High fire safety requirements for saunas and baths are due to the following factors:

- unsafe temperature conditions;

- structure made of wood or covered with it, resinous elements;

- ovens;

- compact space;

- ventilation;

- not all elements come into contact with water;

- presence of electrical wiring.

Examples of causes of fire:

- violation of rules for handling equipment;

- electric oven not turned off;

- insufficient protection between the wood stove and the walls, chimney and ceilings/roof.

Features of fires in the bathhouse:

- pyrolysis gas is released;

- a mixture for spontaneous combustion is formed;

- the effect of air suction with a flame explosion.

Fire safety standards for the construction of a bathhouse

Fire standards are taken from sections of GOSTs, compared with the classification of saunas/baths by flammability. Apply:

- by buildings:

- SNiP 31-05-2003 (SP 117.13330.2011) (clause 6.3.9), 2.09.04-87 (SP 44.13330.2011) (clauses 2.34, 2.35, 2.36);

SP 118.13330.2012 (SNiP 31-06-2009), 53.13330.2011, 54.13330.2016, 55.13330.2016 (SNiP 31-02-2001);

- general rules:

- SNiP 21-01-97 aka SP 112.13330.2011 – PB classes;

NPB 110-03, 88-2001;

- Federal Law 123 – technical regulations, fire resistance limits, fire safety classes;

- projects, planning, placement:

- SP 11.106-97, 4.13130, 60.13330 (SNiP 41-01-2003);

- equipment:

- SP 7.13130;

Rules for electrical installations;

- "Methodological recommendations for the design of baths...".

Baths are built only according to pre-agreed projects according to SP 11.106-97.

Bathhouse: functional fire hazard class

According to PB standards and clause 5.21 of SNiP 01/21/97, baths, saunas, health institutions, sports and training institutions without stands, and household facilities are assigned class F3.6.

PB of a free-standing bathhouse

Fire resistance level of the sauna building:

- fire resistance – not lower than III;

- for 20 places and less – IV – V.

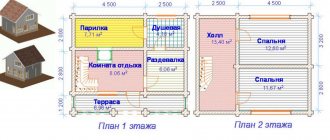

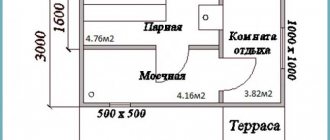

Fire safety requirements for room parameters:

- steam room:

- volume – from 8 m³, but not more than 24 m³;

in height - not less than 1.9 m;

- up to 2 floors;

- separate exit;

- supply and exhaust ventilation;

- gap under the door – from 30 mm;

- compliance with the location in relation to neighboring buildings, from the fence to the bathhouse.

PB saunas inside the house

Safety for placing built-in saunas:

- in objects of I – III degrees of classes C0 and C1 the following are distinguished:

- fire-resistant barriers of type I with resistance limit REI-45;

type III covering elements, REI-45;

- in buildings of IV degree, C0 - C3 - with the indicated structures REI 60;

- a separate exit for evacuation, not combined with other passages;

- seats in the sauna steam room - up to 10 people.

According to fire safety standards, built-in dry baths (saunas) are prohibited in:

- basements (ground floors);

- adjacent (above and below) to objects where more than 100 people stay. or to the living rooms of neighboring apartments;

- in dormitory buildings;

- under the stands.

The restrictions do not apply to establishments put into operation before the adoption of these changes, and the infrared sauna also circumvents the prohibitions.

Distance from the house to the bathhouse according to fire safety

Fire regulations for placement:

- distance between house and bathhouse on one site:

- brick sauna with a non-combustible roof - 8 m from the same building, if the second building with a combustible roof - 10 m;

if the roof of a brick bathhouse is fire hazardous - 10 m;

- both buildings are made of wood - 10 m, if more than 1 floor - 15 m;

- to a neighboring house on a different site from the fence (distance to the border, but the total distance is as indicated above):

- without sewerage – 3 m;

with drainage, drain – 1 m;

- distance from the bathhouse to the bathhouse of the neighboring plot. Distance standards - 10 - 15 m (wooden) and 6 m (brick) - from table. 11 Federal Law 123 is outdated, therefore the rules of the previous paragraphs apply.

Fireproof materials

Fire resistance limits for sauna materials:

- degree – I – III;

- fire hazard of load-bearing elements – C0 and C1;

- fire resistance limit of materials EI-45, EI-60.

Fire safety methods and materials for saunas are usually structural:

- partitions – I, ceilings – III type of fire resistance. It is allowed to use plastic glass blocks;

- fire-retarding valves in ventilation;

- fireproof insulation for all heating elements, chimney: basalt, mineral wool;

- setback, fire gap - the distance between devices and walls;

- cuttings - filled/made indentations (with brick, vermiculite, etc.);

- aprons;

- cladding

Wooden bath structures can be protected with impregnations, but only with special (non-toxic) impregnations intended for objects of this type, preferably antiseptic (against rotting), OE group 1. Deep processing technology is recommended.

The compositions should be used only in certain places, since the OS minimizes the smell of natural wood, as well as for elements that are not in contact with the human body (not in the steam room, near stoves, remote places).

Electrical requirements

In steam rooms, the use of electric furnaces is common. The premises also have wiring for lighting fixtures. Requirements:

- compliance with the PUE;

- reliability of power supply:

- Category 2 – from 100 places;

Category 3 – up to 100 places;

- cable entries made of asbestos-cement pipes from 100 mm with a slope from the building;

- all cables are heat-resistant;

- switches in wet rooms are not allowed;

- wires for maximum room temperature;

- do not place input distribution units, switches under steam rooms, bathing rooms, or other wet places;

- lamps in wet and humid conditions are protected by heat-resistant glass and mesh;

- internal wiring:

- aluminum;

in steam rooms - copper with heat-resistant insulation;

- open, pipeless (attached with staples to the surface) with asbestos cord winding;

- protective grounding.

Instructions for installing a dry pipe in a bathhouse

The fire extinguishing system inside the bathhouse is an installation with a sprinkler or deluge device made of perforated dry pipes connected to a water source. The dry pipe should be installed inside the steam room exactly around the perimeter. The holes must be located at a specific angle, implying full coverage of the surface during a fire. The recommended figure is 20-30 degrees. The entire piping system indoors with high temperatures must consist of steel elements. The diameter of the pipes is calculated based on the intensity of the water supply.

Despite the fact that the dry pipe is connected to an internal or external water supply system, when inactive, there is no water inside the pipes. Only in the event of an emergency, the water supply process is started by opening a special valve. When installing it, you should take into account specific requirements. This element of the system must be located in a zone of visibility and accessibility outside the steam room in a special building. Compliance with all standards and requirements will increase the likelihood of a prompt response in the event of an emergency.

How to protect a bathhouse from fire from the stove

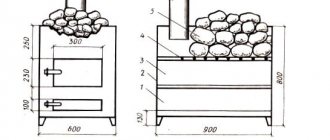

Heating options for saunas:

- brick or metal wood stove;

- electric furnaces (electric heaters).

Wood-burning stove equipment according to SP 60.13330.2012 is permissible only for one-story bathhouses with seats for up to 25 people. Ways to protect a sauna from fire from the stove: cladding, casings, lining, offsets, cuts.

What are the dangers of stoves:

- dumping burning particles;

- release from the firebox and body, especially in case of emergency damage (hull burnout / masonry cracks):

- sparks;

flame;

- hard to detect cracks;

- heating of surrounding elements (floor, ceiling, walls) by the furnace body.

How to cover/cover a stove

Enhanced fire safety measures for heating equipment:

- screens for sauna stoves (casings):

- brick, metal;

corrugated roofing materials;

- plaster 25 mm on an iron mesh chain-link or on asbestos with a thickness of 8 - 10 mm;

- lining (cladding) is required when heating with a metal stove:

- the floor in front of the door is covered with a steel sheet of 50x70 cm. In a long line along the stove. Around there is a steel sheet on asbestos cardboard 150 mm larger than the dimensions of the body;

podium and apron: brick, concrete, ceramic (tiles), asbestos and iron;

- for walls: fire-retardant boards, mineral insulation with a metal base or brick;

- non-combustible floor - higher from the main one;

- fire distances from the stove (setback):

- to combustible floors without protection - from 210 mm (air or brick), with protection - from 100 mm;

to the walls - no less than 200 mm;

- from the ceiling at least 1200 mm, always with a fire-resistant sheet;

- fencing:

- there is a shield under the ceiling (5 cm from the surface);

cases (metal covers) against spilling of fuel, sparks, flames;

- cuttings for brick chimneys – from 500 mm.

Temperature for stoves according to NPB (can only be observed if shielded):

- +120°С for the body;

- +80°C for walls;

- below +50°C.

The standards are not always the same, so they are also guided by:

- manufacturer's instructions;

- engineering considerations;

- recommended materials.

The temperature in places where the stove comes into contact with flammable objects should not exceed +50°C.

How to secure a chimney pipe

Chimney fire protection:

- fencing:

- shielding of walls (metal sheet), one sandwich pipe is not enough;

passage box with backfill;

- interfloor divisions are mandatory;

- the brick pipe is coated with clay and whitened to visually detect cracks and soot;

- at least 380 mm to combustible structures (rafters, roof sheathing);

- chimney cutting:

- interfloor vertical mandatory: height from 70 cm, thickness from 12 cm, for temperatures from 100°C - 25 cm;

desirable horizontal (brickwork) for the attic;

- thermal insulation along the entire length;

- inspection hatches;

- you cannot connect 2 stoves simultaneously to one chimney pipe;

- regular cleaning and inspection.

Danger of chimneys:

- holes become clogged;

- risk of burnout, cracks;

- heating of surrounding elements;

- soot accumulation: a layer of 2 – 3 mm is fire hazardous.

PB requirements for the installation of electric furnaces

Standards on how to protect a bathhouse from fire when using an electric heater:

- power exactly according to the parameters of the sauna, but up to 15 kW;

- self-shutdown after 8 hours of operation;

- control unit in a dry place in front of the steam room;

- all cables are fireproof insulated;

- wiring to the control cabinet:

- copper;

in steel pipes in concrete floor preparation;

- potential equalization grid;

- the distance to the walls is up to 20 cm, under the ceiling above the device there is a heat-insulating shield with a distance to the casing of at least 5 cm.

- in automatic mode, the temperature in the steam room is up to +110°C, automatic shutdown at +130°C.

Rules for safe operation of the bathhouse

Fire safety depends not only on the correct construction of the bathhouse and the correct installation of equipment in it, but also on the correct operation of these. First of all, it is necessary to exclude the possibility of open fire coming into contact with the wooden surfaces of the bathhouse or firewood. The space of the bathhouse is organized in such a way that all structural parts that become very hot during operation of the stove do not come into contact with the finishing of the room.

An important point in ensuring the fire safety of a Russian bath is proper ventilation of the room. Therefore, all insulating fireproof materials must have ventilation openings with an area of 150 (or more) square cm. The openings must be protected with metal mesh. Separators are also installed in those places where the location of the equipment in the bathhouse coincides with the location of ventilation openings and other elements of the ventilation system in the room. There must be a distance of at least 13 cm between the chimney and wooden structures, and when using flammable materials for roofing - at least 26 cm.

It is also important to heat the stove correctly. To do this, you first need to check the draft in the outlet channels, and if it is absent, warm up the chimney by burning a little fuel. If after this the draft does not appear, then you will need to clean the smoke passages from soot. Soot accumulates not only there, but also in the ash pan, which should also be regularly cleaned of fuel combustion products.

It is not recommended to use liquid fuel for kindling, as this can lead to the emission of flames from the combustion opening and subsequent ignition of the bathhouse. And when using a stove-heater, it is necessary to periodically inspect the stones and remove damaged, cracked parts, as they can cause difficulty in the passage of carbon monoxide and smoke.

The fire safety of a bathhouse depends on the development of a project for its construction in accordance with all the prescribed and listed above rules and regulations. It is also important to correctly install the stove in the bathhouse and provide screens around it that will protect the wooden finish of the steam room from fire.

Fire extinguishing agents in saunas and baths

For private steam rooms there are no requirements for alarms or extinguishing installations. But, if this is a public, commercial building, then it is necessary to protect the bathhouse from fire with extinguishing and notification systems.

Which fire extinguisher is better

Features of fire extinguishers:

- – effective, but there is a risk of carbon dioxide poisoning (requires special protection), do not wet, cold burns are possible;

- , ORP - ends quickly, with a weak stream;

- – universal, create a non-flammable layer of powder;

- OVE - effective, harmless.

{banner_downtext} For baths, air-emulsion fire extinguishers are recommended, preferably from 8 liters, and powder ones, especially for objects with an electric heater, since the extinguishing agent does not conduct electricity.

Fire extinguishing systems

Steam rooms in public and commercial establishments must be equipped with automatic deluge fire extinguishing systems:

- dry pipe;

- source - internal water supply;

- automatic and manual start simultaneously;

- remote control, valve in a separate room nearby or in front of the entrance.

Sometimes sprinklers are installed, but with activation from +125°C, and there is logic in this, since the need to open doors, leading to a flame explosion, is reduced. Foam and water installations (drenchers, sprinklers, expansion valves) are standard for saunas.

Do you need a fire alarm in a bathhouse?

The instructions on safety measures do not contain requirements for the presence of fire alarms in private baths, but the equipment is mandatory for public and commercial establishments.

According to NPB 110-03, a sauna is a building for public, domestic purposes and must be equipped with automatic alarms, except for wet rooms (steam rooms, showers, sinks).

Sensors, detectors

In locker rooms, dressing rooms, and auxiliary parts (not wet), heat fire detectors and smoke detectors must be installed. In wet rooms (steam rooms), sensors are installed less frequently or are not used, but they are not prohibited. There are special devices for baths, for example, IP 105-1 G “Sauna-150” with activation at +110°C.

Operating principle of dry pipe fire extinguishing

A dry pipe is an installation, the working part of which is represented by pipes that do not contain water. The diameter for public premises is 6.5 cm, for multi-storey buildings - 8 cm. It is mounted horizontally along the perimeter of the room closer to the ceiling. The lower end of the vertical fire riser is connected to the pumped water supply system through an external valve.

When an emergency occurs, water fills the pipes and the fire extinguishing process starts. The advantage is the ability to carry out fire extinguishing work simultaneously in two directions - inside and outside the room engulfed in flames. There are several options for dry pipe equipment:

- A system of perforated dry pipes connected to an internal water source, or a deluge sprinkler.

- Fire extinguishing system in the sauna using water curtains.

- A dry pipe system for external water sources, allowing you to avoid waiting for a fire truck to arrive.

In order to be able to easily determine the location of pipelines in the event of a fire, they must be marked with indicators of the established type. Since the causes of fire in saunas are most often associated with operating equipment and high temperatures, the use of dry pipes is a suitable option. Their use reduces the risk of reducing the performance of the entire fire extinguishing system.

How to make a dry pipe with your own hands?

If you wish, you can create and install a dry pipe in the sauna yourself. This does not require the use of expensive equipment or special skills. It is enough to remember that the process of installing a fire protection system is carried out at the time of construction of a bathhouse or sauna, and adhere to a specific algorithm of actions:

- Preparation of dry pipe. Holes are drilled in the pipe at a distance of 15–20 cm from each other. The diameter is 3–5 mm. The directional angle should be 20–30°. If there is no desire to engage in this process, you can purchase ready-made pipes.

- Installation of dry pipe. The pipeline is fixed directly under the ceiling using special devices.

- Installation of a vertical riser. This element is a solid pipe without additional holes. Mounted along the wall outside the steam room.

- Installation of the starting valve. Installed at the bottom of the vertical riser. It is advisable to equip the tap with a means of blocking from premature, groundless operation.

- Relay installation. Recommended for automatically turning off electricity when a fire occurs.

If the sequence is correct, installing a dry pipe does not involve any difficulties. However, when using a steam room, it should be remembered that a fire is easier to prevent than to extinguish. To do this, it is recommended to take precautions. Then it is quite possible that there will be no need to start the fire extinguishing system.