From time immemorial, the bathhouse was for the Slavs not only a room for washing the body and spending leisure time, but was also considered a sacred place. In their opinion, the bathhouse combines four elements - air, water, fire and earth, which give a person spiritual and physical health and charge him with energy. A bathhouse is not a luxury, but simply a necessity to maintain vigor and strength in a person’s body. Many owners of private houses already have a bathhouse or just want to build one. The construction of a bathhouse is possible from various materials: brick, cinder block, foam block. A bathhouse made of wooden logs, beams or a log house looks beautiful. But wood is a very expensive material. A do-it-yourself bathhouse made of expanded clay concrete blocks will be less expensive.

Bathhouse projects

Number of projects 687

- 3 rooms

- 1 bathroom

Log bathhouse project BO-030

- To favorites

- 80² Total area

- 6 x 8m Construction area

from 1,080,000 rub.

Construction period 90 days

- 1 bathroom

Log bathhouse project BO-022

- To favorites

- 35² Total area

- 5 x 8m Building area

from 472,500 rub.

Construction period 90 days

- 1 room

- 1 bathroom

Bathhouse Mylenka project

- To favorites

- 26.5² Total area

- 6 x 6m Construction area

from RUB 357,750

Construction period 30 days

Log bathhouse project BO-029

- To favorites

- 38² Total area

- 5 x 8m Building area

from 513,000 rub.

Construction period 90 days

- 2 rooms

- 2 bathrooms

Bani Harbor project

- To favorites

- 110² Total area

- 11 x 9m Construction area

from 1,100,000 rub.

Construction time individually

- 1 room

- 2 bathrooms

Bath Kamenka project

- To favorites

- 65² Total area

- 5 x 13m Construction area

from 815,700 rub.

Construction time individually

Log bathhouse project BO-001

- To favorites

- 17² Total area

- 4 x 5m Building area

from 229,500 rub.

Construction period 90 days

3m barrel sauna project

- To favorites

- 6.6² Total area

- 3 x 2m Building area

from 179,000 rub.

Construction time individually

- 1 bathroom

Bathhouse Pasechnik project

- To favorites

- 26² Total area

- 6 x 6m Construction area

from 351,000 rub.

Construction time 22 days

- 2 rooms

- 1 bathroom

Bathhouse Serduchka project

- To favorites

- 72² Total area

- 8 x 6m Construction area

from 972,000 rub.

Construction time 42 days

- 1 room

- 1 bathroom

Project Baths 6B-B

- To favorites

- 17² Total area

- 4 x 5m Building area

from RUR 259,529

Construction period 15 days

- 1 room

- 1 bathroom

Bani Lisa project

- To favorites

- 51² Total area

- 6 x 9m Construction area

from 674,000 rub.

Construction time individually

- 1 room

- 1 bathroom

Project Baths 14B-B

- To favorites

- 27.1² Total area

- 5 x 6m Construction area

from 334,065 rub.

Construction period 18 days

- 1 room

- 1 bathroom

Bathhouse Mylnya project

- To favorites

- 29² Total area

- 5 x 6m Construction area

from RUB 391,500

Construction period 30 days

- 3 rooms

- 2 bathrooms

Caravel Baths Project

- To favorites

- 107² Total area

- 17 x 11m Construction area

from 1,444,500 rub.

Construction period 50 days

Bathhouse project Standard No. 3

- To favorites

- 15.3² Total area

- 4 x 4m Building area

from 470,000 rub.

Construction time individually

- 1 room

- 2 bathrooms

Bathhouse project "Riga"

- To favorites

- 81.5² Total area

- 12 x 10m Construction area

from 1,630,000 rub.

Construction time individually

- 1 bathroom

Barrel sauna project 6m

- To favorites

- 13.2² Total area

- 6 x 2m Building area

from 259,000 rub.

Construction time individually

- 1 room

- 1 bathroom

Bath Sakura Project

- To favorites

- 80² Total area

- 11 x 7m Construction area

from 1,080,000 rub.

Construction period 35 days

- 1 bathroom

Log bathhouse project BO-005

- To favorites

- 20² Total area

- 5 x 6m Construction area

from 270,000 rub.

Construction period 90 days

View all projects

Many owners of country houses and cottages build a bathhouse on their property, which is often not just a luxury, but a necessity. After all, you can relax in it after a hard day, relieve stress, and also improve your well-being. Recently, a bathhouse made of expanded clay concrete blocks has become very popular. This option differs from others in its low cost and good characteristics. All the features, advantages and disadvantages of such extensions are discussed in detail below.

Bathhouse made of expanded clay concrete blocks Source vosaduly.ru

Advantages and disadvantages of buildings

Positive sides:

- Low specific gravity. Allows you to save on foundation construction.

- Small consumption of mortar for laying walls.

- No shrinkage.

- High strength index.

- Wall decoration with any material.

- Immunity to the formation of mold and mildew.

- High fire resistance.

- Environmental friendliness. The blocks do not emit harmful substances during operation. They include cement, sand, expanded clay, and water.

- Simple and quick installation.

- High breathability of blocks. Increases air exchange in rooms.

- Low level of water absorption.

- Preservation of heat in rooms.

Negative sides:

- In cold and temperate climate zones, additional wall insulation is required.

- Unattractive looking blocks. It is necessary to carry out external and internal finishing of the bathhouse.

If you follow the rules for working with blocks, you can level out the shortcomings of the material.

Expanded clay concrete blocks (Photo: Instagram / kirpichnyy_dom)

What is expanded clay concrete?

Expanded clay concrete is a type of building material. It is monolithic and hardens naturally. It consists of expanded clay, cement, sand, as well as special air-entraining additives. It differs from traditional concrete by its lightweight filler – expanded clay.

Expanded clay concrete block Source beton-house.com

Stages of work to create a foundation for a bathhouse

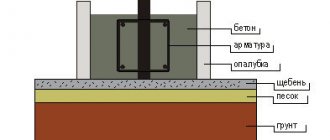

When the trenches are ready, construction of the foundation of the building can begin. All construction work is divided into several stages:

- Laying a sand-gravel or sand-crushed stone cushion.

- Creation of a waterproofing layer.

- Construction of the first base layer from FBS or expanded clay concrete blocks.

- Reinforcement of the foundation with corrugated rods of medium section.

- Filling trenches with concrete solution.

It is worth remembering that the blocks must be bonded together with a solution before the main pouring. The optimal dimensions of the seams should not be more than 1 cm.

Secondary moisture insulation must be installed after the foundation tape has completely dried. This way there is a greater chance of preserving the foundation from constant dampness.

Pros and cons of expanded clay concrete baths

For a properly constructed bathhouse made of expanded clay concrete blocks, the pros and cons are dictated by the characteristics of the material. When choosing expanded clay concrete for the construction of a bathhouse, it is necessary to take into account all the features so that in the future the extension will serve for a long time, and its owner will not regret the previously made choice.

The main advantages of objects made from this building material include:

- Installation work is completed in a short time because there is no need for a technological break in the process of working on the structure: for example, when using foam or aerated concrete, you need to wait three to six months.

- Sufficiently large parameters of the blocks ensure ease of working with them. In addition, despite such dimensions, the material is easy to install, so there is no need to use special equipment.

- The construction of a bathhouse from expanded clay concrete blocks occurs without the use of special masonry mortars, because an ordinary concrete mixture or adhesive foam is prepared for fastening the building materials.

- Quite low cost of expanded clay concrete blocks.

- The walls of the structure are very smooth. In addition, their surface is easily amenable not only to plastering, but also to other methods of wall cladding.

- Long service life of the bath.

- No additional vapor barrier of the walls is required, which also helps to save on the construction of a bathhouse.

- Quite low moisture absorption coefficient.

Expanded clay concrete blocks are smooth and easy to lay Source stroim-dv.com

However, in addition to the advantages, there are also several disadvantages that should not be neglected:

- This material should not be chosen if the project involves the construction of a two-story bathhouse with an attic.

- Expanded clay concrete blocks are characterized by increased fragility, which is why they can collapse even from a slight impact or mechanical damage.

- Also, many experts call a significant drawback the need for mandatory cladding of both external and internal walls, and the use of cladding materials, accordingly, increases the cost of money for construction work.

- You need to build a strong and stable foundation.

Building from blocks has both pros and cons, but the number of advantages outweighs the number of disadvantages. In addition, thanks to the right architectural solutions, even the slightest defects can be easily eliminated. For this reason, you can safely order a bathhouse project made from expanded clay blocks, and it is better to turn to professionals for such a service.

Types and characteristics of building blocks

Building blocks are made using a variety of techniques and materials, with some types of blocks available for making in the home workshop. But they are absolutely not suitable for such a structure as a bathhouse. The following materials are used for casting blocks:

- Gas silicate.

- Arbolit.

- Foam concrete.

- Expanded clay concrete.

- Slag concrete.

The binding element of building blocks can be lime or cement.

Building blocks made from different materials have different structures

The main properties of building blocks are explained mainly by their porous structure:

- Low thermal conductivity.

- Low volumetric weight.

- Medium strength.

- Frost resistance.

- High water absorption.

It is precisely this high water absorption that is associated with the ban by official building regulations (SP) on the construction of buildings and premises with high humidity, which include baths and saunas.

Table: characteristics of the most commonly sold expanded clay concrete blocks

| Name | Thermal conductivity coefficient, W/(m*K) | Strength grade | Density, kg/m3 | Frost resistance index |

| Double-hollow expanded clay concrete block 390x190x188 mm | 0,35 | M50 | 1050 | F50 |

| Four-slot expanded clay concrete block 390x190x188 mm | 0,35 | M50 | 1050 | F50 |

| Eight-slot expanded clay concrete block 390x190x188 mm | 0,35 | M75 | 1150 | F50 |

| Solid expanded clay concrete block 390x190x188 mm | 0,3 | M100 | 1100 | F50 |

| Expanded clay concrete three-slot partition block 390x190x188 mm | 0,35 | M50 | 1050 | not standardized |

| Expanded clay concrete solid partition block 390x190x188 mm | 0,3 | M75 | 1300 | not standardized |

Selecting blocks for building a bathhouse

The choice should begin with a clear idea of what a bathhouse is and what qualities the wall material should have for its construction. So, a bathhouse is a high temperature and almost one hundred percent humidity. The building material for it must have the following qualities:

- Heat resistance.

- Fire safety.

- Moisture resistance.

Comparing the performance of blocks from various materials, we come to the conclusion that the best type of blocks for building a bathhouse are expanded clay concrete blocks, since they have:

- Highest strength.

- Good thermal conductivity.

- Frost resistance.

- Zero shrinkage.

- Lowest water absorption.

Another advantage is the fact that expanded clay concrete blocks cannot be produced at home, which means there is less opportunity to run into low-quality goods.

Expanded clay concrete blocks have the lowest water absorption, so they are best suited for building a bathhouse

Lyubok block is a porous material that absorbs large amounts of moisture under operating conditions. Official current regulations prohibit the construction of buildings and premises with high humidity, but there is at least one way out of every hopeless situation. In our case, this is hydrophobization. In order to close the pores of the material from moisture accumulation and gradual destruction, it is necessary to treat the blocks with a water-repellent solution.

Different compositions are offered on the construction market. One of the most effective and at the same time the cheapest water repellent is based on organosilicon compounds. It is produced ready for use or concentrated, for dilution with water before use. The lowest consumption of water repellent is achieved by spraying.

The blocks must be hydrophobized before they are laid in the walls, this will reduce the consumption of masonry mortar.

Video: construction from blocks based on expanded clay

How to choose the right blocks?

To begin construction of the facility, you need to purchase expanded clay concrete blocks. After all, the performance properties of the finished structure directly depend on the quality of materials.

It is better to purchase blocks from a trusted supplier Source ufasnab.ru

See also: Contacts of construction companies that offer the service of building a bathhouse from expanded clay concrete blocks.

First of all, you need to find a trusted supplier who guarantees high quality products - this will allow you to purchase good material with suitable performance characteristics. When choosing blocks, you should carefully check them for chips, microcracks, and deep scratches. In addition, you need to make sure that they are reliable and durable so that they do not crack even from the slightest blow. An important factor is the color of expanded clay concrete blocks, because, for example, dark gray colored products are made from a mixture with a high concentration of cement - they are stronger and more durable.

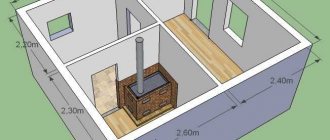

Choosing a size and layout

An important preparatory stage is the selection of a suitable bathhouse design. On specialized forums and construction portals you can find a huge number of projects developed and already tested by someone.

Attention! Perhaps someone you know recently built a bathhouse from blocks on their property and can give valuable recommendations.

If the size of the garden plot is small, then a bathhouse project in the form of a block extension to a garage or utility building may be a good option. Bathhouses with an attic, built using this building material, are also of interest. After studying standard designs and recommendations from experts, you can begin designing the future structure.

And information.

The source of water should not be located at a great distance from the future bathhouse.

Even when building a house, site owners learn everything about how groundwater flows. This information will also be useful when searching for a suitable place for a bathhouse.

During the design, the following factors must be taken into account:

- Correct location of the bathhouse on the plot;

- Coordination of building dimensions and internal layout;

- Creating a project.

Attention! When determining the optimal size of a block bathhouse and layout, it is necessary to take into account the number of people who will simultaneously steam in the bathhouse.

Construction technology

Compliance with construction technology is the key to the longevity of the bathhouse Source openoblokah.ru

In order for a bathhouse built from expanded clay concrete blocks to serve for a long time, you must strictly follow the rules of the technological process:

- Special beacons are installed at the corners of the intended area;

- a strong rope is stretched between them, around the perimeter of which the blocks are laid (before this, it is necessary to clear the entire area of various debris to prevent deformation of the structure being constructed);

- It is best to remove the remaining mortar used to attach the blocks immediately before it dries;

- reinforcing mesh should be laid every two rows;

- to erect a single-pitched or gable roof, the support beams are fastened with anchor bolts, and then the roofing material is laid;

- In order for the bathhouse to be used during the cold season, it must be insulated with mineral wool, which has water-repellent and heat-insulating properties. It is secured from inside the building;

- the outer surface of the walls is covered with waterproofing and protective material;

- Wood or tiles are used as finishing materials indoors, and wood is most often chosen for exterior finishing.

Features of bath design

Design of a bathhouse made of expanded clay concrete Source vashslesar.ru

Before starting construction work, as a rule, they draw up a project that takes into account all the features of the object and the wishes of the owner of the site:

- an accurate model of the planned structure is created;

- the area of the entire structure and the dimensions of each room are determined;

- convenient parameters are established, as well as the location of openings for doors and windows;

- the amount of building materials is determined.

Even if you plan to build a bathhouse from blocks with your own hands, it is better to order the project (photos are posted in the article).

Construction of the foundation of the object

Under a bathhouse made of expanded clay concrete blocks, it is necessary to build a foundation of crushed stone and sand. Its thickness is calculated taking into account the type of soil. The work is carried out in the following order:

- The area is completely cleared of debris.

- The top layer of soil containing plant roots is removed.

- The soil surface is leveled.

- The foundation is marked.

- A ditch is dug, the depth of which is 0.5 m.

- A sand cushion is poured, which must be compacted tightly with feet or special equipment. In this case, you need to constantly add liquid to make the surface hard and well stable.

- A layer of waterproofing is created.

Foundation for a bathhouse Source optopg.ru

After completing all the above steps, you can lay the blocks. The seam between them should not be thinner than 1.5 cm. In order to increase the strength of the foundation, reinforcing mesh is used - it prevents the building from warping.

Step-by-step construction of a bathhouse from expanded clay concrete blocks

to begin the construction of any bathhouse from expanded clay concrete blocks with your own hands with planning. First you need to choose a project that best suits the site and the owner’s needs. This stage consists of several steps:

- Choosing a future building model.

- Determining the location of shower compartments for the steam room and other parts of the bath.

- Selection and accurate calculation of dimensions.

- Deciding on the number of windows and doors.

- Calculation of the amount of building materials.

Important! When the project is ready, you should purchase the required number of blocks and prepare all the necessary tools to carry out the work yourself. It is better to start construction work in good weather conditions.

We design the supporting structure

Figure 2. Laying expanded clay concrete blocks

Since the soil can change its properties, during construction it is necessary to take care of a high-quality foundation. The best option is considered to be the tape version. It is removed quickly and does not require the use of special equipment. To organize it, you need to do the following operations:

- Clearing the area of debris.

- Removing the top layer of soil.

- Leveling the ground surface.

- Marking the foundation.

- Preparing a ditch up to half a meter deep.

- Laying a sand cushion and compacting it.

- Organization of the waterproofing layer.

In regions with difficult soil, preference may be given to the screw method of organizing the foundation. The only limitation is incompatibility with rocky soil. You can install a pile-screw version of the foundation for greater strength.

We mount the walls

The process of creating walls from expanded clay concrete blocks consists of several stages:

- You need to start building supports with your own hands by installing beacons in each of the corners and pulling the rope. Next, the first row of blocks is laid using cement mortar. It is then leveled using a rubber mallet and tied. Remains of cement on the surface of the masonry are removed with a trowel.

- The second and third rows are laid out by analogy.

- You need to put a metal mesh on the third row and press it into the solution as much as possible. Then it is laid out every three rows.

- So-called “pockets” need to be installed from expanded clay concrete blocks for laying ceiling and floor beams.

- The last row is laid out only in solid blocks.

Load-bearing and partition walls are erected simultaneously. Laying walls with your own hands can be done in several ways: in half a block, in a whole block, with two walls, with cladding. You can use a grinder to cut blocks.

Figure 3. Unfinished bathhouse made of expanded clay concrete blocks

Don't forget about ventilation. Condensation will always form on the walls of the bathhouse, so it is important to create a ventilated gap in the walls. Ventilation in a building can be of two types: natural and artificial. Artificial is created using air ducts and fans. With their help, air masses move within a room or from room to another. By creating air ducts, they can be controlled at the request of the owner.

Natural occurs due to the difference in temperature and pressure inside and outside the room. Warm air rises, so each room must be equipped with two air intakes: for the entry and exit of the air flow.

Important! To make ceilings with your own hands, it is recommended to use dried coniferous wood.

We build in a stove and arrange the roof

A stove is important for every sauna. The main criterion when choosing it is thermal power and the ability to adjust the temperature.

Adjustment can be done in several ways:

- by dissipating heat to the outside;

- air control;

- regulation of fuel ingress.

The firebox can be regular or elongated (for installing the stove in a wall). The first option is cheaper, and the second is less risky from a fire safety point of view. Sometimes the Russian stove is reproduced, then you should purchase an autonomous electric steam generator. When calculating the heated area, it is necessary to take into account the dimensions of the walls, ceiling and floor. A separate base is being prepared for the stove.

Important! If the stove is made of iron, it should be lined with bricks. This will keep you warm.

Figure 4. Interior decoration of the bathhouse

After making the stove, you can proceed to the stage of arranging the roof with your own hands. Its production consists of several steps:

- Installation of support beams in places where anchors are fixed and fastening of rafters.

- Organization of a vapor barrier layer.

- Hammering the bars.

- Formation of the sheathing. Its pitch depends on the type of roofing material.

To create a roof with your own hands you can use:

- slate;

- roofing felt;

- tiles;

- metal profile sheets.

If necessary, the roof can be insulated.

Bathroom insulation with expanded clay

Expanded clay is used in the construction of baths not only as a basis for construction. It is often used as insulation. It is poured into free cavities. Granules of various sizes create the necessary insulating layer. At the same time, its cost is quite affordable.

Interior and exterior finishing

To improve the appearance, you need to take care of the interior and exterior decoration. Outside, you can use plaster, and inside, the best material would be lining or wood. They create the effect of comfort and warmth, and the air is filled with a pleasant aroma.

insulation of a bathhouse made of expanded clay concrete blocks using lining is carried out as follows:

- First, a sheathing of 5 cm thick bars is installed.

- Then fire-resistant insulation is laid on the sheathing, which is covered with foil.

- Horizontal slats are fixed in such a way that an air gap is formed between the foil and the finishing layer.

- The finishing layer is attached to the slats.

Clinker panels, curtain wall facades, facing bricks and plaster followed by painting can be used as external finishing. All of them are not only aesthetically pleasing, but also affordable. Metal or vinyl siding looks impressive.

Figure 5. Bath insulation

Plastering is the most affordable cladding option for DIY construction. A cement mixture of sand and cement is prepared for it in a ratio of 4:1. Then the resulting solution is applied in one layer. After it dries, grouting is carried out to obtain a smooth surface of an even shade. A day after drying, the plaster is applied to the second layer and rubbed down. After the process is completed, the wall is covered with paint.

Video description

They tell you more about insulating baths in this video:

Features of external decoration

In order for the finished structure to acquire an aesthetically attractive appearance, the external walls should be finished. For this, as a rule, various materials are used that have not only decorative, but also protective functions. Quite often, preference is given to clinker panels, special facing bricks, plaster, which is then coated with paint, and hanging facades. These materials are beautiful and affordable.

One of the inexpensive cladding options is cement plastering. For it you need to prepare a solution of cement and sand in a ratio of 1:4. The mixture is applied in one layer, and then grouted, so that the result is a smooth surface with a uniform shade. To make the walls look even more attractive, it is recommended that a day after the plaster has dried, cover them with another layer of mortar and rub it in. At the end everything is covered with paint.

Painting as an option for exterior finishing Source blog-potolok.ru

Preparation for construction

In order for the design to be reliable, it is necessary to take ready-made projects. They indicate in detail the dimensions of the future bathhouse and the necessary materials. It is recommended to think about renting construction equipment, as it will make the work go faster.

The tools we will need are:

- Building level or alternative electronic tool;

- Spatulas - it is recommended to take tools of different sizes;

- Pegs for marking;

- Rope;

- Rollers, including rubber ones, for leveling the surface.

- Tools for digging a trench - these can be replaced by rented construction equipment.

Blocks must be purchased from a trusted place; when choosing, check whether there are any chips or cracks on the blocks. To build a bathhouse, you don’t need many of them, so you can spend time checking the blocks.