Advantages and disadvantages of a frame bath

Each building material has its own advantages and disadvantages that must be taken into account. Recently, frame baths have begun to become popular, so it makes sense to find out why they are better than structures made from other materials.

The advantages of such a bath:

- There is no need to make a capital foundation. The structure is lightweight, so it can be installed on a lightweight base.

The foundation for the frame structure can be lightweight

- Low cost. They are preferred by those who want to get a high-quality design for a low price.

- Possibility of production in the shortest possible time. Together with finishing and insulation work, production will take 1–2 weeks. The structure is assembled 3 times faster than stone or timber.

- Heat retention. According to these indicators, a frame building is not inferior to a log or timber structure.

- Environmental friendliness. This bathhouse is made from natural materials that are not capable of harming human health.

- Possibility of production at any time of the year. The structure can be manufactured even at a temperature of -15°C.

- Comfortable microclimate. Walls can breathe as the material will absorb and return air.

- Seismic resistance. Thanks to this quality, the bath can be made even in an earthquake-prone region. It can withstand fluctuations of up to 8 points.

However, it is important to know that a frame bath has significant disadvantages:

- Costs for insulation and finishing materials. The frame building itself is cheaper than a stone or timber steam room, but the cost increases several times during finishing and insulation work. Panels for decoration and plastering are required.

- Shrinkage. The process takes at least 2 years, and the building may sag by 10 cm. This may lead to deformation of the finishing layer. To reduce the effects of shrinkage, it is recommended to use chamber-drying materials during the construction process.

- The difficulty of choosing high-quality material for insulation. If you use budget mineral wool, the bathhouse will not be able to fully cope with its functions. The use of budget polystyrene foam is also not allowed, since the material is easily flammable.

Preparation for construction: project drawings

Creating a drawing requires certain skills. If they are not there, then it is better to entrust this work to a specialist or use a ready-made drawing.

Before drawing up a diagram, it is important to decide on the following points:

- Location of the building on the site. It is important to consider sewer and water drainage. Quite often, the main factor when choosing a location is the laying of communications.

When choosing a place for a bathhouse, it is important to consider the location of communications - Soil at the construction site. If you plan to make a swimming pool in a bathhouse, then groundwater should not be located near the surface of the territory. The type of foundation to be built will also depend on the type of soil.

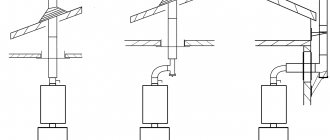

- Bathhouse construction plan and number of floors. If you plan to make a two-story building, it is important to take into account the additional load on the frame structure and foundation. At this stage, you should think in advance about the placement of the stove and what material it will be made of. This will allow you to understand where and which chimney to install, as well as the ventilation passages in the room.

- Laying communications. It is important to take care of ventilation, electrical wiring, vapor barrier and thermal insulation. It is worth considering the features of water drainage.

- An important element of any building is the roof. The service life of the structure will depend on it. You should take into account the material of manufacture, as well as its shape. This will allow you to calculate the power of the floors.

You need to include all the information received in the drawing, as well as supplement the project with the necessary details. The more detailed the diagram, the easier it is to build a bathhouse.

The more detailed the project, the easier it is to make a frame bathhouse yourself

It is recommended to draw up a separate plan for communications. If you have little experience, you should not create a complex project. You can use a ready-made diagram, slightly supplementing it based on your own needs.

A standard bath includes a corridor, a dressing room, a washing room and a steam room.

A standard frame bath consists of a dressing room, steam room, shower and rest room

Quite often a separate room for recreation is provided. It is recommended to mark the installation location of the stove on the diagram. If this is a steam room, then it is best to place the stove in the corner closest to the door. The stove can be stone or brick.

It is recommended to determine in advance the dimensions of each room and indicate them in the drawing. The standard dimensions of the steam room are 200x240 cm. The optimal ceiling height is 220 cm. This design can accommodate 2-3 people at the same time.

In the drawing you can see a bathhouse for a suburban area with a balcony measuring 1.5x4 m. The overall dimensions of the building are 4x6 m. The project is suitable for organizing gatherings in an open area in the summer.

A frame bath can be equipped with a terrace for gatherings in the warm season

This bathhouse consists of 3 rooms:

- steam room;

- washing and shower;

- rest room.

The corridor is shown separately in the diagram. There is no room for a locker room. There is a small changing area in the washing room. The terrace connects to the living room.

The optimal wall thickness of a frame structure is 100 mm or more. The wood that is used in the process of making a bath must be treated with an antiseptic. It is recommended to use dried, calibrated lumber.

It is mandatory to perform a vapor barrier of the insulating material on the internal base. In the steam room you need to use foil vapor barrier. The reflective layer can increase the temperature inside the steam room.

Walls and ceilings in the stove area should be made using non-flammable materials. For example, the frame is made of a rack-mount metal profile, which is coated with zinc. Cuttings can be made from asbestos cord. In these places, a basalt slab can be used as an insulation material.

Supply and exhaust ventilation is required in all rooms. Floors in the sink should be made with a slight slope or along a screed. The top and bottom floors need to be insulated in the same way as the walls.

The minimum size of a frame bath is 3x4 m.

The minimum size of a bathhouse for a comfortable stay of several people is 3x4 m

The budget version of the frame is made in this way: the racks are sheathed on the inside and outside with boards up to 25 mm, basalt insulation or ecowool is laid inside the frame structure.

If you plan to use ecowool inside the walls, it should be carefully compacted and horizontal platforms for unloading should be installed. The frame must be sheathed inside and outside. To do this you will need to make a sheathing. On the outside, the insulation material is covered with a membrane to protect it from the wind. In the horizontal plane, the use of ecowool is a more economical option compared to basalt insulation.

The outside of the frame structure can be covered with any facing material. The inside of the building is covered with clapboard, plasterboard sheets with tiles or imitation timber.

Tips for choosing material

The frame should be assembled from the following parts:

- bars;

- slats for creating sheathing;

- boards for the floor base.

Instead of plank flooring, the floor base can be covered with tiles. You need to choose based on personal preferences, however, in the case of a steam room, it is recommended to give preference to wood. There will also be materials for protection. Quite often, lining is used for wall cladding.

It is recommended to cover a frame bath with wooden clapboard

To cover the structure from the outside, you can use larch lining. The inside of the building is clad with clapboard made of coniferous trees. Sheathing boards must be mounted vertically.

Excess moisture and elevated temperatures will negatively affect structural elements, so it will not be possible to do without the use of special protective materials. You can use glassine, polyethylene or roofing felt. A vapor barrier should be placed between the insulation and the sheathing. The disadvantage of roofing felt is that during the heating process it will emit an unpleasant odor. Therefore, it is not recommended to use it.

You need to pay attention to the selection of material for thermal insulation. If you choose wisely and install the insulation correctly, it will be possible to significantly reduce heat losses, as well as the cost of heating a bathhouse building.

Mineral wool is used as insulation in most cases.

A good insulation material for a frame bath is mineral wool.

A good option is to use fiberglass. In some cases, the ceiling is insulated with expanded polystyrene, and the floor base with expanded clay.

conclusions

It’s quite simple to build a 5x5 frame bathhouse on your site. A light columnar foundation is chosen as the base. The walls are made of beams and OSB panels. It is important to properly waterproof the grillage and roof elements. This will extend the life of the building. Based on ready-made projects, you can create your own drawing of a frame bathhouse that meets safety and cost-effectiveness requirements.

Recommended Posts

Decorating the inside of a bathhouse with your own hands

How to build a cellar under a barn with your own hands

Bathhouse project with a terrace or veranda

Arrangement of a cellar in the garage for storing vegetables

How to make shelves for a garage with your own hands

How to arrange a garage with your own hands

Calculation of materials and list of tools

As an example, we will consider the calculation for a frame bath of the most common sizes. The frame is made of timber, the size of the structure is 5x4 m. The base will be reinforced columnar.

For the frame structure, you can use a lightweight foundation made of asbestos-cement pipes

Coniferous wood lining is used to decorate the walls inside and outside. The roof will be gable, the covering will be metal tiles.

A pressing issue is the choice of wood. The material must be dried. Linden, larch or aspen are most suitable. These rocks have low thermal conductivity; they are capable of maintaining their original structure for a long period of time. The walls are erected from boards 2-3 cm thick. Larch or pine slats are suitable for external cladding.

In terms of cost and reliability, a columnar reinforced base is the best option for frame construction.

Columnar reinforced foundation is suitable for the construction of frame baths in most regions

It can be used in most regions. You will need to prepare materials in the following quantities:

- concrete - 2 m3;

- edged boards for the frame - 0.3 m3;

- reinforcing bars - 80 linear meters

The frame can be made from boards, pieces of plywood sheets or OSB. If the soil on the construction site is clayey, then formwork is not necessary.

The most complex and financially expensive part of the bathhouse is the frame. The purchase of materials at this stage must be approached carefully. List of required materials:

- timber 120x120 mm - 5.3 m3;

- mineral wool 10 cm thick - 36 m2;

- vapor barrier material - 40 m2;

- wooden lining - 70 m2;

- material for waterproofing - 40 m2.

To save money, instead of bars you can purchase 50x100 mm boards.

To save money, you can use 50x100 mm edged boards during the frame manufacturing process

The timber must be of the second grade and lower, the board can only be of the first grade. The cladding of the walls on the outside can be done not with wooden lining, but with plastic sheets or corrugated sheets.

The floor is made of edged veneer boards. The ceiling should be covered with clapboard. If you want to save money, you can use mineral wool for thermal insulation. List of materials:

- edged boards - 1.8 m3;

- boards 150x50 mm - 0.2 m3;

- plinth - 20 linear meters;

- mineral wool - 20 m2;

- wooden lining - 20 m2.

You can save money on attic flooring. If you do not plan to use it, then the mineral wool can be covered with unedged boards or pieces of slabs.

The roof is gable, the attic can be used to store tools.

The best option for a frame structure is a gable roof.

There is no need to insulate the roof. The rafters will be hanging. You will need the following materials:

- drainage system - 1 set;

- slats for rafters - 0.2 m3;

- lathing strips - 0.1 m3;

- cornice slats - 0.1 m3;

- metal tiles - 20 m2.

In a bathhouse, quite often, instead of a drain, a blind area around the perimeter is installed using a cement-sand mortar.

List of materials that will also be needed:

- asbestos pipes;

- self-tapping screws;

- nails;

- staples;

- cement;

- gravel or sand.

You will need the following tools:

- square;

- building level;

- roulette;

- electric drill;

- Screwdriver Set;

- hammer;

- pliers.

It is important to think through all architectural and construction tasks, which include:

- internal lining of the bathhouse building;

- selection of optimal materials for construction work;

- actions that are required to ensure the safe use of the structure.

After preparing the tools and materials, you can proceed to construction work.

Roof structure

Roof arrangement

Any roof can be suitable for panel baths. The main task is the correct calculation of loads. In latitudes where there is a lot of snow in winter, a gable roof with an increased angle of inclination is most practical. With this design, snow accumulates in moderate quantities, which reduces the load on the load-bearing elements of the structure.

Since the columnar foundation is not designed for heavy loads, the roof of the bathhouse must be constructed from lightweight materials. Of course, it should not be tiles, but sheet iron or rolled material. The beams on the ceiling are hemmed with boards and covered with insulation and vapor barrier. If you wish, you can watch a video that clearly demonstrates how to properly build a panel bathhouse.

Tips for finishing and insulation

The outside of the bathhouse is covered with siding, boards, plaster or ceramic tiles. Waterproofing material should be laid under the sheathing. The resulting gaps can be filled with thermal insulation material. You need to leave a small gap between the clapboard and the foil for ventilation. For this purpose, strips several cm thick should be nailed to the vertical supporting parts. The distance between the elements must be selected taking into account the distance between the supports.

In the diagram you can see the design of the wall cladding

To give rigidity to the walls, they need to be covered with plaster shingles. After the cladding work is completed, the outside of the structure must be plastered.

Guidelines for internal cladding of frame buildings:

- The inside of the building should not be painted, as paints and varnishes will release harmful chemicals when heated.

- To make a rough ceiling, you should use OSB boards. They must be secured to the bottom of the floor beams.

- The walls in the steam room should be covered with foil. The remaining walls can be covered with glassine.

- The minimum ceiling height is 2.2 m. In this case, it will be possible to install lining and additionally insulate the ceiling.

- It is important to pay attention to the joints between the walls and the ceiling structure. The vapor barrier material must protrude at least 15 cm.

The slats can be nailed in using different methods - during the fitting process, a selection is made into a groove or a quarter. The slats must be attached to the joists with the front part.

There is no need to make holes between the foil and the corrugated sheet; the sheets are nailed to the foil. Fixation is done using self-tapping screws with rubber gaskets.

After this, the furnace and boiler are installed. It is important to remember fire safety rules. The wall that will be used for the soaring room and resting place must be made of brick. It is recommended to place the heating boiler in the dressing room. The best option is a brick stove, but if you have no experience in laying a similar structure, it is recommended to entrust this work to a qualified stove-maker.

When working with foil, you need to be careful, as the material is easily damaged. Any gaps will significantly reduce the effectiveness of thermal insulation. The vapor barrier should be fixed with a stapler, and it is important to ensure that there is no sagging of the material. The minimum distance between the wooden paneling and the insulating material is 1 cm.

In the bathhouse, it is best to attach the foil using an ordinary stapler

Frame structures are convenient in terms of finishing. Work can be done both inside and outside. If there is a forced break, you can make partition frames at this time, upholstering them with blockhouse or clapboard. In this case, the time will be spent usefully.

For most regions, the optimal thickness of the walls of a frame building is 10 cm. Insulation can be done either with mineral wool or with expanded polystyrene. A layer of mineral wool 12 cm thick can replace a wall made of bars 50 cm thick.

You can insulate a bathhouse from the inside using mineral wool

For northern regions with cold climates, there are 2 methods of insulating a bath:

- Making a frame from slats 15 cm thick. The insulating material must be of identical thickness.

- Sheathing the walls on the outside with OSB sheets or plywood, followed by installation of expanded polystyrene boards 5–10 cm thick.

For northern regions, it is recommended to cover the outside of the frame with OSB boards

If you plan to use expanded polystyrene, then after installing the sheets you need to make a thin screed using a mesh of reinforcement. Finally, a topcoat should be applied.

It is not recommended to use traditional insulation materials made from sawdust and straw.

It is not recommended to use sawdust and clay to insulate the ceiling

During the cooking process, they will be mixed in water with clay, and therefore the insulation will have a lot of weight. In addition, a large amount of liquid often causes wet ceiling parts made of wood. This has a negative impact on the performance characteristics of the bathhouse building.

Frame walls are an excellent bait for rodents who love polystyrene foam. In 2–3 years, solid sheets can turn into dust. Therefore, it is not recommended to use polystyrene foam for insulating rooms inside a frame structure.

Particular attention should be paid to the quality of vapor and waterproofing. Such a bathhouse does not have free supports; each of them will carry the load and hold other parts of the building. If the strength is compromised due to prolonged exposure to moisture with one rack, the sauna may become unstable. In this case, complex repair work will be necessary. It is best to prevent such a situation at the stage of insulating the rooms.

To insulate the insulation, it is best to use aluminum film.

It is best to insulate the insulation with aluminum film

However, the material is not cheap. If you want to save money, you can use plastic film. The material is cheaper, but in terms of steam and water protection parameters it is practically not inferior to foil. It should be remembered that polyethylene can be damaged when exposed to sunlight. For this reason, it is important to cover the frames. This will reliably protect the film from exposure to ultraviolet radiation.

Construction of walls

Start building walls.

First step. Lay a support beam around the perimeter of the future bathhouse and under the wall locations. Use wooden dowels to connect the support bars. First, holes with a diameter slightly smaller than the diameter of the fasteners are prepared for the dowels so that the dowels fit into the holes with some tension.

Lay out the base from two horizontal rows of timber. In the timber of the top row, prepare cuts for attaching vertical posts. The depth of the cut is half the timber. Select the width in accordance with the width of the vertical posts.

Second step. Insert vertical posts into the prepared holes and secure them with spacers. Install the racks in the corners and along the perimeter of future walls with an average step of 1 m. The specific step usually has to be selected individually in accordance with the parameters of the future bathhouse and the timber itself.

Install all planned racks.

Construction of frame-panel baths

Third step. Tie the upper ends of the racks with a support beam. At the same time, it will serve as a Mauerlat, i.e. foundations for the roof structure. First, prepare holes in the support beam according to the size of the vertical posts, place the Mauerlat on these holes and additionally secure it using fasteners that are convenient for you, for example, jibs.

Fourth step. Attach horizontal jumpers to the vertical posts. Do not forget to leave openings for window systems and doors in the right places.