High-quality thermal insulation, resistance to penetration of hot steam, high temperatures, resistance to moisture and external influences - this is foil insulation.

A thin aluminum layer reflects heat, keeping it inside the building. Such characteristics allow it to be used for installing insulation on the walls of baths and saunas.

Bath or sauna buildings require insulation and isolation from external influences. Internal insulation of walls from increased moisture, steam and high temperatures is also required.

A material is selected that is not susceptible to such influences - this is foil insulation for a bathhouse. Construction experts recommend this type of insulation.

Installation of foil insulation

Foil insulation has a fairly wide range of applications, it is used for insulating pipes with cold and hot water, for insulating walls, as a substrate when laying parquet or under laminate, for insulating hives, soundproofing rooms, roofing work, insulating ventilation ducts, thermal insulation of industrial equipment.

This insulation is used to line the walls from the inside of the room behind the radiators to reduce heat loss, since it is heat-resistant. The following brands are represented on our market: Alufom, Ursa, Penofol, Folgoizol, Izolon, Knauf, Lavsan, Magnel, Megaflex, Penoplex, Ecoteplin, the most popular type is with foil and foam rubber.

How much does this material cost? It all depends on the manufacturer you choose; the price ranges from $1 to $4 per meter2. Let's try to take a closer look at how to properly place this material on various surfaces.

On the wall

Often, walls are insulated with similar material in baths, saunas, and balconies; in this case, polyethylene-based material is used. It is recommended to use insulation with a thickness of at least 10 mm; such material can be covered with foil on one side or on both sides.

If we consider the options on what it can be attached to, a construction stapler or double-sided tape is best; you can also use a special rubber-based glue; the joints of the sheet are glued with tape. If we are talking about insulating a balcony, then you need to lay an additional thermal insulation layer, for example, polystyrene foam, basalt material or something else.

Is it possible to insulate without them? Of course yes, however you will not get the desired result. In order for the insulation to fulfill its intended purpose, it is necessary to figure out how to install it correctly. The distance between the material and the sheathing should be approximately 20 mm, this will create some kind of air gap that will serve as an air barrier.

Let's take a closer look at how to properly mount it to the wall:

- Attach the foam to the previously prepared surface.

- Secure foil insulation on top of it.

- Then install wooden blocks on top, then sew everything up with the selected material (gypsum, siding), and seal the joints with foil tape.

To the ceiling

As a rule, the maximum thickness of insulation is selected for the ceiling, since all the heat rises and its maximum losses occur there. Thanks to its reflective surface, the insulation is able to reflect up to 90% of the heat, thus increasing the overall efficiency of the insulation system by 60%. These characteristics can be obtained subject to compliance with the installation rules.

To carry out the work you will need the following:

- Construction stapler.

- Small nails.

- Hammer.

- Insulation material.

- Aluminum tape.

This product is sold in rolls; for ease of installation, cut it into the required lengths. Which side should you lay it on? Installation should be done so that the foil surface is indoors (with the silver side facing you). So, let's figure out how to nail this material.

The gap between the finishing material and the insulation should be about 20 mm; this buffer zone protects the room from heat loss.

When attaching to the ceiling, secure it using a stapler; the fastening should be butt-to-edge, and seal the assembly seams with aluminum tape to ensure hydro- and thermal insulation.

On the floor

Perhaps the installation process on the floor is the most labor-intensive, and there are more possible variations, since you can lay a warm floor system (not just a water floor) under linoleum, parquet, laminate. All this is possible thanks to its non-flammable base, since there is reflective foil on one side and foam rubber on the other.

Some manufacturers have variations with foam on both sides. So, let us describe in more detail the process of installing a wooden floor. To do this, we will need the following: a construction knife, insulation, aluminum tape, meter, grinding machine, antiseptic primer, putty.

For this type of work, it is better to give preference to a material with an adhesive backing, however, you can get out of the situation with double-sided tape.

Work order:

- Prepare the base, remove the baseboard, sand the floor; if there are any uneven spots, remove them using putty.

- Treat with antiseptic liquid. After drying, take measurements and cut into the required pieces. Lay a sheet with foam inside and foil outside.

- Seal the seams using metallic tape.

- Then lay parquet and laminate.

If you are insulating a concrete floor, the technology is similar, however, it is better to use specialized rubber adhesive for gluing. But in all other respects the technology is the same. If you have a very cold floor, in this case, wooden logs are stuffed onto the insulation, the niches in them are filled with insulating material, the top is sewn with sheets of OSB boards, then the selected covering material is primed and laid.

Insulation of the concrete base

Construction of a cake with an insulated cement screed

Insulation of a concrete floor in a bathhouse is usually done using penoplex, expanded clay, glass bottles or foil materials. When covering the base with your own hands, you can also use mineral wool, but only of high density. What is the technology for installing insulation?

- first level the base using a screed;

- after the screed has hardened, a waterproofing film is installed;

- for waterproofing, either polyethylene film or roofing felt is used;

- lay the sheets overlapping with a margin of 15-20 cm;

- the joints are coated with bitumen mastic;

- then install the reinforcing mesh and fill it with new solution;

- After this, the base is sheathed with a heat insulator.

To finish the ceiling in this case, experts recommend using hydrophobic materials such as penoplex, polystyrene or basalt wool. The process of installing insulation in a sauna is described in more detail in the video clip.

Step-by-step instructions on how to insulate a bathhouse with isolon

Before work, it is necessary to calculate the amount of isolon according to the area of the walls and ceiling of the bathhouse. To do this, you need to multiply the length of the wall by the width and multiply between them. The resulting figure is 4. Add the ceiling area to the result and subtract the doorway. The material is laid without overlap, so metallized tape is purchased for a hermetically sealed connection.

The walls of the bathhouse are sheathed with isolon directly onto the wall. You can first perform insulation with mineral wool.

For work you will need materials and tools:

- A construction stapler with 10 mm staples or a hammer with thin nails.

- Izolon.

- Foil tape.

- Scissors, stationery knife (necessary for adjusting the insulation).

After everything has been purchased, we proceed to insulating the walls and ceiling.

Installation of insulation on the walls and ceiling of a bathhouse

It is necessary to insulate the walls and ceiling of the bathhouse with isolon between the finishing and the inner wall. A ventilated gap of at least 0.5 cm must be left between them so that moisture can evaporate.

Finishing material is attached to the insulation on top.

The work is carried out in the following stages:

- The walls are cleaned of dirt and dust using a brush with stiff bristles. The tree is coated with an antiseptic, lapyrimide.

- Izolon is rolled out onto the wall and ceiling with the foil side inward and secured to the wooden wall with a stapler. When the bathhouse is built from blocks or bricks, it is necessary to fill the walls with bars 20–30 mm thick, 1–1.5 m long, in a checkerboard pattern. The insulation will be attached to them. Izolon does not allow moisture to pass through to the wood, so there is no need to use a vapor barrier under it. If you don't have a stapler, use a hammer with small nails.

- The joints are taped with metallized tape. The same applies to places where the material is attached with staples. Untaped joints will not be protected, and moisture will get inside under the insulation. The walls will begin to rot.

- A lathing made of 40x40 mm timber is mounted on top of the insulation, for further finishing with clapboard or other material. The sheathing pitch is no more than 1 m.

Criteria for choosing foil for a bath

From the presented insulating insulation materials, a coating with foil paper is selected. The positive characteristics of bath foil are also taken into account.

To do this you will need a product that:

- protects against ultraviolet radiation;

- has additional moisture-proof and vapor-protective properties;

- thermal insulation;

- soundproofing;

- use on a variety of surfaces, including wood, concrete, brick;

- has dimensional characteristics.

Taking into account the building material from which the room is built, the thickness of the thermal insulation is selected. When choosing, they are guided by studying the number of positive reviews, checking quality indicators and certificates.

Attention is also paid to the condition of the packaging and its tightness.

Folgoizolon - foil insulation for the ceiling

Folgoizolon is a fairly new insulation on the market, providing high-quality heat, moisture and noise insulation. The basis of the material is polypropylene or foamed polyethylene. Based on this, two types of products are distinguished, designated PPE and NPE.

Advantages of folgoizolone:

- the lightness of the material, which makes it possible to finish any base provided there is no need for preliminary measures to strengthen it;

- small thickness - does not reduce the dimensions of the room, maintaining its usable area;

- elasticity - unlike some insulation materials (such as polystyrene foam boards), this foil material allows you to avoid spending time on careful preliminary leveling;

- multifunctionality, or a “3 in 1” combination, contributes to a significant reduction in the costs of purchased materials (mastics, films, fasteners, etc.) and a reduction in construction or repair time;

- ease of cutting - foil isolon can be easily cut with a sharp knife, which eliminates the need to use specialized tools;

- the absence of moisture absorption is one of the most important factors that ensures the extension of the service life of not only the foil-isolon itself, but also the structural elements it covers;

- environmental safety - does not emit harmful substances even at temperatures above 100ºС. Among other things, this material will never harbor insects or rodents.

So, is it possible to insulate the ceiling with foil insulation? Taking into account the material above, we can safely give a positive answer.

Why do you need foil vapor barrier ↑

As mentioned above, a vapor barrier layer with a metal aluminum coating is used in special cases and only in certain types of buildings, why is this necessary?

Firstly, the most important function of a foil vapor barrier is the ability to protect structures from excess moisture entering them. But, unlike other films and membranes, analogues with an existing metallized coating still perform the work of a heat reflector. That is, foil layers of vapor barrier are primarily needed where it is worth increasing energy saving.

2 Secondly, in rooms such as baths and saunas, the use of conventional films and membranes is impractical, since high temperatures will quickly render the protective layer unusable. And in conditions of high humidity, a protective layer is simply necessary.

Also, a good solution would be to use a vapor barrier with a layer of foil in the premises of dachas, outbuildings, balconies and attics, which are poorly or not heated at all. This will both protect structures from condensation and reduce the overall heat loss of the room.

Izolon technical characteristics

During operation, it is necessary to take into account that depending on the type, the characteristics will differ:

PPE – cross-linked closed cell insulation

- thickness ranges from 1 to 50 mm;

- sound insulation reaches about 68%;

- water absorption no more than 1%;

- the density of the material is up to a maximum of 200 kg/m³;

- degree of reflection by foil 95–97%;

- operating temperature ranges from -50˚С to +85˚С

NPE – non-stitched gas-filled

- the thickness size is thinner and varies from 1 to 16 mm;

- sound insulation is already less and reaches no more than 13%;

- almost complete water-repellent effect, absorption rate no more than 0.2%;

- the material is lighter, its density is 19–35 kg/m³;

- can be used in the temperature range from -80˚С to +80˚С.

The service life of both varieties reaches about 100 years. Izolon quite painlessly tolerates negative external environments, such as negative atmospheric phenomena or aggressive chemical compounds - oil or gasoline.

Foil-coated isolon will always find at least one extra advantage over regular isolon. Finding a better material for thermal insulation with the same thickness will be extremely problematic. The use of foil isolon is so widespread that it can be found everywhere, from insulating loggias to arranging medical refrigerators. Incredibly, the thinnest layer of material produced by the industry reduces heat loss by 75%.

Features of foil insulation as insulation

Foil-coated isolon is highly fire resistant. This is an environmentally friendly and safe material that can be used to insulate residential premises. Folgoizolon is not afraid of moisture, almost no heat waves emanate from it, and can also withstand temperatures from 80 minutes to plus 120 degrees.

Foil-coated isolon is widely used in hot southern regions and even at the North Pole itself.

The insulation is made in the form of sheets, which are rolled into a roll. The material is lightweight and is an excellent sound insulator. Izolon has almost no drawbacks, which makes it widely popular among consumers.

Positive features of isolon:

- Thanks to its foil foam structure, the material provides reliable sound insulation. The sound is reflected from the surface covered with foil insulation.

- The material is capable of retaining up to 97% of heat, which indicates its high efficiency.

- Isolon is lightweight, flexible, soft and elastic.

- The service life of the material has virtually no restrictions.

- Foil-coated isolon is not susceptible to chemical influences, does not absorb moisture, and has vapor barrier properties.

- The material is easy and simple to use, so you can do the thermal insulation yourself.

Such features make it possible to use the material for interfloor ceilings and to insulate walls from shocks and sounds. Once again it is worth mentioning the complete hygienic safety of the material. With the help of isolon you can almost completely get rid of heat leakage.

How to use?

The scope of application of isolon goes far beyond the boundaries of the construction field: it is actively used in the production of automobiles, refrigeration equipment, the medical industry, for plumbing needs, and even in the oil industry. It has also found its application in the production of life jackets, sports equipment, and packaging.

Most often, izolon is used for installing heated floors and insulating loggias and balconies. There are technologies that make it possible to use isolon in insulating external and internal walls and roofs, but the principle, as they say, is the same. The only difference is that in cold, unheated rooms, which include a balcony, one isolon is not enough, then a sandwich technology of cotton wool insulation or polystyrene foam and foil isolon is used. If the room is small and you cannot allocate additional space for insulation, then you should increase the thickness of the isolon to at least 2 centimeters. Using the example of insulating a loggia, we will show the principle by which you can insulate (with certain deviations depending on your conditions) any surface.

Very few people still know how to properly attach isolon, since the technology is quite new. Izolon on the walls is placed with foil inside to reflect heat. If you prefer a sandwich, then between two layers of isolon there is a gasket made of mineral or glass wool, polystyrene foam, expanded polystyrene, and a lathing for decorative design materials, such as plastic panels, lining, etc. is mounted on top. All seams are carefully taped with special reflective tape; tightness during the insulation process is very important, so this advice should not be neglected.

In order to describe all the processes more clearly, here are brief step-by-step instructions:

- Clean and dry the surface to which the attachment will be made.

- Measure the area, prepare the required amount of material.

- Lay out and attach the isolon to the surface with the foil facing you.

- Tape all existing seams and fastening points with special tape.

Installation of isolon

The manufacturer gives several more ways to use isolon:

- Using sheets for hardening concrete - isolon prevents heat loss and rapid drying, therefore it is invaluable as a material for laying concrete.

- As a bedding under artificial turf.

- As dividing partitions when pouring the foundation.

- When insulating water supply, drainage, ventilation pipes.

- As heat-reflecting screens (attaching the isolon to the wall behind the radiator allows you to redirect warm air masses into the room, which prevents rapid cooling. According to statistics, energy savings in this case exceed 25%).

Ventilation of bath rooms

Before insulating the steam room, a ventilation system is designed. For room ventilation, natural or forced systems are used.

- Ventilation is arranged with one lower hole, opposite the flue stove mounted on the wall. The heated steam rises and cools. It is mixed with the incoming fresh flow from the inlet window and drawn out by the stove's blower system.

- The heating furnace can be installed below the level of the floor covering, so that the blower system is located in the gap between the floor and the insulation. The entrance windows are located at the top of the basement and in the flooring of the bathhouse. The air passes through the underground passage, into the steam room and is drawn into the stove's ash system.

- The supply window is mounted at the bottom of the steam room next to the heating system. To prevent a draft from forming, an exhaust window is installed at the top behind the partition. The natural system is equipped with a device that regulates air flow.

- The use of such ventilation does not deliver the expected effect because the air quickly heats up when entering, rises up and is drawn out. For additional fresh air, the doors are opened, which is unacceptable when taking the procedure.

- You can install ventilation on one end wall, opposite the heating system. The incoming air flow is further enhanced by a fan, this type of ventilation is called forced ventilation.

- For efficient ventilation, windows are placed in opposite lower planes. The exhaust ventilation window is additionally equipped with a fan. After entering the room, heated air rises to the ceiling, cools and is drawn out by a fan.

There are three holes for air flow for efficient air exchange:

- one window downstairs, near the stove;

- another window in the floor, where there is a gap between the floor of the room and the insulation;

- the third hole is on the opposite wall from the stove in the upper part.

A device for forced ventilation is installed in the upper window. The window area is calculated based on the area of the bathhouse: per 1 m² - volume 24 cm².

Only properly installed room ventilation will extend the life of the sauna room.

Thickness of walls and insulation used

The insulating effect is obtained by using paper-based foil correctly, taking into account its thickness. This table is used to determine:

| Wall composition | Wall thickness, mm | Material thickness, mm |

| Concrete | 350-370 | 80-100 |

| Brick | 250-350 | 100-150 |

| Wooden log house | 100-150 | 60-80 |

| Wooden log house | 150-200 | 40-60 |

| Wooden log house | From 200 | up to 40 |

This calculation involves the development of insulation for the walls of baths and saunas. The reflective layer of aluminum is mounted only indoors.

Types of material

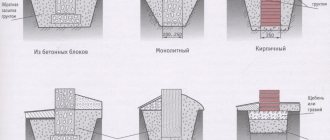

Let's look at what types of insulation are called:

- With foamed polyethylene, it looks like a roll of self-adhesive material, similar to film with foil. Scope of application in various equipment, lining of pipes, shafts, roofs, since it has a high temperature range from -160 to +160 degrees, it is fire resistant.

- Mineral wool with foil coating can have the form of a plate or cylinder. It also has a high degree of fire resistance.

- Expanded polystyrene, coated with foil on both sides. It also has a wide temperature range, the diameter can be 5mm, 10mm, 15mm.

- Basalt, just like the materials described above, is made on the basis of foil material, however, thanks to its unique technology, it can withstand temperature fluctuations from -200 +600 degrees, and is resistant to aggressive chemical environments.

How to put insulation on pipes

As a rule, such material has the form of a pipe “cocoon” made of mineral wool (withstands high temperatures) or polystyrene foam (moisture resistant). And how to insulate them, the question disappears in itself, since they have the appearance of a “cocoon”, which is put on top and fixed. There are main ones for chimneys of various diameters and temperature conditions.

However, if you decide to purchase sheet insulation, you may be faced with the question of how to glue it to metal? Aluminum tape will come to your aid, which is wound onto the insulation over the pipe. And, as in the options described above, you need to wear it with the shiny side facing you.

Types of foil insulation and regulations for their use ↑

In addition to wall materials, the use of vapor barrier is regulated by its type, or more precisely, by the material from which it is made.

The panel has two layers - the base and the actual metallized coating. The vapor barrier base can be of two types:

- Made from kraft paper. Quite a simple and cheap material, but it is subject to mechanical stress and less resistant to moisture.

- Made from polymer materials. This base is resistant to damage, humidity, and temperatures.

The metal coating of insulating panels also comes in two types:

- Aluminum spraying. The layer thickness can be 0.3 microns or more. However, thin metallized films play the role of a heat reflector much worse.

- Aluminium foil. Such vapor barrier materials have a metal layer of 10 microns, which makes them resistant to corrosion, and the degree of reflection is about 97%.

You should select foil insulation based on two factors: the type of room, and the types of film itself. Cloths coated with metal foil on a polymer base are best suited for wet bath conditions. And for dry rooms, you can purchase a cheaper option for spraying on paper. Also, the first option, covered with foil, goes well with heated floors.

Wall insulation technology

Insulation technology:

- The bars are attached to the cleaned walls with dowels in increments of 50-60 cm. Sheets of isolon PPE are laid on them end-to-end with the foil side inside the room and attached to the bars using a construction stapler.

- Then a 2nd row of slats is placed on the PPE isolon layer perpendicular to the first row located under the insulation.

Important: the second row of slats serves as the basis for attaching the final finish - plastic or wood panels, or plasterboard sheets.

The latter need to be puttied and then painted or wallpapered.

Insulation of the base on screw piles

Wooden bathhouses at dachas are often built on screw piles, so the technology for covering the base is practically no different from finishing the lag covering:

- To begin with, the heads of the screw piles are tied using support beams;

- The grillage mounted on the joists is additionally waterproofed to prevent rotting;

- I use bitumen mastic or roofing felt as a waterproofing agent;

- Then, on screw piles, inside the grillage, logs are installed that will serve as a rough foundation for the floor;

- A cranial beam is attached to the lower part of the log, after which it is sheathed with boards;

- At the final stage, the floors on screw piles are sheathed with a heat insulator (foil insulation, mineral wool, penoplex).

In the video clip, experts talk about the advantages and features of hydro- and thermal insulation of floors on screw piles.

Penofol ceiling insulation technology

The product can be laid on a floor made of any material, but operations must be performed in a certain sequence. Deviation from the technology of installing penofol on the ceiling will reduce the expected effect. In addition to the insulation, you will need glue to fix the insulator and metallized tape for the joints. The rules for choosing the components of the insulating “pie” are written below.

Selecting consumables

For reliable insulation, along with penofol, glue is purchased for fixing to the surface and adhesive tape for connecting parts of the canvas.

There are several modifications of penofol that can be used to insulate the ceiling:

- Type "A". Foil on one side only. Usually used with other thermal insulators as additional insulation.

- Type "B". Foil film is located on both sides. It has proven itself well as the main heat insulator.

- Type "C". There is a sticky layer that makes it easy to attach.

- Type "ALP". The metal coating is protected with polyethylene film. They are often placed on the floors of specialized premises - greenhouses, incubators, chicken coops. Film-reinforced insulation is used in basements where it is not protected by a suspended ceiling.

It is not recommended to buy Penofol-2000. Its cost is low, but it retains heat poorly.

Before insulating the ceiling with penofol, check the quality of the product. Pay attention to the following factors:

- The product must be manufactured in accordance with the requirements of TU 2244-056-4696843-98.

- The material is sold in rolls, the length of the product depends on its thickness.

- Tears and through holes are not allowed on the canvas.

- The winding of the rolls is tight, without distortions. The product is packaged in plastic film, the edges of which are secured with adhesive tape.

- Make sure that the product is stored on racks or pallets at a temperature of 20 degrees and a relative humidity of 50-70 percent. It is not allowed to store material closer than 1 meter from heating devices.

Products must have a label containing basic information:

- Name of the manufacturer;

- Basic dimensions;

- Release date and warranty period, usually the manufacturer allows storage of the material for no more than 1 year;

- Thermophysical indicators;

- Scope of application of the material;

- The protective layer on type “C” samples should be easy to peel off.

For gluing to the ceiling, special or universal adhesives are used. The requirements for their composition look like this:

- The product is intended for indoor use. The certificate of conformity for the adhesive indicates the degree of toxicity of the composition.

- Ability to withstand large temperature changes.

- The solution contains antiseptic additives.

- Retains its properties for a long time.

- The composition does not contain solvents that negatively react to the material from which the ceiling is made.

- The product takes into account the operating conditions of the room. For example, sauna glue must withstand high temperatures and humidity. MV-40 has these properties. In residential premises, it is necessary to use a solution that is non-toxic and completely safe for humans. Typically, “Universal” or “Express” adhesives are used; they dry quickly.

- Welcon Easy-Mix PE-PP 45 is intended exclusively for penofol. The only drawback is that it takes 1 day to completely dry.

For fixation, it is also possible to use the following solutions: 88Luxe; Nairit-1 (88-P1); Foam rubber-2(88-P2); 88 Metal. If the insulation area is large, take large packages of Facade and BOLARS substances. They are sold in bags of 25 kg.

To reliably connect pieces of fabric to each other, the adhesive tape must have the following properties:

- A reinforced metallized product with an adhesive layer at least 20 microns thick.

- The instructions for use indicate its purpose - sealing and thermal insulation of the surface.

- The tape does not lose its properties when interacting with water and dust, and is well resistant to bacteria.

- The product has great strength and wear resistance.

- Maintains quality in the temperature range -20+120 degrees.

Gluing penofol to the ceiling

The use of glue can significantly reduce the time it takes to insulate the ceiling with penofol from the inside. This method is low-cost because it does not require special devices and is easy to implement. The sample is very light, so strength calculations of the adhesive joint are not required. If the insulator is used as the main insulating layer, choose a thick product.

Perform the following operations:

- Clean the ceiling from loose plaster and decorative coating. Make sure the surface is level and, if necessary, finish it with plaster.

- Scrape off mold and mildew, dry the area with hot air and treat with an antiseptic.

- Wipe oil and grease stains with solvents.

- Seal cracks in concrete slabs with cement-sand mortar.

- In wooden ceilings, fill small gaps with caulking, large ones with tow and foam.

- Cover all wooden structures with special means to protect against fire and rot. Apply new protective layers only after the previous one has completely dried.

- Remove any sharp objects that could damage the foil.

- Treat the ceiling with a primer whose composition matches the adhesive. Fulfilling this condition will create the strongest possible connection.

- Prepare the adhesive solution. If the material has a sticky layer, it is enough to remove the protective coating.

- Apply a thin layer of the mixture to the surface without foil and spread it evenly over the surface. No omissions are allowed. Coat the edges of the sheet especially carefully. Allow 5-60 seconds to thicken the solution, which will provide better adhesion.

- Press the canvas tightly against the ceiling (or other insulation) and gently smooth it until it sticks. Seal the joints with reinforced tape. If this is not available, you can use silicone sealant. Do not leave joints untreated.

- When laying, make sure that the sheets do not end in the corners of the room. Pieces must not be overlapped. Also check where electrical wires and foil touch. Aluminum conducts electricity well, so check the insulation of wires located close to the insulating layer.

- Install the suspended ceiling.

Laying penofol on a wooden sheathing

This option is much more effective than simply gluing it to a flat surface, due to the presence of an air gap. The gap also allows air to move between the ceiling and the insulation and remove accumulated moisture, preventing condensation from forming.

The work is performed in the following sequence:

- Secure penofol to the surface with wooden slats 15-20 mm thick. The distance between the bars is no more than 100 mm. Glue the joints of the sheets with reinforced tape. Make sure that the bottom of the slats is located in the same horizontal plane.

- Attach the second layer of penofol to the bars from below using a furniture stapler. In this case, sheets with double-sided foil are usually used.

- Install the second row of sheathing.

- Install decorative finishes, such as MDF panels, plastic lining, etc.

Advantages of foil vapor barriers ↑

A metallized layer on a vapor barrier base significantly improves the properties of the barrier and gives it tangible advantages over conventional films.

- Low weight. With decent functional properties, foil vapor barrier is lightweight, which does not create large loads on the load-bearing structures of the building.

- Slight thickness. The layer laid on the attic ceiling or ceiling does not in any way affect the volumes or height of the room due to the minimum thickness of the base and the metallized coating itself.

- Ease of use. Vapor barriers with foil can be easily installed on curved contours of buildings and in hard-to-reach places. In addition, it is very easy to make a workpiece of any shape by simply cutting the panel with scissors. You also do not need to have specialized tools and skills to install the insulating layer.

- Temperature stability. The presence of a foil layer makes the vapor barrier less susceptible to high temperatures. And in combination, the film provides maximum protection to structures from high humidity.

- Cleanliness of materials. The production of such insulation does not require toxic materials and compounds that can be released under the influence of heat.

- Versatility. Using the same type of panel, you can insulate various building elements adjacent to the installation site.

Manufactured assortments of reflective vapor barrier can be selected for any room based on the price-quality factor. It will equally have vapor barrier protective properties. And long-term use in conditions of even excessive humidity (typical of a bathhouse) will not lead to the formation of mold and mildew.

But, you can get a fully functioning vapor barrier in a room only taking into account its specifics, and most importantly, compliance with the installation rules.

Insulation of ceiling and floor with Izolon

Metallized lavsan film Izolon.

The simplest option for insulating a floor with Izolon is to use it as a lining under a laminate, although it is also possible to lay linoleum on top of foamed polyethylene. In addition, this material can be used in structural elements of a building, for example, on the ceiling and wooden floor laid on joists. The installation technique in both cases is very similar, so we will consider them together.

Naturally, Izolon thermal insulation as an independent insulation gives insignificant results, since its thickness is too small. Therefore, in order to get a high-quality thermal insulation cake, you need to use more solid insulation materials, for example, mineral wool. In this case, in addition to auxiliary protection against heat loss, foamed polyethylene can act as a vapor barrier. Mineral wool, especially glass wool, is prone to absorbing moisture from the air, especially if it is laid on the ceiling. Therefore, insulating the ceiling with Izolon in some cases is not only desirable, but necessary.

Correct insulation method:

- Mineral wool is laid between the floor or ceiling joists;

- Izolon is tensioned along the joists;

- the counter-lattice is stuffed;

- finishing is being installed.

It is quite acceptable to lay this material directly under the finishing, as sound insulation. To do this, it is enough to secure the material with a construction stapler on the working surface end-to-end and seal the joints with tape. If it is technically possible, it is better to leave a gap between the polyethylene foam and the finish. Even if there is moisture on the insulation, it will successfully evaporate and will not be absorbed into the finishing materials, which will significantly extend their service life. Many people are interested in the question of whether it is possible to insulate the floor with Izolon in a wooden house. This is allowed, but again, as independent thermal insulation, it gives almost no results.

Rigid thermal insulation cylinders made of mineral wool are used to insulate communications.

You can read about which non-flammable insulation materials for roofing are best here.

Insulation of a wooden base

Layout of an insulated wooden floor on joists

A wooden floor in a bathhouse can be based either on a strip foundation or on screw piles. But from a technological point of view, the thermal insulation process will be the same in both cases. High-quality heat and waterproofing will be needed directly in the washing room, as well as in the steam room. How to cover a wooden floor on screw piles with sheets of foam plastic and other thermal insulators?

- first of all, the bars are mounted on the sides of the support piles;

- the beams are attached to the lower edges of the beams on both sides;

- screws or nails are used to fix the cranial beam;

- wooden boards are laid between the support piles;

- then they install the waterproofing film with their own hands;

- and only after that the heat insulator is fixed without gaps.

Important! Before making thermal and waterproofing on screw piles, the ceiling is inspected: rotten logs are replaced, and deformed ones are reinforced with wooden blocks.

Advantages and disadvantages of ceiling insulation with penofol

Today the product is very popular due to its versatility and easy installation. Masters also appreciate it for the following qualities:

- The material is lightweight, making it ideal for work performed at heights.

- To lay penofol on the ceiling, no special equipment is needed.

- The metal coating does not allow steam and water to pass through, does not absorb liquid and is not destroyed under its influence, so it is indispensable in damp rooms, for example, in baths. It does not require additional protection with hydro- and vapor barrier membranes.

- The material performs several functions. Once attached to the ceiling, it not only retains heat in the apartment, but also dampens sounds transmitted through the air or through the ceiling. It is often used with other products to increase thermal insulation properties. For example, in saunas it additionally maintains the temperature by reflecting heat.

- When heated, it does not emit harmful substances. In its production, the same polyethylene and foil are used that are used in the food industry.

- After installation, the distance between the floor and the ceiling decreases slightly. A 1 cm thick canvas can be used instead of 8 cm thick mineral wool or 4 cm thick polystyrene foam, so insulation is often used in rooms with low ceilings.

- The sheets are sold rolled up, which makes installation work easier.

- The product does not burn and is often used in fire hazardous areas.

- Rodents don't like him.

Penofol has few disadvantages. Negative factors include the high cost of the material and the need to use other insulation materials to improve the result. It is also glued to the surface to ensure the integrity of the coating, which increases financial costs. The material is soft, so it cannot be used if plastering or wallpapering is planned.

Why do you need a foil layer?

Bath insulation with foil is called two-layer. It consists of an outer covering of a layer of aluminum foil, which is perfectly polished.

The metal coating reflects heat into the building, retaining over 95% of it indoors. This coating repels moisture and steam. The foil layer can withstand air heating up to +150°. The temperature inside the room increases by 2-4°.

The insulation base consists of foamed air bubbles, which prevents the conduction and absorption of heat.

Foil insulation thickness: which one to choose

You can buy folgoizol in several types. Izolon is used as a waterproofing and thermal insulation material. When choosing a waterproofing material, you should pay attention to the fact that it has only one thickness option - 3 mm.

Folgoizol is a type of rolled material that consists of two layers: bitumen-polymer binder reinforced polyester and foil.

The roll has a length of 10 meters, a weight of 28 kg and a thickness of 3 mm. The roll is one meter wide. Folgoizol is absolutely waterproof. The material can be welded and self-adhesive.

What thickness to use:

- For insulation, you can use 3mm thick isolon.

- To insulate a wooden house, you can use 3 mm film.

- If the house is reinforced concrete or expanded clay concrete, then for its insulation you can use material 10 mm thick.

- For insulation of brick, shell tile, gas silicate, foam concrete, 5 mm thick isolon is used.

Isolon is the latest thermal insulation material, which has found wide application in industry and everyday life. An additional layer of foil increases the strength of the material without making it heavier. Folgoizol consists of uniform cells and a reflective surface, which affects its low thermal conductivity.

Measures for indirect heat saving of a typical bath

Of course, insulating the walls in a bathhouse from the inside with your own hands is an important and necessary step, as well as solving, in a number of situations, the problem of how to insulate the walls of a bathhouse from the outside. However, there are indirect measures, the use of which will help preserve the heat of the internal volume and minimize its leakage to the outside:

- Arrangement of a well-insulated vestibule or dressing room in the bathhouse;

- The use of low doorways with a high threshold to cut off cold air from below;

- Organization of a stove with a through firebox, which will allow, in addition to the steam room, to heat a dressing room or rest room;

- Equipping window openings with multi-chamber double-glazed windows with high reflectivity. By the way, it is obvious that many indicators of modern packages are of purely marketing origin, which has nothing to do with the context of the question of how to properly insulate a bathhouse inside;

- Placing the bathhouse structure in open, well-lit areas that are not subject to shadowing by other buildings and exposure to draft winds;

- Furnace smoke ducts must be designed and constructed in such a way as to minimize direct exhaust of hot flue gases into the atmosphere.

It is very likely that the implementation of these recommendations will help eliminate questions of how to insulate a bathhouse from the inside or how to insulate a bathhouse made of timber from the outside from the agenda altogether.