Modern bathhouse designs made from gas silicate blocks are worthy competitors to traditional buildings made of brick or wood, despite its high hygroscopicity (ability to absorb moisture). Just a few years ago, bathhouse projects made from gas silicate blocks were impossible due to this negative parameter of gas silicate, but today the market is saturated with special impregnations that reduce the moisture permeability of this building material several times. And if you add modern waterproofing materials to the impregnations, the result will exceed the wildest expectations of builders - all the characteristics associated with thermal conductivity and moisture permeability will be much higher than those of wood or brick.

Ready-made gas silicate bath

Gas silicate bath

Experienced craftsmen have a saying that there is no building material from which a steam room cannot be built. The only exception may be frankly toxic building blocks, with a high content of bitumen, phenol and sulfur cements, used for arranging foundations on swampy soils.

Therefore, building a bathhouse from gas silicate with your own hands can be considered quite realistic, especially if the area in which the bathhouse is planned to be built is replete with strong winds. In this case, bathhouse projects made from gas silicate materials turn out to be much more interesting than frames or buildings made from rounded logs.

The gas silicate block is interesting for two reasons:

- You can make it yourself or order it from the manufacturer. At the same time, it is possible to include in the block those characteristics that are most important for building a bathhouse;

- The low price of gas silicate with a fairly high durability of the material. For the money spent on the construction of a timber bathhouse, which will last for a maximum of 10-12 years before repair, you can build a gas silicate box with a service life of 30 years.

Important! Gas silicate is often confused with another cellular material - foam concrete. The technologies for producing blocks are very similar, only the raw materials and conditions for stabilizing the final product differ.

Gas silicate blocks are “printed” from lime and purified quartz sand, in this they are more similar to sand-lime brick. Whereas foam concrete is made from concrete mortar saturated with plasticizers and pore-forming additives.

Is it possible to build a bathhouse from gas silicate blocks?

In order not to resort to listing characteristics and indicators, it can be mentioned that gas silicate blocks of the same density as foam concrete materials have higher strength, retain heat better and do not give secondary shrinkage.

For your information! Aerated concrete material has a very important difference: due to its high porosity, it absorbs water vapor, volatile substances and even gases, like a sponge.

It turns out that building a bathhouse from gas silicate blocks, on the one hand, is very profitable, since with lower costs for walls and compliance with technology, the room turns out to be very warm.

On the other hand, when agreeing to build a bathhouse from gas silicate blocks with your own hands, you need to understand that the high absorption capacity of the walls will haunt the owners of the steam room and bathhouse building for the rest of their lives. If you do not properly insulate the surface, the walls of the bathhouse will absorb odors and water from the atmosphere and soil until they turn into an eternally wet and completely frozen monument.

Bathhouse made of gas silicate blocks: pros and cons

Not everything is as bad with gas silicate as opponents of the new material sometimes try to present the situation. If gas silicate blocks were not suitable for the construction of bathhouse walls, then no one would use foamed silicate material. Despite all the pros and cons, gas silicate baths are actively being built; according to the most conservative estimates, their number is approximately 31% of all new bath buildings.

To the advantages listed above, you can add several more important advantages:

- The bathhouse box turns out to be light, so the building can be erected on relatively weak soils; all that is needed is proper drainage of surface and “deep” water;

- Gas silicate blocks are easy to process, cut with a regular hacksaw, their low weight simplifies the laying of walls;

- If you use the porosity of gas silicate correctly, you can achieve the formation of a special microclimate in the bathhouse.

We are not talking about a steam room or a waiting room; there is always high humidity, so porosity can only do harm. Another thing is a relaxation room or a glassed-in veranda of a bathhouse. In this case, gas silicate blocks can select and release water vapor, creating a certain microclimate in the bathhouse.

Unfortunately, such miracle projects - saunas from gas silicate blocks are rarely created with your own hands. For cladding the internal walls, a dense gas silicate material with micropores is used, allowing only air and water vapor to pass through, but blocking any other heavy gases and volatile substances. Such material is quite expensive, and in addition, special knowledge and skills are required. This is the main disadvantage of gas silicate blocks; you cannot build a good bathhouse “by eye”.

In addition, gas silicate is afraid of moisture and strong temperature changes, accompanied by the formation of water condensate. When planning the stove and chimneys, one must take into account the fact that the material cannot withstand heating above 400°C.

What is needed for the job?

To do the work yourself, prepare the following materials and tools:

- ingredients for preparing concrete mortar (cement, crushed stone, sand, water) necessary for the foundation;

- gas silicate blocks, the number of which is determined at the design stage;

- concrete mixer necessary for preparing the solution;

- shovels and buckets used in the construction process;

- reinforcing bars to strengthen the concrete base;

- pegs and cord for marking the site.

After marking the site, removing vegetation, planning the surface, proceed to further work.

Project of a bathhouse made of gas silicate blocks

The construction of a full-size bathhouse from a light and non-rigid material will require special measures, such as reinforcing and strengthening the walls with concrete belts, using a full-fledged slab foundation or installing piles. Therefore, either professional builders or desperate fans undertake to build a full-fledged bathhouse 6x6 m or 6x7 m from gas silicate blocks.

Most lovers of good steam are limited to bathhouses with a maximum wall size of no more than 6 m. There is also a positive side to this; due to the high popularity of 6 by 4 m bathhouse projects made from gas silicate blocks, choosing a suitable option will not be difficult.

Classic steam room made of gas silicate

The construction of a bathhouse measuring 6x4 m will fit perfectly into a home yard. Despite the fact that this is not a tiny annex steam room with a dressing room, which is extremely difficult to use without a shower in the house.

Thanks to the use of gas silicate blocks, a warm and spacious building is obtained, so much so that there is enough space for a full-fledged recreation room and a small terrace covered with a roof slope.

It should be noted that there is a very correct layout of the interroom passages inside the bathhouse. Thanks to the use of a “snake”, that is, a layout when the doors in the passage rooms are located at the maximum distance from each other, the steam room is well protected from drafts. And four window openings provide a qualitatively high level of ventilation in the room.

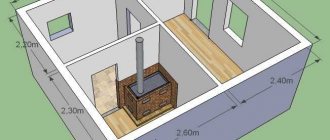

A simpler version of a home sauna made of gas silicate is shown in the photo below.

In this project, the design of the bathhouse is simplified to the minimum; most of the free space is allocated for a relaxation room and steam room.

This is more of a summer version of a bathhouse for a summer cottage. In this case, most of the time between visits to the steam room is spent under a canopy.

Country version of a bathhouse made of blocks

If the size of the garden plot allows, then using a standard design for a sauna building made of gas silicate blocks, you can easily expand the structure and turn it into a place for a summer vacation for the whole family.

In this case, you will need to abandon the terrace in favor of a full-fledged canopy with a brick stove and barbecue, a place for a guest table and a kitchenette in the corner. In this option, the rear partition covering the stove and the canopy space is built from heavier red brick, so the area in front of the entrance to the bathhouse will need to be concreted with a screed.

What do you need to know about the general principles of insulating block baths?

Building blocks are good because they retain heat well, are hygroscopic and resistant to temperature changes (this is important for the winter period). The thermal insulation properties of blocks , as a rule, are higher than those of brick or concrete, but in any case they are inferior to those of natural wood.

Baths built from blocks, regardless of their type, require insulation from the inside without fail. This is explained simply - by insulating the bathhouse exclusively from the outside, you will get a structure that will need to be heated for an incredibly long time.

After all, in order for the air inside to heat up, it is necessary to heat all the structures of the bathhouse: walls, ceiling, floor, etc. But in fact, you only need to keep the heat inside while using the bathhouse.

This distinguishes residential buildings from bathhouses (exception: bathhouses that combine their functions with a place for permanent residence). In residential buildings there is a constant source of heat that maintains a permanent positive temperature in the premises, but the bathhouse has a different procedure for use: it is heated 1-3 times a week, and even less often in winter.

It is impossible not to mention such a feature of the blocks as the ability to heat up to high temperatures. And if their surface is not covered, then the risk of getting a burn is quite high at the slightest contact .

Therefore, our recommendation is simple: insulate the baths inside, apply the rules for composing the insulation “pie” and do not forget about ventilation and vapor protection.

Do-it-yourself bathhouse made from gas silicate blocks

The smaller the size of the walls, the easier it is to install a gas silicate box, the smaller and lighter the foundation for the building is required. In some cases, it is possible to make a foundation for a bathhouse from gas silicate blocks, such as Minsk. Due to the high density and closed structure of the bubbles, the material practically does not absorb liquid water, and thanks to the excellent thermal insulation of gas silicate, the bathhouse building is well protected from freezing of the base and partially from soil heaving.

Stages of construction work

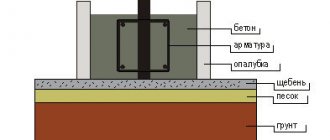

The first step when building a bathhouse is to make a full-fledged cushion under the foundation, remove turf and clay to a depth of at least 50 cm, and remove all layers of soil in which moisture can accumulate.

Most bathhouse projects made from gas silicate blocks, photos, require a solid foundation.

It is best if it is a concrete slab laid on a sand and gravel bed and EPS insulation. Walls made of gas silicate, even in a one-story version, require support, so a rigid concrete foundation will be the best solution to the problem.

The second step is to lay out the plinth and waterproofing of the walls. The starting and last rows of aerated concrete blocks are always reinforced with a concrete belt with a reinforcement frame. The roof and floor must be insulated, most often with fill-in insulation.

Immediately after installing all the elements of the roof and roof, you need to complete the external finishing of the walls, before rain and dampness destroy the bathhouse frame.

Important! To avoid the blocks getting wet, the building is covered with a protective film.

As soon as the roof and ceilings of the bathhouse are assembled, you can close the walls; it makes no sense to start finishing earlier, since the walls have not taken their size under the weight of the rafters and beams.

Exterior decoration

The walls of the bath box must be protected and insulated at the same time. It is important that the outer surface of the gas silicate blocks “breathes”, that is, water vapor and air are able to freely penetrate through the thickness and escape into the surrounding space.

Therefore, correct and reliable finishing of the outer surface of the walls of the bathhouse is carried out as follows:

- Initially, timber and roll insulation are sewn onto the walls, usually mineral fiber mats;

- The second step in insulation is to install a vapor barrier membrane;

- The next step is to sew a lining made of PVC, aspen or galvanized steel onto the sheathing.

In this case, the bathhouse turns out to be warm, the walls do not get wet and always remain dry, even if the steam room is heated several times a day.

Interior decoration of a bathhouse made of gas silicate blocks

It is best to start finishing work indoors with a steam room. First of all, vertical sheathing slats are sewn onto the walls. You can use aspen or pine with a section of 50x50 mm. The material can be fixed to a gas silicate wall using ordinary self-tapping screws. The steam room must be insulated with mineral wool and foamed polyethylene with a foil surface. A vapor barrier like Metaspan must be sewn on top of the mineral insulation.

Horizontal rows of aspen lath are placed on top of the warm cake, on top of which the lining of the steam room is laid.

The washing compartment of the bathhouse is covered with tiles without any options. The gas silicate is first primed with liquid waterproofing, otherwise in winter moisture from the ceiling can flow into the wall and tear off the lining.

The rest room of the bathhouse is most often simply sheathed with clapboard along the laid sheathing strips. If there is no supply and exhaust ventilation in the room, then a vapor barrier film will need to be laid under the tree, and gratings will need to be installed in the ceiling part of the walls.

For summer bath options, the lining can be sewn directly onto the walls from gas silicate blocks.

Ventilation device and insulation

The main disadvantage of all bath rooms is high humidity, therefore both natural and forced ventilation are necessary for all rooms. This measure will not only bring the humidity back to normal, but will also protect all surfaces from the appearance of fungal diseases and mold. The foundation for ventilation is laid by the construction of walls - these are small ventilation vents in each room, which are made both above and below. To prevent a draft from occurring while in the steam room, the ventilation openings are closed.

Ventilation

External insulation of the walls of the bathhouse is designed based on the climatic conditions in the region. So, for central Russia, a thickness of basalt wool of 100 mm will be quite enough. To the north the insulation is made thicker, to the south - thinner. The disadvantage of mineral wool is its high hygroscopicity, so it is treated with special compounds such as “Penetron” or “Kalmatron”. The same applies to foam block walls.

In order not to buy impregnations and not make construction more expensive, instead of mineral wool, you can use extruded polystyrene foam (EPS), which does not absorb or allow moisture to pass through, has a low thermal conductivity coefficient, and is not interested in rodents and pests. Extruded polystyrene foam performs two functions at once - hydro- and thermal insulation. A frame is constructed on top of it for future decorative cladding made of clapboard. In addition to lining, EPS can be plastered by first attaching a fiberglass mesh to it.

Internal insulation of a steam room is carried out as follows:

- The walls are impregnated with a cement-based composition;

- A beam with a cross section of 50 x 40 mm is stuffed;

- Thermal insulation is placed inside the frame;

- Vapor and waterproofing is attached to the frame on top;

- Assemble the second frame from timber with a cross-section of 25 mm;

- The lining is attached to this frame.

In other rooms, the thermal insulation layer does not need to be installed. If the shower room will also be lined with clapboard, then it is first necessary to lay a layer of foil vapor barrier and impregnate the walls with hydrophobic compounds. In drier rooms, the walls are also impregnated with hydrophobic liquids, but without vapor barrier. After this, a frame is installed to secure the lining.

Interior decoration in the bath

The ceiling in a steam room should be insulated from the bottom up. Layers of building materials for insulation from outside to inside:

- lining;

- Foil vapor barrier;

- Surface of the rough ceiling;

- A layer of thermal insulation from the attic.

A ventilation gap should be left between the layers of lining and vapor barrier foil, for which a special thin sheathing (frame) is assembled.

Video: bathhouse made of gas silicate blocks (interior decoration)

There are many subtleties and technological tricks in construction using porous blocks. For example, the most painful question that will definitely arise when building a bathhouse from gas silicate blocks concerns the correct planning of finishing and waterproofing. The essence of the problem and one of the options for solving it are shown in the video

It will also be useful to familiarize yourself with some important points in the general construction of a gas silicate building

Material composition

Among the building materials suitable for building a bathhouse, blocks made from gas silicate stand out. The material is a type of cellular concrete, hardening in special containers - autoclaves. Gas silicate is made based on a mixture including:

- Portland cement

- Quartz sand.

- Aluminum powder.

- Lime.

- Water.

The quality of gas silicate is determined by the peculiarities of manufacturing products in production conditions, where manufactured products are controlled by laboratory methods.

Baths made of gas silicate blocks: photo

Buildings made from light foam silicate can be not only warm, but also beautiful.

After laying the exterior finishing, it is almost impossible to guess what exactly the bathhouse is built from.

Insulation of a bathhouse from the outside

In fact, most often it is not required. Indications for thermal insulation of a bathhouse from the outside may be:

- harsh climatic conditions caused by critically low temperatures in winter;

- location of the bathhouse (for example, if it is located in a lowland with constant fog);

- combining insulation with external decorative finishing.

External insulation additionally plays the role of protecting the structure from the effects of precipitation and other natural phenomena of high humidity. The pie of external insulation is essentially similar to the internal one: sheathing, insulation, vapor barrier, ventilation gap and finishing materials.

The installation of external insulation is justified if you are going to cover the walls of the bathhouse with finishing materials. A thin layer of insulation will perform several functions at once, and you would do the sheathing for attaching siding or other finishing materials either way.

Bathhouse made of gas silicate blocks: reviews from owners

Semyon Stepanovich Ivliev, 69 years old, Tver:

We built a gas silicate bathhouse ourselves. A month later, a crack appeared along the blank wall. Experts said the cause was shrinkage of the foundation. It was made just according to the mind, to match the brickwork. It turned out that the box was too light and the soil was heaving. They caught it in time; the neighbors across the street had a wall that was completely bent into a bubble. We had to dismantle part of the masonry and seal it with concrete, in the end we lined the bathhouse box with bricks, as planned, and that was the end of it.

Valery Eduardovich, 60 years old, Moscow:

My son-in-law bought a ready-made sauna project using gas silicate blocks. They built according to the accompanying note to the plan. The walls are made of gas silicate, 50 cm thick, despite the fact that the box itself is only 6x5 m. The foundation is slab, and the roof is made of ready-made sections, covered with corrugated board. It turned out to be a little more expensive, but the sauna box has been in use for three years now, and no problems. But some kind of smell appears in the spring, in the summer, as the sun warms up, everything disappears.

Recommended Posts

Ventilation of the foundation of a bathhouse

Aerated block bathhouse

Bathhouse projects with an attic

Finishing a bathhouse with a block house inside

Japanese bath

Do-it-yourself bath drain

Foundation

Various types of foundations can be used as the foundation of a future bathhouse:

- Tape, repeating the perimeter of the building. The foundation is formed into a wooden formwork with a reinforcement frame by pouring it with concrete mortar. The finished foundation of the bathhouse is immersed 0.5 m in the ground and is located on a compacted sand and gravel backfill.

The monolithic foundation is poured with a single reinforced structure

- Columnar, representing concrete supports installed at the corner points of the building and in the areas where walls adjoin. Pay attention to the horizontal surfaces of the supporting elements, which should be located at the same level. Concrete is poured into pits with pre-installed reinforcement.

Any foundation must be waterproofed with bitumen or two-layer roofing felt, since gas silicate blocks require enhanced waterproofing.

Advantages of using expanded clay concrete blocks

This building material has the following advantages:

- environmental friendliness and absolute non-toxicity;

- insignificant moisture absorption, non-susceptibility to the destructive effects of steam and liquid;

- excellent thermal insulation properties that help retain heat in the room;

- relatively light weight expanded clay concrete blocks.

Thermal protection of a bathhouse, due to the specific use of this building, requires the use of various methods of thermal insulation in each section. For this reason, it is necessary to have knowledge and experience on how to insulate a bathhouse made of expanded clay concrete blocks shown in the photo.

To ensure high-quality thermal protection, you need to take into account the structural features of the structure and the influence of the environment on its various elements. Of course, insulating a bathhouse made of expanded clay concrete blocks from the inside differs from external thermal insulation.

This building material is made from several components using vibrocompression technology. The process consists in the fact that baked and foamed clay (expanded clay is made of it), as well as sand and cement, are thoroughly mixed and compacted under high pressure and vibration loads. The resulting expanded clay concrete block is characterized by lightness and at the same time increased strength.

Selection of tools and preparatory work

Before starting construction, you must purchase the following materials:

- Blocks.

- Sand, Portland cement.

- Lumber (boards, beams, slats).

- Construction adhesive mixture.

- Thermal insulation (mineral, basalt or stone wool).

- Waterproofing (preferred material is rolled).

The preparatory stage includes design work. When creating a project, you need to consider the following aspects:

- Communication connection points (electricity, water supply, sewerage).

- The area of the building, the number of people planning to use the bathhouse.

- Layout. The classic version includes a steam room, a dressing room, a technical room; larger buildings can contain a relaxation room, a room with a swimming pool, a jacuzzi, and a veranda.

- Finish type.

Typical bathhouse layout with detailed layout and dimensions of the building

Arrangement of openings for windows and doors

The process of laying blocks does not change significantly when it comes time to create openings. The wall should be laid as evenly as possible and the rows above future windows and doors should be strengthened so that the frame meets the criteria of reliability and safety. When arranging openings, it is recommended to consider the following:

- To create, non-standard shaped blocks are used.

- The cavities are filled with reinforcement and filled with concrete mixture.

- To facilitate installation, it is advisable to use support structures.

- Between the upper surface of the opening and the next row it is necessary to lay thick reinforcement: this will avoid deformation.

Stages of internal insulation

Regardless of the material from which the bathhouse is assembled, the general vulnerability of the blocks is their high hygroscopicity. In severe frost conditions, moisture-impregnated raw materials are easily destroyed. In winter, after heating, the room cools down, no one monitors the temperature inside, and the frost resistance resource will quickly be exhausted. Therefore, it is important to ensure high-quality insulation inside and outside in order to neutralize the impact of changes and ensure the safety of the building resource.

Regardless of the specifics of the blocks, a single internal cladding technology is used.

This is the first stage of insulating the bathhouse. General sequence of work:

- The soil base is covered with glass wool, slag or expanded clay. To achieve an optimal level of heat retention, you should create a layer at least 35 cm thick.

- Next, the expanded clay concrete screed with reinforcement is assembled.

- A floorboard is sewn on top or ceramic tiles are mounted.

If you plan to install a concrete floor, the following guidelines for action are relevant:

- the rough concrete pad is equipped with coating or roll-type waterproofing;

- The next layer is to lay the insulation directly - mineral wool, polystyrene foam, expanded clay. The optimal thickness of the bookmark depends on the physical properties of the selected option;

- To create a ventilation gap, plastic screens are introduced and covered with reinforcing mesh on top. The latter should be hidden under a concrete screed.

The final stage here is the laying of ceramic tiles; if desired, you can finish the concrete base with wood material. This method of strengthening the foundation minimizes heat leakage.

For arranging wooden floors, experts recommend:

- create a subfloor by equipping the lower perimeter of the beams with cranial bars;

- fill the top with cheap wood adjusted to size;

- the subfloor must be equipped with vapor-tight waterproofing. The film should cover the entire area with an allowance of 20 cm on the walls. Fixation can be done using a construction stapler; to strengthen the joint area, you will need double-sided tape;

- You need to lay thermal insulation on top and cover it with film or roofing felt.

Gas blocks: dimensions and characteristics

- Dimensions - the height and length of the blocks are usually standard (625x250), the width differs (100 - 600 mm). The choice of thickness affects the load-bearing capacity and depends on the load on the walls. Also, the choice of thickness affects the height of the walls. The thinner the wall, the less stable it is.

The stability of the wall can be checked by the permissible ratio of floor height to thickness (H/h). As a result, we get a coefficient, which we check using the table below (in it we are interested in column II - masonry group). If our result does not exceed the data from the table, then the condition is satisfied. If there are openings in the wall, then we additionally multiply our parameter by the coefficient k from another table. The permissible table values can be increased in the presence of longitudinal reinforcement.

- Density – indicated by the letter D and a number. The thermal conductivity and strength of the material depend on the density. For a bathhouse, it is optimal to use aerated concrete with a density of D400 and a strength of B2.5 .

- Thermal conductivity is the ability to transfer thermal energy. For aerated concrete D400 the parameter is 0.17 - 0.12 W/m*C.

- Heat capacity is the amount of heat that a material can absorb per unit mass, i.e. how quickly can we heat the bathhouse? For aerated concrete this parameter is 0.84 kJ/kg*C, for coniferous wood it is 2.4. This suggests that in the case of a wooden bath we heat the walls for a long time and only then does the heating of the air inside the room begin.

- Tolerances on block geometry - according to tolerances, aerated concrete is divided into several categories. Blocks of the first category are suitable for laying with a thin joint.

Also, gas blocks may differ in their format.

With flat ends - the standard configuration of aerated concrete blocks. No trimming required at corners.

Groove-ridge - have handles for transportation, glue is applied along the edges of the end plane. Trimming or plastering at corners is required to hide protruding grooves.

Groove-groove - when joined, two grooves form a hole, which is filled with a liquid solution or adhesive foam. Requires trimming or caulking at corners.

Groove-to-flat - fill like a tongue-and-groove, but do not require caulking or trimming at corners.

Tray block (U-block) – serves as permanent formwork when forming reinforcing belts and installing lintels.