Aesthetic and useful linden lining often used to decorate a bathhouse, but it is important not to confuse it with other breeds. Unscrupulous sellers or simply companies, due to employee mistakes, may sell boards not made of linden, but, for example, aspen. These trees are very similar in appearance, but knowing all the differences between them, everyone is able to gain a skill that helps them avoid making mistakes.

Larch bathhouse

When choosing a material for a bathhouse, you need to take into account not only the heat capacity of wood, but also other characteristics. Unlike a residential building, the wood here is exposed to intense exposure to steam, water and temperature fluctuations, because the building is heated only during bathing. Not every material can withstand such a load.

An excellent option for a bathhouse is larch. The tree is a coniferous tree, meaning it contains a fairly large amount of resin. High resin content ensures amazing resistance of larch to rot, fungi, and water.

If the products are made of pine, it is necessary to varnish and protect them from moisture. Larch does not need this. On the contrary, over time it only becomes stronger than oak.

The advantages of wood are not limited to unique resistance to decay. Accordingly, a larch bathhouse will have the following features:

- strength - the density of larch is only slightly less than that of oak, a structure made from this tree will last a long time, as it is not subject to mechanical damage;

- resistance to rain, snow and heat ensures the longevity of the bath;

- larch lining includes a small number of knots, and this means not only aesthetics, but also greater strength of the boards and logs themselves;

- the wood has a beautiful texture and is very attractive;

- a log bathhouse made of larch does not require any protective measures; there is no need for periodic treatment with antiseptics, insect repellents, or stains;

- lining made from this material has the same advantages as logs.

There are also disadvantages to a bathhouse made of larch:

- it is at least 2 times more expensive than pine;

- wood is processed with some difficulty, so the bathhouse itself will also cost more.

Comment! Larch floors are still used in European castles. Its age reaches 300–400 years.

Beautiful finishing examples

White lining can look quite attractive even in a very light interior. The skillful use of black and colored accents, even if they are inserted succinctly, can demonstrate their charm in this case too. For color contrast, it is a good idea to use various decorative objects and patterns on textiles.

A light yellow surface looks quite good if a dark cherry shade window is used for contrast. But it’s better not to blindly focus on ready-made samples, but to take into account your taste and specific situation; By following these principles, you can get a high-quality interior that will last as long as possible.

You will learn about the installation of eurolining in the following video.

The exterior decoration of the building with wooden lining with an “American” profile looks stylish and beautiful.

Finishing a sauna with linden lining is an expensive cladding option that will immediately indicate to guests the status of the owner of the room.

Finishing the room with plastic PVC panels in the interior looks very stylish and emphasizes the main design of the room. When combined with white, this setting can become even more attractive.

You will learn about what mistakes you should avoid when choosing eurolining from the following video.

Aspen bathhouse: pros and cons

If larch is used both as the main material and as a finishing material for the steam room, then with aspen the situation is different. This tree is very specific and not cheap. Moreover, the cost is determined not by high qualities, but by the features of the workpiece.

Aspen grows in wetlands, which causes the inside of the trunk to rot. You can only harvest aspen tops up to 4–5 m in length. The rest of the tree is unusable and is simply thrown away. In addition, aspen harvesting is only possible from March to May, while aspen is relatively easy to process. This “seasonality” makes the collection and supply of material a very expensive endeavor.

And yet, this is the material that people often prefer to linden and alder. In fact, the disadvantages of aspen turn into advantages when it comes to the steam room:

- aspen - hardwood, boards or lining from it do not emit resin, which is a valuable quality for a sauna;

- wood does not heat up as much as many other species, this eliminates the possibility of burns;

- out of 3 trunks, only one turns out to be suitable for construction, but it is extremely resistant to moisture and does not rot;

- wet aspen is easy to process; when dried, it shrinks greatly, but at the same time the tree acquires exceptional strength.

An aspen bathhouse lasts for decades, and over time it only becomes stronger.

Important! Aspen wood is very wet and shrinks greatly when dried. However, once it dries, it becomes rock hard.

Steam room lining. Peculiarities

Boards and lining (linden or aspen) are well suited for finishing the “insides” of baths and saunas.

What is good about lining (aspen) for finishing steam rooms and dressing rooms:

- Does not emit resin, which distinguishes it from coniferous lining;

- Does not burn the body due to low thermal conductivity;

- Very moisture resistant material.

After treatment, it is not afraid of damage by fungi or bacteria, and does not rot.

Some varieties may turn slightly black over time from exposure to moisture.

Features when covering baths and saunas: it is recommended to place the lamellas horizontally - with the tenon pointing towards the top (that is, the sheathing bars should stand vertically). This is necessary so that condensation does not accumulate at the joints, and air will circulate freely between the frame elements, and the external walls will become less damp.

One of the disadvantages of the vertical arrangement is that if the central board(s) are damaged, you will have to disassemble the entire wall, but the advantage is the speed and ease of assembly, even alone.

When installing the frame, it is recommended to use stainless steel screws; with high humidity, the metal quickly rots. To lower the ceiling, special galvanized hangers are used, and lathing is attached to them. The lathing is treated with an antiseptic before assembly.

You can completely assemble the frames of the walls and ceiling, and then finish everything together with clapboard. Or do the ceiling completely first, and then move on to the walls.

To insulate the steam room, it is better to use mineral wool. For the outer layer, it is recommended to use a thin foil vapor barrier, preferably with foil on both sides.

To fix the lamellas, be sure to use clamps (special brackets for fastening). They are more difficult and take longer to work with, but their presence will make it very easy to disassemble the wall if necessary. Hammering nails and screwing self-tapping screws into the lining is not recommended. It is advisable to use nails and screws with small heads.

When the lining is not long enough, it is increased. The lamella is mounted on the sheathing, the length of the additional piece required is measured, it is cut off (can be selected from other scraps) and attached end-to-end to an already fixed panel.

When assembling a wall, you should check the parallelism of the boards of the already assembled side, for self-checking, so as not to redo the whole work later.

A gap of 2 cm should be left between the floor and wall panels (as well as between the ceiling and walls). Some craftsmen also install compensation gaps in the corners, covering them with decorative slats or plinths.

When installing vertically, you should start from the corner, when installing horizontally, from the top.

Linden or aspen for a bath: which is better?

It's really difficult to choose between these two materials. Linden is traditionally considered the best tree for a bathhouse and deservedly so. However, aspen, despite its external ugliness, poses serious competition to it.

Linden wood is soft, it is easy to process, and accordingly, the construction of a bathhouse requires less cost. If dried logs were used, the building does not shrink and can be used immediately after completion of construction.

Aspen, on the contrary, is processed with great difficulty. Since a bathhouse requires well-dried material, this makes construction an expensive and time-consuming task.

The softness of linden is also its disadvantage - the tree is short-lived, but dry aspen acquires the hardness of stone and lasts an exceptionally long time. Linden does not need to be processed for aesthetic purposes; even an unsanded log looks great, not like lining. To give aspen an aesthetic appearance, you should trim the bark from the log, sand it and plan it. In addition, repeated grinding will be required - the latter is performed 3 years from the date of laying. Otherwise, instead of a silver-white bath, you get a gray, unsightly one with dark spots.

Linden is not resistant to rotting and fungal attack. The bathhouse requires periodic treatment with special preparations. Aspen is not susceptible to rot or fungi. The only treatment that may be needed is for wasps. For some reason, the latter really love this tree.

The cost of linden is higher than that of aspen, so it is really difficult to choose.

Important! A log house for a bathhouse made of aspen and linden, as confirmed by reviews from builders, does not require additional finishing of the steam room. Both breeds are certainly suitable for sauna lining.

How to distinguish linden from aspen

Lining made from linden and aspen is very easy to confuse. It is not so easy to distinguish wood.

First of all, pay attention to the color. The wood of linden lining is very light, but still has a coffee tint. Against its background, the aspen is almost snowy white.

Linden boards have a characteristic sweet aroma. The smell of aspen is bitter, more reminiscent of birch sap. Aspen lining is rarely truly smooth, since this wood is difficult to process, but linden is smooth and silky;

Knots in aspen lining are more common. They are darker and clearly visible. In category B, even falling knots are possible here.

To distinguish linden boards from aspen boards, you need to not only inspect them, but also try them by touch.

What is better in a steam room: aspen or linden

The choice between linden and aspen lining is even more difficult. The materials have a number of common properties that are very useful for saunas and steam rooms:

- both linden and aspen do not heat up as much as other types of wood;

- shelves and walls finished with clapboard remain pleasant to the touch and do not burn;

- the wood of both species releases aromatic oils that are beneficial to health;

- the lining looks equally aesthetically pleasing;

- Both linden and aspen tolerate steam well.

There are also differences between linden and aspen:

- the smell of linden wood is deservedly considered the most pleasant, while that of aspen is bitter and not everyone likes it;

- linden darkens over time, aspen practically does not change color;

- linden lining is susceptible to fungus, the finishing must be treated, but aspen does not have this drawback;

- linden costs almost 2 times more than aspen lining, but linden wood contains far fewer knots and stains and looks more beautiful.

For a steam room, linden or aspen linings are equally good. The choice determines the taste of the owner.

What are the differences between varieties?

The classification of lining is determined solely by the quality of the raw materials. There are no standards on this matter. More precisely, there is also GOST 8241-88 and East German DIN, but both regulations have not met modern realities for a long time. The standard from the GDR, for example, allows even for class A the loss of knots up to 0.5 cm wide; In category B, the appearance of bluish tints is not considered a violation at all.

If you need to get an “Extra” grade product, the method of joining boards is usually used. Without it, we would have to pay an absolutely unimaginable amount for such a product. After all, the number of ideal pieces of wood of sufficient size, even in a forest of the highest quality, is small. To protect the material, it is often even transported in a vacuum container. The delivery set most often contains fasteners. It is rare that a 21st century consumer will agree to buy products with such characteristics. A typical description of European lining of the “Extra” group according to technical standards provides for the complete absence of cracks. The required material is obtained using a number of mechanisms.

In addition to the drying chamber, you need:

- circular saw;

- end;

- jointer;

- thicknesser;

- four-sided grinding machine.

The authenticity of the category must be verified by direct inspection. No labeling or accompanying documentation can replace such a test. If the seller refuses to demonstrate the product, it is better to refuse the purchase. It is recommended to selectively check several boards from the top, middle and bottom. As for category A, it may be even better than premium products or a little worse than them, it all depends on the specific manufacturer.

What is important is that detected defects should not be covered with paint if they meet the requirements for the grade. Only varnish is used for masking. Additionally, wax and oil help decorate the surface and give it a luxurious look.

Even on eurolining of the worst grade the following are unacceptable:

- through cracks;

- cracking reaching the end;

- rot coverage of more than 10% of the material;

- the appearance of more than 3 wormholes per 1 linear. m.

Various types of lining are used in finishing. Below is a description of each class.

There are 4 classes:

- class "Extra";

- class A;

- class B;

- class C.

The “Extra” category includes light-colored boards with a complete absence of knots. The board in this class is completely free of cracks, chips and other defects. The humidity of a product of this type should not exceed or be lower than standard values by 12-14%. The “Extra” class implies the highest quality of the material - it can easily be used for finishing residential premises. The boards are extremely carefully processed and have a pleasant appearance without flaws.

Class “A” includes light-colored boards, on the surface of which there may be small amounts of knots, resinous areas, cracks and chips. However, their presence does not significantly affect the strength of the board. The moisture content of the material should not exceed or be lower than standard values by 12-14% percent. Also suitable for interior decoration.

Class “B” includes dark-colored boards, which are often characterized by the presence of knots, chips, cracks and other defects. But their number should be no more than 20%. The dimensions of the resin areas should not exceed 15 cm. The moisture content of the material in this grade should also be within standard values with a deviation of up to 12-14%.

Class “C” includes the lowest quality boards of various colors. Defects can occupy up to 30% of the entire board area. The material of this grade is not finished, so indoor installation is undesirable. This type of lining is used for exterior finishing.

Cedar for a bath

Noble cedar wood belongs to the elite category. The material has exceptional qualities, not only functional, but also medicinal.

Cedar wood is impregnated with unusual resinous substances. They call it gum, emphasizing its special qualities. It has an antibacterial effect not only on the wood itself, but also on the environment. When heated, the substances begin to evaporate, disinfecting the room and relieving a person of a wide variety of diseases, so cedar is ideal for a steam room.

Important! In Siberia, a bathhouse decorated with cedar clapboard is recommended for those suffering from diseases of the respiratory system. The tree can even cure bronchial asthma.

Log bathhouse made of cedar

Cedar is the best option for a bath. The qualities of wood provide the log house with durability, beauty, and convenience:

- cedar has the lowest thermal conductivity compared to other conifers; a cedar bathhouse is warm even in the bitterest frosts;

- the wood is resinous, provides excellent antiseptic properties, therefore, it does not rot, is not susceptible to fungus, and even insects are not able to damage it;

- cedar resins are healing, cedar finishing provides an excellent antibacterial effect and natural air ionization;

- cedar is resistant to moisture and temperature changes. A cedar bathhouse is very durable and will last at least half a century;

- both the logs and the lining are very beautiful and do not need any processing: the natural color and texture are beyond praise.

There is only one drawback to cedar wood or lining - high cost.

Cedar lining for a bathhouse

Cedar lining for a bathhouse has all the advantages of a log. This material is ideal for a steam room, although it is not as effective as aspen:

- gum resin evaporates, but does not release when heated, so cedar lining does not burn and does not leave resinous stains;

- cedar lining guarantees an excellent healing effect;

- the specific fibrous structure of the wood ensures the absence of cracks and chips even at the ends;

- the lining is very beautiful: the colors are even, muted, the knots are small, the panels are smooth and delicate to the touch;

- the material is not afraid of moisture, steam, mold, or rotting, so it does not need any processing.

Important! Over time, cedar lining darkens, or rather, acquires a brownish tint.

Cedar bath: photo

Cedar is an excellent building material and allows you to implement any project - from a traditional Russian bathhouse to a complex hotel complex.

Finishing with paired cedar lining is no less impressive and beautiful and is suitable for any style.

Features of aspen lining

Aspen lining - almost without eyes or knots.

No resinous secretions, noble light smooth surface, high strength. All these properties make it possible to use lining not only for finishing walls and ceilings, but also for making furniture: benches, tables, cabinets.

According to the structure of the outer edge, the lining (aspen) is:

- With a semicircular edge shape;

- Flat edge;

- Profile edge (wavy, tapered).

All these types can be used either individually or in combination of different types, for example, in the manufacture of furniture or arranging a bathhouse.

The standard for board sizes differs in that during the cutting and drying of wood there is a lot of waste, so boards longer than 4 m are extremely rare.

Standards:

- thickness – 12-15 mm;

- width – 87-88 mm;

- width with spike – 95-96 mm;

- length - from 1.0 to 3.0 meters (rarely 4 m).

Separately, it is necessary to say about aspen lining of the “Euro” type. Firstly, its cost is quite high. It is distinguished by high-quality surface treatment and a special type of connecting lock.

Standardization of manufacturing quality in Russia is regulated by GOST 8242-88, and if the country of manufacture is a European state, then there must be compliance with DIN 68126. Based on humidity and the quality of planed surfaces, the lining is divided into grades:

- “Extra” is the highest grade. There are no defects or knots. Smooth white and flat surface;

- “A” - there are deviations, a small number of knots, uneven color;

- “B” - knots, the color is not even, there may be defects: scratches, etc.;

- “C” – low quality board, a lot of dry knots, cracks and chips, rotten parts at the end. Used for rough work or finishing of utility rooms.

Eurolining belongs to the “extra” class.

The deeper the lock on the lamellas, the stronger the connection. The lock groove should not be less than 8 mm.

If you use lining (aspen) with some minor defects, then using dark varnishes you can hide the defects, and even small cracks can be hidden with putty.

Varnishes are divided according to the substance that makes up the base:

- Acrylic;

- Polyurethane;

- Acrylic-polyurethane;

- Alkyd;

- Water-based.

Acrylic varnishes are universal. Will not allow dirt to concentrate on the surface. Dries quickly. Negative property - they begin to emit a specific odor when heated.

Varnishes containing polyurethane are suitable for treating indoor and outdoor surfaces. There are translucent compositions and darker ones - tinting. Lacquered panels will not turn yellow.

A combination varnish containing both acrylic and polyurethane gives some shine to the coated products. Protects against fungal colonies and mold.

Alkyd compounds will protect the wood from moisture. The negative property is the long drying time and unpleasant odor, so the room will have to be ventilated for several hours. Complete drying is guaranteed after two days.

Water-based varnishes are almost completely odorless, dry very quickly, and most importantly, there is no harm to health. In addition, water-based varnishes do not support combustion and do not emit harmful substances when heated.

When purchasing any varnishes and paints for residential premises, you should carefully read the instructions on the can. There must be a note stating that the composition is allowed to be used inside houses and apartments. If necessary, it is better to consult the seller.

In most cases, the surfaces will have to be primed before varnishing.

A number of craftsmen prefer to use factory-made varnishes and impregnations based on oil and wax. They penetrate deep into the pores of the wood, flow into all microcracks, and provide protection from moisture and mechanical stress.

For example, alkyd-oil solutions have a beneficial effect on the properties of aspen lining, protecting it from cracks and deformation. It is believed that treating wood with impregnations and varnishes can extend the life of products by 3-4 times.

Varnishes are applied in accordance with the rules:

- On dry and clean surfaces;

- After applying the primer;

- The ends are painted first;

- Temperature not lower than 5 degrees;

- Humidity not less than 70%.

An antiseptic is applied before varnishes. In addition to a brush and roller, you can use a spray bottle; with good skill, you will get the most even surface without defects.

For the dressing room or kitchen, water-based or wax varnishes are suitable.

In some cases, aspen lining is coated with special fire retardant compounds. There are combined mixtures: fire protection and antiseptic.

When finishing wood products, common mistakes occur. Firstly, the use of cheap products from the Chinese chemical industry, which can cause harm. It is not recommended to purchase varnishes, paints, impregnations and primers in markets without the appropriate certificates.

Secondly, the type of impregnation/primer does not match the finishing varnish or type of paint. Otherwise, high-quality coverage will not be achieved.

We suggest you familiarize yourself with How to choose the size of a clamp for lining

Alder for a bath

Another traditional material is gray and black alder for the bathhouse. The wood of these species has a very unusual porous structure. This feature makes alder lining a suitable option for a bathhouse:

- gray and black alder practically does not shrink. Due to its high porosity, moisture evaporates very quickly, this quality makes the lining an extremely suitable solution for a steam room;

- the wood is soft, easy to process at any stage, so the construction of an alder bathhouse will not require large expenses;

- sauna lining made of alder does not warp or deform even after several decades;

- wonderfully beautiful shades - from fiery to brick, give the building real beauty;

- In the dressing room, it is recommended to open the lining with wax to emphasize the color and texture.

However, judging by the reviews, alder for baths also has serious disadvantages.

- Wood is not very resistant to water. On the one hand, in the steam room moisture evaporates from the pores, and this is a plus. However, at low temperatures it stagnates in the pores and causes rotting. The external side of the log house requires periodic processing.

- Over time, the alder darkens almost to black.

- The cost of the lining is quite significant. The fact is that alder wood includes many knots. To get rid of them, a very thick layer of wood is cut from the trunk. In this case, the whips are short, and the material is expensive.

- The alder bathhouse needs insulation: there are too many joints.

Alder baths are built in mid-latitudes, where there is no need to insulate it.

Dimensions

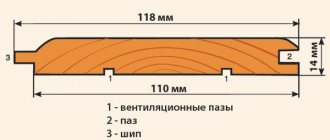

Having understood the varieties of material, it’s time to familiarize yourself with its standard dimensions. The groove size is 0.9 cm (0.4 cm more than simple types of lining). If the lamellas are joined, the groove can increase to 1.5 cm. The length ranges, as already mentioned, from 1.2 to 4 m; The standard thickness varies between 1.3, 1.6 and 1.9 cm.

The width has the following standard values:

The indicated dimensions are suitable for cladding even a large room (hall). The size of the studs of 8 and 9 mm equally meets the standard requirements. Differences from standard dimensions in length are no more than 0.5 cm, in width - 0.1 m. The maximum deviation in thickness is 0.07 cm, and in the scale of the spike - only 0.05 cm. These requirements were invented for a reason, but in order to prevent the occurrence of cracks and loss of appearance.

It should be noted that eurolining and ordinary lining have different sizes, which are often indicated in tables on the manufacturers’ websites. The dimensions of ordinary lining are set directly by the manufacturer of the material, however, there are the most popular parameters that have become standard.

The dimensions of wooden lining can vary widely:

- thickness – from 12 to 40 mm;

- width – from 76 to 200 mm;

- board length – from 20 cm to 600 cm;

- spike height – 4-5 mm.

Dimensions of eurolining

Eurolining has more standardized parameters:

- thickness – 13, 16, 19 mm;

- width – 80, 100, 110, 120 mm;

- board length – 50-600 cm;

- spike height – 8-9 mm.

Possible errors:

- thickness – up to 1 mm;

- width – up to 1 mm;

- length – up to 5 mm;

- spike height – up to 0.5 mm.

It should be mentioned that short lining boards have a much lower price. This is explained by the fact that short pieces are often offcuts from the final processing of long boards. The reason is that on long parts during the final processing you can notice dead knots that need to be removed, as they can fall out during use - this will preserve the grade of the lining.

Reviews

Boris Nevelov, 42 years old, Novosibirsk

I hesitated for a long time between linden and aspen, but in the end I made the traditional choice: linden. It costs more, but for a steam room, I think, you won’t find a better one. The wood is warm, silky, and does not heat up. And the smell in the steam room will make you pumped.

Nikolay Morozov, 35 years old, Omsk

There used to be a bathhouse on the site - made of pine. The inside of the steam room was lined with linden. But something went wrong: it began to rot. And in the bathhouse there was always mold or something else. They dismantled and built a new one - from aspen. It has been standing for more than 6 years, nothing rots, there is no trace of fungus. But, of course, it took me a long time to choose a tree. I went to the base three times to take away the barrels.

Alexander Fedorov, 52 years old, Ufa

A bathhouse was started on the site as soon as the house began to be built. I chose aspen: the price is lower than cedar, and it is not afraid of water, if it is good. Banya is already 15 years old. The color, of course, is not the same, it has become gray, but the tree is like stone. During all this time there was never mold in either the steam room or the dressing room.

Recommended Posts

Bathhouse made from a sea container

Bathhouse made from sleepers

Sauna tent

Do-it-yourself bathhouse repair

Russian wood-fired sauna

Why is there no draft in the sauna stove?

Surface finishing

Varnishing will help extend the life of wooden surfaces and change their appearance at the discretion of the owner. It is not recommended to use ordinary paints; they will obscure the texture of the wood. Before varnishing, you need to treat the surfaces with fine sandpaper and then remove dust.

Varnishes are applied to the surface with a roller or soft brush in several layers. The coating should be renewed every few years; this will extend the life of aspen lining panels. There is no need to apply synthetic varnish in the steam room; when heated and temperature changes, it will most likely fall off; in addition, the fresh smell of wood is very pleasant in the bathhouse.

One of the ancient ways to protect walls in a bathhouse is impregnation with vegetable oil in two layers. Now there are special impregnations from European and Russian companies. You need to focus on the purpose of the composition: for baths or saunas.

What is better to pay attention to

When choosing a material, in addition to price and tactile perception of the wood surface when touched, you need to pay attention to two important points:

- Wood workability;

- Resistance of the material to moisture and high temperature;

- Decorative qualities and smell.

All three categories have their leaders and outsiders. For example, linden and aspen have the best workability, cedar and larch are considered to be moisture-resistant, alder and abash are considered the most beautiful and comfortable to touch.

Of course, there are universal types of wood, the qualities of which are no better than those of the leaders, but they can be used to a certain extent for any parts of the bathhouse. Such materials include aspen, larch and cedar.

How to compare materials correctly

Of course, there are financial resources and time, quite realistically, and universal solutions. For example, build a log bathhouse from cedar, preferably Canadian, and use African oak to decorate the steam room. Even with a successful design, steaming in such a bathhouse is not much better or more comfortable than in a regular one, but it will last ten times longer than a log house made of aspen or even larch. But such a box will be very expensive. Perhaps, with the money spent on arranging such a bathhouse, it would be better to build four full-fledged wooden saunas made of cedar pine and linden.

Wood used in bath construction is divided into three categories:

- Finishing material for steam room walls, shelves, bath accessories;

- Material for arranging the wettest parts of the bathhouse;

- Wall block or timber.

This division did not arise by chance; as a rule, a certain type of wood performs best under certain conditions. For example, oak or larch are better suited than pine or alder for a bathhouse when it comes to constructing a log house or building frame. At the same time, heavy oak, acacia or birch are never used for wall decoration of the steam room. The denser the wood, the more it burns the skin, and birch board also produces bitterness.

Do-it-yourself lining for a bath: a step-by-step process

Before you sheathe a bathhouse with your own hands, you should lay out all the engineering communications inside that need to be checked. And only after that the finishing itself begins.

First, the sheathing is assembled from timber (aspen, linden or alder). You need to buy 6 cm self-tapping screws, the cost of which is low, with which the hangers are attached at a distance of 60/70 cm from each other. The level will help you set the upper and lower bars correctly. A flat plane will be obtained if you attach a mounting cord to the beams. The bars are fixed to the hangers using 3.5 cm self-tapping screws. The lathing is assembled horizontally and vertically with your own hands.

Afterwards, the frame should be coated with an antiseptic and allowed to dry. Next, the mineral wool between the sheathing beams will serve as thermal insulation. A waterproofing film is placed on top, which is attached to the frame beam with a stapler, overlapping the material 10 cm over each other and isolating the joints with special tape.

Then comes the DIY interior finishing. Boards are cut to the height of the room. To fix the slats, you should buy staples, nails or invisible clamps. You can just buy nails. But if the surface is decorative, then it is better to buy invisible clamps. You can buy nails if the planks will be fixed directly in the locks. Finishing is done from one of the corners, gradually moving around the perimeter. The last rail is selected according to width and cut to size.

The final stage, how to cover the lining inside the bathhouse? You can cover the boards with varnish that prevents any texture changes or color of the wood, a stain that gives the desired shade, protective wax or oil. The boards in the washing and steam compartments must not be painted or varnished. For these premises, special treatment of the bathhouse lining is carried out before it is fixed to the walls. The wood is impregnated with a colorless water-based antifungal antiseptic composition, which will prevent the growth of mold and mildew, the appearance of dark spots and protect against harmful insects. Before impregnating the boards, the material is sanded with fine sandpaper on both sides. The material dries within 2 days. For the steam room, the material is covered 1 time, for the washing and changing rooms - 2 times.

What should you consider when choosing?

Will coniferous or deciduous wood be required for finishing work? When choosing, you should take into account not only aesthetic characteristics - color, texture, it is important to know under what conditions the room whose walls are lined with clapboard will be used.

For sauna washers, you need to choose the wood that best resists the destructive effects of moisture. The budget option is spruce, the expensive option is larch. You can also use deciduous ones - alder or linden, but you should not forget about ventilating and drying the room after use.

Coniferous species other than cedar are not allowed in steam rooms. Only it has a minimal amount of resin, and is devoid of resin pockets. If it is not possible to take cedar lining, give preference to hardwood. Aspen, linden, and alder are perfect.

In recreation rooms and living spaces, you don’t have to limit yourself in choice. Almost any type of wood is suitable here; all that remains is to be guided by personal preferences and the design project.

Features of coniferous lumber, their advantages and disadvantages

It is worth noting that most of the moldings offered on the market are made of softwood. Moreover, most often you will find one of two options - spruce or pine. But this largely depends on the price segment.

The cheapest and most common coniferous trees in the middle zone are used to produce lumber, and this is absolutely natural. At higher prices you can find moldings made of Angara pine, larch, cedar (Siberian cedar pine).

Raw materials for such lumber are brought from the northern part of the country, which is reflected in the cost. Even more rarely, and at exorbitant prices, you can find lining made from more exotic conifers - Daurian larch, Siberian or Caucasian fir, Canadian cedar. But this is rather an exception; there are very few such lumber; they are more likely intended for creating decorative elements when creating a unique design, rather than for full-fledged finishing work.

Among the characteristic advantages of coniferous lining:

- resistance to moisture (due to high or medium resin content);

- pleasant yellowish-reddish color of wood;

- a special aroma due to the volatile compounds contained in the array (although not everyone likes it);

- beneficial effects of phytoncides on the body.

The last two points can be excluded if the lining is coated with varnishes or paints that do not allow air to pass through.

A disadvantage in some conditions may be resinousness. For example, spruce lining is not used in steam rooms precisely for this reason. When heated, the lined surface begins to “cry” - releasing large drops of resin. In addition, the wood of most conifers is quite soft, and as a result, unstable to physical damage.