Insulating the roof of a bathhouse is an important task, the correct implementation of which determines the temperature and humidity in the steam room and other rooms of the bathhouse. First of all, for proper insulation of the bathhouse roof, it is important to decide whether the bathhouse will have an attic floor or a ventilated attic. The sequence and choice of materials for insulating the roof of a bathhouse largely depends on this.

Bathhouse roof insulation

There are two main stages of thermal insulation of the roof in a bathhouse: insulation of the ceiling of the steam room and dressing room and insulation of the roof slopes. The feasibility of the second stage for a bathhouse with an unheated and well-ventilated attic is very controversial - if the temperature in the attic is close to the street temperature, there will be no problem of condensation, and therefore rotting of wooden structures. Therefore, in a bathhouse with a cold attic, the roof slope is usually not insulated - this is a waste of money. Ventilation is provided by installing attic windows, and the attic itself is used for drying and storing brooms and other necessary items.

When insulating the roof of a bathhouse with an attic floor, it is necessary to insulate both the ceiling and the roof slope. This will make it possible to arrange a full-fledged recreation room on the second floor. In such a bathhouse, it is necessary to pay close attention to the vapor barrier of the floors in order to avoid an increase in humidity on the second floor. Otherwise, the principles of insulating a bathhouse roof are no different and are performed using similar technology.

Methods

Insulation of the attic floor in the bathhouse must be done in any case. It is this element that is the last line that traps heat inside and prevents the penetration of cold air. There are three methods of thermal insulation - hemming, flooring, panel.

Grazing

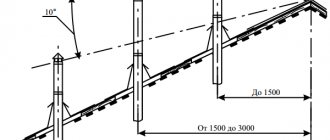

A simple method that is suitable for inexperienced builders. To complete it you need a small amount of building materials. Floor ceilings cannot be installed in rooms whose width exceeds 2.5 meters. The flooring should rest only on load-bearing walls, and not partitions.

Laying features:

- The maximum distance between load-bearing walls is 2.5 meters.

- The minimum thickness of the boards is 50 mm. They must be of high quality, free from cracks, knots, and rot.

- Before nailing the boards, they need to be sanded and coated with an antiseptic.

Flooring assembly process:

- Attach the prepared boards to the wall beams.

- Lay a vapor barrier film and attach it with a stapler.

- Lay mineral wool in rolls or slabs.

You can make homemade insulation - sew flat bags from waterproof fabric, fill them with padding polyester, foam rubber, red moss or dry pine needles.

When installing a floor ceiling, the attic cannot be used as a room.

Hemmed

Build process:

- Cut the lumber to the required size, correct any unevenness, and coat it with a protective antiseptic.

- Since stove equipment that runs on solid fuel is often installed in bathhouses, it is necessary to consider the location of the chimney. Install a special sleeve in the selected location. You can make it yourself from metal sheets or buy a finished product at a hardware store.

- Secure the vapor barrier film over the ceiling beams. Fix the individual sheets overlapping each other, with an overlap of 10 cm. It is recommended to seal the seams with metal tape.

- Hem the ceiling with pre-treated boards.

- Secure the foil insulation, which is nailed down with slats.

- On top of the vapor barrier film, which runs along the ceiling beams, make a wooden frame from 50x50 mm bars.

- Insert mineral wool slabs into the sections.

- Install a vapor barrier membrane. Cover it with slats to create a ventilated gap.

You can fix the lining on top of the slats.

Panel

Build process:

- Panel thermal insulation involves the assembly of a massive panel. Its base is two beams measuring 50x100 mm.

- Place the bars on the floor in front of you, leaving a distance of 50 cm between them. Align the edges in one straight line.

- Prepare the boards, cut them 60 cm long. One edge should protrude 50 cm. It is important to choose boards of the same thickness (25–30 mm).

- Make a shield.

- Attach a vapor barrier film to the inside of the structure.

- Place mineral wool on top of the film, tightly to each other.

Several such panels need to be prepared to insulate the entire ceiling. The finished structures are laid out on top of the last crown. The modules are connected by jumpers. They are attached to the crown with self-tapping screws.

On top of the finished flooring, it is necessary to lay another layer of vapor barrier and fill the slats to create a ventilation gap.

Proper thermal insulation of the roof of the bathhouse is important

Even people ignorant of physics know that hot air and hot steam always tend upward.

This is what determines the increased requirements for waterproofing and insulation of ceilings in bathhouses. Poor ceiling insulation will always have the following unpleasant consequences:

- Increased heat loss. No matter how hard you heat it, your sauna will quickly cool down, which in itself is a significant minus.

- Excessive fuel consumption. Actually, this point is a direct consequence of the previous one. Whatever you heat with, gas, wood or coal, a significant part of this fuel will go to waste, since heating the street is a thankless task. Having once invested money in good insulation, you will save on fuel every time you use the bathhouse.

- Formation of condensation. If the ceiling of your bathhouse is poorly insulated, condensation will collect on it, and the ceiling will periodically drip. There is nothing pleasant about such artificial rain. If the steam room is not very hot, the drops will be cool, but as the temperature rises, the “rain” can become very hot and even burn.

- Humidity is a slow enemy. Condensation dripping from the ceiling is a quickly noticeable consequence of poor insulation. The long-term effects of moisture penetrating into building structures are not so noticeable and noticeable. Increased long-term humidity can cause rotting of wooden elements, corrosion of metal elements, the occurrence of rot and rot in hidden places, the appearance of mold and various fungi. All this may soon require a major overhaul of your bathhouse.

Expert opinion

Konstantin Alexandrovich

From this we can draw an unambiguous conclusion - you cannot save on thermal insulation. When constructing any buildings, and especially when building a bathhouse, it is necessary to think through not only good insulation, but also the creation of effective barriers to steam and humidity.

Types of insulation for ceilings and roofs

When choosing insulation for a bathhouse roof, you need to take into account its technical characteristics. The material must be resistant to moisture.

Styrofoam

These are foam plates or granules that are made in different ways. Thanks to this, the required performance characteristics can be achieved.

Advantages of polystyrene foam:

- ease;

- ease of installation;

- durability;

- low price;

- resistance to moisture.

Flaws:

- The material is highly flammable.

- Polystyrene foam does not allow moisture to pass through itself. This leads to the accumulation of condensation inside the bath rooms.

On sale you can find varieties of polystyrene foam, during the production of which various modifiers are added. They reduce the flammability of the material.

Extruded polystyrene foam

It is similar to polystyrene foam, but other technologies are used in its production. The finished product is obtained with increased performance characteristics.

Advantages:

- high strength;

- resistance to chemicals;

- environmental friendliness;

- immunity to moisture;

- ease of installation;

- low specific gravity.

The disadvantages are similar to polystyrene foam.

Penoizol

One of the types of polystyrene foam, which belongs to cast-in thermal insulators. Since penoizol does not accumulate moisture, condensation does not form inside the walls. Penoizol is immune to high temperatures.

Flaws:

- release of harmful substances when heated;

- complex installation.

Not the best type of insulation for baths. It is relevant to use for industrial and utility premises.

Minvata

A common material for insulating baths and residential buildings. Made from natural ingredients.

The basis is molten rocks, to which synthetic substances are added.

Advantages:

- ease of installation;

- chemical resistance;

- low flammability of the material;

- removal of water vapor without delay;

- immunity to temperature changes;

- low thermal conductivity.

Flaws:

- Mineral wool loses its technical properties when exposed to moisture for a long time.

- When heated strongly, it releases harmful substances.

- The mass of the material is greater than that of polystyrene foam.

Mineral wool is used for insulation of industrial equipment, highways, networks, suspended facades, ceilings, walls, floors, wet facades.

Ecowool

Shredded waste paper with a reduced flammability index. When mixed with water, it produces a sticky mass that can be used to cover various surfaces.

Advantages:

- high level of noise absorption;

- environmental friendliness;

- resistance to high temperatures;

- economical consumption;

- ease of installation.

After application, a homogeneous layer without joints or seams is obtained. The manufacturer claims that fungus and mold do not form on the surface of ecowool.

Expanded clay

A porous, lightweight material that is made by firing shale or clay. Advantages:

- high thermal insulation rate;

- ease of installation;

- low specific gravity;

- low flammability;

- environmental friendliness;

- durability;

- resistance to household chemicals.

Flaws:

- When laying granules horizontally, you need to use a special substrate.

- To prevent the material from getting wet during operation, it is necessary to lay an additional layer of waterproofing.

To create a high-quality insulation layer, expanded clay is poured in a layer of at least 15 cm. This reduces the free space.

Vermiculite

A complex mineral that consists of magnesium, silicon, aluminum, and iron. Thanks to this, a multilayer structure of crystals is obtained. Advantages:

- environmental friendliness

- good vapor permeability;

- resistance to the formation of fungus and mold;

- no shrinkage;

- low thermal conductivity.

To prevent moisture from accumulating, ventilation gaps must be left.

Other types of insulation

More often, clay is used to insulate the roof and other surfaces in the bathhouse. It can be found on the territory of any summer cottage, but it is important to remember that clay is heavy. When insulating the ceiling, clay must be mixed with sawdust or other lightweight material.

Which insulation is better?

The choice of insulation is influenced by a number of factors:

- financial opportunities;

- design features of the ceiling, roof;

- necessary technical specifications.

When choosing a thermal insulation material, you need to take into account a number of rules:

- It must be environmentally friendly so as not to emit harmful substances when heated strongly.

- Rot, mold, and fungus should not form on the surface.

- The material should not be destroyed by rodents or insects.

- The insulation should not be destroyed at high temperatures.

- Thermal insulation must be strong and durable.

For thermal insulation outside

The best options for thermal insulation materials for external surfaces:

- Styrofoam;

- liquid thermal insulation;

- mineral wool;

- polyurethane foam.

For thermal insulation from the inside

Thermal insulation materials for interior decoration:

- Styrofoam;

- mineral wool;

- ecowool.

Options for bathhouse ceiling insulation and materials used

Insulation of the ceiling can be done using a plank method, when thick boards are laid on the upper crowns of the log house, or by hemming - fastening from below to the floor beams. There is also a panel method of insulation using pre-made multilayer panels.

Natural materials, for example, clay mixed with sand, straw or sawdust, and modern insulation materials such as mineral or basalt wool can also serve as thermal insulation for the roof of a bathhouse. The role of insulation is also played by boards hemmed or laid as a ceiling, so their thickness should be the maximum possible for this type of insulation. It is not recommended to use foam plastic for ceiling insulation for two reasons: it is a fire hazard and when heated it emits harmful substances. To insulate the slopes of a bathhouse with an attic floor, you can use polystyrene and other slab foam insulation materials under one condition: the brand of insulation must be non-flammable with the addition of fire retardants, for example, polystyrene foam PSB-S.

Laying layers of insulation on the ceiling

In addition, it is necessary to pay attention to the vapor barrier of the ceiling. It is performed from the steam room side and usually uses metallized hydro-vapor barrier films, for example Izospan FB. The metallized surface not only insulates the steam room from moisture evaporation, but also reflects infrared radiation, which improves thermal insulation. If insulation is carried out using fibrous materials, it is necessary to ensure the removal of moisture from the insulation layer, so they are covered on top with membrane waterproofing with one-way vapor conductivity towards the attic. When insulating slopes, it is also necessary to ensure one-sided vapor permeability of the entire insulation layer so that the humid air of the attic does not condense on the walls and ceiling.

Features of thermal insulation depending on the type of roof

The principle of insulation depends on the design of the roof in the bathhouse. Therefore, you first need to study the specifics of the work.

Single-pitch

Features of insulation of a pitched roof:

- The basis for installing thermal insulation is the rafter system. It is also the supporting foundation of the entire roof.

- A vapor barrier film is only needed over heated rooms.

- Thermal insulation is a “pie” consisting of hydro-, heat- and vapor insulation.

It is important to leave a ventilation gap to prevent moisture from accumulating under the roof.

Gable

Features of gable roof insulation:

- For two slopes, it is better to use polystyrene foam, since it is easier to work with.

- When insulating a gable roof, you need to use polyurethane foam, which can be purchased in liquid form.

Example of roof insulation

Nuances of insulating a sauna roof

At first glance, how to insulate the roof of a modern bathhouse does not seem complicated. Indeed, to the inexperienced eye, the process itself is no different from ordinary house construction. For example, this is how a gable roof of a steam room is insulated:

And flat like this, often using foam plastic:

But there are even special standards that are responsible for regulating the design of a bathhouse roof - these are SNiP II-26-76. And the thermal insulation of any roof must be as fireproof as prescribed by clause 5.21 of SNiP 01/21/97.

Why are we talking about this? The fact is that burning bathhouses are not uncommon. Somewhere the stove was insulated incorrectly from the walls, somewhere the thermal insulation for the chimney when passing through the ceiling was of poor quality, or the system itself was not installed professionally. In addition, over time, any wooden building dries out, and sparks often fall from the chimney. But the most vulnerable in this regard is the roofing insulation. Consider this issue more carefully!

What does thermal insulation consist of?

Proper thermal insulation is a layered “pie”. Each layer is responsible for separate functions.

Waterproofing

A hydrobarrier that protects the base from exposure to hot steam and moisture. Polymer-based film is used as waterproofing. Installation:

- Cover the ceiling on the attic side with slats and form a frame.

- Secure a waterproofing film between the beams. A construction stapler is used for this.

In order for accumulated water to be removed from under the roof, the film must be brought to the overhangs of the roofing material.

Thermal insulation

Features of installation of the thermal insulation layer:

- For insulation you need to make a ventilation gap. Thanks to it, condensation will disappear and moisture will not accumulate.

- Mineral wool and polystyrene foam must be laid in two layers.

- You can secure the mineral wool slabs between the rafters using a stretched fishing line.

Where the insulation joins the chimney, the pipe must be covered with a layer of asbestos.

Vapor barrier

To protect the insulation from steam penetration, film membranes are used. The film itself is attached to a stapler. Individual sheets should overlap each other with an overlap of 10 cm. It is recommended to glue the joints with metal tape.

For insulation from outside

The roof of the bathhouse should be insulated from the outside during the assembly of the wooden frame. The process will have to be repeated in a year, when the tree has “settled” and new cracks and gaps appear.

The best materials for external insulation are flax tow, felt, hemp hemp and moss.

All of them are created on the basis of natural fibers, environmentally friendly, fit perfectly on the surface, and all are affordable.

I would like to draw your attention to the use of moss for insulation purposes . A wonderful material, which, however, has one significant drawback: it rots very quickly.

But even among such materials there are exceptions: red moss, for example, which is not subject to rotting. It’s inexpensive, about 300 rubles for a 40-kilogram bag, and it holds heat excellently.

Carrying out work

Any person without extensive experience in construction work can do the insulation of a bathhouse roof with his own hands. Initially, you need to prepare consumables and tools.

Materials and tools

List of required materials and tools:

- slats, bars for sheathing;

- insulation, waterproofing film, vapor barrier membrane;

- metal tape;

- construction stapler;

- sharp knife;

- nails, hammer or screwdriver with self-tapping screws;

- jigsaw, wood saw;

- Sander.

Additionally, you will need a protective antiseptic for wood and wide brushes for applying it.

Preparation

Preparatory work:

- Cut the bars and slats to the required sizes in advance.

- Sand the lumber and correct any unevenness.

- Coat the wood with an antiseptic to protect it from rot, mold, and mildew.

There is no need to cut the insulation in advance. It is better to do this after filling the sheathing.

Thermal insulation outside

The process of arranging external thermal insulation:

- Secure the vapor barrier layer over the ceiling beams using a stapler.

- Stuff the wooden sheathing from the bars.

- Place insulation in the empty sections.

- Lay a layer of waterproofing.

- Secure the slats on top of which the facing material can be attached.

Thermal insulation from the inside

Features of insulating the roof of a bathhouse from the inside with foam plastic:

- It is recommended to fasten the boards with special glue.

- There is no need to fill the sheathing with bars.

Features of working with glass wool:

- The waterproofing film must be attached tightly to the glass wool.

- In order for the insulation to hold, you need to build a structure from wooden beams.

- It is necessary to attach cotton wool to the outside of the sheathing only if it is solid.

- If the sheathing is arranged in sections, glass wool should be placed between the rafters.

Insulating a barrel sauna: a step-by-step master class!

The barrel sauna is a brilliant invention: it is compact, does not require a foundation and is not at all expensive to build. Everything about it is good, except for one thing: it cannot be used in the cold season. At least, that's what most bath attendants think. Still putting up with this shortcoming? Would you like to insulate the acquired know-how, but don’t know which way to approach it? After all, there is no separate roof on such a bathhouse...

It's simple! Study the master class we prepared on the internal and external insulation of a barrel bath:

Of course, it is better to insulate a barrel sauna from the outside, so as not to steal valuable internal space:

As you can see, the principle is the same - the main thing is to choose the right insulation materials and take care of fire safety!

Thermal insulation of slopes

Stages of thermal insulation of roof slopes:

- Attach a waterproofing film over the inner surface of the slopes.

- Place mineral wool panels between the rafters. If one layer is not enough, you need to put together a wooden sheathing and secure the second layer.

- Attach a vapor barrier film over the mineral wool.

All that remains is to fill a simple wooden sheathing from slats and line it with clapboard.

General information

Types of roofs

The ceiling itself can also be of two types - suspended and laid. The latter is extremely simple - it does not have beams, there are only boards that stretch from one wall to the second. This ceiling is fragile, it cannot bear excess weight, and even walking on it is dangerous, and the weight of the thermal insulation should be moderate.

The false ceiling has a stronger base - beams. Using skull blocks, you need to attach flooring boards to the beams (across the beams). This overlap can become a durable floor on the second floor. We will tell you in more detail below when we talk about thermal insulation technology. Insulated roofs are usually done either in order to actively use the attic space as a living space, or as a warehouse for necessary and not-so-necessary things. In any case, they do insulation there using the rafter system.

Ceiling pie for a bathhouse with a cool roof

A good option for insulation would be either expanded clay or foamed vermiculite. Naturally, these are fairly light insulation materials, but it is still worth consulting with professionals about the strength of the boards, foundation and walls, because the floor ceiling is made in the most inexpensive projects, and this means it is possible that the load-bearing characteristics of the walls and foundation are reduced. It should be assumed that the expanded clay or vermiculite layer can be from 0.15 to 0.3 meters thick. Roughly speaking, a square meter of such backfill area is 1/6 or 1/3 of the total weight of a cubic meter of both the first and second material. But their fractions are very different - larger ones can weigh less (a cubic meter of vermiculite, for example, weighs 65-350 kg). The weight of the specific fraction purchased should be checked with the seller.

Please note that for greater backfill density, coarse and fine fractions are usually mixed. This will complicate the calculations, and therefore it is possible to make calculations with a “reserve” for the heaviest fraction. Or you can do this as the arithmetic average of the weights from all fractions. For an even backfill, it is recommended to divide the floor ceiling from the attic side using boards of the required width into “paths” the same way a swimming pool is divided. It turns out that you put the boards on edge and attach them to the ceiling, and then you will get long “containers”, and you need to fill the thermal insulator into them - it will be more convenient. Just don’t forget about waterproofing and vapor barrier from below, and also cover with something on top. The pie itself in a bathhouse with a cool roof is very simple:

- Insulation.

- Waterproofing and vapor barrier.

- Flooring board.

Next about the attic.

How to insulate the ceiling near the chimney of a bathhouse?

It is very important to comply with all fire safety rules when building and insulating a bathhouse. The chimney pipe has a high heating temperature; if you do not follow the technology, then instead of enjoying the bath procedures, you can lose your property.

- It is best to use a sandwich pipe as a chimney; it is also possible to use a simple metal pipe or brickwork, but in no case should you use a cement-asbestos pipe. When heated and moisture gets on it, pieces will fly off.

- It would be better to make the chimney dismountable, this will make it easier to install and subsequently replace worn-out elements as necessary.

- A square hole is made in the ceiling on each side 10 cm larger, chimney pipes, if the chimney diameter is 20 cm, then a 40X40 square is cut out.

- 2 sheets of 50X50 are cut out of galvanized iron, in one a hole is made according to the diameter of the pipe, and in the second an oval hole according to these dimensions.

- The first sheet is attached to the ceiling from the inside of the bathhouse, a chimney is inserted into it, and expanded clay, slag or mineral wool is poured on top around it.

- The second sheet is attached to the roof using fire-resistant sealant and the chimney pipe is inserted.

In this way, both insulation and compliance with fire safety standards are carried out.

Tips for choosing insulation

When choosing a material for insulating the ceiling in a bathhouse, it is important to focus on your capabilities and the indicators that need to be achieved.

- Price. The cheapest and most accessible would be insulation using sawdust and clay; the most expensive is using mineral wool.

- Environmental friendliness. Here again, preference is given to old-fashioned methods.

- Convenient insulation. In this indicator, on the contrary, preference is given to mineral wool.

- Speed of operation. It will take up to several months for the insulation solutions to dry.

Ecowool

Completely environmentally friendly insulation based on cellulose impregnated with sodium tetraborate and boric acid. The advantages of using the material are:

- low thermal conductivity of the coating; resistance to temperature changes; light weight; long service life; almost complete resistance to attack by insects, microorganisms, fungi.

Among the disadvantages, it is worth noting the complexity of installation. If it is produced by the so-called “wet” method, and this happens most often, the use of special equipment is required.

These are not all coatings that are used for insulation. Sometimes environmentally friendly materials, which have been successfully used by home craftsmen for decades, are chosen as an insulator. This is clay with sawdust or leaves.

The composition of the mixture may vary. Wood shavings, cement, peat, black soil, straw, etc. are added in various proportions.

Layer No. 1: vapor barrier

The main task of this layer is to prevent vapors from entering the insulation. All vapors rising from the heated room must be contained.

Proven materials such as glassine or roofing felt can be used as an insulator for this layer. Or more modern geosynthetic coatings, various membranes and thermofol. It’s good if the coating is foil, then it can also shield heat, returning it to the room.

The second layer of insulation cake should retain heat without letting it escape.

A variety of materials can be used here. Which one to choose will be determined by your budget and your own skills in carrying out construction work. It is important that the insulation is as light as possible (then it will not create unnecessary load on the structure that is resistant to moisture) and non-flammable, as simple and easy to install as possible.

For insulation, protection from water only from the side of the room is not enough.

Another barrier is required, but from the roof side. Water can also penetrate from there. Therefore, a layer of waterproofing must be laid on top of the heat insulator.

This is a film or membrane. It is optimal for one side of the material to be completely moisture-proof and the other to allow steam to pass through. Thus, the insulation will be able to “breathe” and water will not get into it.

An important nuance. If the bathhouse is built without an attic, insulation is carried out only from the inside.

If there is an attic, then thermal insulation can be installed both inside and outside the room. The material used for insulation will play a decisive role here. For example, slab and roll coverings can be laid in any way, but self-leveling or bulk coverings can only be laid outside.

For thermal insulation, you can use different materials. Let's look at the most popular solutions.