For any admirer of good steam, the use of a stainless steel tank for a bath is considered an unrecognized standard, an indicator of a high-class heater and steam room in general. In addition, this concerns the appearance of the container and the safety of using the stove. The only worthy competitor to stainless steel water tanks are copper and brass soldered structures. They are rarely found on sale, at exorbitant prices, so most owners make do with alloy steel containers.

Do you need a stainless steel hot water tank in a bathhouse?

The answer to the question is not as obvious as it might seem at first glance. Most owners of steam rooms, before buying stainless steel water tanks for a bath, doubted for a long time about the correctness of their choice, and it’s not even the high price of a stainless steel tank, they were frightened by the shortcomings that few people know about.

Everyone knows about the benefits of using stainless steel for baths:

- The tank does not rot or rust, as in the case of using conventional ferrous metal;

- Remarkable appearance of polished steel, decorative qualities;

- Easy care and maintenance of the stainless steel tank. The body can be washed and cleaned with a brush, detergents and even phosphoric acid;

- A container made of alloy steel is not afraid of thermal and mechanical shocks, mechanical load, and there are no chips on the surface of the coating, like enameled products.

For your information!

Stainless steel is an extremely capricious and inconvenient material. It is especially difficult to weld a tank for a sauna stove from thin-sheet stainless steel blanks. Therefore, a good alloy steel cylinder for hot water is usually ordered from companies that have good equipment, and most importantly, high-quality welders.

It is clear that a container for hot water in a bathhouse is not cheap, more expensive than the 70-100 dollars for which you can buy a stainless steel tank in any salon that sells equipment for bathhouses and stoves. Of course, this does not mean that you only need to make a stainless steel tank for a bathhouse with your own hands; far from it, you can buy an excellent model made of alloy or stainless steel with additional functions that will last for several decades without a single comment. You just need to try to choose the right quality product.

Choosing a water tank for the bath

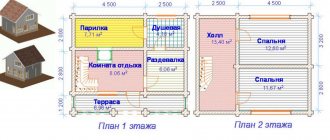

If you decide to build a bathhouse on your site, you have to solve many problems. Firstly, you should consider the external and internal appearance of the future structure. And if earlier the whole design, as a rule, boiled down to the construction of the simplest log “chicken coop” with a combined sink and steam room and a tiny dressing room, now luxury baths with many separate rooms are being built. Some even manage to equip them with a mini-pool. Secondly, the choice of materials and components. The bathhouse will have to be equipped with all the necessary things and, among other things, a water tank will have to be placed in it: separately for cold and for hot. As it turns out, today there are many options, and choosing containers is not so easy.

Hot water tank

There are quite a lot of requirements for a hot water tank. It must be resistant to corrosion, temperature changes and retain heat well. And naturally, it should be a metal water tank. All that remains is to find out what metal it is made of. Hot water containers are made of stainless steel or cast iron. Theoretically, a welded square tank made of sheet material can also be installed, but it will rust and leak much faster. At first glance, a stainless steel container seems preferable: it is lighter (therefore, it will be easier to install), heats up quickly and is not subject to corrosion. However, such a water tank will cool down faster. In addition, thin-sheet containers can become deformed over time. Nothing like this can happen with a cast iron product, but it will be much more difficult to install.

Now let's talk about the form. In principle, any will do, but experts do not recommend purchasing square tanks. This will inevitably lead to the emergence of zones with different temperatures, which lead to expansion and deformation of the metal. When choosing a shape, you should be guided by the method of heating water (direct or indirect), as well as the installation location. There can be three of them: directly above the firebox (traditional option), a remote tank with a heat exchange system through copper or brass pipes, or directly on the chimney (“samovar” tank). It is unknown which method is preferable, but recently the second and third options are increasingly being chosen. This allows you to increase the space in the bathhouse due to the fact that the water tank is moved outside of it.

The dimensions of the container should be calculated based on the fact that each person needs approximately 10-12 liters of boiling water. However, it is not recommended to install a hot water tank less than 50 and more than 100 liters.

Cold water tank

In principle, such a container can be made of any material: either metal or plastic. However, there is one caveat: plastic containers should not be placed near the heating zone or in the steam room - they can become deformed due to high temperature. And some types of plastics, when the temperature rises, begin to release harmful substances, sometimes with an unpleasant odor. Connoisseurs can be advised to return to old Russian traditions: use a wooden barrel or tub as a water tank. Such containers are not only functional, but also create a special atmosphere and are an excellent addition to the interior.

fb.ru>

Construction of stainless steel tanks for a bath, what to look for

In a modern steam room, several standard options for containers for obtaining boiling water are used. The design of stainless steel water tanks depends on the method of heat extraction from the stove, so the container is selected, first of all, taking into account the structural features of the chimney, installation location and the need for boiling water for the washing department.

The salon most often offers to buy one of three models:

- The most popular and safest is a mounted tank, made of thin-walled stainless steel, most often in the shape of a “suitcase”. To heat water, it is mounted on one of the side walls of the stove;

- An attached tank, or samovar, is a cylindrical container, inside of which a section of the stove chimney pipe is embedded. Heat for water is removed from combustion products and flue gases through the walls. Available in a variety of stainless steel grades;

- A wall-mounted or wall-mounted tank, heat is removed from the stove using a coil built into the firebox. The stainless steel container is located a short distance from the heater, so this model is considered the safest.

If in the first two cases the use of stainless steel is justified by the high temperature of the hot furnace walls, then a hanging stainless steel tank for a bathhouse is considered to be an element of room decor.

Is it worth buying a stainless steel hanging tank?

According to many experts, the beautiful, shiny body of the container does not experience any stress, either thermal or mechanical, therefore, thanks to the alloyed metal of the walls, it can last an unlimited amount of time.

If, when purchasing, you have the opportunity to choose the type and material of the container, then it is best to opt for a hanging tank made of stainless steel. Any containers made of ferrous metal, even with galvanization and a protective layer of paint, rot within 2-3 years of operation. As an illustration, mention may be made of electric boilers used for hot water in apartments.

The walls of a low-carbon mild steel tank, even if coated with a layer of ceramic enamel, are still subject to pitting due to the simultaneous action of water, high temperature and atmospheric oxygen. The service life of this container is extended thanks to built-in magnesium anodes. A similar situation arises with hot water tanks in the bathhouse. The production of stainless steel tanks, especially large ones, requires serious expenses, so they are not cheap, but in any case, the money invested in the purchase is worth it.

For your information! Stainless steel has very poor ductility; even a small amount of water in the tank, left in a bathhouse at the summer cottage in winter, can cause cracks in the welds.

Stainless steel tanks are actively used in baths, steam rooms, and saunas. We create high-quality tanks that will last for a long time. At the same time, we offer clients an individual approach, the opportunity to create products of any size.

The use of stainless steel tanks

A stainless steel tank is used to create a water heating system in a bathhouse. In this case, heating can be carried out in various ways - through a gas burner, boiler, central water supply. You can use a proven, albeit outdated, method: simply heat water on the stove. Almost any stove can be supplemented with a special hanging container. This is why you should use a stainless steel tank. We create a variety of tanks that have different volumes. In this case, not only stainless steel is used, but also other materials. The dimensions and configuration of the container can be either standard or non-standard.

We have been designing, manufacturing, and installing metal structures since 2005. During this time, we have accumulated enormous experience; we have designed, manufactured and installed thousands of metal structures of various kinds!

If we consider the characteristics of the metal that we use to create tanks, then the following material thickness can be used:

- 0.8mm,

- 1.0 mm,

- 1.5 mm,

- 2.0 mm,

- 3.0 mm.

Steel grades can be as follows:

- AISI 304 (08x18n10),

- AISI 321 (12x18n10t),

- AISI 430 (08x17),

- AISI 201 (12x15g9nd),

- AISI 409 (08x13).

Features of stainless steel

Tanks are created from a variety of materials, but stainless steel is recognized as the best solution. By displacement, such tanks can be:

- 20l,

- 30l,

- 50l,

- 100l,

- 200l.

Don’t be upset if you are not satisfied with this volume, we are ready to create containers of any size. Such products are perfect for both hot and cold water. The material is famous for its durability, resistance to physical influences, and corrosion. It is worth noting the small thickness of the walls, which affects the overall mass. Light weight is a huge advantage over analogues. Also, the low weight makes transportation and installation of the tank easier. There is no special load on the foundation.

Stainless steel itself is considered a plastic and aesthetic material, which makes it possible to create containers of any size. Therefore, you can be sure that our company will take into account all your wishes when ordering a tank.

About the advantages

It is necessary to consider the main advantages of such tanks:

- The material is not afraid of moisture, the products will last for as long as possible. Reliability and performance characteristics do not change when exposed to water. The bathhouse experiences high humidity conditions that are considered difficult for any other material.

- During use of the product, you will notice that it does not deform. Experts say that only minor deformation is possible.

- Excellent thermal conductivity ensures that the water in the container will heat up as quickly as possible. This fact will make it possible to significantly reduce water heating costs. Such tanks quickly release heat into the bathhouse. To eliminate this drawback, appropriate insulation can be used.

- Affordable price, our company strives to offer the most favorable conditions. Interest in stainless steel is increasing every year, making it more accessible.

Where to buy a tank?

If there is a need to select a stainless steel tank, then it is worth considering not only standard models; you can give preference to models that are created to order. You can always contact our company’s specialists who will help you choose the appropriate container. We use exclusively high-quality material that has proven itself on the positive side. Our material is highly reliable, has a long service life, and does not require additional maintenance.

Our company offers to create a variety of stainless steel products. These can be tanks of different shapes:

- oval,

- rectangular,

- square,

- with heating element.

We try to work as quickly as possible, providing orders on time. If you have any questions, you should contact our specialists directly. We will be happy to answer all your questions, help you place an order, and also choose the appropriate container parameters.

Tank reliability

In particular, it is worth highlighting the reliability of the products being created. Stainless steel prevents corrosion, so you can count on the product to last for a long time. Products such as bunkers are similar to tanks, only the latter are used to accumulate bulk substances. Making a tank may be required for a variety of projects.

Corrosion resistance is the main advantage due to which the products have become so popular. You don’t have to worry that the tank will rust in the near future. It will serve you for a long time. Do not limit the scope of application only to bath rooms. In addition to a bath, such a tank is used as:

- Tanks for storing drinking water for production needs.

- Household tanks intended for cold and hot water.

- Tanks for fuel.

Our products are characterized as simple, reliable and high quality. Such stainless steel products have attractive external qualities. After all, there will be no corrosion not only inside the product, but also outside. In this case, the containers will not have to be treated with any protective compounds. No maintenance is a significant advantage. The shelf life of the container is not limited.

Do we choose for ourselves?

When choosing a tank for your own purposes, you should give preference to containers that are not overly large. Small containers are suitable for individuals. A large tank is in demand among manufacturing enterprises. At the same time, a large product must be especially durable. But with us you can order containers of any volume. When choosing, consider the following points:

- It is important to think about such things as contact with food or drinking water.

- Prioritize additional process load. Often a heated tank is installed in bathhouses.

- Fire safety is also important; the degree of fire danger directly depends on the storage of flammable and flammable liquids.

- When choosing, do not forget that the geometric shape of the product can vary significantly. Choose the option that makes the most sense.

- Features of fasteners, it is important that the fastenings are as reliable as possible.

- Pipeline equipment and fittings necessary for use.

About the tank design

Any container is produced only after the customer has explained exactly what he needs. You need to decide on the design. The procedure for creating a tank:

- Cutting stainless steel blanks.

- Preparing the workpiece for the assembly process. During this process, edge processing, folding where necessary, drilling, and creating the necessary holes are carried out.

- Additional structures are assembled, these could be chimney pipes, for example.

- Welding tank assembly.

- Complementing the design with the necessary fittings.

- Checking the strength and tightness of connections. If the container has a significant volume, then it should be checked more carefully. The same applies to those tanks that are created for fuel. They can be used in transport, therefore they require special tightness.

When purchasing products from us, you can be sure of their quality. We sell products from the best materials that have been carefully selected. At the same time, you will be pleased with the affordable cost of the products, due to which you can save a lot.

Metal structures made to measure from ! To place an order call! Or write to email - [email protected]

Features of the operation of mounted tanks

Cylindrical containers, or “samovars,” operate under the most severe conditions of high temperature. The chimney wall can heat up to 500-600°C. The metal of the walls burns into scale, as they say, to holes. In this case, using a stainless steel pipe for a sauna tank can be considered the best option.

The lower part of the tank is a metal glass with which the container is placed on the flange of the heater. This is the most loaded part of the structure. In addition to the high temperature of the walls, the weight of the tank itself and the water supply presses on the lower part of the stainless steel body. Plus, the hot glass gets the most boiling water and steam from the stones. In such conditions, ferrous metal burns out into rusty dust within a few months, so when choosing a specific tank model, pay attention to the bottom of the container; the thickness of the metal in this place should be at least 1.5 mm.

When choosing and inspecting stainless steel tanks for a bathhouse stove, it is imperative to pay attention to the quality of the welds on the bottom of the tank. The bottom part of the container of tanks from well-known Finnish and Swedish manufacturers is made of thicker metal or reinforced with stiffeners. In addition, the welding seams at the junction of the inner pipe, bottom and outer walls must be smooth and continuous, this indicates high quality welding.

Attention! Stoves and heaters in the bathhouse, equipped with mounted stainless steel tanks, cannot be heated without water.

If a container for hot water made of non-alloy steel is often deliberately not filled with water until the heater is ignited and completely lit, in order to speed up the process of gaining temperature, then in the case of stainless steel, such a “trick” can result in a burst wall or a dented bottom. Alloy steel has low thermal conductivity and a high coefficient of thermal expansion, therefore, during “dry” heating, severe stresses arise in the stainless steel glass and bottom part.

If a similar situation occurs, then you cannot pour water into an alloy steel container; you need to turn off the firebox and allow the stainless steel tank to cool to at least 50-60°C.

Water bath containers: how not to make a mistake when choosing

The main elements of a bathhouse, if you intend to get maximum pleasure from the process, are a stove and a water tank. To ensure that everything related to the water tank in the bathhouse is done correctly, we will dwell on the main issues that may arise when setting up a steam room yourself.

The main questions that arise when choosing an element such as a tank for a bath are:

- Its parameters

- Which type should I choose: remote, built into the oven, on a pipe?

- What should it be made of: steel, stainless steel, cast iron?

Tank parameters

If you are used to doing everything with your own hands, then, of course, you will try to make a sauna tank yourself.

However, you should first think about what type of container is suitable for your steam room, what principle of water heating will be used, what material to make the tank from, so that later you do not have to invest money in re-equipment again. So, you must decide whether you will heat the stove in a sauna or simply heat the water using the heating element built into the tank. And in order to understand what is more profitable for you, heating a stove or using an electrically heated container, estimate how many people will steam at the same time. Another important factor is the volume of water that needs to be heated and the allowable time for heating to the required temperature.

Let’s say that if you want to steam alone, a person is unlikely to need more than fifty liters of hot water. But to please the whole family or group of friends, you need to install a water heating tank with a capacity of seventy or more liters.

Also pay attention to the thickness of the tank wall. It is this parameter that determines how evenly the water in it will be heated and how long its temperature will remain. But remember that the thickness of the tank wall directly affects its price and weight.

In any case, a stainless steel bath tank with a volume of up to fifty liters should have a wall thickness of 0.8-1 mm. For containers of larger volume, a wall thickness of 1.5 mm is desirable.

Advice from the master!

And do not forget that no matter what material the tank in the bathhouse is made of, you need to equip it with the optimal number of outlets and make an inlet for water. When choosing a tank in a store, ordering it in a workshop, or preparing to brew a canister for a sauna yourself, take into account all the parameters mentioned, and the process of washing in a sauna will be a complete pleasure for you.

Return to content

Selecting the type of container

It is known that when choosing a tank for a bath, you will need to compare the parameters of the main three types of tanks:

- Traditional, built-in oven

- Remote

- On the pipe

Just a few decades ago, no one would have doubted that the best option for a sauna tank was the one built into the stove. That is, the bottom of the boiler is completely placed in the upper part of the firebox, and, being in the hottest part, has the ability to accumulate the greatest amount of heat to heat and maintain the temperature of the water.

In the case of a built-in one, there is direct contact of the flame with the walls and bottom of the tank and the design of the container does not depend on the chosen method of smoke removal. You can take water from the tank built into the stove either with a ladle through an openable lid, or through a tap, where water from the tank flows by gravity.

Equipping the furnace with heat exchangers connected to the container with copper tubes allows you not to tie it to the location of the furnace, providing the opportunity to install it in any convenient place. In addition, under the influence of the natural laws of physics and following the convection principle, cold water will descend through the tubes down into the heat exchanger located in the furnace, and, having heated up to the desired temperature, return to the container. The remote tank in the bathhouse can be placed in the washing room, where the main hot water is collected.

Of course, it is important that the water in the tank not only heats up quickly, but also that the required water temperature is constantly maintained with minimal energy consumption. For this purpose, many people prefer to place the sauna tank on a pipe that serves to remove smoke from the stove. The smoke released during the combustion process can reach a temperature of 500°C and, of course, the water in the tank located around the pipe heats up quite quickly.

The above means that when planning to place the tank on a pipe, you can choose containers of a fairly large volume, since the heating element can be used along its entire length - from the stove to the ceiling. In this case, the water will heat up not only quickly, but also evenly. This happens because by making an elliptical tank, you can heat even a large volume quickly, since the pipe in this case, passing through the center of the tank, is a kind of heat exchanger with a significant working heat exchange area.

In addition, when placing the tank on a pipe, the unpleasant situation with the possibility of carbon monoxide entering the room is eliminated, since the canister serves as a kind of fuse in the event of smoke leaks.

If the type of tank is selected, it remains to decide on the type of fuel that will be used to heat the stove. In modern conditions, wood-burning stoves are increasingly being replaced by electric heating elements, because electricity is a cheaper and faster way to heat water compared to wood. However, many will argue that the smell of a burning log cannot be replaced by anything. And it’s hard to disagree with this.

But, on the other hand, if you really want to breathe in the smell of burning firewood without having to fork out too much to heat the sauna with wood, then after the steam room you can sit in the relaxation room in front of the fireplace with logs crackling under the influence of the fire.

Return to content

What material should the tank be made of?

Previously, cast iron was almost always used for bathhouses. And although it took several hours to heat the water in such a tank, which required a considerable amount of firewood, the temperature of the water in it was maintained long enough for the whole family to steam in the bathhouse. In addition, cast iron is not afraid of high temperatures and has a high degree of corrosion resistance. The main disadvantage of cast iron canisters is their heavy weight.

The most popular are stainless steel sauna tanks. Firstly, it doesn’t hurt your head that they will need to be protected from the corrosive effects of moisture. Secondly, stainless steel is characterized by a high coefficient of thermal conductivity and the water in such containers heats up quickly. Thirdly, the coefficient of deformation of stainless steel under the influence of sudden temperature changes is insignificant compared, for example, with ferrous metals.

The best material for making tanks is stainless steel, which is used in the production of cookware. It is steel grades 8-12X18H10 (304) and 08X17 (430) that are endowed with such properties as high heat resistance, resistance to deformation under the influence of high temperatures, hygiene and corrosion resistance.

If you purchase a stove complete with a tank at, as they say, a low price, then be prepared for the fact that you will soon begin to worry about the question of why the tank in the bathhouse rusts. Don’t be surprised: at a low price you won’t find a stove complete with a stainless steel container. In order to avoid the unpleasant consequences of contact with “rusty” water, it is necessary to wipe the tank dry after draining the water.

Of course, using an enameled version in a bathhouse can also protect you from rust. But the enamel can chip, which is a significant drawback of enameled containers and is absolutely not inherent in stainless steel tanks. When using a tank made of metal that is susceptible to corrosion, you can get rid of rust only by coating the metal with a special heat-resistant paint.

Painted tanks can be used in a bathhouse if they are not built into the oven, but cover the frying plate with their bottom, which serves as a kind of dissipator of temperature shock, evenly distributed over the entire area of the stove.

So, the most practical and durable option is a stainless steel tank.

The most modern designs of sauna tanks have long been no longer built into the stove, but are more often remote. Such containers have a rather aesthetic appearance and do not spoil the pleasure of healing steam and the healing effect it has on the body and the organism as a whole.

A modern bath tank is a rigid welded structure, which is made of thin stainless steel sheet, equipped with an inlet for introducing water, as well as shut-off and distribution valves in the form of ball valves for drawing hot water from it. Such a tank does not rust, and therefore does not need painting. In addition, caring for him is simple and will not cause any difficulties for his owners. Typically, a sauna tank is made of stainless or chrome steel. This material not only does not absorb light, but also additionally illuminates the room, increasing the illumination when reflected.

Advice from the master!

The main thing is to observe all the installation features described in the instructions when installing and operating the container. Or, when making it yourself, comply with the necessary safety conditions. Especially if draining water in winter to avoid freezing of the system is not a problem, then any tank will last a long time and will not cause unnecessary trouble.

poparimsya.com>

Attached containers made of alloy steel

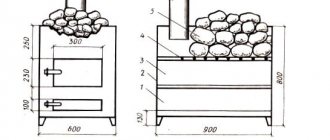

Structurally, an attached stainless steel tank is a rectangular, square or semicircular container, at least with a fairly large flat wall. A metal box is installed on a cast iron or steel stove in such a way as to ensure maximum close contact between the side or bottom of the tank and the hottest part of the firebox.

Due to lower thermal conductivity, water in a stainless steel cylinder takes much longer to heat up than in steel and, especially, copper tanks. This is one of the reasons why they prefer to make the walls of alloy steel containers as thin as possible. For ease of carrying, the design is equipped with side handles.

At the bottom of the container, a coupling or fitting is welded under the tap for drawing hot water. When choosing a specific model of an attached tank, you need to pay attention to two conditions:

- The hole for installing the tap should be located on the wall opposite the firebox. If you install a ball valve with polyethylene liners closer to the furnace than 20 cm, then during the heating process the internal parts of the valve, made of polymers, very quickly melt and lose their tightness;

- The stainless steel tank body must be equipped with its own fastening to the base, even if the cylinder will partially rest on the wall and parts of the furnace.

Attached stainless steel tanks are very reliable and durable in operation; the container is often used to heat water not only for use within the steam room, but also for any other purpose where warm-hot water is required. It is quite possible for two adults to heat and carry a cylinder of boiling water.

How to make a stainless steel container with your own hands

The retail price of one stainless steel tank of 50-70 liters, regardless of shape and design, is within 7 thousand rubles, a good quality cylinder will cost 10 thousand rubles. If you do it yourself, then making a 50 liter tank will cost only 30-40 dollars.

The amount of work is small:

- Select materials, thin-sheet stainless steel and welding material;

- Cut the body blank, adjust the dimensions;

- Weld a stainless steel tank, check the tightness of the seams;

- Conduct a test within the walls of the bathhouse.

The process is simple, but before you make a stainless steel tank with your own hands, you need to figure out the right choice of materials and select the welding mode.

How to make a tank for a bath

Making a sauna tank with your own hands is not a difficult task, especially if you are an experienced welder. But you won’t be able to work with every material yourself, and some types of tanks are easier to buy ready-made. Let's talk about what types of tanks there are, what material they are made of, and also how to install a water tank in a bathhouse. A bathhouse is a place where it is customary for a large group or family to go. Therefore, you should make sure that there is enough hot water for everyone. When choosing a tank capacity, it is better to choose 70–80 liter containers. This volume is quite enough for a family.

Making a tank for a bath

If you take on making a sauna tank yourself, it is better to use stainless metal. There are also enameled and cast iron tanks - it is preferable to buy them ready-made. Before you cook the sauna tank, you need to prepare:

- Sheets of stainless metal (about 105 thousand rubles per ton);

- Welding machine (about 10 thousand rubles);

- Metal brush (from 100 rubles per piece);

- Electrodes with a diameter of 2.5–3 mm (from 100 rubles per kilogram);

- Pliers (about 100 rubles);

- Hammer (from 170 rubles).

Next, you should make a small drawing of the future tank. It is necessary to correctly calculate the dimensions and determine how much metal is needed for a rectangular or square tank - these forms are the simplest and most practical.

The basic workflow looks like this:

- We cook the tank of the desired shape.

- We weld bends into it, which will act as water inlet and outlet.

- We make the ceiling seam. This is the case if the tank is planned to be mounted on a pipe. Ceiling seam is a very important job, you need to be especially careful. Otherwise, water may leak through it.

It is beneficial to make a homemade sauna tank when you are a truly experienced welder. The quality of such a tank mainly depends on how correctly the joining seams were made. If the seams are not given due attention, the tank will soon begin to leak. You'll have to redo it or even replace it with a new one. This will entail unexpected expenses.

Choosing a ready-made tank for a bath

As already mentioned, not all tanks can be welded yourself. In addition, most of us want to play it safe and purchase a ready-made sauna tank and be confident in its quality and reliability. On sale you can find tanks made of steel, stainless steel and cast iron. Each material has positive and negative properties, let’s try to figure it out:

- Stainless steel sauna tanks

. Such tanks are made of thin but quite strong steel. They are the easiest to maintain and do not deform at all over time, and are also not subject to corrosion. Stainless steel tanks have excellent thermal conductivity and are absolutely not afraid of moisture. This is perhaps the most popular tank at the moment. - Cast iron tanks

. Cast iron is a very heavy material and quite thick. The water in such a tank takes a long time to warm up, but also maintains its temperature for a long time. For example, in a stainless steel tank, water warms up quickly, but also cools immediately after the heat supply is stopped. A cast iron tank can keep water hot throughout the day. - Enameled tanks

. Such bath tanks are quite fragile and require special care. Although they are not susceptible to rust, corrosion often occurs with them. If you decide to purchase an enameled tank for a bath, then remember that they cannot be built into the stove itself, and should also be treated with heat-resistant paint.

The best materials for a stainless steel tank

Of the hundreds of existing grades of stainless steel, we need thin sheet metal with the best ductility and weldability. It is not difficult to weld a structure, even if you have to work with a thin sheet, but it is much more difficult to make a weld so that it does not become covered with microcracks.

If possible, it is best to choose austenitic steel, for example, the most popular and well-known stainless steel grade X18N9T. It is easiest to weld in a makeshift garage. As consumables, you can use wire for carbon dioxide semi-automatic machines with a diameter of 0.8 mm. If a stainless steel tank is made for sale, then it is best to look for specialized wire, any kind, as long as the marking contains a link to GOST 2240-60.

It is better to cook a stainless steel tank with wire in argon or carbon dioxide, because the metal is very thin. If you plan to make a tank from a 3-5 mm sheet, then it is best to use a plasma torch or a three-phase welder with a rectifying bridge and ballaster.

Recommendations from the experts

We've collected some tips from professional welders. They will be useful for beginners and garden craftsmen.

It is better to use stainless steel grade 8-12Х18Н10 or AISI 430 08Х17 as a material. These brands are best suited for storing water, including long-term storage. However, it is still better to drain the water before winter.

Before welding a stainless steel water tank, you need to decide on its volume and make a drawing based on this. For a bathhouse, a tank of up to 60 liters will be enough for two or three people. On average, about 20-30 liters of water are needed per person.

If you are cooking a tank for household needs, it is better to stock up on a volume of 100 liters or more. 200 liters is just right for watering gardens and collecting rainwater.

As for the wall thickness, it is better to use sheets no thicker than 2 mm. In factories, tanks are made of metal 1 mm thick, but at home it is more difficult to weld such thin metal well. The wall thickness does not depend on the shape and size of the tank.

It is better to abandon the idea of welding a water tank from aluminum. It is not easy to make high-quality sealed seams at home. Stainless steel is also not easy to cook, but this task is quite doable. But to work with aluminum you will need experience and a good welding machine.

Depending on the size of the tank and your experience, the entire process can take anywhere from a couple of hours to several days. If you have never cooked before, it is better to practice on unnecessary pieces of metal. After all, stainless steel is far from a cheap material. And you are unlikely to be happy if, out of ignorance, you weld a tank with defective seams, and it turns out to be unusable.

Features of the manufacturing process

The easiest way is to make a container of a rectangular or cubic shape; to work, you only need a grinder with a disk, a measuring stick, several bench clamps and the welder itself. The cut wall blanks are joined in pairs using clamps and secured with welding points or small seam strips.

After the side walls and bottom have been assembled, the stainless steel body is finally assembled with clamps and heated with a blowtorch. As soon as the sliver applied to the metal begins to smoke, you can begin to completely scald all the seams. Upon completion of the work, the welded block must be immediately covered with any heat-resistant, non-flammable material and allowed to cool slowly for a couple of hours.