Thanks to the growing popularity of ceramic blocks over the past few years, many future owners of private houses, country cottages and even country houses have begun to think about using this particular material. For a long time now, an increasing number of manufacturing plants in Russia have been mastering the production of warm ceramics. Some are repurposed and simply expand their range, while others are built from scratch. The increased popularity is not surprising and is easily explained by the numerous advantages of the material.

In addition to the construction of residential buildings, there is increasingly talk of building baths from ceramic blocks. What are the pros and cons of this choice and what are the features of building with warm ceramics? Let's get a look.

Construction of a foundation for a bathhouse using heat blocks

Prepare the intended site for the future foundation. Vegetation and turf must be removed, all mounds leveled, and the surface made smooth.

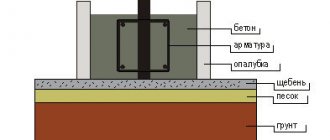

The best foundation for laying heat blocks consists of a strip reinforcement cage. To place it, you need to dig a trench, having previously marked the length and width of the future bathhouse.

To build walls from thermal blocks, you do not need an extremely large-scale foundation . The width of the trench for the foundation depends on the diameter of the selected heating blocks, as well as on the massiveness of the entire bathhouse building. Usually a width of 40 cm is sufficient. The height of a monolithic foundation is also quite small. The trench goes 60 cm into the ground.

The first underlying layer of the foundation is a sand cushion . The height of the sand cushion should not be less than 15 cm, usually 20 cm. After pouring the required amount of sand, it must be well leveled, removing mounds and depressions. Next, the sand is compacted with a special tamper, constantly pouring small portions of water.

The next stage of work is installation of formwork . It can be made from wooden boards; for formwork under the foundation it is better to use metal panels. The approximate thickness of the formwork supports is 50 cm. The height of the formwork is equal to the height of the foundation being laid.

Before pouring the foundation, it is necessary to make a reinforcement cage. After its installation, a concrete mixture is poured into the place of the future foundation. There are recipes that help you make this mixture yourself.

- mixing cement and sand 2:1;

- mixing crushed stone with sand and cement 5:3:1.

For the construction of walls made of heat blocks, the standard foundation height is 60 cm .

The formwork supports in this case are also 60 cm in height. The majority (about 40 cm) should be located in the ground, and the smaller part of the foundation (the remaining 20) should be on its surface.

Production Features

The production of heat blocks with your own hands can be carried out both on complex expensive equipment and on primitive home machines. To do this you need:

- Prepare a solution in a mixer from the components - sand, cement, expanded clay, chemical additives, water.

- Install a polystyrene foam insert into the matrix. It should fit tightly, but without force.

- Pour the previously prepared solution into the matrix.

- Compact the mixture as much as possible.

- Place the hardened workpiece in a heat chamber to dry completely.

- Remove the finished heating block and clean it from technological deposits.

Installation of reinforced concrete spatial frame

For the reliability and stability of the wall structure made from thermal blocks, a reinforced concrete monolithic frame . A reinforced concrete frame increases the strength of the building and creates clear contours for the construction of walls. It is important for the construction of the internal roof structure.

Reinforced concrete is stronger than brick or thermal blocks, therefore it has better load-bearing qualities compared to frameless construction. Its service life is more than 120 years, it protects the structure from possible destruction, greatly simplifies the laying of walls and makes possible repair work in the future uncomplicated. The use of the frame is recommended for large buildings. If you are planning a fairly large bathhouse with a large steam room and additional compartments, install a reliable frame for the building.

The frame is installed using removable formwork. The formwork is constructed and tightened, and reinforced concrete mixture is immediately poured into it. When the frame hardens, the formwork is removed.

What are the best stones for a bath? You will find out the answer to this question by reading this article. And this article talks about bathhouses made of laminated veneer lumber.

Rotenstein – ceramic houses according to European standards

By contacting Rotenstein, you are placing the construction of a warm ceramic house in experienced and reliable hands. Each stage of construction, from laying the foundation to landscaping work, is carried out according to European quality standards. The warranty on all construction work is 10 years.

Rotenstein builds turnkey houses from ceramic blocks in Moscow and throughout Russia. We work for those who value their own time, comfort and quality. To select a ready-made project and evaluate the level of our work, look at the catalog and gallery of completed projects. Architect Rotenstein is ready to answer your questions by phone.

Basement ceiling

The basement floor is a space filled with solid material. This is a load-bearing base for walls and floors. Serves as a barrier against cold air and moisture from the soil passing into the foundation structure.

Since the monolithic strip foundation was built from reinforced concrete, the basement floor can also be made from it.

The best option for creating a floor is the installation of reinforced lightweight reinforced concrete (like the foundation itself) T-section beams. Expanded polystyrene slabs with a thickness of 10 to 20 cm are laid between them. The frequency of placement of reinforced concrete beams helps determine the width of the expanded polystyrene slab. The covering is laid out alternating beams with slabs, joining them tightly. The distance between two parallel beams is equal to the width of one polystyrene foam slab.

The basement floor, made by laying reinforced concrete beams and expanded polystyrene slabs, simultaneously serves as heat and sound insulation for the floor and the bathhouse.

Construction of bathhouse walls from heat blocks

Thermal block is a heat-efficient monolithic block for the construction of building walls. It is distinguished by its ability to retain heat indoors during the cold season and keep it cool in the summer.

Its design consists of three layers .

- The inner layer performs a load-bearing function and is made of porous expanded clay concrete.

- The middle layer is polystyrene foam insulation.

- The outer layer performs a decorative function and is formed from ordinary concrete. It has different textures, the most common stylization is crushed stone.

All three layers are connected to a fiberglass rod.

The mass of blocks is of great importance. Depending on their size, the mass and load-bearing properties of the blocks vary significantly.

If the building frame has been previously installed , you can use heat blocks measuring 400x300x200 mm. The width of the supporting layer of expanded clay concrete in it is only 13 cm. They are very convenient for installation due to their low weight: from 12 kg to 18 kg. Due to the frame, such load-bearing characteristics are sufficient for the safe laying of walls and installation of a roof structure.

reinforced concrete frame, They will weigh significantly more, from about 35 kg. This weight greatly complicates the process of laying blocks. Blocks of a given size are used in frameless structures to maintain reliable load-bearing qualities.

The blocks are laid in one layer. The blocks must be laid absolutely evenly , this is necessary to comply with technical parameters and aesthetics.

The heat blocks are connected at the seams using a special adhesive paste . It is recommended to apply the glue with a notched trowel. It is prepared from a dry mixture

Glue can be applied in two ways . Heat blocks can be produced factory painted or in a standard gray color.

It is easier to work with unpainted heat blocks, since glue can be applied to all three joint layers at once. Even if glue appears on the front side of the block, after painting them yourself it will become completely invisible.

Another gluing technique for painted heat blocks. The glue is applied only to the inner, load-bearing layer of the block. After the wall is completely built, the joints that are not coated with glue are fixed using acrylic sealant. The use of sealant entails additional costs, and therefore, since the area that needs sealing is usually very large, the additional costs will be quite noticeable.

When choosing suitable heat blocks, take into account the possibility of problems with their geometry. Blocks from some companies do not produce them with an exact calculation of the width (20 cm), but allow differences from the norm by 1-2 mm. When laying a long wall, there may be a significant difference in the width of the different layers of walls.

The optimal solution would be to install an additional block, which creates additional difficulties. To avoid such problems, be responsible when choosing a block manufacturer.

Metal stove in the bathhouse. Read about this in our next article. And from this article you will learn how to make a garage from corrugated sheets.

About the material

In fact, ceramic blocks are an enlarged type of brick. They are made from clay, have the same color and, in general, characteristics. But there is also a significant difference. Warm ceramics also known as porous bricks. What is “porous” and how does it affect technical characteristics?

As you know, the process of producing ceramic bricks includes stages such as molding and subsequent firing. So, during molding, a porous agent is mixed into the clay mass. This can be small wood shavings, buckwheat and other husks, etc. Then, during firing in the oven, the porosizer burns out and in its place tiny cavities are formed - the so-called air pores. It is thanks to them that in the future it turns out that the material retains heat perfectly. At least, much better than traditional ceramic bricks, which are hollow and, moreover, solid. More details about the characteristics can be found in the review of brick blocks.

Advantages and disadvantages

It is clear that the pros and cons of a bath made of ceramic blocks are closely related to the advantages and disadvantages of the material itself. Let us briefly list the main things you should focus on. So, the positive aspects include:

- Fire safety. This is a very important factor for a bathhouse, especially if you plan to use wood.

- Light weight, due to which the foundation may not be so massive.

- Excellent level of thermal insulation. Warm ceramics are only slightly inferior to wood and gas blocks, but! This is in dry condition. If the humidity level increases (both wood and aerated concrete blocks strongly absorb moisture), then their advantage is practically neutralized.

- High level of resistance to mold and mildew.

- Long service life.

- Environmentally friendly, because the raw material is ordinary clay - a pure natural material.

- There is no need to use insulation, especially in blocks with a thickness of 440mm and 510mm (Porotherm 44 and analogues). Although, given that the bathhouse is not a living space, blocks with a thickness of 380mm and even 250mm will be quite sufficient.

- Quick laying, which is made possible by the absence of vertical seams and large-format size.

There are also certain disadvantages. These include:

- The need to use a special electric saw for cutting blocks. You can, of course, stab from the “old fashioned” way, but this must be done carefully.

- The strength grade is often inferior to solid brick. However, for the construction of a bathhouse this does not matter, since you will not build load-bearing walls for a 9-story building. And for the construction of houses up to 5 floors, the strength of warm ceramic blocks is sufficient with a margin.

- It is advisable to use non-standard fasteners. Due to the many technological voids and holes, conventional dowels and anchors may not always be firmly installed.

However, specifically for a bathhouse, the disadvantages of ceramic blocks are not so important and, in general, are noticeably offset by the advantages.

Roof installation

For the construction of bathhouses, shed and gable roofs . It is recommended that the frame structure be made of wood.

For the roof of the bathhouse, special holes must be equipped, which are planned even when laying the rafters. They are necessary to be able to remove steam from the bath.

It is necessary to pay attention to the hydro- and thermal insulation layer. Layers of hydro- and thermal insulation are located on the ceiling beams. The most effective and common coatings are: mineral wool, ecowool and penoizol.

Famous manufacturers

Among all the manufacturers of heating blocks, the most famous in the building materials market are:

- SRL Casa Perfecta, delivery from Moldova.

- AZAG LLP, delivery from Kazakhstan.

- Panteliman LLP, delivery from Kazakhstan.

- Sterk LLC, delivery from Ukraine.

- Engineering Systems LLC, Russia.

- Russfom LLC, Russia.

- ADIGEL HEATING BLOCK LLC, Adigel, Republic of Bashkortostan.