A classic Russian bathhouse involves the construction of a log house. In recent years, the rounded variety of this lumber has gained the greatest popularity, which is not surprising, given the ease of use and affordable cost of construction. The key point, which largely determines the characteristics of the future building, is the choice of the diameter of the log used in the construction of the building.

Choosing a log type

Currently, the following types of lumber can be used for the construction of log houses:

- A simple sanded log, the structures from which have a traditional appearance. The main advantage of the material is the protection of the core due to the preservation of the top layer.

- The planed log has a beautiful texture and light shade due to processing with hand planes. It is expensive and requires the use of protective compounds.

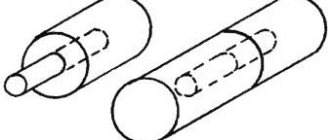

- A rounded log, thanks to the use of special equipment in production, has a smooth surface and the same diameter along its entire length. The disadvantages are similar to those of planed lumber.

- Square beams have an affordable price. Structures made from it have smooth, even walls. The disadvantage is the complexity of assembly, requiring adjustment of each element on the construction site.

Advice! Regardless of the type of lumber chosen, it must be treated with special compounds to increase the durability and aesthetic appeal of the structure.

How to choose a wood type

The construction of a log house is possible from forest materials of coniferous and deciduous species. The types of wood allowed for use and the parameters of building materials made from it are prescribed by state standards.

Conifers

The buildings are erected from pine, spruce, fir and larch logs of grades 1 and 2, average thickness - 14–24 cm, length 3–6.5 m. You can often find a wild log bathhouse - this is when the logs can vary greatly in diameter from crown to top crown, the projections of logs from the walls may also differ. All this creates a picture of the chaotic nature of the construction of the log house, but at the same time it makes the construction more natural, more natural.

It is impossible to build a log bathhouse from cedar due to the fact that when heated, this tree releases substances hazardous to health into the air!

Traditionally, resinous, soft, warm species are used for a coniferous log bathhouse - pine and spruce. One or two lower crowns are made of larch - harder, denser and more durable. (Larch also goes on beams - under the floor and under the rafters).

Information. It is more pleasant to steam in a spruce bath, and healthier in a pine one. Spruce removes excess moisture well, while pine breathes better. In terms of durability, one is not inferior to the other.

Building a bathhouse from larch will cost more (due to the higher price of the material and labor - larch is difficult to process). The walls of the bathhouse will be colder (almost a third) and heavier. The smell of this wood when heated is not to everyone's taste.

But the fire resistance of larch is twice that of pine. It tolerates high humidity much better than other breeds and is not inferior to rounding. (The core of its trunk is strong and moisture-resistant, the sapwood is weaker and very narrow).

Hardwood

For a log house made of deciduous wood, grade 2 logs with a thickness of 12–24 cm and a length of 4–6.5 m are suitable.

Moreover, if the walls of the log house are designed to be longer than 6.5 m, then the design is complicated by internal capital partitions.

Baths are built from the trunks of maple, birch, aspen, poplar, linden, willow, beech, elm, and hornbeam.

Ash is not suitable for wet areas. Oak is used for the crown molding (and floor joists).

Aspen is considered ugly and too soft (it grows quickly and does not have time to gain strength). The tree gains a thickness suitable for construction late, when the trunk begins to collapse from the inside. But if the aspen was felled healthy, it remains strong for a long time. An unsightly, but useful protective film for the wood is formed on the surface of the planed log. As a result, aspen:

- not afraid of humidity;

- flammable;

- unattractive to most pests;

- sold at a low price.

Log cabins made of aspen are common: you can buy a large amount of wood, select commercial logs, and use the rest for firewood. After sanding, the aspen log house looks decent, and the steam in the aspen steam room is “softer” than in the log bathhouse made of pine.

An aspen bathhouse does not “breathe” well; the room requires proper ventilation after its intended use.

Linden is similar in roughness and softness to aspen, but is susceptible to rotting. They build linden log cabins from logs with their own hands because of the unique aroma of wood. As a last resort, only the top crowns, or only the shelves, are made linden - they do not heat up as much as those made from dense wood.

Birch is harder than aspen and linden and less prone to rotting during growth. Birch wood warms up better.

What influences the choice of log diameter?

As a standard, lumber with a size of 20-36 cm is selected for baths. Rounded logs have a 1 cm smaller diameter than unprocessed logs, which are measured together with the bark.

Factors taken into account when choosing lumber:

- Air temperature in the region in winter;

- Frequency of use of the bath;

- Log size;

- Drying technology.

Advice! For construction in central Russia, it is advisable to choose coniferous trees grown in the northern regions. This material has greater density and less moisture absorption, which, accordingly, increases the service life of the structure.

Dependence on winter temperature in the region:

| Maximum temperature in winter | Recommended log diameter, cm |

| Below -30°C | 26-36 |

| Up to -15°С | 20-25 |

*For the middle strip, the cross-section should be within 22-30 cm.

For a one-story bathhouse on a summer cottage, used exclusively in summer, logs with a diameter of 18-20 cm are sufficient. The construction does not require the construction of a powerful foundation and can be erected with one’s own hands. Such a building warms up quickly, but retains heat for a short time.

A bathhouse for year-round use is built from logs with a diameter of at least 24 cm. The foundation requires a monolithic or massive strip foundation.

Important! When using large-diameter lumber for construction, it is necessary to involve assistants or special equipment.

It is more difficult to warm up a two-story bathhouse or a building with an attic, so to reduce heat loss and increase the load-bearing capacity of the walls, they are built from logs with a diameter of at least 25 cm.

Wood drying technology affects its moisture content, which determines the degree of shrinkage of the structure, which is:

- Lumber of natural moisture, obtained by hand cutting - at least 15 cm;

- Winter forest and natural drying - no less than 4-6 cm;

- Rounded chamber-drying log - 3 cm.

This parameter must be taken into account when designing the height of the building and calculating the amount of wood required.

General description of a log house

Information. A log bathhouse is good because its walls heat up faster, breathe, and absorb moisture. It is easier to maintain the desired microclimate in a log structure.

The logs of adjacent crowns are joined along a semi-cylindrical surface 12–14 cm wide. The joints are closed from moisture, since the groove is selected from the underside of the log. Carefully caulked, they do not become bridges for heat escape. The connections of crowns in bathhouses made of chopped logs are insulated with moss, linen tow, jute tape, felt).

The log must be a construction log (for construction), and not a saw log (for creating lumber). For a bathhouse, a “twenty” log is often chosen, less often a 24-centimeter log.

Tips for purchasing and harvesting lumber

Logs must be free from insects and mechanical damage. You should choose straight trunks without curvature that have the smallest discrepancy in the diameters of the ends - up to 3 cm. For lumber longer than 3 meters, a permissible deviation of 1 cm per 1 linear meter is accepted.

Important! The complexity of the work, as well as the cost of the log house, is directly proportional to the thickness of the logs - the thicker it is, the more difficult it is to carry out construction and the more expensive it will cost.

Self-harvesting logs:

- Self-cutting of forests is carried out in winter, when the wood has a moisture content of up to 10-12% - this ensures minimal shrinkage of the building and makes it possible to use material with a smaller cross-section.

- When choosing trunks, 1 cm is added to the calculated diameter of the logs for subsequent processing.

- When using an electric or chainsaw, it must be taken into account that after using these tools, the treated surface becomes significantly tousled, as a result of which it is more susceptible to rotting. To prevent this, craftsmen recommend not to reach the marking of 5-10 mm, to cut down the wood between pre-made cross-cuts and to do the finishing hew with an axe.

- For construction, freshly cut logs are used, which are easier to process. After drying in a laid frame, such wood is less deformed and cracks.

- After removing the bark, the lumber is stacked, placing bars between the layers to organize air circulation. The logs are stored under a canopy or covered with moisture-proof material, which also protects from direct sunlight. Drying lasts two weeks, after which the felling of the log house begins. Overdried wood is difficult to process.

- To reduce cracking of logs on the facades, notches are made in each of them on the side opposite to the longitudinal groove. Their depth should be up to ¼ of the diameter of the lumber. These cuts are designed to compensate for internal stresses arising during the processes of wetting and drying under the influence of atmospheric factors, and, as a result, to prevent the occurrence of cracks.

Proper selection and harvesting of timber for construction allows you to obtain a durable, warm and aesthetically attractive bathhouse.

Protection of log walls

They place a log bathhouse on a shallow strip foundation (with a base half a meter high) or on screw piles.

To protect the logs from getting wet, the foundation is made ventilated - vents are installed on all sides (they are closed for the winter). They don’t skimp on roof overhangs. The larger the overhangs, the better. And the higher the bathhouse, the longer the overhangs will be required.

It is worth remembering that the distances between buildings are the distances between their projections on the ground.

Important! The minimum possible distances between buildings and trees are calculated by specialists and specified in regulations. Their compliance is checked by public services and local authorities. The aspect of fire safety has rightly received special attention. The most important thing is to maintain the distances between wooden structures (or if at least one of them is wooden).

There are distance standards that apply specifically to bathhouses, regardless of the material (for example, from a bathhouse to a poultry house). The maximum of all values must be observed.

A log bathhouse is treated with an antiseptic and fire retardant. The floor, the joists for its flooring, and the lower crown - under the floor - are especially carefully protected.

After using the bathhouse for its intended purpose, it is well ventilated.

Shrinkage

When freshly cut, wood contains a significant amount of moisture. Free moisture is found in wood cavities. Leaving the material, it does not affect its shape and linear dimensions. Bound moisture is another matter - that which is present in the thickness of the cell membranes. Its content in wood reaches up to 30% and removal entails warping, cracking and shrinkage (reduction in linear dimensions) of the timber.

During construction, you will have to add 5–7 cm for each meter of height to the expected height of the bathhouse from the log house. The allowance for sedimentary deformation is also included in the height of door and window openings. The gap above the box is temporarily filled with insulation, and after two years it is caulked or covered with an additional element (if the shrinkage was less than expected).

Installation of internal partitions (non-shrinkable) and cladding are timely only one to two years after the construction of the log bathhouse for shrinkage from logs. The period of “rest” depends on the size of the log house and the weather.

For a small bathhouse, 10–11 months of settling may be enough - if construction began after the autumn rains and the summer was dry.

Attention! The gap between the partition and the ceiling is required even after drying, at least 1-2 centimeters.

Horizontal shrinkage - along the wood fibers - is only a few tenths of a percent, so when building a log bathhouse, no attention is paid to lengthwise shrinkage.

A bathhouse can be built from brick, but many people see a log house as a “historically correct” solution.

If you say the word “bathhouse”, then most likely an image of a log house will appear.

In order for log houses and bathhouses to serve for a long time, the work of professional carpenters, assemblers, roofers, healthy timber and their competent processing are needed. Proper use will prevent early cracking and twisting of the wood.