Today, along with the traditional building material for Russia - wood, new materials are used. Among them, polystyrene concrete has already proven itself well. It is lightweight or cellular concrete filled with expanded polystyrene. Serves as a construction and thermal insulation material.

Project of a bathhouse made of polystyrene concrete with a tiled roof

Modern material for building a bathhouse

Thanks to its unique properties, it successfully competes with other modern building materials: aerated concrete and foam concrete. Advantages of polystyrene concrete:

- Minor shrinkage, about 0.1%;

- Density ranging from 150 kg/m³ to 600 kg/m³;

- Low operating humidity;

- Rot resistance;

- Strength;

- Fire resistance;

- Excellent sound insulation;

- Long service life, more than 100 years.

If the owner of a summer house strives to use every opportunity to save his money, then the use of polystyrene concrete blocks in the construction of a bathhouse is the right way to do this. Walls and ceilings may have a small thickness, however, the heat will not escape outside. When exposed to high temperatures, polystyrene does not emit harmful substances.

Structure of polystyrene concrete blocks

Therefore, people can safely take water procedures and steam without fear for their health. It takes a little time to build. All construction work can be done with your own hands.

Disadvantages of polystyrene concrete baths

It would be great if we could limit ourselves to just the advantages. But, unfortunately, there were some negative aspects. To avoid disappointments, they should be discussed in more detail. The main disadvantages include:

- The density of the material is not high enough , which makes it difficult to install windows and doors. Therefore, during operation, the fittings may sag.

- Plaster both inside and outside . Many people say that the building material has insufficient adhesion to the plaster, so the wall surface will have to be further processed.

- The blocks must have perfect bonding . If you allow the slightest error in sealing the seams, the building material will quickly crack.

- Vapor permeability is also low . This means that the walls do not breathe, therefore creating a microclimate with high humidity.

- A significant disadvantage is low fire resistance . When exposed to high temperatures, the granules begin to break down, which means they become less strong. Therefore, additional treatment of the walls with special means will be required, which not everyone knows about.

- If you purchase ready-made blocks, the buyer cannot be sure that the manufacturer correctly complied with all storage periods .

After studying all the properties, positive and negative characteristics, everyone will be able to decide whether they should use polystyrene concrete in the construction of a bathhouse. Many are stopped by the presence of existing disadvantages, so they prefer to make a choice in favor of other, more proven, reliable materials. Most likely, this approach is more appropriate, since the risk of undesirable consequences is quite high.

What you need to remember when starting to build a bathhouse

If you have always been far from construction, then be sure to consult with specialists. They will help draw a plan for the future structure. Professionals will answer all questions regarding the specifics of working with polystyrene concrete. After all, in addition to the advantages, there is also the other side of the coin.

There is no building material that has no flaws at all. Polystyrene concrete is also no exception. There are many nuances that you should be aware of before construction begins. Disadvantages of the material:

- Porosity. The bathhouse will need additional steam and heat insulation.

Insulation scheme for a bath made of polystyrene concrete - The need to use special glue to better hold the blocks together. Poorly sealed seams lead to rapid cracking of the building material.

- Susceptibility to destruction when exposed to ultraviolet rays. It is necessary to make a ventilated façade and plaster the outside of the building.

When making your project, it is possible to take into account all the details, from size to decoration. Based on the calculations made, you can easily find out how much building materials you will need to buy and how much it will cost to build the entire structure.

We build a bathhouse from polystyrene concrete

So, you decided to build a bathhouse, and now you are faced with a number of questions: what should it be like? How much money will be required for construction? And, most importantly, what materials should be used to build a bathhouse so that the bathhouse is environmentally friendly, cozy, and resistant to moisture and heat? Polystyrene concrete is just such a material, and at an affordable price.

Polystyrene concrete blocks consist of polystyrene foam granules, cement, additives, water and are produced in accordance with GOST 51263-99. It is the polystyrene chips that give the material lightness and low thermal conductivity.

The lightness of polystyrene concrete blocks allows you to reduce the load on the foundation, as well as save on special lifting equipment, since they can be lifted manually. This also saves the time required to build walls. When choosing a material when building a bathhouse, it is important to consider its ability to retain heat. The low thermal conductivity of PSB blocks allows not only to retain heat in the room, but also makes it possible to build a warm bath with a wall thickness of only 30 cm, thereby reducing the cost of materials.

Another advantage of PSB wall blocks over analogues is minimal water absorption (up to 4%) and, accordingly, high frost resistance (up to 100 cycles). It does not absorb water, and therefore does not crack or deform. The use of PSB blocks for the construction of walls will, in addition, minimize the shrinkage of the house (no more than 1 mm/m), and also protect it from rot and mold.

When building a bathhouse, it is equally important that the construction material is fire-resistant. In terms of fire safety, buildings made of polystyrene concrete are comparable to structures made of brick and concrete. Among other things, polystyrene concrete is non-toxic - its level of environmental friendliness is as close as possible to wood.

Why choose polystyrene concrete

If you need a warm bath, then using blocks made of modern building materials is a thoughtful solution. Laying is quite easy to do. Using blocks allows you to save up to 30%. They are easy to transport: three times more polystyrene concrete fits into a truck than ordinary bricks.

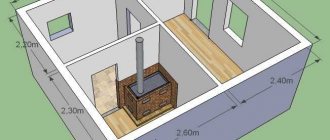

Bathhouse layout with dimensions of polystyrene concrete blocks

The dimensions of one block are 600 x 300 x 400 mm. In other words, it is capable of replacing 17 bricks. The speed of building construction increases several times. The products are in demand because they are easy to process. Communications are laid within the walls of the bathhouse. The structure is easy to make original. You can implement unusual design ideas using an arch or semicircular elements. If desired, the owner can build two floors with floors made of wooden beams. Polystyrene concrete is cut and processed with a hacksaw.

Advantages of a bath made of polystyrene concrete

The popularity of this material was achieved due to many positive properties. The main ones include the following:

- Thanks to good insulating properties , it was possible to achieve maximum noise absorption, as well as maintain temperature at the required level. At the same time, energy consumption is reduced to a minimum. Buildings made of such material do not require additional external insulation.

- Another advantage is its presentable appearance , so the bathhouse will look stylish and modern, which is an important condition for many. It will harmonize perfectly with any nearby buildings.

- Polystyrene concrete blocks are lightweight , which helps reduce the load on the foundation. In addition, workers can lift them on their own, which is not only convenient, but also economical, since they do not have to spend money on lifting equipment.

- This building material is easily subjected to the necessary manipulations , so no difficulties will arise during construction. It is easy to saw, can be drilled, and holds screws well.

- Thanks to simple processing, you can fulfill unusual design ideas . For example, you can make an arch or other semicircular elements.

- The next advantage is the possibility of making the material yourself , which will also help save money. Preparing the batch does not require great skills, so it will be enough to familiarize yourself with specialized literature.

- The material has good resistance to all kinds of aggressive environmental conditions. He is not afraid of moisture and frost. Fungus and mold do not appear on it.

Stages of bathhouse construction

- Make a simple strip foundation. Dig a shallow trench (60 cm) around the perimeter. It is enough that its width is 30 cm. Take care of the sand base. Make the markings. Use a level. Insert pins into the ground at the corners and along the perimeter in 1.9 m increments. Pull the cord and check how evenly the pins are positioned. Make a reinforcement frame and assemble the formwork.

Ready-made strip foundation for a bathhouse made of blocks.

Lay a receiver with sewerage in the foundation. Make a screed and fill it with concrete. The height of the foundation should be from 70 to 75 cm. Perform waterproofing. Ruberoid will protect the foundation from moisture better than other waterproofing materials. - Build walls from polystyrene concrete blocks. The first row is laid on a solution of sand and cement. It is important to avoid any drops or protrusions. Using a level with a rubber hammer will help you achieve even masonry. A stretched cord between the corners of the room will make it easier to complete the task. The second row and subsequent ones are planted with special glue. The adhesive is diluted at the construction site. The mixture is prepared using a drill in a container.

Step-by-step construction of a bathhouse made of polystyrene concrete

When making openings for windows and doors, use additional elements. The walls of the bathhouse are erected in three rows of blocks. To make the structure strong, reinforcement is performed between the individual rows using a metal mesh. - Start building the roof for the bathhouse in three days. This structure consists of a frame. Roofing material is attached to it. The roof consists of a truss, mauerlat, sheathing, and roofing.

Installation of a gable roof frame for a bathhouse made of polystyrene concrete.

Construction involves the construction of a straight chimney. It is necessary to isolate the chimney from the rest of the structure using fire-resistant heat-insulating material. Install a metal apron inside.

Slate and tiles are used more often than other roofing materials. Their price is affordable for anyone who wants to have their own bathhouse.

How to build a bathhouse from polystyrene concrete?

Foundation construction

When building a bathhouse from PSB blocks, it is better to use a strip foundation with a sand base. To do this, you need to dig a trench around the perimeter (60 cm deep, 30 cm wide), and also make a frame from reinforcement with a diameter of 12 mm and formwork from 25 cm boards.

The formwork must be filled with concrete. It is advisable to lay a masonry mesh on top. Fill with concrete again. Then waterproof the foundation with a two-layer roofing material. A sewerage system and a receiver need to be laid inside the foundation.

Construction of walls made of polystyrene concrete

We lay PSB-Blocks purchased at a width corresponding to the width of the wall, checking them with a horizontal and vertical level. The first row of blocks is laid on a cement-sand mortar using a level, a rubber hammer and a cord stretched between the corners of the future bathhouse.

From the second row, PSB blocks are placed on a special masonry adhesive. It is laid in a very thin layer, no more than 0.5 cm, and eliminates the appearance of joints and “cold bridges”. The glue does not require a long time to set and hardens within a few minutes. If the masonry is done in the cold season, then you need to take glue with a special anti-frost additive.

The walls of the bathhouse must be erected in three rows of blocks, laying a reinforcing layer of metal mesh between them to strengthen the structure. Reinforced PSB lintels are ideal for covering door and window openings. They are lighter and warmer than reinforced concrete lintels and eliminate the appearance of cold bridges, and the reinforcement frame makes them as strong as reinforced concrete lintels.

After erecting the walls, you can proceed to constructing the roof.

Completion of the construction of the bathhouse - interior decoration

It is better to make a durable, warm and high-quality floor from a polystyrene concrete mixture, having previously reinforced it around the perimeter. It is better to line the internal walls of the bathhouse with wood, laying foil insulation underneath for waterproofing. It is also very important to arrange proper ventilation in accordance with the technical requirements, according to the area of the room.

After building the bathhouse, all you have to do is install inside the font, benches, shelves and other accessories that will create a comfortable environment conducive to rest and relaxation.

Pros and cons of insulating bath floors with foam plastic

The huge advantage of the material is its versatility. Polystyrene foam is ideal for insulating most wooden floors in the relaxation room and even in the steam room. Without being distracted by searching for other options, you can make concrete floors in the bathhouse under the tiles using polystyrene foam in the same sink or shower.

The second serious advantage is resistance to pathogenic microflora and mild heating. Microbes and mold do not multiply on polystyrene foam, and gentle heating of the floor insulation to 60-70°C does not in any way affect its strength.

There are, of course, disadvantages. Firstly, foam sheets are a favorite wintering place for rats and mice, but if food is not stored in the bathhouse, then you don’t have to worry too much. Secondly, foam plastic allows warm water vapor to pass through, so if you lay the material on a wooden bathhouse floor, you will need at least a vapor barrier along the lower edge and waterproofing of the upper surface. Otherwise, in cold weather, accumulating and condensing steam will tear the lower layers into small granules.

For your information! Many garage owners, trying to insulate their doors with foam plastic, skimp on vapor barrier on the outer surface of the insulation; as a result, after a couple of years, the bottom threshold and floor end up strewn with foam dust.

Price

The wall material has an affordable cost and allows the use of a shallow foundation or screw piles with a channel tying the lower belt. Compared to traditional construction technologies, this will reduce costs by 1/3.

A screed made of this material with embedded electrical cables reduces heating costs. When using flexible small-format roofing on OSB boards, the construction will be extremely economical.

Construction time

All materials used allow us to reduce construction time:

- Shallow foundation or screw piles – week, 2 days, respectively

- Walls, partitions, ceilings – month

- Roof, roofing – two weeks

- Communications – two weeks

- Finishing - a month.

Thus, if the weather is favorable and there is no precipitation at the initial stages, the structure is erected during the season. The materials of the foundation, walls, and roof have a similar resource; the cladding can be easily changed entirely, individually. If necessary, any structural unit can be repaired.

Gable ceiling

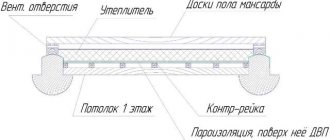

Overlapping scheme

Gable structures are used to construct a roof overhead in bathhouses made of aerated concrete blocks.

The instructions for the construction of such a floor include the following list of works:

- Arrangement of a rafter system consisting of a rafter leg, a crossbar and a base;

Advice. The construction of this system is carried out from edged boards with a section of 4/10 cm.

- Collection of overlap front triangles;

- Performing a continuous type of sheathing or with the beams located at a distance of 50-100 cm from each other;

- Gable trim;

- Waterproofing the sheathing and covering the structure with roofing material.

Features of floor insulation in a bathhouse with foam plastic

It is clear that, if desired, you can use more modern materials, including perlite backfills and slabs, polyurethane foam and Knauf polystyrene foam granules, and even roll thermal insulation is used. All the same, in practice, building a warm floor with foam plastic in a bathhouse turns out to be faster and easier. Everything would be fine, but foam boards have low strength and, at the same time, are bad, but still allow water vapor to pass through.

Therefore, if you try to insulate the floor of a bathhouse with sheet polystyrene foam, then there are only two schemes for using the material:

- You can roll foam panels into a concrete screed, and this will be the safest and most durable option for insulating a bathhouse;

- Make a wooden floor in the bathhouse by laying expanded polystyrene in the niches between the joists.

For your information! The last scheme is the most convenient and at the same time labor-intensive. If necessary, you can always open the floor and eliminate any problem.

Concrete with plasticizers protects the insulation well from water and vapors

Whereas with a concrete bathhouse floor there is always a risk that, having opened the screed even in a small area, to restore the floor you will have to fill the cement-sand coating with a new layer. On the other hand, a concrete subfloor allows the installation of tiles or heating elements, which makes the foam insulation system indispensable for showers and washing areas.

How to choose polystyrene foam for floor insulation in a bathhouse

For insulation, you can use any foam with a density higher than 25 kg/m3. You can come across a lot of recommendations that the floor in a bathhouse should be insulated with thin sheets, always with overlapping joints. In fact, this is clearly overkill; the thermal insulation of walls is laid in this way; for a bathhouse floor, especially a wooden one, the number of sheets does not matter. The only important thing is the presence of mounting grooves and tenons at the ends in order to lay the foam between the joists in one path, without cold bridges at the joints.

It is recommended to use high-strength grades like PS-1 with fire-resistant impregnation with nickel and chromium sulfate salts. Concrete screed also requires high-strength material to avoid pushing through the insulation. The thickness of the PPS is selected depending on climatic conditions, usually 80-100 mm.

Bathhouse construction technology

Required tools and materials

- blocks;

- cement;

- sand;

- level;

- cord;

- rubber mallet;

- trowel or plane;

- glue;

- Master OK;

- spatula comb;

- brush.

Before starting to lay the first row of blocks, it is recommended to prepare the base. In order to level the surface, a solution based on cement and sand should be applied with a trowel or comb; the mixture is made in a ratio of 1:3. You should evaluate the evenness of the base using a level. The process of laying the products that make up the first row must be given special attention. The convenience of further work and the quality of construction will depend on how smoothly the masonry is done in the first row. Levelness should be checked using a cord and a level.

Scheme of laying walls made of cellular concrete blocks.

The horizontal alignment of the products that make up the first row must be done with a rubber mallet. If the first row of masonry creates a gap the size of which is less than the length of a standard block, an additional block should be made. When making a block, cutting the material should be done with a hacksaw designed for blocks; you can use a hand or electric saw. The sawn base should be leveled. For these works, as a rule, a grater or plane is used. The ends of such a block should be completely coated with glue during installation. For installation, glue is used, bringing it to the appropriate consistency; for optimal density, you should use the consistency of thick sour cream. The adhesive solution is applied with a trowel; the width of the tool should be equal to the width of the masonry. After the glue has been applied, it should be leveled with a spatula comb. Small fragments and dust remaining after leveling should be swept away with a brush.

Alignment is carried out after installation of each subsequent row. To do this, it is necessary to install lighthouse blocks in the corners, and further laying should be done along stretched cords. Differences in levels will lead to the appearance of local areas of increased stress, in the area of which cracks may subsequently appear. All work should be carried out in strict compliance with the specified parameters and technologies. Once the adhesive solution used for masonry has hardened, the polystyrene concrete wall can no longer be disassembled into individual blocks; it can only be broken.