Date of publication: April 16, 2020

Stove and fireplace equipment is a source of not only comfort, coziness and warmth, but also a fire hazard. The risk of fire is associated with the use of flammable fuels, as well as high temperatures of internal and external surfaces. It is important to understand that proper installation of heating equipment and components eliminates the risk of fire. It is always possible to make a heating device and chimney absolutely safe for use if you follow the established rules, fire safety standards, and follow all recommendations for installation and insulation of equipment.

This article will discuss the use of mineralite, an insulating material that is used to protect surfaces from the effects of heated areas of fireplaces and chimneys.

Why is it necessary to insulate surfaces near the fire?

The surface of many home and sauna stoves can become very hot during use and heating. Temperatures can rise to 400 degrees Celsius, sometimes even higher. An additional load on the surfaces surrounding the heating device is infrared radiation, which also affects heating. The vast majority of bathhouses and residential buildings are built of wood, or the walls are covered with wooden boards for interior purposes. Exposure to high temperatures and infrared radiation from heating stoves, especially sauna stoves, can lead to fire in wooden areas near the fireplace. Therefore, any fire safety rules dictate the need for protection - insulation of such areas with non-combustible materials. Non-flammable, such insulating surfaces will protect wooden areas from heating, charring, and the risk of fire.

Basic requirements for refractory materials

There are at least a dozen points and places where heat-resistant protection is required in a modern bathhouse. The shortest list for installing fireproof and fireproof cladding looks something like this:

- Furnace base and box;

- The walls of the bathhouse around the stove or heater;

- Chimney, passage unit through the ceiling;

- An area on the floor in front of the ash pan and the furnace firebox;

- Screens and tunnels in wooden walls, if the stove in the bathhouse is loaded from an adjacent room or even from the street;

- Elements for fastening the chimney inside the bathhouse.

In any case, the materials used for fire protection equipment must have fire-resistant qualities and withstand prolonged heating without changing their physical and chemical characteristics. Heat-resistant bath material used to protect wooden walls from infrared radiation must withstand heating up to 400°C without releasing decomposition products and without interacting with oxygen and water vapor in the air.

Heat-resistant mineral fiber material

Heat-resistant materials in the bathhouse are used to backfill the thermal insulation of the chimney and arrange screens around the stove body. With good heating, the screen and the outer surface of the stove can heat up to almost 1000°C.

Fireproof silicon fiber mat

The third type, fireproof materials for a bath made of sintered metal oxides, are used for laying out parts and structural elements of the furnace, as well as for the construction of floor heating, if part of the flue gases in the building are discharged through channels made of refractory clay in the underground.

Advice! Refractory bricks, canvas or granular backfill cannot be selected, as they say, by eye. Most of them have their own shelf life, which depends on storage and operating conditions.

Effective methods of protection

Among the most effective methods of protection against exposure to high temperatures and heat are screens made of:

- mineral wool

- basalt wool

- foam glass

- glass wool

- vermiculite

- drywall

- minerite

- of stainless steel

Using the materials listed above, as a rule, so-called screens are created - surfaces of a certain width, length and thickness, installed in close proximity to the heating product and sections of the chimney.

Thermal insulation materials for fireplaces

04/12/2016 4819 Pechnik (Moscow) The full functioning of the fireplace, as a rule, depends not only on what type of heating device you choose for your cozy home, but also on the accuracy of installation of thermal insulation and correctly selected thermal insulation materials. Among other things, well-made thermal insulation is considered a reliable guarantee of fire safety, which is why the price of such materials and the installation procedure often exceeds the cost of the fireplace itself.

It must be said that this indicator is considered one of the most significant characteristics of insulating materials. Moreover, when heating sources, the thermal insulation material behaves as follows: the lower the thermal conductivity, the greater its ability to interfere with heat transfer. Thus, thermal conductivity is considered one of the most significant criteria for purchasing thermal insulation materials. We will consider the main issues that should be read when selecting and purchasing thermal insulation materials today in our article.

Content:

1. Basalt wool 2. Kaolin wool 3. Superizol 4. Vermiculite boards 5. Silica wool Supersil 6. Minerit and analogues 7. Knauf-supersheet (GVL) 8. Other thermal insulation materials

Basalt wool

When choosing this type of material, it is best to give preference to foreign European manufacturers.

Material from abroad is considered to be of higher quality and meets the necessary standards required by the construction industry. Basalt wool, also called “stone” wool, is characterized by a fibrous structure. For the manufacture of the material, basalt, metallurgical slag, and their mixtures are used.

An important component of the material is considered to be a binding substance (this can be bitumen, synthetic substances and bentonite clays). Such substances help in bonding cotton wool fibers to each other. Basalt wool is marketed in the form of slabs (“mats”), rolls (“cylinders”) or in bags. In the latter case, no binder is used.

The main advantage of the main characteristics of basalt wool is considered to be excellent heat resistance, since the material does not ignite or melt, is resistant to rotting, and has good water-repellent properties. If we highlight the disadvantages of stone wool, it should be said separately that if the temperature reaches six hundred to seven hundred degrees Celsius, then the connecting element in the structure of the wool will collapse, resulting in a change in the properties of the heat-insulating material itself. Among other things, the disadvantages include the high price category of wool, the presence of seams in installation areas, dust accumulation during the assembly process and a fairly large vapor permeability, and this limits the utility of the material.

Basalt wool is widely used in various fields, but it is mainly used for the construction of buildings, for thermal insulation of pipelines, technical devices, floating floors, installation of chimney systems through ceilings, thermal insulation of ceilings and walls, assembly of insulated sandwiches and production of sandwich panels .

Kaolin wool

Kaolin wool, also called ceramic wool, is considered an alternative to glass wool. Kaolin wool is a heat-insulating type of material that is made from technical alumina. Currently, ceramic wool is produced in the form of rolls, slabs and lump wool. The fibers that make up ceramic wool are connected to each other with all kinds of binders: refractory clay, aluminous cement, silicate glass, organosilicon substances.

The material is highly popular among buyers due to its increased fire resistance, as it can withstand temperatures from one thousand one hundred to one thousand two hundred and fifty degrees Celsius, provided that zirconium or alumina fibers are used for production, their temperature criterion can increase to one thousand four hundred - thousand six hundred degrees Celsius. In addition to the listed indicators, it is worth noting low thermal conductivity, high sound insulation, water resistance, electrical insulation, and the fiber density is one hundred and thirty kilograms per cubic meter. The material is blown, which is one of its disadvantages; it is not environmentally friendly.

Kaolin wool is used in different directions, it can be the production of plates, sealing inserts; reliable insulation of building vaults, ceilings, use as a specialized lining of fireplaces, for the release of insulated chimneys, insulation of chimneys through wooden ceilings, and also as a backfill thermal insulation material.

Superizol

Superizol is a lightweight material with a porous structure, characterized by excellent thermal insulation properties. Such high levels can be achieved due to the presence of small pores inside superisol, which help withstand temperatures within two hundred to one thousand one hundred degrees Celsius. The substance is made on the basis of calcium silicate. It is worth noting that despite the rather high price category, the material is in demand among Russian buyers. Superizol is distinguished by its lightness, so one sheet of material weighs only eight kilograms; among other things, it is environmentally friendly and dense. At the same time, when buying superisol, you should not forget that it does not absorb moisture well, but some foreign companies are already offering it with increased moisture protection.

Superizol is perfect for thermal insulation of various types of fireplaces. But usually it is used for insulating ceilings, conducting chimney systems through the roof of a building, as well as for installing fireproof fireplace trims, installing high-power fireplaces and making decorative fireplace boxes. Note that the material today is considered one of the most suitable options for the construction of hearths, which allows its use in the most difficult joints.

Vermiculite boards

Vermiculite slabs are produced using special minerals from the mica group, distinguished by their layered structure, as well as using binders such as bitumen and silicate glass.

Vermiculite boards are distinguished by their environmental friendliness, since they do not contain organic fibers or asbestos in their array, and therefore are characterized by an increased level of heat resistance and thermal insulation, that is, they can withstand temperatures from fifty to one thousand two hundred degrees. The material has a long service life, is simply cut and easily glued.

To summarize, we can confidently say that the material is well suited for insulation. However, due to the fact that the slabs have a high density, it is not suitable for the construction of lightweight structures.

In addition, it should be noted that vermiculite is a fragile substance, therefore, if you are not careful, it breaks and crumbles. Typically, slabs are used for fireproof lining and thermal insulation of fireplaces and chimney systems, as well as increasing the fire resistance of load-bearing structures.

Silica wool Supersil

Supersil silica wool stands out among the mass of mineral wool insulation.

The characteristics of this heat insulator are quite high, including the environmental friendliness of the material, which does not emit harmful substances into the atmosphere of the building during heating. Supersil has increased fire resistance, reaching one thousand two hundred degrees, excellent heat and sound insulation. Cotton wool does not contain carcinogens or fibrous inclusions. The material is available for sale in the form of mats and is used for insulating chimneys, wooden walls, fireplace inserts, air ducts, exhaust pipes and heat-insulating ducts.

Minerit and analogues

Minerit slabs are produced on the basis of a special fiber cement substance, a fibrous substance, and also a lime filler. The material has a durable surface and good density. Plates of this type do not absorb moisture, do not rot, and are characterized by high levels of sound insulation, strength and thermal insulation. The heat resistance of the substance varies between eighty and one hundred degrees Celsius. The slabs are simply easy to decorate and maintain; when heated, they do not emit harmful volatile substances.

Knauf-superlist (GVL)

The Knauf supersheet material (GVL) is made from a mixture of pressed fibers made from fluffed waste paper and gypsum (as a binder). Supersheet is distinguished by its low price category, while in combination with superisol / mineral wool, the substance can provide increased thermal insulation and a strong frame for installing fireproof units. Supersheet is an environmentally friendly material and has a good level of sound and heat insulation.

Since gypsum fiber board sheets can be painted, boxes are often made from this material. Among other things, Knauf supersheet is used for cladding frame devices, as fire protection for installations, partitions, and thermal insulation of wooden floors and walls in the fireplace area.

Other thermal insulation materials

Let us note some more materials that are used for thermal insulation.

Other thermal insulation materials

- Solid bricks are characterized by excellent thermal insulation, which also prevents fire. Typically, this type of material is used where the temperature mark does not reach the firing mark;

- Hollow bricks reduce heat exchange between the atmosphere and the internal space of the fireplace. This phenomenon occurs due to heating devices specially formed during the construction of internal air voids;

- Cement-sand bricks are characterized by high thermal inertia, which allows for stable thermal protection;

- Diatomite foam bricks can provide high thermal insulation properties at temperatures reaching nine hundred degrees Celsius.

It is important to know that when selecting a thermal insulation material, you must, first of all, determine in advance the goal being pursued. If you need to increase the productivity of the fireplace, it is more advisable to use the bricks that we have listed. Provided that as a result of the work the fire safety of the entire heating system should increase, preference should be given to mineral wool insulation, as well as superisol and similar materials.

Video

What is minerite?

It is an insulating material in the form of a cement-fiber panel (slab). It is often used for finishing work on building facades. It is heat and fire resistant, therefore it is often used in bathhouses, steam rooms and residential areas for wall insulation. The composition includes cellulose (about 10%), cement (about 60%) and mineral filler components (about 30%). The composition may vary depending on the manufacturer. Plates of material come in various sizes and colors. On top of mineralite slabs it is possible to carry out decorative finishing with other materials. It is characterized by high quality, therefore it is actively used during construction work.

Minerite is used:

- during the construction of facilities with increased fire safety requirements

- for decorative cladding of buildings

- for creating loggias and covering balconies

- for installation of ventilation facades

- as a thermal insulation material for fireplaces and stoves

Asbestos in the bathhouse

If you are planning to build a bathhouse, then during construction you are probably planning to use the material that we will talk about in our article. However, during installation the question may arise as to whether asbestos is harmful to health when heated. Let's talk about this, the properties of the construction product and its analogues.

Where is it used

If you study the question of what asbestos is needed for, you will notice that it is used in various fields, including industrial production and construction.

Is it harmful to health?

There is a popular belief that building materials are extremely dangerous to human health due to harmful fumes. There is another version that speaks of its safety, which has not yet been definitely confirmed. Let's look at why asbestos is dangerous.

When heated, asbestos does not cause any more harm than when it crashes. Experts do not recommend using this mineral for fireplaces, but this is not due to heating. The use of material in fireplaces means the use of carcinogenic material in a residential area in an open form. The risk of asbestos dust release increases significantly.

Is asbestos harmful to health? 6 facts

Is asbestos or asbestos dust harmful to health? This topic has been exciting the minds of ordinary citizens for decades. Should the roof of a country house be covered if it is covered with slate and some of the world and Russian facts.

This material brings together reviews backed by years of research and hard facts regarding slate and asbestos.

Are there toxic building materials and is asbestos-cement slate one of them?

There is no official list of toxic building materials in the Russian Federation. Nevertheless, the building materials market is under control, and a prerequisite for a particular product to hit the shelf is the presence of a hygienic certificate of product conformity. This document is issued by Rospotrebnadzor services after checking the compliance of products with established hygienic standards and regulatory and technical documentation approved by Rosstandart. Thus, at least two government agencies monitor the safety of building materials.

If we talk about international experience, the use of hazardous chemicals and pesticides is regulated by a special international agreement - the Rotterdam Convention. But even in this document, chrysotile asbestos (this is the form of the mineral used today in industry and production) is not subject to a ban and is not called toxic.

Is asbestos harmful to health?

This paragraph should begin with the fact that asbestos is different from asbestos. In many ways, it was the differences in the physical and chemical properties of different forms of the mineral that became the basis for whipping up unfounded fears among the population.

- Thus, chrysotile (white) asbestos does not pose a health threat when used in a controlled manner. Even if it enters the body, its fibers dissolve and are excreted within a few days.

- But amphibole (blue) asbestos is resistant to acidic environments and has a long fiber length. Once in the lungs, its particles remain in the body for a long time and can cause diseases.

However, in Russia and the CIS countries, amphibole asbestos has never been used for civilian purposes. So even the old slate that may cover your country house does not pose a threat.

An international group of biological researchers from Switzerland, Great Britain, Germany and the USA in 1999–2010 studied the duration of elimination of various fibers from the body. According to the research results, the period of dissolution and removal of chrysotile asbestos fibers was 0.3–11 days.

Russian-made slate is resistant to alkaline environments, but decomposes in acids with the formation of amorphous silica. This is what distinguishes it from prohibited asbestos.

Asbestos is used in Russia for production

- paper, cardboard,

- filters,

- tarpaulin,

- fire-resistant fabrics from which suits for firefighters are sewn,

- asbestos cement pipes,

- asbestos-cement corrugated and flat sheets,

- asbestos cords and sheets, much more.

Main characteristics

Minerite slabs have a wide range of applications. This is largely due to a certain set of qualities – universal and convenient. So, among the characteristics of this material are:

- A light weight

- High strength

- Environmental friendliness

- Sound absorption

- No emissions of harmful substances when heated

- Increased resistance to various loads, including temperature changes

- Moisture resistance, waterproofing properties

Light weight, environmental friendliness, non-flammability, moisture resistance and resistance to temperature changes and influences have made this material in demand for creating protective screens in bathhouses, saunas, and country houses when using solid fuel heating devices.

Rules for installing mineralite panels to the wall

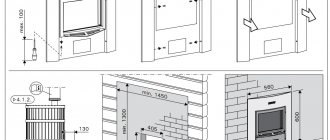

There are various ways of attaching slabs to wooden walls next to the furnace equipment:

- If the stove is very far from the wall, the insulation can be attached directly to the wall

- If the stove is about 50 cm away from the wall, the mineralite should be mounted on the wall with a gap of about 3 cm. Ceramic bushings should be installed in the gap itself, which should be located between the wall and the insulation board

- If the stove is located quite close to the wall of the building, it is recommended to install several insulation panels at once. One sheet can be installed flush against the wall, the second sheet can be installed with a gap, the distance of which is determined by the length of the bushings

Important! When placing a mineralite panel on the wall of a wooden structure, especially a bathhouse, it is recommended to leave about 30 mm of clearance between the bottom of the panel and the floor. This action will ensure free circulation of oxygen, which will prevent strong heating of the wall surface.

For greater reliability, it is recommended to install special supports between the bottom of the slab and the floor, which can be removed after shrinkage occurs. After removing the supports, tighten the mounting screws completely. The floor directly under the sauna heater-stove should also be reliably insulated. To do this, you need to place a sheet of mineralite under the hearth, which can be fixed with self-tapping screws. Deflection and deformation of the insulation under the stove can only be avoided if the floor at the installation site is level.

Important! It is necessary to maintain safe distances between the mineralite sheets and the stove equipment, including the chimney: it must be at least ten centimeters.

Protective screens around or near the oven

Protective screens are insulation panels that cover the side surfaces of the furnace to reduce the intensity of thermal radiation. They are divided into two types: metal and brick.

Metal screens (cast iron or steel sheets). Such shields are installed around the stove at a distance of 1-5 cm from the walls of the firebox. Front and side models are available. They allow you to reduce the temperature of external metal surfaces to 100 degrees Celsius and thereby reduce the fireproof distance to 50 cm. Moreover, the total distance from the firebox to the wall will be from 51 to 55 cm. As for installation, metal screens are easily attached to the floor using bolts

Brick screens. They can cover all the side surfaces of the stove, thus representing its outer casing. In another case, this shield is a wall that separates the stove and the flammable surface. The use of brick screens allows you to reduce the distance from the stove to the wooden wall to 22-42 cm.

Solid fireclay bricks are used to lay the protective screen. Clay or cement mortar acts as a binder. It is preferable to do the masonry in half a brick (thickness 120 mm). Moreover, small holes must be left in the lower part of the shield to ensure air convection between the stove and the brick wall. The walls of the protective screen must end at least 20 cm above the top surface of the oven. In some cases, the masonry can reach the very ceiling. The brick screen does not need to be installed too close to the walls of the furnace. The optimal distance in this case should be 5-15 cm.

Installation of slabs on a wooden wall can be roughly divided into the following stages:

- Installation of brackets on a wall requiring insulation (no longer than the thickness of the insulation board itself)

- Laying preliminary insulation (for example, basalt wool) with dowel fastening - umbrellas

- Installation of a frame - metal profiles placed vertically and horizontally to obtain a conditional rectangle, square, or other chosen shape

- The insulating material itself is mounted directly onto the resulting frame. For slab thicknesses up to 15 mm, you can use simple self-tapping screws for fastening. When the slab thickness is more than 15 mm, clamps are used.

- The joints should be carefully treated with heat-resistant sealant

- If there is a corner, it is recommended to cover it with a metal profile

Tip: it is recommended to use a special sealing tape between the frame and the mineralite in cases where self-tapping screws are used for installation.

Professional installation of bath equipment and insulation

Any furnace equipment is a source of fire hazard, so the installation of fires and installation of insulating materials must be carried out by professionals. Insulating materials vary, and not all are suitable for contact with very hot surfaces. Even mineralite, although it is a fire-resistant material, with increased exposure to high temperatures and fire can begin to melt or char, creating a risk of fire. Minerite is suitable for insulation purposes, but it should be installed with knowledge of safe distances, maximum operating temperatures, equipment heating temperatures, and other nuances. This material is often installed together with other insulation solutions to achieve the highest level of safety.

Our specialists have impressive work experience and unique knowledge, which is recommended for anyone who is organizing their bathhouse, home, or installing a heating product. The company’s specialists will prepare an individual plan for installing insulation and carry out a range of installation works with the selected insulation material within a prompt time frame.

Attention! Only professional installation of mineralite and other insulating solutions can be a good guarantee of fire safety, health and property.