Screw piles are a popular solution to problems in construction today. They are quite widely used and are gaining more and more recognition among lovers of practicality, thanks to their easy installation and reliability. These structures are successfully used both in the construction of houses, baths, greenhouses or utility rooms, and when installing a stove or fireplace.

Why do you need a separate base for the stove?

Regardless of where the stove is located - in a house or a bathhouse, fire safety rules require the installation of a separate power structure under the heating structure.

Ovens can be made of brick or stone; in any case, these are heavy buildings that exert significant pressure on the base and produce sediment during operation.

To choose a foundation for a furnace, you need to calculate the total weight of the structure, which consists of the mass of the building material, the water entering the water heating tank (if any), as well as the fuel itself.

Building codes allow not building a foundation if the weight of the stove does not reach 0.5 tons, but for safety reasons, experts advise installing a power structure under any heavy heating device.

Do you need a foundation for a stove in a bathhouse?

It is quite difficult to answer unequivocally the question of whether a foundation is needed for a stove in a bathhouse. Often its presence is determined by the dimensions of the furnace. If the bathhouse has a large area, there is a need to install appropriate heating structures that are quite heavy. The oven must be well supported, and as a result, a foundation will be required.

Without a base, a stove can be built whose weight does not exceed 700-750 kg. If the indicator exceeds these data, it will be necessary to establish a separate basis.

It should be noted that a stove in a bathhouse requires a foundation that is not connected to the support of the building. Otherwise, the structure will have an additional impact on the base of the structure, which will lead to deterioration in operational parameters.

This requirement can be explained by the need to reduce the load. In turn, this will prevent deformation and destruction caused by subsidence of the soil under the bathhouse structure. The walls and the stove create pressure, as a result of which the foundation will sag faster. This will lead to deformation and subsequent destruction of the bath.

When deciding to install a foundation for a sauna stove, you need to take into account many additional factors, in particular weight, type of main support, soil, material of manufacture, boiler volume and much more. All of these structures can increase mass, which may require an additional base.

Even small changes in the bathhouse, which cannot cause harm to the wall coverings, can have a negative impact on the stove. When cracks appear, sparks can enter the bathhouse, carbon monoxide and smoke can enter. That is why the construction of a concrete lining is mandatory for large-sized furnaces.

Its installation is not required in situations where the mass of the stove structure is less than 700 kg, or the bathhouse building is placed on a solid concrete pedestal. Such buildings, especially if they are made of metal, are more durable compared to brick options. They can even be placed on a wooden base, while complying with the minimum fire safety requirements.

If the plan includes the installation of a brick stove, an additional base will not be required if the mass is less than 700 kg, and the base of the bathhouse is a monolithic concrete covering.

Important! If the bathhouse is built on a solid concrete foundation, you can refuse to install a separate stove foundation.

Requirements for the foundation for the furnace

When arranging a concrete base, the main requirements for it will be stability and immobility, excellent performance and strength characteristics. To achieve your goals, you need to focus on some key points, including soil characteristics, type of stove and its weight, immersion depth of the main foundation, material for making the bathhouse, etc.

Experts recommend paying attention to the following points:

- The base of the stove and the foundation of the bathhouse must be separated from each other by at least 5 cm.

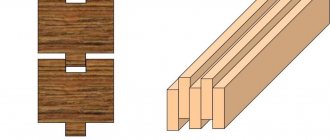

- When arranging a support, it is necessary that it be of a similar type to the foundation of the bathhouse base. For example, if the structure is built on a pile-screw type, the center of the furnace should also rest on piles screwed into the corners of the base.

- The stove foundation must be immersed in the ground at least 50 cm. This is necessary in order to give the foundation additional strength and stability, and to prevent possible deformations of the stove associated with subsidence of the bath.

To create the most durable and reliable structure, it is necessary to take into account many factors, including the climatic conditions of the area (how deep the soil freezes), the proximity of groundwater, the topography of the site, the composition of the soil and much more.

Furnace foundation options

The classic version is a rubble based on cement or concrete. In this case, the base should be 50-100 mm larger than the area of the furnace structure along the entire perimeter. As for the height, it must correspond to the size of the main foundation of the bathhouse.

Often, when choosing a base, preference is given to three options: rubble concrete, support-pile and concrete.

Rubble concrete base

To equip it, a pit is dug, the size of which exceeds the dimensions of the furnace by 10-15 cm. This is necessary in order to prevent possible heaving of the soil. For maximum strength of the foundation, crushed stone is poured into the bottom of the pit, the layer thickness of which is at least 15 cm. Next, the stone should be thoroughly compacted.

Then a layer of large bricks, the diameter of which is no more than 15 cm, is laid at the bottom of the pit. To get rid of the voids between the stones, it is necessary to fill in small crushed stone. Once this operation is completed, you can begin laying the cement-sand mixture. It is prepared in proportions of 1 to 3, and cement is needed with a grade of at least 400.

Each layer of crushed stone and stones is laid at intervals of 24 hours. This is necessary so that the stones form the most dense structure possible. If you ignore this requirement, the durability and strength of the rubble foundation will decrease.

Filling the base stops after 7 cm remains to the floor level. Next, the surface is carefully leveled. After this, the foundation should be given several weeks to completely harden. At the same time, it should be watered daily and protected from direct ultraviolet radiation.

Pile foundation

This option is considered the most preferable; it is the most modern and effective way to build a stove foundation. This type of foundation is a structure where a reinforced concrete slab 15-20 cm thick is installed on support piles or columnar supports (the specific type of piles is chosen depending on the depth of soil freezing).

To equip such a foundation, you need to drill holes in the ground with a diameter of 20 cm. Fine crushed stone is poured onto the bottom, a layer of at least 10-15 cm. This layer is thoroughly compacted, after which special tubular structures made of roofing felt are inserted into the holes. The concrete mixture is poured into them, after which the base is allowed to dry for 2 weeks.

As soon as the pillars acquire maximum strength, you can proceed to installing a reinforced concrete slab. It is recommended to cover it with roofing felt, which will act as a waterproofing material.

Solid poured concrete base

To install it, you need a pit that is at least 10-15 cm larger than the furnace in size. The dimensions of the pit for pouring the base of the bathhouse are formed based on climatic details; the bottom of the pit should be below the freezing level of the soil. If sandy soils predominate on the site, the recommended excavation depth is 80 cm, if heaving soils - at least 100 cm.

After the pit is prepared, a cushion consisting of sand, crushed stone and broken brick is laid on its bottom. The thickness of the sand layer is 15 cm, the brick layer is at least 20 cm. The pillow must be filled with water several times until the sand stops settling.

Formwork is installed along the perimeter, for which you need to make supports within 50 cm of each other. Then the reinforcing mesh is installed, after which the concrete base is poured. In order for concrete to be as strong as possible, it is necessary to take 1 part of cement of at least 400 grade, 3 parts of sand and 5 parts of crushed stone.

Important! A solid concrete base dries within 3 weeks. All this time it must be thoroughly watered and prevent sunlight from entering the structure.

Is stilt construction suitable?

According to SNiP rules, the load-bearing structure under the furnace is not connected to the rest of the foundation . In practice, any type of foundation can be used, including slab, strip and pile.

In this case, the feasibility of the chosen technique is calculated from the point of view of economy, practicality and durability.

Since the foundation for the furnace has the same requirements as the rest of the load-bearing structure, erecting a slab or strip can add significant costs to the overall estimate.

In this case, priority is given to supporting elements in the form of piles, which are not inferior in terms of load-bearing capacity and service life, but are more economical.

Preparation

Before starting any land and construction work, you must definitely decide on the future type of stove. The need for laying additional foundation elements may depend on the type of heat source itself (read also the article “Strip foundation for a bathhouse: from excavation work to pouring concrete”).

It will perform a protective function and is suitable for baths that are used once a week, because in winter the ground freezes to a considerable depth and its homogeneity is destroyed.

Experienced experts recommend laying the foundation for a sauna stove no less than the depth of soil freezing. You can learn this parameter from building climatology; in the southern districts of Russia the figure will be about 60-70 cm, and further to the north it will increase.

An important factor for construction is the type of soil, it can be:

- Sedimentary or alluvial. It is found in areas where previously there were reservoirs and is well suited for any foundation. If you come across porous clay, then you need to dig a little above the freezing level, because it swells greatly from water and expands when freezing;

- Soil containing sand and gravel is least susceptible to frost and is perfect for any building;

- Bulk soil consisting of crushed stone or gravel, after a few years, becomes a good basis for the foundation for a stove in a bathhouse. In the case when it is not “seasoned”, it must be thoroughly mixed with crushed stone and compacted;

- Permafrost - northern Siberia, etc. In such a situation, the foundation must also provide good thermal insulation from frozen soil.

Scheme of the required layers

Important. It is not recommended to place such a foundation for a bathhouse stove closer than half a meter near walls and main structures. The fact is that if it subsides or gets washed away, it can damage these structures.

The dimensions of the base will depend on the dimensions of the stove itself, but it must protrude ten centimeters from all sides.

Construction for an iron stove

It must be said that although iron stoves are light in weight, they also need to build a foundation. The fact is that with even small distortions, such a device will wear out more, and only if there is a high-quality base, there is a guarantee of its long-term operation.

Iron stove

It should be noted that building a foundation for an iron stove in a bathhouse is a simple matter and can be done with your own hands; this requires:

- Dig a pit of the required dimensions, with the required depth depending on the type of soil and location;

- Then crushed stone is poured into the bottom of the hole and compacted. When compacted, this layer must have a thickness of at least 300 mm;

- Next, cement mortar is taken and poured on top of the crushed stone. In a few days it will dry out and you will need to put waterproofing on it;

- A layer of concrete is poured on top of it, and the resulting surface is carefully leveled. If you have bricks on hand, they will work well instead of concrete.

This foundation is solid and its price is reasonable. And the main thing is that it does not require much physical labor.

Foundation for a metal stove in a bathhouse - approximate sketch

Brick oven base

Such stoves are heavy, so the foundation for them must be more massive. Note that it weighs up to 4 tons dry and about 8 tons wet. In order to approximately calculate this indicator, you need to multiply the weight of one brick by their number and add 40-50% to the weight of the mortar.

Monolithic foundation for the structure and heat source

Important. The ideal option is when the foundation for the stove in the bathhouse is poured simultaneously with the laying of the foundation of the structure itself. In this case, it will be monolithic and more resistant to external environmental influences.

If you have non-heaving soils on your site, then a reinforced concrete slab with a thickness of 150-200 mm will be enough for you, but provided that it is completely monolithic (without voids). To increase the stability of such a structure, it is recommended to make piles; in this case, they can be made from asbestos pipes with reinforcement filled with concrete.

The construction instructions allow the use of roofing felt sheets as formwork in such conditions. To do this, they are rolled up and additionally reinforced and filled with concrete.

The piles are installed below the freezing point of the ground. A hole is dug under them, crushed stone is poured onto the bottom and compacted, and after that the pile itself is made (see also the article “Columnar foundation for a bathhouse with your own hands - a real master can do anything”).

After a week and a half, a slab is laid on it, and then waterproofing is organized. A good option is metal screw piles. They are screwed into the ground in a short time, but their noticeable drawback is the price and the call of a team of specialists.

Photo of a brick stove

Concrete and rubble base for a brick kiln

The foundation for a sauna stove made of bricks can be made of concrete and rubble.

To implement this you need:

- Carry out excavation work - dig a foundation pit;

- Crushed stone is poured onto its bottom and compacted. It is recommended to make this layer at least 150 mm. If you have very heaving soil at the construction site, then it is better to apply another layer. It is made from sand and filled with water twice and only after that with crushed stone;

- Next, work is carried out on pouring the foundation;

- Work is being carried out to install waterproofing on the inside of the formwork; for this, rolls of roofing material and bitumen impregnation are used. Large stones are laid at the bottom and crushed stone is poured between them;

- Cement mortar is poured over the stones so that at least 60 mm remains to the floor level. The surface is leveled and covered with roofing material to dry for two weeks.

Important. When building the base of the furnace, it is necessary to leave a distance between it and the foundation of the building. This is done so that during operation it can rise and shrink. If you neglect this advice, the oven may collapse.

Foundation construction plans

Types of supports

Among all types of piles, the following meet the criteria for fire safety and sufficient load-bearing capacity:

- driven reinforced concrete pillars;

- bored reinforced concrete piles;

- screw rods.

The first type of structural elements is characterized by high load-carrying capacity, long service life (up to 100 years), resistance to moisture and mechanical loads, but it is impossible to build such a foundation on your own. The method of driving such piles involves the use of special equipment with diesel hammers.

It is advisable to use reinforced concrete driven piles if the same structural elements are used for the main load-bearing structure.

You can lay the foundation for the furnace with your own hands using bored and screw supports . In the first case, the supports are made directly on the construction site in prepared wells. Screw rods are factory-made inexpensive products that can be immersed in the ground with the effort of three people.

Pros and cons of such a foundation

The popularity of pile technology is primarily due to the relative cheapness and availability of building materials. The cost of constructing a pile foundation for a furnace will be 40–60% cheaper than laying a slab or tape.

Other benefits include:

- Possibility of construction on heaving, silty, moisture-saturated and, conversely, high-density soils.

- You can lay the foundation at any time of the year.

- The installation time for some types of piles can be reduced to one day.

- They have a load-bearing capacity of up to 18 tons.

Reasons why piles are not always used as a load-bearing structure for a furnace:

- the quality of factory products does not always correspond to the declared characteristics;

- not recommended for use in areas with increased seismic activity;

- the need to conduct geological surveys to prevent uneven shrinkage.

Advantages of screw rods

Screw piles are increasingly used in private construction to lay foundations for houses and separately for furnaces.

The demand for products is explained by their advantages:

- Lowest construction costs.

- Significant load capacity.

- Non-flammability.

- The ability to plunge into the ground with your own hands without renting equipment.

- Resistant to the buoyancy forces of frost heaving.

- Maintainability.

- Possibility of strengthening the foundation in case of reconstruction of the furnace.

Pile foundation for a brick oven

Another option that is suitable for a brick stove and which you can make with your own hands is a pile stove. Driven piles provide a kind of reliable support.

Here is the sequence of work:

- Using a drill, make holes 1 m deep and 0.2 m in diameter.

- Place crushed stone at the bottom of each hole and compact it thoroughly.

- Install the roofing felt formwork by first wrapping the material in tubes.

- Fill with concrete to the level of the bottom slab.

- After 10 days, install a 15 cm thick concrete slab.

- Perform waterproofing using roofing felt or hot bitumen.

Which supports to choose?

Regarding the operating conditions of the foundation under the heat-generating device, it is necessary to take into account sudden temperature changes, which almost always lead to premature destruction of power structures.

This disadvantage can be mitigated by using piles with a protective layer applied by hot-dip galvanizing. Such products are more expensive, but their service life is 1.5–2 times longer than that of pile models with a different protective layer.

Knowing the total weight of the heating device, the parameters of the screw piles are selected. As a rule, products with a rod diameter of 89 or 108 mm are used, which have a load capacity of 3 and 4.5 tons, respectively.

The length of the pile is selected based on two conditions:

- the depth of the pile foundation is laid below the seasonal freezing level;

- the tip of the pile must rest against a solid load-bearing layer of soil.

For Moscow regions with a freezing point at a depth of 1.5 m, piles 200–250 cm long are suitable.

Rubble concrete foundation for a brick oven

If you have chosen the rubble concrete type, follow these instructions...

- Prepare the pit. Its dimensions must exceed the dimensions of the planned base by 15 cm on each side.

- Fill the bottom of the pit with crushed stone in a layer of about 15 cm.

- Compact the crushed stone . After the compaction process is completed, check that the layer is level. For this you will need a level.

- Install wooden formwork . The dimensions of the formwork are identical to the dimensions of the foundation.

- The inner surface of the formwork should be treated. For this, either roofing felt or high-temperature bitumen is suitable. When the processing stage is completed, pour medium-sized stones into the formwork (the diameter of the stones should be approximately 12 cm).

- Add fine crushed stone to fill the spaces between the stones.

- Prepare a solution of sand and cement in a ratio of 3 to 1. The finished mass should have the consistency of thick sour cream.

- Fill the stove base cement-sand mortar. That is, fill in the layer obtained by pouring crushed stones and stones.

Please note that the finished foundation for a brick stove should be 7 cm below the floor level.

- Level the top surface of the masonry thoroughly using a level.

- Cover the surface with thick polyethylene.

- Let it sit for 10 days, then start laying the stove.

Screw mounting technology

The number of screw piles for the furnace is at least 4 pieces, for each corner of the structure . Construction is carried out at the stage of laying the foundation for the entire structure.

After marking the area, screw in the supports to the designed depth, using a crowbar as a lever. It is important to strictly observe the verticality of the axis of each support.

After this, the upper parts of the pile are cut off at the same level so that there is space left for mounting the support platform, which should not be higher than the plane of the basement floor.

The internal cavity of the pipes is filled with concrete mortar , and when the mixture gains strength, the ends are welded, the channel piping is mounted and the structure is covered with waterproofing material.

Features of construction from other types of piles

The distance between the driven and bored elements is selected based on the condition that at least three supports must be installed under the furnace. In this case, experts recommend driving a pile under each corner of the structure.

Driven reinforced concrete pillars are installed in the ground using impact force . When the elements enter the ground to the designed depth, their upper ends are aligned on one plane, and then proceed to the construction of a support platform for the furnace.

For bored piles, wells are drilled in the ground to the designed depth. For heaving lands, compacted sand cushions are installed at the bottom of the pits. Then casing pipes made of waterproofing material (for example, roofing felt) are placed in the wells, a reinforcement cage is laid inside and filled with concrete mortar.

Making a foundation for a sauna stove with your own hands

The base for a stove in a bathhouse is a simple operation that does not require much experience. Any steam lover can do the job. How to pour a foundation for a stove in a bathhouse - for this it is important to determine the design of the base, calculate and order the required amount of materials, and prepare tools. You need to make a foundation for an iron stove in a bathhouse with your own hands - just lay several rows of refractory bricks on a ready-made foundation for the entire building.

General requirements

Several points can be highlighted here:

- Large margin of safety and reliability of the design.

- High level of resistance to ground movement.

In this case, the depth of soil freezing in your climate zone when digging a pit, as well as the structure and type of soil, must be taken into account. When following the recommendations, the foundation is not subject to cracking or damage throughout its service life.

For various soils, the minimum pit depth is accepted, regardless of the climate conditions in this place:

- dry sandy soils - minimum pit depth 50 cm;

- rocky soils – up to 400 mm;

- clay soil, loam - you will need to make a pit up to 1000 mm deep. This also takes into account the soil freezing depth for your region;

- wet marshy soils - the distance increases and becomes from 1000 mm.

It is not recommended to make strong foundations on bulk soils, especially if large fragments of soil were used during filling. The size of the foundation for the stove in the bathhouse is made taking into account the protrusion beyond the dimensions of the stove by at least 100 mm on all sides.

Monolithic

How to pour a monolithic foundation for a stove in a bathhouse, in what cases is it necessary to equip a heater with such a foundation? In a small individual bathhouse there is no need to make such a separate base.

To work you will need:

- dig a pit according to the size of the stove, to the depth required for your region;

- make a sand cushion, 150-200 mm thick, compact the layer;

- fill the pit with expanded clay for a thermal insulation layer and cover it on top with film or roofing felt for waterproofing;

- make formwork along the contour of the slab from boards or other available material. In the case of a large base, the formwork is secured with several stiffening ribs, which also serve as beacons for pouring an even layer of concrete;

- make a reinforcement layer from reinforcement with a thickness of 10 mm. It is better to knit the reinforcement with wire; for welding you will need to prepare or buy couplings;

- We gradually fill the base with concrete and stretch its excess with a rule of a flat board or steel profile;

- the layer needs to be compacted. For this it is better to use a vibrator.

- While the concrete hardens, it must be watered with water, in this case the top layer will not crack.

The monolithic foundation is ready, the surface can be strengthened by ironing it with a layer of cement

Columnar with base plate

The foundation for a stove in a bathhouse of this design can be installed on top of the main one. In this option, use a reinforced concrete slab of a suitable size or you will have to fill it, making permanent formwork for it from corners or channels. This design protects the stove and the building from damage due to shifts in the layers of the earth in different seasons. It is recommended to install on loams and clay. All work is carried out in several stages:

- Having marked 4 installation points for the pillars, we drill holes in the ground for them to the required depth. The minimum size of pillars for large stoves is 200 mm; for small steel heaters, use a section of 80-100 mm;

- the bottom is filled up and compacted with crushed stone. Layer size 15-20 cm;

- We make permanent formwork from roofing felt or other durable material, roll it into a roll of the required size and insert it into the hole;

- we fill the cavities with concrete and compact the layer;

- after a week, we lay several layers of waterproofing on top of the pillars. To do this, you can use polyethylene or roofing felt, the main thing is that the edges extend beyond the dimensions of the oven;

- we lay the finished one or fill the area with mortar, making a homemade monolithic slab.

Work is done. This type of foundation is most suitable for a metal stove in a bathhouse.

On stilts

This foundation for the stove in the bathhouse is made in the same way as the previous one. With its help, steam rooms are equipped on marshy soils and bulk soil. For piles, concrete or steel rods of the required size are used. For installation, smaller diameter holes are drilled to the main soil and then the piles are driven into the ground.

A monolithic reinforced concrete slab larger than the stove by at least 200 mm is poured on top.

With the help of such a foundation, those who like to cool off after a steam room in an ice hole can set up a bathhouse not far from the river bank, the main thing is that the environmental prosecutor’s office agrees with this.

From rubble stone

The foundation for a stove in a bathhouse with a base of rubble stone is carried out in the following sequence:

- make the pit larger in size by at least 15-20 cm;

- make a sand cushion;

- We make formwork along the contour and place several spacers - beacons;

- We lay a layer of film from the inside to waterproof the foundation;

- lay out 1 layer of rubble and fill the voids with crushed stone. Layer thickness 150-200 mm;

- fill a thin layer with cement mortar;

- After the cement has hardened, lay out the 2nd layer of rubble and apply a layer of mortar. We repeat the operation several times;

- Having checked with a level that the installation is correct, we level the layer, adding solution to the required areas;

- the foundation should not reach the top of the formwork by 70-80 mm. We cover the entire area with a layer of roofing material with melted bitumen.

Next, you can begin to lay out the brick oven, making an ash pit with an ash pit at the bottom.

The foundation for a small iron sauna stove is best made of brick, laid out in rows on the finished concrete base of the sauna.

Brick

Making such a foundation for an iron stove in a bathhouse with your own hands is not difficult. Let's look at the option of making a base for a heater from a barrel.

For this:

- we mark the area for the stove, making it 300 mm larger;

- Lay out the first layer of brick longitudinally on the cement mortar and clay;

- the second row is laid out across. This is done to connect the layers.

- in the middle part of the foundation from the middle of the front part we make a niche for the ash pan and the blower. We close this cavity with a door.

For metal furnace

The foundation for a metal stove in a bathhouse is made at the stage of the main work on making the base for the room.

For this:

- We deepen a separate pit to a depth of 500 mm at the location where the furnace is installed. At the same time, we take into account an increase in the dimensions of the pit by 20 - 1000 mm, depending on the material of the future floor in the bathhouse. If wood is to be used, the foundation must extend at least 500 mm on each side;

- Having leveled the bottom and removed the soil, we fill the base with an even 200-300 mm layer of slag;

- We compact the layer using a manual tamper. Then expanded clay is poured on top for thermal insulation;

- fill the base with a solution of cement and sand and let it harden;

- lay out a layer of roofing material, fill it with ready-made or homemade concrete;

- Having laid the flooring, we proceed to the final operations. We lay out several rows of refractory or ordinary building bricks. The first row can be laid on edge to increase the gap to wooden floors.

Remember - if the walls and ceiling of the bathhouse are made of wooden parts, in this case the foundation for a metal bathhouse stove must be planned taking into account the required minimum distances:

- to walls – from 700 mm;

- ceiling – 1000 mm;

- floor - 140 mm.

To protect the walls you will need to make screens. It is better to make them covered with foil on the front side. In this case, the heat will be reflected from the screen, spreading throughout the room.

Making a support platform

The supporting platform for the furnace on a pile foundation can be made in the form of a reinforced concrete slab or a thick metal sheet with an anti-corrosion coating.

The first option is more suitable for bored and driven reinforced concrete piles, while sheet metal will be the optimal and more economical solution for screw piles. In the latter case, the sheet is welded to the strapping channel. The optimal size of the support platform is chosen so that there is a margin of at least 5 cm on each side of the oven.

How much will it cost to build it yourself and on a turnkey basis?

The economic feasibility of building a foundation for a furnace can be assessed using average market prices presented in the table:

| Type of power structure | Cost of one support, rub. | Installation of a foundation for a stove with your own hands, rub. | Installation of a foundation for a furnace - turnkey service, rub. |

| Screw piles | 1400–1550 | 7500–10000 | 10500–14000 |

| Driven piles | 4000–5000 | – | 40000–60000 |

| Bored piles | 2400–3000 | 9600–12000 | 15000–17000 |

Installation subtleties

A brick stove on screw piles does not come into contact with the ground, and therefore does not require special thermal or waterproofing; this factor is of particular importance when constructing a bathhouse. The piles are screwed into the depth of the house supports, this allows you to combine the main home foundation with the stove foundation; this criterion is important when installing a stove or fireplace in the middle of the wall. During installation, all individual features and conditions are taken into account, such as the weight of the expansion tank, the weight of the stove itself, and humidity.

The foundation for a furnace on screw piles must withstand heavy loads and be reliable. To ensure such reliability, careful measurements and calculations are carried out, thanks to which the required diameter can be selected. For example, corner piles will have a smaller diameter than central ones.

A stove on a screw foundation is the choice of practical and economical people. The foundation for a stove on stilts in Moscow is easily dismantled, universal in relation to uneven terrain and soil instability, can be installed quite quickly and requires lower costs compared to other types. The construction of a foundation for a brick stove in Moscow is carried out by teams of specialists who are able to efficiently fulfill any client’s wishes in a short time. Professional installation is a guarantee of strength, convenience and longevity of the structure.