Specifics of the ventilation device in the sauna

In a sauna, a high level of temperature and humidity usually prevails; without adequate air exchange, fungus and mold quickly grow here, since wood is the main building material. In the absence of a well-thought-out inflow-outflow system, the service life of the room and the stove installed in it is reduced several times.

With insufficient air exchange, irritating odors accumulate, the sources of which are mold processes, wood destroyed as a result of rotting, and sweat released by steam room users. Over time, these aromas are literally absorbed into all surfaces, becoming stronger as the air temperature rises, which negatively affects the comfort of relaxation in the sauna.

An improperly designed ventilation system can lead to the proliferation of pathogens indoors. Instead of the positive effect of staying in a steam room, users may get sick.

To determine insufficient air exchange, you should pay attention to several points:

- the walls and ceiling are covered abundantly with condensation;

- a burning match, located as an indicator at the exhaust hole, produces a strictly vertical flame that practically does not fluctuate;

- When entering the sauna, a musty smell is strongly felt.

You can determine the lack of ventilation by holding a burning match to the exhaust hole

. If there are no obvious greasy marks on the exhaust grille, it means that the system is ineffective - during vaping this metabolic product is always released, and it should preferentially settle where the air flows go.

Cost savings or efficiency?

The main requirements for ventilation of a sauna or bathhouse are comfortable conditions (the absence of drafts is especially important) and ensuring constant air exchange. Therefore, any omission can lead to ineffectiveness of the system. After completing the work, it is recommended to immediately check the quality of ventilation of the steam room. For the test, use a lit match (or lighter). She is brought to the canals. If the flame deviates, it means the job was done correctly.

Is ventilation needed in a sauna, or can it be done without it? To feel comfortable and not breathe stale air, it is better to do everything according to the rules. Neglecting them will make the system ineffective. Even the simplest natural ventilation will help eliminate the disadvantages of a hot and humid room. However, if the sauna steam room is large, then a mechanical system is much preferable.

Comfort is impossible without fresh air. The following video can also answer the question of whether ventilation is needed in a sauna:

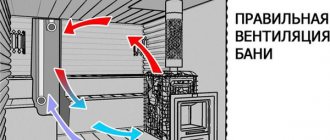

Proper sauna ventilation: technical requirements

Supply and exhaust ducts in the steam room should be designed in such a way as to create air balance. The masses should not stagnate or be rapidly removed; the outflow and inflow should be regulated so that it is possible to predict the direction of the flows. The formation of drafts is unacceptable.

When deciding how to properly ensure air exchange in a sauna, you need to design it correctly at the initial stages: at least one wall of the steam room must border on the street - an exhaust hole will be made in it. Under the door leading directly to the heated area, it is necessary to provide a two-centimeter gap.

Every hour there should be at least 4 complete changes of air in the room, the flows should be directed from the recreation area to the utility areas and bathrooms. The system is designed so that the air passes from the steam room to the washing room with toilet, then to the vestibule and onto the street.

The outlet of the exhaust duct must be above roof level. The inflow, in turn, is installed at a level no higher than 50 cm from the floor in close proximity to the stove on the wall opposite the exhaust air duct. The introduction of forced air exchange is accompanied by the installation of a ventilation grille; it is located 2 meters above ground level.

If a gas water heater is used in conjunction with a steam room, a separate exhaust duct is installed for it. It is advisable, if possible, to reuse the hot air generated in the steam room: for example, it can be directed to heat the rooms adjacent to the sauna.

How to make ventilation in a sauna: types and diagrams

The air exchange system can be natural, mechanical or combined. The last two types require the introduction of supply and ventilation equipment.

Natural ventilation

This scheme is based on the pressure difference between indoors and outdoors. Its main advantages are low cost and ease of operation, no need for expensive maintenance and the ability to install it yourself. Natural ventilation is based on the laws of wind pressure or aeration.

Natural ventilation of the sauna is carried out through vents in the lower segment of the steam room

As it moves upward, it displaces hot masses, thus directing them into the air duct. This solution is optimal for servicing very hot rooms in which steam is used abundantly - in such conditions there is intense air exchange.

Wind pressure is provided only in saunas made of logs. The necessary air pressure is created by strong gusts of wind, and a rarefied atmosphere appears on the leeward side. Streams through the cracks between the logs enter on one side and exit on the other.

The natural method does not involve regulating air exchange parameters. If there is a strong wind, a draft will occur and it will be difficult to maintain the required temperature.

Mechanical System Features

Forced schemes are used in cases where it is not possible to create a natural inflow and outflow. This requires expensive equipment - filters, coolers, fans, heaters.

Forced outflow is provided using exhaust fans. The equipment filters the air before it is released outside. Artificial evacuation of waste masses is most necessary in large saunas with washing rooms and in intensively used steam rooms. The system is useful for quickly getting rid of foreign odors and gases.

Mechanical ventilation in steam rooms made of wood involves the use of forced air flow from the street

Such a system has a complex configuration; it necessarily includes noise reduction devices, check valves, distribution grilles, a supply chamber and diffusers. Before serving in the sauna, the street masses are heated and filtered.

The simplest scheme of combined supply and exhaust ventilation is to create a supply opening 20 cm above the floor near the stove, and install an exhaust opening on the opposite wall. The street air, heated by the hot stove, gradually rises. This mass, as it cools, falls towards the exhaust duct. This solution helps maintain a high temperature in the sauna, while ensuring the supply of oxygen in the proper volume.

If only one wall of the steam room is in contact with the street, inflow and exhaust are installed on one wall - the first near the floor, the second near the ceiling along with a fan.

Conclusion

So, these days, ventilation in the bathhouse is becoming more and more popular. In most projects of bath complexes, ventilation is already included by the designers. Ventilation can be done either with your own hands or ordered from specialized companies. When choosing a ventilation system, everything depends primarily on the type of structure and on what kind of steam room the owner of the future bathhouse wants to get.

It is important to remember that the type of future bath will also depend on the selected ventilation. If you decide to do the ventilation yourself, be sure to follow all safety requirements and be extremely careful when making calculations. Remember that a design mistake can ruin all the sensations you wanted to get from your future bathhouse.

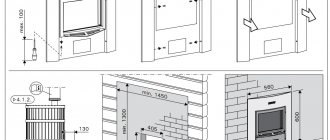

Arrangement of ventilation in a sauna with an electric heater

Do-it-yourself installation begins with arranging a special channel in the sauna, which will provide a flow of fresh air to the heater; this air duct is located under the floor in close proximity to the heat source. The cross-section of the stroke should be a quarter smaller than the box for the hole. Oxygen will come from the street. The box is installed along the baseboard, it is protected from the inside by a grille, and a mesh is installed on the outside to prevent the penetration of insects.

An exhaust channel is made diagonally to the supply channel, which is responsible for the outflow of air. It should be placed at a height of 23-27 cm in relation to the floor. This outlet extends to the ceiling and from there goes out onto the street. To install a high-quality ventilation system, it is recommended to use plastic pipes.

Where should the hole for cold air flow be located?

When creating a bath complex project, you need to lay a pipe that will lead to the steam room. The hole for the flow of cold air into the steam room should be located at the bottom. Fresh air will come from the adjacent room, so the outlet of the processed gas should be in the same room and not outside.

The most popular option these days is to locate the inlet under the shelves. The hole will be invisible and will not show through. A small disadvantage is that due to inaccessibility, it is difficult to adjust the position of the damper.

Placing the ventilation supply behind the stove is also a very common option. It is important to take into account that the dampers in this case must be metal, since plastic ones melt at high temperatures, which can lead to a fire. However, this method is not suitable for those who have a stove installed in a wall.

Installation of the outlet outflow can be done as follows:

- when constructing a building, lay it in the wall;

- mount into the ceiling, having previously made a box for output through the roof.

Common mistakes

If you provide only one ventilation vent under the ceiling through which exhaust air will be discharged - even with a damper, it will quickly remove heated masses. This design flaw complicates the process of achieving the optimal temperature in the steam room and leads to a significant increase in fuel consumption.

If all functional openings - supply and exhaust - are located at the same height in relation to the floor, a draft will appear. There will be minimal air exchange, which is not effective enough to fully service the room.

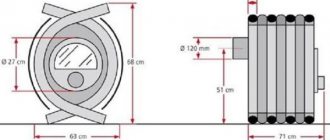

Another common mistake is when the diameter of the supply duct is larger than the exhaust duct, in which case air exchange will also be difficult. To choose the optimal ratio of the air duct, you need to use the standard rule: for every cubic meter of steam room there are 24 square meters. cm sections.

Dimensions of ventilation ducts inside the steam room

The best option would be 100-150mm . Ventilation holes that are too large will quickly cool down the steam room. To improve circulation, the diameter of the outflow can be slightly increased, but openings that are too large will quickly cool the room. It is also worth remembering that for safety reasons, it is forbidden to make supply systems larger than exhaust systems.

For comfortable use of the ventilation system in any weather, it is necessary to install dampers. By adjusting their radius, you can regulate the intensity of circulation.

There is an opinion that if the influx is insufficient, then the person will not have enough oxygen. This is a misconception; a cubic meter of air is enough for a person for an hour and a half.