical resistance . Therefore, it is recommended to use only special electrodes for welding stainless steel.

- If you choose the wrong welding mode or select the wrong machine, stainless steel may lose its anti-corrosion properties . This happens as follows: when the product is heated to a temperature above 500°C, chromium and iron carbide is formed on the metal along the edge. This leads to oxidation. To prevent rust formation, structures should be cooled quickly using various methods.

Methods

Welding of stainless steel structures can be carried out using several methods. We will talk about how to weld stainless steel further.

Manual arc welding with coated electrodes

One of the most common methods is manual arc welding using coated electrodes. The demand for such welding is due to the fact that as a result the performer will receive a high-quality weld. When there are no special requirements for the connection, this method will be the best solution, there is no reason to look for an alternative.

The selection of the electrode is carried out in accordance with the grade of the base metal. The consumable must have an optimal coating composition. There is a wide variety of welding consumables on the market that are used to work with corrosion-resistant steels. The full list is presented here. Welding is most often carried out using direct current of reverse polarity.

The video, without detailed explanations, shows in close-up how the welding process occurs.

Tungsten electrodes

For performers who have not yet decided how to cook 1 mm stainless steel, the following method is suitable. Stainless steel welding can also be carried out using tungsten electrodes in a protective gas environment .

This method is used for working with thin metal, when increased reliability requirements are placed on the connection. Also, the seam must meet special conditions.

Tungsten rods are also ideal for welding stainless pipes used for transporting liquids. In this case, the process is carried out in an argon environment, using direct current of direct polarity.

The video clearly shows the process of TIG welding of a pipe.

More detailed information on welding corrosion-resistant steels with various types of rods is presented in the article “Welding stainless steel with electrodes.”

How to weld stainless steel, with the exception of electrodes, will be discussed below.

Semi-automatic welding in argon

Semi-automatic argon welding is used to obtain a high-quality connection and achieve high productivity. For this you should use semi-automatic welding machines. Stainless steel wire for this welding method is produced in accordance with GOST standards.

There are several types of wire: universal, alloyed, copper-plated, flux-cored, flux-cored, steel or aluminum.

The welding process begins with preliminary preparation. The contractor needs to set the operating mode of the semi-automatic welding machine: current, voltage and wire feed speed. For metal less than 3 mm thick, the optimal current is from 120 to 145 A. The wire speed is 900 m/h. In this case, direct current of reverse polarity is used.

The work surface should be cleaned, for example with a metal brush.

Then the main stage of work begins. The performer turns on the switch that feeds the wire. Then the arc is ignited. If a melting wire is used, the metal must be touched to initiate the arc. It is necessary to move the burner nozzle exclusively in one direction; there is no need to allow transverse movements. The best option is to weld products at high speed with a single-layer seam.

In the video, a welder who is not entirely confident is welding, but it is quite possible to get an idea of the process.

If a performer has a question: how to cook 2mm stainless steel, then this method will be an excellent option.

Laser

Laser welding of stainless steel is carried out exclusively in industrial conditions, as it requires special equipment. Welding is carried out using spot and seam methods.

Corrosion-resistant steels are laser welded only butt-welded, since the overlap joint creates thermal stresses that negatively affect the overall strength of the product.

The advantages of this method: no reduction in strength in the tempering zone; eliminating the appearance of thermal cracks; The speed and accuracy of the laser beam does not allow the formation of an oxide film. The main feature of the method is faster cooling of the weld.

Plasma

There are manual and automatic plasma welding . Manual welding is carried out using an arc formed between the electrode and the base metal. Another name for the manual method is micro-plasma or mini-plasma. The welding process is performed using alternating current from 0.1 to 15 A. This method is intended for performers who need to weld thin stainless steel. There is also a “beamless nozzle” technique with a voltage of 15-100 A.

The beam flux during automatic welding is produced using a plasma torch. Exposure to alternating current above 100 A and gas flow creates a powerful plasma beam.

Advantages: stability and “rigidity” of the arc allow you to control energy costs; narrow heat-affected zone; fairly accelerated welding rate; the ability to change the distance between the nozzle and the working surface without negatively affecting the quality of the seam. Read more about plasma welding here.

See how you can cook with a small plasma device.

Recommendations from the experts

We've collected some tips from professional welders. They will be useful for beginners and garden craftsmen.

It is better to use stainless steel grade 8-12Х18Н10 or AISI 430 08Х17 as a material. These brands are best suited for storing water, including long-term storage. However, it is still better to drain the water before winter.

Before welding a stainless steel water tank, you need to decide on its volume and make a drawing based on this. For a bathhouse, a tank of up to 60 liters will be enough for two or three people. On average, about 20-30 liters of water are needed per person.

If you are cooking a tank for household needs, it is better to stock up on a volume of 100 liters or more. 200 liters is just right for watering gardens and collecting rainwater.

It is better to abandon the idea of welding a water tank from aluminum. It is not easy to make high-quality sealed seams at home. Stainless steel is also not easy to cook, but this task is quite doable. But to work with aluminum you will need experience and a good welding machine.

Depending on the size of the tank and your experience, the entire process can take anywhere from a couple of hours to several days. If you have never cooked before, it is better to practice on unnecessary pieces of metal. After all, stainless steel is far from a cheap material. And you are unlikely to be happy if, out of ignorance, you weld a tank with defective seams, and it turns out to be unusable.

Features of the operation of mounted tanks

Cylindrical containers, or “samovars,” operate under the most severe conditions of high temperature. The chimney wall can heat up to 500-600 o C. The metal of the walls burns into scale, as they say, to holes. In this case, using a stainless steel pipe for a sauna tank can be considered the best option.

The lower part of the tank is a metal glass with which the container is placed on the flange of the heater. This is the most loaded part of the structure. In addition to the high temperature of the walls, the weight of the tank itself and the water supply presses on the lower part of the stainless steel body. Plus, the hot glass gets the most boiling water and steam from the stones. In such conditions, ferrous metal burns out into rusty dust within a few months, so when choosing a specific tank model, pay attention to the bottom of the container; the thickness of the metal in this place should be at least 1.5 mm.

When choosing and inspecting stainless steel tanks for a bathhouse stove, it is imperative to pay attention to the quality of the welds on the bottom of the tank. The bottom part of the container of tanks from well-known Finnish and Swedish manufacturers is made of thicker metal or reinforced with stiffeners. In addition, the welding seams at the junction of the inner pipe, bottom and outer walls must be smooth and continuous, this indicates high quality welding.

If a container for hot water made of non-alloy steel is often deliberately not filled with water until the heater is ignited and completely lit, in order to speed up the process of gaining temperature, then in the case of stainless steel, such a “trick” can result in a burst wall or a dented bottom. Alloy steel has low thermal conductivity and a high coefficient of thermal expansion, therefore, during “dry” heating, severe stresses arise in the stainless steel glass and bottom part.

If a similar situation occurs, then you cannot pour water into an alloy steel container; you need to turn off the firebox and allow the stainless steel tank to cool to at least 50-60 o C.

Application of welded metal containers.

Using electron beam welding, you can weld conical and cylindrical shells, as well as perform welding work on containers with a diameter of up to 800 cm. Unlike arc welding, the electron beam method allows you to reduce the number of residual deformations, the width of the temperature-affected zone and increase resistance seams.

Welding must be of excellent quality, reliable and carried out according to the approved design, and control at each stage of production guarantees the safety and durability of welded containers. Welding can be manual, semi-automatic and automatic. With manual welding, all work is performed manually, and with semi-automatic welding, the material is supplied to the arc zone by a welding installation.

In automatic welding, all work is performed by a welding installation, which is a power source in combination with various elements for supplying the arc zone. The use of innovative semi-automatic and automatic welding equipment allows not only to reduce work time and minimize costs, but also to achieve high quality welds.

The production of welded containers is a rather complex and labor-intensive process that consists of several stages. At the initial stage, specialists perform incoming inspection of the materials used and select the required steel grade. For steel containers, corrosion-resistant steel grades are used, the thickness of the sheets is 0.5-1 cm.

At the second stage, the manufacture of walls, hatches, end elements and pipes, as well as supports and wells made of metal is carried out. At the next stage, the container is assembled and anti-corrosion treatment is carried out. The sequence of technological operations depends on several parameters, which include steel grade, rolled product thickness and type of weld.

- with pontoon and fixed roof. The main task of the pontoon is to reduce the rate of vapor saturation of the stored substance;

- without pontoon and with a fixed roof. Used for storing substances with low volatility and flammable products;

- with a floating roof. The protective roof reduces product evaporation, and its buoyancy is ensured by sealed boxes;

- cylindrical with a protective wall. Designed for installation near residential buildings and bodies of water, ensuring environmental safety.

Steel horizontal containers are used for storing water, petroleum products, lubricants, alcohols and food products, the volume of which is up to 100 cubic meters. m., and for large volumes vertical tanks are used. The cost of horizontal tanks depends on the grade of steel used and the thickness of the structural elements.

Horizontal containers are single-walled and double-walled, above-ground and underground, and the space between the walls is filled with nitrogen or liquid. Welded containers can be single-section or multi-section, and the latter can store different types of liquids.

For many residents of high-rise buildings, the problems of owners of private houses are not known. For example, welding a tank to fill it with water can only cause an ironic smile among city residents. Meanwhile, the question is not idle. The urgency of the problem lies in the question of which path to take - order a finished product or weld a water container yourself.

It’s no secret that buying a water tank today is not difficult, but if you want to save some money, you can weld a water tank of the required size with your own hands.

We will weld a metal water tank using a joiner's table, as well as metal sheets of standard size 2500x1250x2 mm. They will need to be cut in half using a grinder saw.

When you weld a water tank yourself, it can be difficult to ensure that the ribs and sides of the tank are perpendicular. To avoid such problems, you will only need to use four 30-40 mm corners.

Important

They are screwed to the upper corners of the cube. After this, you can begin to directly weld the metal tank: the side edges are welded to the bottom, and then the vertical ribs.

All eight ribs are welded externally and internally.

In order for the lid to be installed on the tank, you can secure the corners. They will also stiffen the top ribs of the welded water tank.

After you have welded the water container, you need to take care of convenience and safety. You can drill special holes 10 mm from the top edge through which excess liquid will drain.

And to prevent the welded water tank from rusting from the inside, it can be coated with special food paint. It will not spoil water and at the same time protect the metal.

It is recommended to paint the seams along which you welded the water tank several times, because these are the places that are most susceptible to rusting and corrosion.

You can modify the finished tank to suit your needs: attach wheels to it, drill a hole for water outlet in the bottom, attach tubes to the sides. Performing these operations will not be difficult.

As you can see, in order to weld a water tank with your own hands, you need to have certain skills, and you also need special tools and equipment.

Therefore, the right decision would be to entrust this work to professionals.

Experienced specialists of our company will produce any tanks for a wide variety of needs from various metals and at affordable prices with high quality and in the shortest possible time. All products undergo strict quality control.

Argon-arc welding

| Name of works | Price, rub |

| Welding of aluminum copper tube with a diameter of up to 10mm | From 300 |

| Welding aluminum copper tube with a diameter of more than 10mm | From 500 |

| Welding seam up to 100 mm | from 20 for 10mm |

| Welding seam more than 100 mm | Negotiable |

| Double welding seam up to 100mm | from 20 for 10mm |

| Double weld seam over 100mm | Negotiable |

| Welding the engine sump | From 1000 |

| Welding the engine manifold | From 700 |

| Welding the engine block | From 1500 |

| Welding the block head | From 1700 |

| Welding the cylinder head cover | From 500 |

| Welding the gearbox housing | From 1200 |

| Welding suspension parts | From 300 |

| Radiator welding | From 500 |

| Welding of any other parts | Negotiable |

We suggest you find out how much water an apple tree needs

Prices for soldering non-ferrous metals (aluminum, copper, titanium and their alloys)

| Name of works | Price, rub |

| Soldering 1 hole up to 10 mm | 500 |

| Radiator soldering honeycomb 1 damage | 500 |

| Radiator soldering with 1 or more damages | 300 for 1 damage |

| Soldering copper tubes | From 300 |

| Soldering of household appliance parts | Negotiable |

| Soldering an aluminum tube | From 300 |

Prices for welding work (Semiautomatic, Campy)

| Name of works | Price, rub |

| Welding seam up to 100 mm | from 5 |

| Welding seam more than 100 mm | Negotiable |

| Welding muffler pipes | From 500 |

| Small welding work | Negotiable |

Expert advice

If you nevertheless decide to carry out your plans on your own, you should take into account that the most suitable grades of steel for storing water in this case will be 08Х17 (aisi 430) and 8-12Х18Н10 (304).

As for the volume of the stainless structure, in a bathhouse designed for 2-3 people, it is more advisable to install a water tank from 50 to 80 liters. According to the formula, 25-30 liters of water per visitor.

Manufacturers usually offer 1 mm thick sheets for tanks. When welding yourself, it is recommended to use sheets with a thickness of 1.2-1.8 mm. Design options may vary in size and shape.

Welding water tanks made of aluminum is a complex process that requires the master to have practical skills in working with this metal, an understanding of the drawings and two hands that are friendly with the tool.