Bathhouse projects

Number of projects 687

- 2 bathrooms

Project Baths BD-36, Beshtau

- To favorites

- 35.7² Total area

- 6 x 6m Construction area

from 590,000 rub.

Construction time individually

- 1 room

- 2 bathrooms

Bani Khvoynaya project

- To favorites

- 66² Total area

- 9 x 9m Construction area

from 891,000 rub.

Construction period 35 days

- 1 room

- 2 bathrooms

Bathhouse Dunno project

- To favorites

- 53² Total area

- 10 x 7m Construction area

from 715,500 rub.

Construction period 35 days

- 1 room

Lazur Baths Project

- To favorites

- 12² Total area

- 4 x 4m Building area

from 350,000 rub.

Construction time individually

Barrel sauna project Compact with canopy

- To favorites

- 7² Total area

- 4 x 2m Building area

from 127,000 rub.

Construction time individually

- 1 room

- 1 bathroom

Project Baths 6B-K

- To favorites

- 20.6² Total area

- 4 x 6m Building area

from RUR 161,807

Construction period 15 days

Bathhouse project “Russian Steam”

- To favorites

- 36² Total area

- 6 x 6m Construction area

from RUB 420,968

Construction time individually

- 1 room

- 1 bathroom

Pelageya Baths Project

- To favorites

- 61.4² Total area

- 11 x 5m Construction area

from 826,000 rub.

Construction time individually

- 2 rooms

- 1 bathroom

Bathhouse project Privat-banya

- To favorites

- 114² Total area

- 11 x 8m Construction area

from 1,539,000 rub.

Construction period 50 days

- 2 rooms

- 1 bathroom

Project Baths made of timber AR-038

- To favorites

- 43² Total area

- 7 x 9m Construction area

from 580,500 rub.

Construction period 90 days

- 1 room

- 1 bathroom

Anna Bath House Project

- To favorites

- 24² Total area

- 6 x 4m Construction area

from 159,000 rub.

Construction time individually

Mini bathhouse project No. 1

- To favorites

- 6² Total area

- 2 x 3m Building area

from 255,000 rub.

Construction time individually

- 1 room

- 1 bathroom

Bani B-5 project

- To favorites

- 4 x 7m Construction area

from 360,000 rub.

Construction period 12 days

- 1 room

- 2 bathrooms

Bathhouse project "Azov"

- To favorites

- 33.5² Total area

- 7 x 5m Building area

from 931,000 rub.

Construction time individually

- 1 room

- 1 bathroom

Bath Luigi Project

- To favorites

- 38² Total area

- 9 x 9m Construction area

from 513,000 rub.

Construction period 27 days

- 2 rooms

- 2 bathrooms

Bani Kauri Project

- To favorites

- 100.7² Total area

- 7 x 8m Construction area

from 1,257,900 rub.

Construction time individually

- 2 bathrooms

Bath Captain project

- To favorites

- 32² Total area

- 6 x 8m Construction area

from 800,000 rub.

Construction time individually

- 1 room

- 2 bathrooms

Vanessa Bath Project

- To favorites

- 46² Total area

- 8 x 7m Construction area

from 621,000 rub.

Construction period 35 days

- 2 rooms

- 2 bathrooms

Bathhouse project BKm-3

- To favorites

- 63² Total area

- 6 x 6m Construction area

from 850,500 rub.

Construction time individually

- 2 rooms

- 2 bathrooms

Omella Baths Project

- To favorites

- 85² Total area

- 7 x 9m Construction area

from 1,147,500 rub.

Construction period 35 days

View all projects

To provide yourself with a durable, inexpensive and spacious structure for relaxation and wellness treatments, you need to build a bathhouse from timber. If you approach the design correctly, there will be the required number of rooms inside the bathhouse. It could be a Spartan set of a steam room, a shower and a relaxation room - in this case, the prices for a turnkey laminated timber bathhouse will be quite affordable. For those who are more demanding, they offer an extended option with a separate bathroom, vestibule, dressing room and a host of additional rooms.

Turnkey laminated timber bathhouse Source hi-news.ru

If you have the proper experience, materials and a team of skilled workers, you can manage the construction yourself, but it is more profitable to order a turnkey bathhouse. This will save you from unnecessary waste of nerves, greatly reduce construction time, and eliminate the possibility of errors during calculations and installation, because professionals in their field will take care of the work. This approach allows you to obtain high quality at minimal cost. One of the materials that will make an excellent bathhouse is laminated veneer lumber; any project can be made from it on a turnkey basis.

Glued laminated timber is the best choice for a bathhouse

For a bathhouse, laminated veneer lumber is the optimal building material. It allows you to get a lot of benefits without the disadvantages that are inherent in wood:

- Light weight. Saving on the foundation and eliminating shrinkage from calculations.

- High strength characteristics. Often, when creating laminated veneer lumber, different types of wood are used, which allows you to evenly distribute the load on the part and increases protection from mechanical damage.

Bathhouse made of laminated timber with a large open terrace Source spb-cr.ru

- Resistant to fire, fungus and insects. The use of special impregnations in the process of manufacturing laminated veneer lumber significantly reduces the risk of wood destruction by insects and fungi, and ensures fire safety.

- Durability. When connecting lamellas (individual layers of timber), sorted, clean, dried wood is used, which significantly increases the service life of the material.

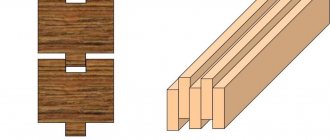

- Easy to assemble. Even ordinary timber is produced in a certain, geometrically correct shape, this allows you to avoid the formation of gaps when connecting individual elements. The use of profiled laminated veneer lumber will further strengthen the connection and increase the speed of assembly of the structure, thanks to the presence of special grooves or locks.

Construction of a bathhouse from laminated veneer lumber Source anticafe-sandbox.ru

- Low thermal conductivity of certain types of wood. The characteristic is responsible for the speed of heating the bath and maintaining the temperature by reducing heat leakage.

An additional advantage is the low cost of the material and attractive appearance. You can easily verify this by looking at the timber baths, photos of which are presented in the article.

Features of the construction of a bathhouse made of laminated veneer lumber

You don’t need to delve into all the intricacies of the question of how to build a bathhouse from timber - just figure out what parameters you need to focus on when ordering from professionals in order to get a high-quality building that will last for decades. A turnkey bathhouse made of laminated veneer lumber, made by a good team, will be much better than a “homemade” one.

Laminated timber bathhouse with a small open terrace Source vsedlyastroiki.ru

Dimensions of a bathhouse made of laminated veneer lumber

Everyone decides for themselves what size a bathhouse made of laminated veneer lumber will be. There are no uniform parameters, but there are important characteristics that will make the selection task easier:

- Number of visitors. For a large group or family, you will need enough space so that everyone can fit comfortably. If the bathhouse will be visited by one or two people, a small building will suffice.

- Seasons of use. If you wash in the bathhouse only in the warm season, then you can neglect thermal insulation and a separate heating system. For a building that operates all year round, the organization of heating and thermal insulation is necessary, which automatically increases the dimensions of the bathhouse.

- Additional areas. Equipping a terrace where it’s so nice to sit after a steam room, building a second floor with a lounge or bedroom, or a room with a swimming pool increase the required size of the building.

Based on the specified parameters and your own taste, it is easy to choose the best option for the dimensions of your laminated timber bathhouse.

Laminated timber bathhouse with attic and balcony Source domostroy96.ru

Foundation

If the main material of the bathhouse is laminated veneer lumber, the structure will be light in weight, so you can avoid laying a capital foundation, but choose one of the three most common types:

- Tape. Allows you to obtain a strong single structure that can easily support a building of several floors at low cost.

- Columnar. At each corner and at the junction of the walls, a pole is mounted, which is buried in the ground. This allows the load from the building to be evenly distributed.

- Pile. Used on moving soils. Deep digging or screwing the pile into the ground allows you to reach stable layers of soil and securely secure the bathhouse.

Depending on the amount of average annual precipitation, floodability of the land, quality and density of the soil, and the overall construction budget, you should focus on one of these options for constructing a foundation.

Construction of a strip foundation Source rockstroy.ru

Waterproofing

A bathhouse means high humidity, which poses a danger to laminated timber, even despite the appropriate impregnation of the material. Protecting individual parts of a building will improve its performance.

- To insulate the foundation, molten bitumen is used, which, after hardening, is covered with a layer of roofing material.

- Waterproofing the walls, ceiling and floor covering in the bathhouse will protect them from water getting inside and prevent rotting.

- Materials for protecting the interior space are selected depending on the type of room. For a steam room, the waterproofing must have additional resistance to high temperatures.

High-quality waterproofing will improve protection from water and increase the durability of a bathhouse made of laminated veneer lumber.

Foil waterproofing material Source iv-proect.ru

See also: Contacts of construction companies that offer the service of building a bathhouse from laminated veneer lumber.

Insulation

When using a bathhouse made of laminated timber all year round, it is necessary to take care of the insulation of the walls and ceilings. This will reduce heating costs, prevent the formation of condensation inside the walls and prevent mold from appearing. Insulation will also protect the bathhouse from freezing in cold weather. Low temperatures can negatively affect the strength characteristics and cause the formation of microcracks in the wood.

Felt insulation for bath walls Source srubdacha.ru

Materials for interior and exterior finishing

A good bathhouse made of laminated veneer lumber involves the use of certain building materials for interior decoration, which are suitable for installation in all rooms except the steam room.

- Plastic deforms when heated.

- Natural stone and brick can burn.

- Cork moisture-resistant material is highly thick, which reduces the usable volume of the room.

Therefore, the steam room must be lined with clapboard made of natural wood, which is sufficiently resistant to high temperature and moisture. You cannot use coniferous wood for this; when heated, they release resin.

Steam room lined with natural clapboard Source poselok.com.ru

For the outer cladding of a bathhouse made of laminated veneer lumber, you can use any materials.

- Decorative brick allows you to give the building a solid look.

- Wood panels create a natural decor.

- The block house imitates rounded logs.

- Thermal panels perform a double function - they give a nice look to the bathhouse and reduce thermal conductivity.

The choice of material for the exterior finishing of a bathhouse made of laminated veneer lumber can be discussed with the designers when ordering a turnkey construction.

Bathhouse made of laminated veneer lumber, trimmed with decorative wood panels Source oooarsenal.ru

Table. Connection types

| Name | Illustration | Description of the lock connection | Description of the insulation method |

| 1. Finnish profile with round bowls | The beam profile itself has connecting tenons at the top and a groove for them at the bottom. Between the spikes there is a stepped recess, which is shallower at the edges and deeper in the middle. Bowls are cut into semicircular shapes | For insulation, use a wide insulation tape in the center, for example, PP-TERMO, and two narrow strips of sealant on the sides | |

| 2. Finnish profile with flat bowls | The profile of the timber does not differ from the previous one, but the bowl is cut flat to simplify the process and save time | A profile with flat bowls is insulated with tape only along the central groove or with a seal (polyethylene foam) only along the outer grooves above the tenons | |

| 3. German profile with flat bowls (one-sided, two-sided or four-sided) | For corner connections, bowls are cut parallel to the cross-section of the beam | The corner joints are sealed with sealant or tape insulation, which is rolled out without tension only in the locks. The insulation is fixed with a stapler with short staples. You can use PSUL or flax jute. The crowns themselves are not insulated along their length, because... the connection of the tenons and grooves is quite tight and windproof | |

| 4. Profile with a reduced number of spikes | This is a domestically produced profile, similar to the German one, but has a maximum of two grooves for two tenons | Insulation is carried out along one or both grooves | |

| 5. Austrian or German profile with a “labyrinth” corner connection | Joining cuts are made only on enterprise machines. Provides a very tight, windproof connection | The seal is not used | |

| 6. German profile, “Tyrolean castle” | The cross section of the lock is trapezoidal, the upper and lower planes form a “dovetail”, i.e. are on a slope | You can use PSUL by inserting it into a rectangular groove on the side surfaces of the paws | |

| 7. Connection of the German profile without residue or “in the paw” | The lock can be cut at a right angle or with a bevel, like half a dovetail. | The lock joint is sealed with jute | |

| 8. T-shaped splices of all types of profiles | Notches and grooves are made in the beams of load-bearing walls, and a tenon is cut through the beams of interior partitions | Jute seal is used | |

| 9. Bay window connections at an angle other than straight | The coupling of parts is carried out due to vertical grooves and tenons | Wind protection is low, but insulation is usually not used |

We suggest you familiarize yourself with: How to treat lining in a steam room: what to cover in a steam room, impregnations for the sauna inside, what to paint wooden walls, oil, photos and videos

Video description

For a detailed review of a bathhouse made of laminated veneer lumber, watch the video:

A one-story bathhouse made of laminated veneer lumber imposes certain requirements on the layout and number of rooms. The minimum project includes a relaxation room, washing room and steam room. An increase in the number of rooms requires a corresponding increase in the total area of the building or a decrease in the size of each room.

The advantage of a one-story bathhouse will be its low cost and reduced maintenance costs. The disadvantages include some limited free space and the difficulty or impossibility of combining with living space.

Project of a one-story bathhouse Source banya-ili-sauna.ru

A two-story bath house made of laminated veneer lumber allows you to significantly increase the usable area and delimit zones of space use. The first floor is made functional, there is a steam room, a swimming pool, a shower room, a bathroom, a dressing room with kindling and other rooms with similar characteristics.

Design

Be sure to think through and draw up a plan for your bathhouse. Designate the necessary rooms: steam room, shower, bathroom, rest room, wardrobe, etc. Calculate the area of the entire bathhouse and each room separately, compare the values with the length of the timber that you plan to purchase in order to reduce the number of trims.

Scattering with markings

Example of scattering project

Include in the estimate not only wall beams, but also joists, as well as floor boards, floor beams, rafters, door and window frames with frames, and roofing material.

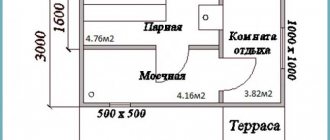

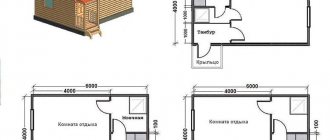

Below are three interesting projects that you can build without changes or make adjustments and create your own version.

Project 1 - facade Project 1 - side view Project 1 - side view Project 1 - rear view Project 1 - visualization Project 1 - visualization from the other side Project 1 - bath plan

Project 2 - left view Project 2 - left view and partial facade Project 2 - facade Project 2 - facade after finishing

Project 2 - bathhouse plan

Project 3 - façade

Project 3 - bath plan

Photo examples of bathhouses made of laminated veneer lumber

Project of a one-story bathhouse with a large terrace Source ytong.by

Project of a bathhouse with a glazed terrace Source avoka.do

Laminated timber bathhouse with porch Source www.rwhouse.ru

Project of a two-story bathhouse with an outdoor pool Source stroy-good.ru

One-story bathhouse Source lineyka.net

Project of a bathhouse made of laminated timber near an artificial reservoir Source sk-brusnika.ru

Bathhouse made of laminated timber on a strip foundation Source market.sakh.com

Two-story bathhouse with an attic Source remontik.org

Bathhouse with a residential attic and terrace Source profipluspz.ru

Small sauna for 1-2 people Source rinnipool.ru

Design and drawing

Bathhouse project

You do not need to obtain special permission to build a bathhouse on a private plot. If you don’t want to come up with something unique, you can use ready-made projects:

- Small bathhouse - 3x3 meters. Suitable for 1–2 visitors. The internal space can be divided into a steam room, a washing room, and a dressing room. If the steam room with shower needs to be made larger, it is recommended to reduce the space for the rest room, leaving a small vestibule for changing clothes.

- Bathhouse 4x4 meters. Suitable for 2–4 visitors. If you distribute the space correctly, you can make a steam room, a shower, or a small vestibule.

- Bathhouse 8x8 meters. Suitable for a large family or group of friends. There is enough internal space to arrange a spacious steam room, shower room, relaxation room, veranda, which can be converted into a place for cooking.

If you have enough funds and free space on the site, it is better to make a large bathhouse. The drawing must indicate the dimensions of the building, the location of window and door openings, stove equipment, electrical appliances, plumbing fixtures, water drain points, and large furniture.