Kryza device

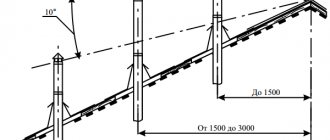

Master Flash is a pyramid of rings of different diameters, attached to an elastic base in the shape of a square or rectangle. Each of the rings corresponds to a specific pipe diameter, so this design is universal. The rings can be attached to the base at an angle of 90º, or at an angle of 30 or 45º. Depending on this, the penetration is used for fastening on a flat surface or on an inclined one.

Advice! If there is no corner master flush on sale that matches the angle of inclination of your roof slope, then take a straight one, but of a larger size.

The chimney cover can be made of silicone or rubber. Silicone is a more elastic material and more resistant to high temperatures. But its disadvantage is its lack of resistance to UV radiation, which leads to its shorter service life. If solid fuel is used for combustion, the temperature of the waste products discharged through the pipe will be higher. In this case, the installation of a silicone master flash is required.

Advantages and disadvantages

Modern craftsmen prefer installing a master flush for the chimney for the following reasons:

- elasticity, which ensures a tight fit between the pipe and roofing materials;

- a form that allows it to be installed on roofs of a wide variety of shapes and slopes and made of different materials;

- durability and strength, which ensures resistance to mechanical stress, including corrosion;

- tightness achieved due to the tight coverage of the pipe by the upper ring;

- thermal resistance to changes in low and high temperatures;

- wide scope of application - it is possible to install master flash on corrugated sheets, metal tiles, ondulin and other coatings;

- the ability to install master flash in any weather;

- ease of installation of a chimney penetration with your own hands.

- affordable price.

The only downside we can mention is that it is somewhat labor-intensive to install master flash on a roof ridge.

Installation of master flash on corrugated sheets with your own hands

- The upper plane of the cone is cut off, on the basis that the diameter of the resulting hole should be 20% less than the diameter of the chimney pipe. It is necessary to cut off excess sections carefully; it is better to use cable cutter scissors or a sharp hooked knife.

- The seal is placed on the pipe with the base down.

- The cone gradually moves downward so that the flange fits tightly to the roof surface. It is not recommended to pull the flange by the edge; the device can be advanced by pulling on the flexible corrugated cone. To facilitate movement along the pipe, it is recommended to lubricate the surface of the chimney with a soap solution.

- If the seal is installed on a roof covered with individual elements (tiles, slate), the upper part of the device flange is tucked under the previous row, and the lower part is brought up and secured with self-tapping screws. This fastening method promotes free flow of water and snow removal. If the flush is mounted on a ridge, the upper part of the base is set under the flashing.

- On flat roofs and on roofs covered with sheet covering (roofing felt, corrugated sheets), the base is fixed with a moisture-resistant sealant or coated with bitumen. If the inner side of the base is equipped with a porous sealing gasket, gluing with silicone or sealant is not required.

- To complete the installation, the master flashes the corrugated sheeting with his own hands - the flange is secured to the roof using self-tapping screws. Decide on a reasonable number of holes. After some time, any sealant loses its properties, and moisture will penetrate through the holes for the screws. The recommended distance between screws is at least 35mm. If the roof covering is ribbed (corrugated sheeting, slate), it is not recommended to make fasteners in recesses through which water flows.

Necessary materials

Before installing the master flush on the roof, check its contents. You will need:

— Master flush for a pipe of the appropriate diameter. When choosing, also focus on the temperature of the exhaust gases, since the choice of material from which the roof is made depends on it.

Advice! When choosing a penetration, keep in mind that a flash master with a reinforced base has a longer service life, but provides insufficient adhesion when installed on metal tiles, corrugated sheets or other embossed roofing materials.

— A plate used to protect the wing from sunlight. It can be purchased at building materials stores or made with your own hands. It looks like an ordinary plate without a bottom.

— Screwdriver, self-tapping screws, metal scissors and heat-resistant silicone sealant

Master flush selection

To choose the right penetration, it is not enough just to know the dimensions of the chimney. Master flash on sloping roofs made of polyprofile, roofing steel without relief, flat tiles, with an angle from 10 to 45º, a roof with a base in the form of a circle or square is selected. For the same roofing materials and a slope of 45-60º, a device with a reinforced flange is selected. In case of a slope of more than 60º, you need to select a seal with an enlarged flange. On flat roofs, perpendicular cuffs will be required. For tiled and slate roofs, penetrations with enlarged flanges are selected. Also, depending on the slope of the roof, choose a corner or straight roof. For some types of chimneys it is impossible to use a standard type of penetration. This may be due, for example, to the fact that the pipe has a square cross-section (wall size up to 15 cm). In this case, a special hood with a clasp is used. Such devices are also used to repair existing insulation. For larger square pipes, a rubber or silicone strip with an aluminum base is used. If it is impossible to use a flash master for compaction, it is recommended to use a special elastic roll material reinforced with aluminum.

In order to decide on the material from which the master flash is made, start from the temperature to which the chimney heats up. In the case of a gas hood, the heating of which does not reach very high temperatures, you can choose a rubber device. A silicone sealant is suitable for a stove chimney.

The Flash Wizard is installed as follows.

First, cut off the upper part so that the diameter of the resulting part is approximately one fifth less than the chimney pipe. This will ensure a tight fit. The resulting structure is placed on the pipe with the base down and moved along the pipe until it fits against the roof. When installing master flush on corrugated sheets and metal tiles, it is better to use a rubber penetration.

The next step will be to secure the resulting structure with sealant. At the very end, you should screw it to the roof using self-tapping screws.

There are several tricks when installing master flash.

- To make it easier to thread the pipes through the roof, cover them with soapy water. This will make pulling easier.

- If you were unable to immediately successfully cut a hole in the master flash, you can try to use it, sealing it tightly with a clamp.

- When buying a sealant for master flush, make sure that it is resistant to moisture.

- There should not be too many self-tapping screws, since in any case the sealant will someday begin to let moisture through, and then it will seep through the holes. Try not to screw self-tapping screws into recesses in the roofing material, as this is where precipitation flows.

- When installing the master flush on a chimney ridge, place its top under the flashing.

There are some features that you need to know before installing master flush on metal tiles. And other roofing materials that are installed with one sheet overlapping another. When performing installation in this case, you need to bring the upper part of the canopy under the nearest adjacent sheet. By performing this maneuver, you will achieve free flow of liquid regardless of the tightness of the penetration connection. This way you can increase the service life of the connection.

Note! Not every chimney is suitable for installing a roof, since in some of them the temperatures of the gases passing through the pipe exceed those permissible for a master flash. You will not have to face this problem in the case of a steel sandwich pipe and chimney connected to a gas-fired condensing boiler, since it does not heat up more than 100º.

If you use a chimney without insulation, as well as boilers running on solid fuel, temperatures can reach 600 º, which can lead to failure of the roof. How to install the master in this case? You need to select a pipe whose size exceeds the diameter of the chimney by about 10-12 cm. Its length should be up to 50 cm, or you can use regular galvanized metal. In the place where the chimney passes through the roof, it must be covered with basalt, and a selected sleeve must be placed on top. The master flash is installed, the dimensions correspond to the sleeve used. The open section of the insulation at the top is covered with a hopper, which is made of galvanized steel. You can attach it using a clamp.

The canopy with fastener is installed according to the following scheme. The top of the cone is also cut to a size 20% smaller than that of the pipe. Then the clasp is removed from the lock. The cuff is wrapped around the pipe, its sides are connected. Then the fastener returns to its place, the teeth tighten. The sealant is then applied to the appropriate area of the roof. Then the fastener and all places that need to be insulated are treated with it.

Having completed the installation, install the plate, thus giving the structure a finished look.

Thus, installing a master flush with your own hands is completely easy to do even for a novice, inexperienced builder. After all, all the tools needed for it can be easily found in many construction stores or even made with your own hands. This will not require special time or material costs from the master. At the same time, the installation of such a device will reliably protect the roof from precipitation, which otherwise could lead to unpleasant consequences.

What is Master Flush

Cuffs with a good degree of compaction are called Master Flash. Flash master for pipes has good elasticity. The cuff performed well when passing through the junction of the roof and the chimney pipe. For the manufacture of Master Flash, different materials are used.

Structural properties of the seal

The differences compared to other systems are as follows:

- Installation in any weather;

- Self-installation. Significant savings on specialist services;

- Long service life. At the same time, companies provide a long-term guarantee;

- Fire resistance at a high level;

- Restores previous dimensions after exposure to maximum temperatures;

- A low degree of looseness gives high tightness;

- Does not rust. Doesn't rot. Does not flake;

- Serves stably under constant temperature changes;

- Elasticity contributes to good envelopment of the pipe.

The big advantage was the reduction in material costs during installation. Waterproofing is not needed.

Differences between seals

Pipe aprons, used previously, became a thing of history after the appearance of the cuff. They are similar in their properties, but the chimney roof seal shows the following advantages:

- Made of silicone, sometimes rubber;

- Cone shape with bendable cuff;

- The cuff ensures that the pipe adheres tightly to the roof without gaps;

- Protection from water and dust is an additional bonus;

- The top of the cone copies the shape of the chimney;

- At the bottom there is a connection with a seal.

Flange base. Made from different types of materials. Silicone, rubber coated roof assembly base with heavy duty ribs, includes metal plates. It helps ensure that the flange matches the shape of the profile.

For a flat roof, insulation cuffs are used that stand at a slight angle. A cone-shaped corrugated element that forms round holes with marks along the radius allows you to arbitrarily change the angles, making a slope in certain ranges. It often turns out that the base is perpendicular to the axis. In this case, a cuff is used for a smooth, flat roof.

General installation principles

Innovative flexible seals have left obsolete seals behind in several ways. The ability to withstand sudden, constantly recurring temperature changes.

No repair required. Service life is not limited, subject to quality compliance by the manufacturer. Assembly does not require extraordinary abilities. The top of the cone is cut to create a small hole. The cone is threaded onto the pipe and then moved down to the base. In order for the work to proceed quickly, you need to smear the pipe with laundry soap. As a last resort, if you don’t have soap on hand, you can simply wet it with water.

The method of fastening the system is directly dependent on the roof covering. Bitumen mastic and silicone glue are used in the case of a flat, smooth roof made of rolled material. If there is a slope on the roof, self-tapping screws are used.

The base of the flanges and the cut of the cone are covered with silicone sealant after installation is completed. This is done to obtain increased reliability. You can additionally put on a clamp for the top of the edge. Regardless of the fixation force, the system will be movable. For example, when exposed to strong heat, Master Flash will not crack or lose its water resistance. When the house shrinks, the cuff will repeat the shape of its surroundings.

Master flush for a chimney: advantages, equipment, installation features

The passage of chimney channels is not without reason called one of the most difficult sections during installation. It is very difficult to make a truly airtight transition and protect your home from fire. Previously, they used various tricks, such as asbestos, galvanized sheets, bitumen and the like. As a rule, the result could last only a few months, and rarely a full season. All due to the characteristic climatic features. Therefore, today, more and more respect and reliability are given to the sealant called master flush for the chimney.

With the help of such a simple device, a person unfamiliar with construction can carry out penetrations in the roofing even with his own hands.

Installation features

When installing a roof, a master flush for your chimney with your own hands, you need to understand some features and rules that will facilitate installation and installation. So, when installing the cuff, consider the following nuances and life hacks:

- To make it easier to thread the device onto the pipe, the pipe coating, the inner wall of the ring, it is better to treat it with a special solution for sliding.

- For sealing, it is better to use only fire and water resistant sealants.

- Do not screw in too many screws; over time, the sealant loses its properties and then water will leak through the screws.

- When installing the roof, for reliability it is best to attach its upper part under the roof ridge.

- If the roof covering is wavy and not uniform, then the upper part of the master flush is moved under the top sheet of roofing material, thereby ensuring the free flow of precipitation.

What is a master flush?

Thanks to such a device, the chimney roof gains elasticity; the master flush is designed to design transitions to the roof. Master flash is produced in the most common configurations and formats; in addition, different sizes and shapes are possible. Today, manufacturers are ready to offer rubber seals for roofs made of tiles, corrugated sheets, slate, and the like. Such systems have come, so to speak, to replace the classic “aprons”; they are often made of special rubber labeled EPDM or silicone. The cuff allows for a hermetically sealed connection to the pipe, excluding the penetration of even dust.

The design also has a flange, a device that serves as a base and is also made of rubber. Along the perimeter, for reliable fastening, the base has an aluminum or galvanized tape, which allows not only to create the necessary relief identical to the roof, but also to install the “apron” tightly and, most importantly, hermetically.

Advantages and disadvantages

The chimney roof seal has the following characteristics:

- It is elastic, which allows you to create shapes identical to the overlap and make a hermetically sealed joint.

- Withstands flash and temperature changes over a fairly wide range.

- Inert, that is, they have a high degree of resistance to oxidation.

- Extremely low porosity of the surface and structure, resulting in amazing tightness.

- Fire resistance.

- It is possible, even after exposure to temperature, to take the same shape and configuration.

- Wear resistance within 30 years.

- No special tools are required for installation.

- There are no contraindications due to weather conditions during installation.

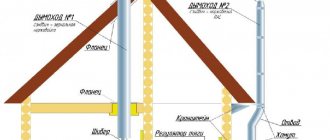

Master Flash for a chimney with your own hands - device and installation

The roof is built in order to protect the house from precipitation, but it will not be able to perform this function if the smallest cracks and gaps between the roofing material and the adjacent elements are not eliminated. The outlet of the chimney pipe needs more careful sealing. Since the size of the hole in the slope is 2-5 centimeters larger than the diameter of the smoke exhaust channel, a gap is formed between them, through which water penetrates into the rafter frame. To prevent leaks, bitumen mastic, cement mortar and sealants are used, however, the effectiveness of these materials decreases over time. To solve the issue of insulating the joint between the pipe and the roof once and for all, experienced roofers advise installing Master Flash elastic penetration.

Installation

Any Master Flash penetration is supplied with detailed instructions to facilitate DIY installation. Since the work is performed at height, it is necessary to carry out safety precautions, use a safety rope and a helmet. Installation is done as follows:

- If a protective cap is placed on the pipe, it is removed. The top of the penetration is cut with a knife to the required diameter.

- Pull the device onto the pipe through the head. If the penetration moves through too tightly, the pipe is treated with a soap solution, which makes the task easier.

- A heat-resistant silicone-based sealant is applied to the base of the penetration in an even, thick layer and pressed against the surface of the roofing material.

- Additionally, secure the base using self-tapping screws with a press cap. Do not overdo the number of screws, because while the sealant is washed off, water will begin to flow into the holes.

- If the installation takes place on a roof made of bituminous shingles, the upper part of the base is tucked under the covering elements.

- A decorative plate in the color of the roof is installed on the penetration.

Fundamentally important! If, while cutting the penetration, you made an inaccuracy and made a hole of a larger diameter or damaged the device, you can try to secure it to the pipes using a steel clamp and sealant.

Device

The Master Flash penetration is a stepped pyramid on a rectangular base made of silicone or rubber. Each of the steps has a corresponding diameter, so it is used for waterproofing pipes of any diameter. The Master Flash penetration is put on through the head, moved to the base of the chimney outlet to the roof and secured to the surface of the slope using self-tapping screws. Manufacturers offer models made from two different materials:

- Made of rubber. Master Flash is made from ethylene-propylene rubber, which belongs to the class of synthetic elastomers, has high elasticity, flexibility, and a high degree of moisture protection. They are used for chimneys in which the gas temperature is not higher than 100-120 degrees, since this material melts and burns. EDPM rubber has a porous structure and has low resistance to chemical compounds that contain fat and mineral oils.

- Made from silicone. Master Flash made of silicone is used for chimney pipes whose operating temperature exceeds 120-130 degrees. They tolerate heating well up to 220-240 degrees. Therefore, they are used to isolate the smoke exhaust duct of devices operating on solid fuel. Silicone products do not tolerate direct sunlight well, so they last less. This type of passage isolation device is non-flammable.

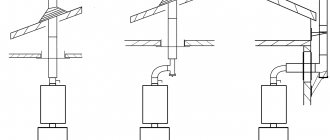

Important! Manufacturers produce straight Master Flash penetrations, which are used for installation on flat roofs, and angular penetrations (30 and 45 degrees), intended for pitched roofs. When choosing a model for installation with your own hands, be guided by the slope of the slopes; if only straight lines are available, take a larger penetration.

Equipment

Using the Master Flash penetration is the simplest way to insulate the joint between the chimney and the roof. Its installation takes no more than 30 minutes, and it lasts at least 15 years. To do the installation yourself, you will need:

- Master Flash penetration of the appropriate size made of silicone or rubber. Choose a model based on the diameter of the chimney pipe and the temperature of the gases inside it. Pay attention to the base of the product: products with a metal-reinforced flange last longer, however, it provides a poor fit to textured roofing materials.

Note! At each penetration stage, the corresponding pipe diameter is indicated. To prepare the Master Flash for installation with your own hands, you need to accurately determine the size of the chimney and cut the device according to the mark with ordinary scissors. Experienced roofers say that the hole in the flexible penetration should be 20% smaller than the pipe.

Parts included in the package

Installing a master flush chimney is an affordable and uncomplicated option for providing strong insulation between the roof and the chimney. The whole procedure, even for a beginner, will not take more than half an hour, and such a device will last for many years. For installation you will need the following equipment:

- Direct penetration of suitable dimensions, made of rubber or silicone. It is very important to take into account the diameter of the pipe being installed and the temperature of the products leaving through it. The basis of the purchased product is of great importance. Options supplemented with a flange with metal reinforcement have a long service life. One of the disadvantages is the loose fit to the relief-type materials with which the roof is equipped.

- The plate is a special device made of galvanized steel. It is placed on top of the penetration, protecting it from sunlight. Structurally, this is an ordinary plate without a bottom, which can be purchased at any hardware store. If desired, such a part can be constructed independently from sheet steel.

- During the work you will need a special sealant for master flash and a screwdriver with fasteners. When choosing a sealing composition, you should pay attention to heat-resistant options with a silicone base. The best self-tapping screws are those equipped with press caps.

Important! Each penetration stage corresponds to a certain pipe diameter. During self-installation of the flush master, it is necessary to determine with maximum accuracy the diameter of the chimney along which the protective product should be cut. It is recommended to create a hole in the penetration 20% smaller in relation to the pipe.

Advantages

Elastic products for sealing the passage of pipes through the roof have earned the trust of craftsmen and have become more popular than traditional methods of sealing gaps. Master Flash is optimal for DIY installation due to the following qualities:

- Tightness. It reliably protects the gap between the pipe and roofing materials from moisture penetration, preventing the possibility of leaks.

- Elasticity. Due to their flexibility, rubber penetrations tightly cover the pipe and fit tightly even to profiled roofing materials. These devices are suitable for roofs of any shape and slope.

- Versatility. It is suitable for roofs covered with corrugated sheets, metal tiles, roofing felt, slate and bitumen shingles.

- Easy to install. Do-it-yourself installation can be done in 10-15 minutes alone; even an inexperienced craftsman can do this work.

- Durability. Due to their resistance to temperature changes, chemical influences, and moisture, rubber penetrations have a long service life and do not require frequent replacement.

- Strength. Products made from high-quality rubber have a durable structure that is resistant to mechanical damage.

- High temperature resistance. The maximum permissible temperature at which silicone can be used to insulate a chimney meta-inlet is 220-240 degrees. This heat resistance allows Master Flash to be used for heating devices using any type of fuel.

Important! In some cases, the elasticity of Master Flush is the main advantage over other types of insulation. Only rubber and silicone penetrations have the ability to compensate for changes in the dimensions of the roofing material under the influence of thermal expansion.

Characteristic advantages

Elastic protective products, which can be used to easily seal a pipeline passage on the roof, are highly appreciated by craftsmen. They have replaced many traditional materials previously used to seal gaps. Do-it-yourself flash master is a task that even an inexperienced person can handle, and all thanks to certain qualities of the device:

- Elasticity. Rubber penetrations are very flexible and fit tightly to the pipe, enveloping it on all sides. Such products fit well even on profiled material, which is used to cover roofs with any slope and various shapes.

- Tightness. Reliable protection of gaps is provided from leaks through which atmospheric moisture can enter inside.

- Simple and uncomplicated installation. One person can complete the described task in a short time; no additional help is required.

- Versatility. Master Flash is installed on roofs covered with slate, metal tiles, corrugated sheets, bitumen shingles and others.

- High strength indicators. The structure of the material is porous and quite dense, withstands large mechanical loads.

- Durability. Rubber penetrations are not damaged for a long time and do not need to be replaced due to their resistance to chemical environments and temperature changes.

- Operation at high temperatures. The maximum permissible value at which silicone insulation for the chimney inlet can work is 240°C. Such heat resistance allows the described devices to be used when equipping heating systems operating on various fuels.

Important! In many cases, it is the elasticity of the described products that is the main advantageous factor compared to other insulators. A silicone or rubber part compensates for changes in the parameters of the material on the roof undergoing thermal expansion.

Terms of Use

Elastic rubber penetration Master Flash is the best option for waterproofing the gap where the chimney passes through the roof. However, it is not suitable for all cases. Professional roofers and manufacturers recommend using this device for DIY installation on the following types of smoke exhaust ducts:

- Sandwich chimneys. Between the two galvanized steel contours of these pipes there is a thermal insulating layer of basalt fiber. The insulation retains heat in the inner pipe, so the outer surface of the chimney remains cool. Rubber models are used to waterproof sandwich pipes.

- Stainless steel chimneys. Stainless steel chimneys that remove combustion products from solid fuel stoves are heated to high temperatures. Therefore, heat-resistant silicone penetrations are used to seal the target between the roof and the pipe. The use of conventional rubber models is possible if the chimney is connected to a condensing-type gas boiler.

Note! If you want to insulate the outlet of a bare pipe with Master Flash, you can use a special sleeve. A section of 50-100 cm is cut out of a pipe whose diameter is larger than that of the chimney. The section of the chimney passing through the roof is tightly wrapped with fireproof material, and then the sleeve is put on and secured with a steel clamp.

Each passage of Master Flash is supplied with detailed instructions to facilitate DIY installation. Since the work is performed at height, you should follow safety precautions, use a safety rope and a helmet. Installation is performed as follows:

- If a protective cap is placed on the pipe, it is removed. The top of the penetration is cut with a knife to the required diameter.

- Pull the device onto the pipe through the head. If the penetration is too slow, the pipe is treated with a soap solution, which makes the task easier.

- A heat-resistant silicone-based sealant is applied to the base of the penetration in an even, thick layer and pressed against the surface of the roofing material.

- Additionally, secure the base using self-tapping screws with a press cap. Do not overdo it with the number of screws, because when the sealant is washed off, water will begin to flow into the holes.

- If the installation takes place on a roof made of bitumen shingles, the upper part of the base is tucked under the covering elements.

- A decorative plate in the color of the roof is installed on the penetration.

Important! If, while cutting the penetration, you made a mistake and made a hole of a larger diameter or damaged the device, you can try to secure it to the pipes using sealant and a steel clamp.

About the conditions of use

An elastic rubber penetration would be an excellent option for ensuring reliable waterproofing in the chimney passage area. But it will not be appropriate in all cases. Experienced experts say that such a device is suitable for equipping the following smoke exhaust channels:

- Sandwich chimneys. These pipes have two contours made of durable galvanized steel, between which there is a layer of thermal insulation, most often represented by basalt fiber. This material retains heat through the inner pipe, which is why the outer part of the chimney does not warm up much, remaining practically cold. Optimal waterproofing of sandwich pipes - rubber models.

- Stainless steel chimneys, through which combustion products are discharged into the external environment when heating premises, are distinguished by the fact that they heat up very much. It is customary to fill the gaps between them and the roofing surface with heat-resistant penetrations made of silicone. In this case, master flush rubber models are also suitable, but if the chimney is powered by a gas condensing boiler.

Important! To reliably equip a non-insulated chimney, it is recommended to use an additional sleeve. For these purposes, you will need a pipe section from 50 to 100 cm, which is slightly larger in diameter than the working part. The part of the chimney coming out of the roof is wrapped with fire-resistant material, a sleeve is put on top of it and secured with a clamp.