The stove in the bathhouse is the main element; without it, heating is impossible, which means, in principle, it is impossible to steam. Due to the rather high complexity of constructing a brick stove, as well as problems with finding an experienced stove maker, metal structures have become very popular.

Ready-made options in special stores or even purchased directly from the manufacturer are quite expensive. Owners who own welding machines come to mind to make a sauna stove themselves in order to minimize costs and implement exactly the design that will give the best effect.

Tools and materials

In order to make a sauna stove with your own hands, you will need the following materials:

- Sheet steel . The optimal thickness is 2 - 3 mm. Sheets of greater thickness are expensive and heavy; smaller ones can quickly burn out. And only for the firebox it is better to take a thicker sheet, for example, 5 mm.

- Cast iron for grate . If the design of the stove includes a grate between the ash pan and the ash pan, it is better to buy it ready-made or make it from cast iron beams - this material is more fire-resistant.

- Asbestos thread . Braided into a cord, it serves to seal the connections.

- Special fire-resistant paint for finishing coating.

For the firebox, it is better to take not ordinary black steel, but chromium steel containing 13% Cr.

It holds a higher temperature and does not burn out. The minimum set of necessary tools looks like this:

- Inverter welding machine with a set of electrodes, mask, leggings.

- Angle grinder (grinder) with cutting and grinding wheels for metal.

- Drill with a set of metal drills.

- A set of plumbing tools: a hammer, a pair of files, pliers.

Types of gas generator furnaces

Modern heating stoves, the operating principle of which is based on the pyrolysis process, can be classified according to several parameters:

Material type

Heat-resistant steel and fire-resistant red brick are used to make the housing of the heating units.

Purpose and method of use

Furnaces are available intermittently and continuously.

The first version of the devices uses fuel materials that can accumulate and release thermal energy for a long time after the completion of the combustion process.

The second option involves continuous loading of fuel material to ensure the required level of thermal output.

Location of working chambers

Structurally, the units are of two types:

- An upper chamber for producing gases and a lower chamber for burning pyrolysis products. In some models they may be located on the same level. The pyrolysis process is carried out due to forced draft, which is provided by smoke exhausters or blower fans.

- A lower chamber for gasification and an upper chamber for afterburning gases. Such devices provide a natural traction system.

Heat transfer type

Gas generator furnaces can be equipped with:

- water heating circuit with an additional circuit for heating water (water heating systems);

- air heat exchangers (air heating systems).

Long-burning potbelly stove

The potbelly stove has become a real symbol of Russia since the times of the Revolution and Civil War.

This is the name given to the simplest iron stove of a cylindrical or cubic shape. Its advantage was that the smoke channel - an ordinary iron pipe - could be taken out anywhere - through a wall or roof, into a window.

Taking the simplicity and practicality of a potbelly stove, you can make a small stove that will embody some simple ideas that significantly increase its efficiency, safety and environmental friendliness.

Basic scheme

The classic potbelly stove has a cylindrical design. However, it is difficult to do this when making it yourself, so you need to take a cube or parallelepiped as a basis.

Contains the following structural elements:

- Firebox _ This is the chamber in which fuel combustion occurs, most often wood. The walls and bottom of the firebox must be thick, since they bear the main temperature load. There is a door in the front for storing firewood in the firebox; if desired, it can even be equipped with heat-resistant glass.

- Ash pit (ash pit) . The compartment under the firebox is separated from it by a grate. The ash pan is also equipped with a door, only of a smaller size. It is used to remove ash and ash. which fall through the grate from burnt firewood. But this is not the only point of the ash pan - air is sucked in through the ash door and passes through the fuel layer from below, ensuring the best combustion.

- Smoke channel . To arrange it, a round hole is cut out in the upper part of the stove, a piece of steel pipe is inserted into it and scalded. In the future, you can attach other sections of the pipe here or use a factory sandwich chimney with special locks.

Expert opinion

Levin Dmitry Konstantinovich

Some manufacturers of homemade stoves believe that the design with a blower and grate is not suitable for a sauna stove - it creates too much draft, which prevents complete combustion of the wood. Instead, it is proposed to lay the firewood directly on the bottom of the stove, and ensure air flow by drilling several round holes in the lower part of the combustion door and equipping them with a sliding damper.

How to make a door

The door is made of a thick sheet of metal. For fastening, you can use store-bought factory hinges or make your own. To seal the fit, an asbestos thread is used - it is wedged in a groove cut by a grinder.

If there is a suitable sheet of heat-resistant glass, it is inserted as follows: cut a window in the door and grind the cut area. Then they lay the glass, lay asbestos fiber around the perimeter, invisibly from the outside of the part, after which, using small steel tongues, I make tacks on each side.

The turning handle of the latch is easiest to make from the outside.

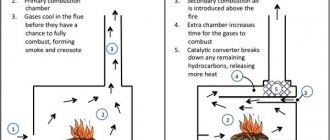

Homemade secondary gas afterburning system

The main disadvantage of a potbelly stove is its low efficiency. A stream of air passes quickly and strongly through the entire oven, carrying with it not only unburned food, but also heat. As a result, the case does not warm up sufficiently and gives off less heat. To solve this problem, a simple but ingenious modification was invented.

By placing two steel sheets above the firebox, the smoke passage channel can be significantly increased the length of the path that burnt gases travel before exiting through the chimney opening:

- The first horizontal sheet is welded directly above the firebox so that a channel remains for the passage of gases in the rear part of the stove.

- The next sheet is cooked higher, offset so that the passage is now at the front of the oven. It turns out that smoke, gases and heat, once in this labyrinth, snake through it all the way to the chimney. Along the way, they give off all the accumulated heat to the sheets, side walls and top plate of the oven.

If you drill several holes from the bottom from the back and cover them with a screen made of steel sheet, then at the top point, when fresh air, but already heated by the screen wall, meets unburned gases, the process of afterburning secondary gases will take place in the channel, which will lead to a significant increase in efficiency ovens.

Operating principle of a pyrolysis oven

Let's understand the principle of operation of a gas generator boiler, and understand how it differs from other furnaces.

For all types of furnaces, except for the option we are considering, full access to oxygen is necessary , otherwise the combustion process will not occur intensively enough. In pyrolysis furnaces, the loaded fuel undergoes slow smoldering with a lack of oxygen.

You ask: “What are the advantages of this method?”

With the standard method of combustion of any carbon material, energy is released, which provides the necessary heat , oxidation processes occur, unburned gases escape into the atmosphere, and unburned residues are thrown away.

In a pyrolysis furnace, due to the lack of oxygen, a lot of flammable gases and coal are released. The gases released during such combustion are called pyrolysis , hence the name of the furnace. This furnace has two combustion sections; fuel is loaded into one, where it slowly smolders in a small amount of oxygen. Then, due to draft, the resulting combustible gases move into the second chamber and burn there together with a sufficient amount of oxygen, and the remaining coke or coal burns out in the first section.

Thanks to this boiler design, the time of one pyrolysis cycle can reach 30 hours.

So, let's go over the stages of operation of a pyrolysis furnace.

- The fuel you select is supplied to the gasification chamber.

- Smoldering, it gradually begins to release flammable gases.

- Oxygen begins to flow into the section where the fuel burns out.

- Due to the strong increase in pressure, the gas moves to the second afterburning section.

- Next, air enters this chamber and mixes with the pyrolysis gas and begins to burn. At the same time releasing a large amount of heat.

- All these processes heat the water, which is located in a special section and it is sent through a pipeline through the entire heating system, simultaneously cooling the furnace system.

Gate equipment

Another way to combat increased draft, which causes wood to burn out too quickly and not completely, is to install a damper on the chimney.

A damper is a valve that closes the chimney exhaust duct and blocks the draft:

- In the closed position there is practically no draft - almost no air is sucked in through the blower and combustion doors.

- In the fully open position of the gate, the thrust is maximum - this is the kindling mode.

- By partially retracting the damper , you can reduce the draft so that the wood does not burn, but smolders. This way you can steam on one tab longer than usual.

In factory long-burning furnaces, the gate is made rotary. In a summer cottage it is easier to make it movable. To do this, you just need to cut the sheet to size and make a gap in the chimney. You can pull out such a flap by the tongue.

Homemade sauna stove with glass door

The master showed the stove, which he welded with his own hands. The design is not new; many manufacturers offer such forms. The master needed a special design, so he did not purchase a new one.

Some features. The air supply comes from under the bathhouse and from inside the steam room. Initially, the idea was for the stove to stand in a steam room and be heated in it. Because the dressing room is small, there is no place to heat from there. The advantage is the viewing window: you can lie down and look at the flames. This has a beneficial effect on mood and nervous system. A shut-off valve allows you to completely close the chimney when the stove is heated and the stones are heated. This is so that the heat does not evaporate, but remains. “Clean glass” system. At first there was nothing special, but the glass was smoking. There must be a “clean glass” system. Everywhere around the perimeter there is a fiberglass cord on the client. In one place it is cut off to allow air to flow in. You can hear it being sucked in through a small gap. Thickness and 1 mm. Air enters there and hits the guide. This is a strip made of iron sheet. Then it flows down, washing the glass. It prevents soot from sticking to it from the inside and settling.

How to arrange a heater

The heater is an integral part of the sauna stove. Thanks to it, thermal inertia increases, and there is also a wonderful opportunity to add steam by pouring a ladle of water on the stones. The two types of heaters are constructed in different ways.

Open

It's easier to make it. In fact, all that is needed is to build a tray for the stones at the top of the stove.

To do this, you can weld the sides onto the top panel - either from solid sheet metal blanks or from mesh. By laying stones in several layers, you can achieve a significant increase in heat transfer.

The second option for constructing an open heater is around the chimney duct. Although the air in it is colder than at the exit from the firebox, it is still hot enough to heat the stones.

To do this, a ring of the required width is put on the pipe before installing the chimney, then it is boiled and becomes motionless.

A mesh stopper is attached around it - you can either buy it in a store or make it yourself from a chain-link mesh. By filling this container with stones, we get a small but effective heater that takes up little space.

Expert opinion

Levin Dmitry Konstantinovich

An open heater allows you to achieve the effect of a Finnish sauna - rapid heating up to 100 degrees and hot, “dry” steam, which is instantly formed when a ladle of water is poured onto the hot stones.

Closed

This is a cavity inside the oven where stones are placed. In this case, the stone aggregate itself should not come into contact with water. The stone hopper is usually located at the back of the stove, directly next to the firebox. In order for the stones to warm up better, sometimes they make channels from pipes that run along the firebox and open into the heater - this way the temperature rises faster.

A channel also leads inside the closed heater, but it is a funnel. When water evaporates, it does not immediately rise into the air, but gradually comes out in a superheated state - this is how you can achieve the effect of a Russian bath with soft steam.

Which version of the heater would you make?

OpenClosed

Good sauna stove made from a pipe

Stove for saunas, baths with a large heater volume for a large family. It is characterized by a large heat transfer area, therefore, it will warm up a large bath well. Equipped with a blower and ash pan - this is very convenient. A plasma cutter was used for work.

Two comments for this video. Kanat Abramovich Guys, I made the same one myself using this principle, I’ll be honest, it’s a super oven. So far I have made the chimney straight, like titanium. And I placed the tank at 500 liters right on top, a distance of 60 cm from the stove and the pipe runs along the inside of the tank, warming it up. In short it turned out great.

alexey kosarevsky I made almost the same one, but for home. Door with glass, length 80 cm, chimney with gas afterburning. The temperature in the house (if you forgot to close the vent) is up to 45 degrees. Once tested it was 59. I can give you advice on your stove (if needed). Make a blower at the top of the door, there will be an air supply and the gases will be burned out + the heat is better reflected in the heating of the stones, make a pipe in the stove with a bend halfway down (can be cut). With a pipe like yours, the fire will come out into the pipe. Therefore, you can put more stones in the brickwork and create a gray steam room. Really liked the fit. And what kind of cutter is this?

How to make a water tank

Only stainless steel should be used as a material. If there is no suitable material, you can try to fit a stainless steel container under the tank. A rectangular tank shape would be optimal. It is not welded to the furnace wall, but simply touches it closely.

If the top of the stove is free from the heater, the tank can be placed on top. If this is not possible, the tank is placed at the side or rear wall - a shelf is welded to the wall, the tank is placed on it, and then it is pulled in with a tire and two studs with wing nuts on them.

Advantages of pyrolysis ovens

This technology makes it possible to make such a stove virtually smokeless and more environmentally friendly, provided that dry wood is used as fuel. Due to the fact that the main amount of gas burns, only steam and carbon dioxide are formed at the outlet of the chimney. The advantages of this technology can be characterized by the following qualities that these stoves have:

- Good efficiency, reaching up to 85%.

- Formation of very small amounts of ash and soot when burning dry fuel.

- Heating the room in a fairly short time;

- Possibility of maintaining long-term combustion in autonomous mode with one addition of fuel.

- Adjustment of thermal energy release in the range from 30 to 100%.

- Savings on fuel costs.