The use of wood in a bathhouse is varied, the operating conditions are different, so in order to name the best tree for a bathhouse, you need to describe it specifically - the best one for what purpose.

Actually, this is what our entire article is about. We will not delve into the features and characteristics of each of the breeds discussed in the text, but we recommend reading the relevant articles, links to which will be given.

Types of wood for baths and saunas

The division into types is made according to two criteria: by type of lumber and by species. In the first case, there are two main types: lining and edged boards.

- Lining. Convenient type of lumber for installation. It is a profiled board with locks cut out along the edges. They allow strips of lining to be very tightly fitted to each other, forming a continuous surface. This type of finishing looks good both on the ceiling and on the walls in the bathhouse. For steam rooms and washing rooms, lining made of hardwood is usually used. The rest room can be lined with pine needles.

- Edged board. Most often it is used for finishing floors and ceilings. Durable hardwoods are the most common.

Sometimes unedged boards are also used. It allows you to create interiors in the style of a taiga bathhouse.

By species, wood is divided into coniferous and deciduous.

- Hardwood is suitable for finishing all rooms in the bathhouse. Most hardwoods are durable and can withstand warm, humid atmospheres. They can be used both as a floorboard and as a finishing material for walls and ceilings. In addition, treatment with special means can significantly increase the service life of linings and boards.

- Coniferous species are not inferior to deciduous ones in terms of thermal insulation qualities. However, they have one drawback - at high temperatures, resin is released from the wood. Therefore, steam rooms are rarely lined with pine needles. The optimal place of application for conifers is rest rooms, corridors and bathrooms.

Video - Which tree is best for a bathhouse

How do the conditions in the steam room affect the tree in it?

Since we are now talking exclusively about shelves in a wooden bathhouse, let’s briefly go over the conditions that prevail in a Russian and Finnish steam bath, and how they affect the shelves where, in fact, the steamer spends his time.

So, in our sauna the temperature is high , around 90-110 degrees, and the humidity is somewhere around 5-15%. With such heat, all the bodies that are inside the steam room heat up. Including wood, although any type of wood has a fairly low thermal conductivity.

However, among the wood species there are conifers, the vessels of which contain resin. This is a thick liquid that flows out when the temperature rises, with a completely different thermal conductivity - it burns when touching the wood is quite tolerable .

The low humidity of the sauna is good because it allows the use of wood that is more sensitive to humidity. Sensitivity in this case is swelling when wet and shrinking (often with cracking) when drying.

The Russian bath differs from the sauna in having higher humidity (55-60%) and lower temperature (40-60 degrees). Some breeds deteriorate more quickly than others under these conditions. However, this depends on their resistance not to moisture, but to rot, that is, to organisms that parasitize the tree and successfully reproduce in a warm and humid environment.

The same conifers, prohibited for saunas, are suitable for Russian baths (if the owner is not a fan of changing modes). And they would even be out of place here, because it is precisely due to resins (natural antiseptics) that they perfectly resist rot . And some coniferous species generally become stronger - larch, for example. (Some deciduous trees also grow stronger in water - oak is the same.)

So, how to choose wooden shelves for a bathhouse based on the temperature and humidity conditions in it?

Cedar

Finishing a bathhouse with cedar allows you to create beautiful and noble interiors. The surfaces have a pronounced texture and smoothly transitioning shades into each other. In addition, cedar is immune to temperature changes and humidity levels. This tree is not liked by insect pests; fungus on its surface is very rare.

The aroma that appears in rooms decorated with cedar is also attractive. The source of the pleasant smell is the essential oils contained in large quantities in this wood. However, you need to understand that after some time these oils will disappear and the aromatic effect will stop. There are two more disadvantages of cedar: high cost and the ability to release drops of resin.

Finishing the bath with cedar

Oak

Oak boards and lining are durable. The dense structure does not allow moisture to penetrate into the wood and destroy it. Oak is also attractive from an aesthetic point of view: the surface of the boards has an original texture.

Disadvantages include high cost, as well as difficulties with finishing work associated with the high hardness and weight of the material.

Finishing a bath made of oak

How to seal gaps between boards in a bathhouse

As the boards dry, their volume changes and deforms. This may cause gaps to form. There are several ways to get rid of cracks and associated drafts.

The first way to seal the cracks in a bath between the boards is to mix PVA glue and wood dust, or small sawdust. When the wood swells from the moisture of the glue, this thick mass must be tightly packed into the cracks. You can leave humps - all this will be sanded later.

The second way is to use acrylic sealant. They are sold in the color of the wood you will be touching up. After drying, just as in the first case, you need to sand it.

The third method is not for the steam room. You can fill cracks with either wax or oil wax. But in the steam room, when heated, everything will simply leak out.

The fourth way is to remove the board and re-cut it. Or choose planks that fit the size of the cracks and drive them into the gap between the boards.

***

Well, if the topic is relevant, we are waiting for your comments and share your experience! And those who want to keep abreast of all new publications - subscribe to our channel in Telegram.

Larch

Resinous larch surfaces have a reddish tint that does not change over time. This tree is notable for containing a wide range of substances beneficial to humans that are released when heated.

In terms of density, larch is close to oak. Therefore, in a hot and humid bathhouse atmosphere, it can also last for decades.

The disadvantages of this tree include the difficulty of mechanical processing and poor thermal insulation qualities.

Finishing a bathhouse made of larch

Alder

Alder has a valuable quality - it has low thermal conductivity. This allows you to avoid burns from contact with heated wood in the bathhouse. Alder boards and linings smell pleasant and have a reddish tint. Moreover, these qualities acquire even more pronounced forms over time.

For a steam room, alder finishing fits all criteria. It does not warp due to shrinkage, does not emit drops of resin, and successfully withstands regular exposure to hot steam.

Among the disadvantages, the difficulty of mechanical processing of alder is noted. This material is not flexible, although it is quite soft. Taking into account the fact that perfectly smooth alder lining is almost never found on the market, it can be difficult to properly sheath a steam room with this material. In addition, alder is not the cheapest tree.

Finishing a sauna made of alder

Dimensions

Of the three parameters - thickness, length and width - we will talk below about only one: thickness. This is the most important parameter, because the thickness of the boards on the ceiling in the bathhouse differs from the floorboards. The width can vary at the request of the owner, although even here there are conditional average values to which the majority tends. And the length is determined not by the length of the lumber, but by the length of the building section. where it will be applied.

Thickness for walls

Of course, here it would be better to distinguish the profiled board, which is called “lining,” from other boards that can also be used for interior cladding (for example, unedged).

That is, the walls can be finished inside and outside with boards. Sometimes even unedged. Inside they will be better fitted and sanded, outside they will be nailed in a herringbone pattern and perhaps only planed beforehand.

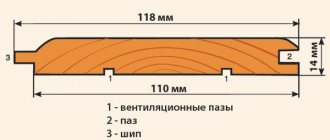

Another option is the same lining inside. It is attached vertically or horizontally to the sheathing. At the same time, the thickness of ordinary lining can vary in the range from 12 to 40 mm , and eurolining has only three thickness options - 13, 16, 19 mm.

The thickness of edged or unedged boards that can be used to cover a bathhouse can be as follows: 16, 19, 22, 25 mm .

Ceiling thickness

Everything here is quite simple: even if you do not have a floor ceiling, but a false ceiling, you should not make the structure heavier for no particular reason. Therefore, the thickness of the boards on the ceiling in the bathhouse should be minimal, because we are talking about finishing, and not about what the floorboard will be like from the attic side.

Most often, if the walls are covered with clapboard, then the ceiling is finished with the same material.

If there is a desire to finish with unedged boards in two layers, 16-22 mm will be sufficient . There is no point in making them thicker - they will not provide a vapor barrier, there is a vapor barrier for this, the insulation also rests on a special heat insulator, so the ceiling boards are purely decorative.

Thickness for floor

If you focus on manufacturers of tongue and groove boards, then there is a standard pitch: 28, 30, 32, 35 and 40 mm. But the bathhouse owner has a wider choice than the manufacturer offers.

A tongue and groove board is good everywhere except in the washing room and steam room. As for these two rooms, most people there prefer to make a poured floor, and in order for the board to serve longer, they use a thick edged board - 40-50 mm.

Of course, this is not the law. In fact, the thickness of the board depends on how far apart the joists or support posts . You can learn more about the relationship between the distance to the support points and the thickness of the board from this article.

Linden

The main advantage of linden boards and lining is their ability to have a beneficial effect on the respiratory system. The reason for this is the high concentration of active substances in wood. Linden is easy to machine. The lining made from it does not crack or curl as the bathhouse is used. Even taking into account the softness of the wood, alder can last for many years.

The freshly cut surface of linden has a slight texture and a pleasant pink color. At the same time, there are no knots or resinous discharge on it.

Among the shortcomings, soiling is noted, which manifests itself in the form of spots on the surface. However, sanding easily eliminates this problem, simultaneously restoring the original color.

Finishing a bath from linden

Birch

Birch lining is used to decorate the steam room only in the case of a very limited budget. This type of wood does not tolerate fluctuations in temperature and humidity. Over time, surfaces begin to rot and warp. This is due to the low fiber density.

At the same time, birch is perfect for decorating a recreation room. The fumes from this tree help fight colds and have a general strengthening effect on the body.

In addition, birch is a light and elastic material. Fitting the lining from it will not cause any difficulties. In the absence of sharp temperature fluctuations, such cladding can last for many years, simultaneously serving as additional thermal insulation.

Finishing a birch bath

The right choice is the key to rest and good health

Making a decision regarding finishing with natural wood paneling should be accompanied by awareness of certain nuances. For example, the ceiling should not be sheathed with resinous rocks. This also applies to beds, handles, and windows.

Any wood is susceptible to dampness to one degree or another. Therefore, it is necessary to periodically update the coating with waterproof compounds. It is also important to protect the lining from biological damage with antiseptic impregnations. This event will ensure safety for humans as well.

Aspen

In relation to the conditions of a sauna or bathhouse, finishing with aspen lumber has a number of advantages:

- does not warp or crack;

- resistant to moisture and high temperature;

- not susceptible to rot and damage by insect pests;

- does not deform under loads;

- due to its low density, it heats up slightly, which eliminates burns;

- no tar discharge;

- has a healing effect on the human body;

- has a peculiar aroma;

- easy to process.

The disadvantage is that the wood darkens as the bath is used.

Finishing a bath made of aspen

Conifers - pine, spruce

Softwood lining is one of the cheapest finishing materials on the market. It retains heat well and has a very pleasant aroma.

However, the use of these lumber for finishing baths and saunas is quite limited. Due to the high content of resins in wood, it is completely unsuitable for finishing steam rooms. As coniferous wood heats up, a significant amount of resin begins to release.

In addition, conifers quickly become unusable with regular contact with water or steam. Therefore, in relation to baths, coniferous lining can only be used for finishing such types of premises as a recreation room or a bathroom.

Finishing a pine bath

What is important to consider when choosing wood for a bath

To summarize, we can say that buyers have many options to choose from - for every taste and budget. If you want a traditional, aromatic “northern” bathhouse, choose coniferous wood. Light-colored buildings made of deciduous wood are suitable for those who do not want to waste time on interior wall cladding and cannot stand the smell of resins. In each segment there are affordable and elite breeds. However, it matters not only what kind of wood was supplied to you, but also how it was processed. This is especially important for coniferous species. Their outer hard layers, the cambium, retain heat and protect the logs from cracking, damage by moisture, mold and pests. If logs are rounded on machines or made into timber, the surface “protection” is removed along with the bark and accessibility results in losses due to low performance properties. The hand-cut logs that are used are optimally suited for baths. Treatment with a scraper and debarker preserves the hard layers, and the log houses last for decades even with constantly high humidity and temperature inside. A sauna made from hand-cut logs will be reliable, durable, and it will be pleasant and useful to steam in it.

Abashi

Abashi oak is an African species of oak, widespread throughout our country. Therefore, many of its characteristics are similar to classic oak:

- high strength;

- durability;

- immunity to temperature changes;

- resistance to moisture.

- However, there are significant differences:

- abashi, unlike ordinary oak, is much lighter wood;

- Due to the very low thermal conductivity, burns are completely eliminated. To the touch, even in a heated steam room, the abashi will always have the temperature of a human body.

In addition, this wood can be sanded to a perfectly smooth state that will not deteriorate even after many years of intensive use.

The only drawback is the high cost due to long-distance transportation from Africa.

Finishing a bathhouse from abashi

Prices for wooden lining

Lining for baths

Laying methods

There are two types of wooden flooring for the steam room:

- leaking;

- leak-proof.

The second design option is more expensive.

Preparing the soil base:

- For leaky floors. If the soil is sandy, the ground needs to be leveled, a 20 cm layer of crushed stone is poured over it. Moisture will pass through it unhindered, and various debris will linger on the crushed stone. If the soil is clayey, you need to arrange a special tray in which water will accumulate. A drain is created from it, through which the liquid is removed from the bath.

- For non-leaking floors. The ground is leveled and a layer of expanded clay is poured on top of it. The insulation should not reach 15 cm to the beginning of the joist. A hole must be made in the wall of the strip foundation, near the drain point, through which a pipe will be drawn to remove the used liquid. Secure a special sleeve or casing into the hole and pass the tube through it.

Laying non-leaking flooring

Features of the work:

- First you need to prepare the subfloor.

- The flooring must be sloped in one direction so that water flows along it on its own.

- There should be a drain point with a grate at the lowest point of the flooring.

- It is necessary to lead the pipe from the drain to the sewer or drainage well.

Foundation preparation process:

- Erect columns of brick or concrete blocks that will hold the joists.

- Lay the logs on top and secure them at a slope in one direction.

- Secure the logs with metal corners to the first strapping crown, and with anchors to the support posts.

Features of laying lags for non-leaking floors:

- You need to start laying from the walls at an angle of 10°.

- Make the outermost joists higher than the rest.

- To ensure better ventilation, a gap of 3–4 cm should be left between the outer joists and the walls.

- Lay a layer of waterproofing. For this it is better to use roofing material.

- Treat the joists with an antiseptic.

Work on arranging the floor with rough, floorboards:

- Under the joists, secure a subfloor made of unedged boards and bars.

- Lay a layer of roofing felt.

- Lay the insulation over the waterproofing. For this, it is better to use expanded clay, since it is not afraid of moisture. Mineral wool will not work.

- Cover the insulation with another layer of waterproofing.

- Stuff the tongue and groove board.

If you need to strengthen the flooring, you can use self-tapping screws.

What is important to remember when choosing wood for finishing baths and saunas

High temperatures and high levels of humidity, characteristic of the atmosphere of a bathhouse or sauna, impose certain requirements on finishing materials.

- The wood from which the boards or lining are made must be absolutely safe. Some breeds may release toxic or overly aromatic substances when heated. Therefore, before making your final choice, you need to make sure that there are no such manifestations.

- Wood trim should have as little thermal conductivity as possible. This will get rid of burns. This point is of utmost importance when choosing wood for finishing steam rooms.

- It is advisable to use one type of wood in one room. Different breeds change color differently when exposed to hot water and heat. Therefore, there is a risk of getting a completely unexpected combination of finishing colors.

- If you are on a limited budget, do not worry about the inability to purchase expensive cedar or oak. Among the cheaper options you can find materials with similar characteristics: alder, aspen, linden, etc.

- In the steam room, it is advisable to use the most durable wood available. In other rooms, cheaper options will also successfully cope with their task.

Video - Which lining is better for a bathhouse

It is also worth considering that without proper care, even the highest quality and most expensive lining will eventually become unusable. Therefore, it is worth finding out in advance what specific means will need to be used to prevent rapid aging of the material.

The variety of types of wood suitable for finishing rooms in a bathhouse or sauna allows you to implement any design solutions. However, before choosing one or another option, you must make sure that the wood will withstand the expected operating conditions and will not cause harm to human health.

Golden hit parade of “bath” wood species

Preface

As a rule, a Russian bathhouse consists of the following premises:

- dressing room - a room that serves as a regular locker room;

- washing room - a room designed for performing water procedures before and after visiting the steam room;

- steam room - the central room, which is the “heart” of the bathhouse, since it is in it that the stove-heater flaunts;

- relaxation rooms are a place for a pleasant pastime after and before visiting the dressing room, steam room and washing room.

Of course, if you wish, you can arrange many other rooms. It all depends on the taste, imagination and financial capabilities of the owners.

Why this preface? And then, so that you understand which wood species to give preference when decorating this or that room.