Home |Reinforcement |Knitting reinforcement for a strip foundation

Date: January 14, 2019

Comments: 0

The service life of a building depends on a high-quality foundation reinforced with reinforcement. The reinforcement frame preserves the spatial configuration of the foundation, the most common option of which is a strip foundation. Tying reinforcement for a strip foundation is a serious construction operation that determines the durability of the building and its resistance to external factors.

Naturally, the correct choice of concrete for pouring the foundation is important. However, the quality of installation of reinforcement in the frame plays an equally important role. Correct knitting of reinforcement for a strip foundation ensures reliable fixation of steel bars to each other and constant spacing when pouring concrete.

To ensure the strength of the reinforcement cage, it is important to understand how to properly knit the reinforcement for the foundation. The method is available for beginner builders who have mastered the manual technique of fixing steel bars. Let us dwell on this operation in detail, consider how to knit the reinforcement, and how to knit it correctly.

Performing this operation will require certain skills and perseverance.

Preparatory activities

Having decided to independently carry out the work of fixing steel bars, perform the preparatory work:

- Calculate the load that the future foundation will bear. Considering the seriousness of the task, use the services of professionals.

- Based on the calculation results, select the required brand and diameter of the rods, which should not be less than 12-14 millimeters. The use of rods of class A3 will allow, when making a frame, to bend them by 90⁰ without cracks, and rods of class A2 - at an angle exceeding 90⁰, while maintaining their integrity.

- Calculate the need for tying wire and steel rods. The basis for determining the total volume of material is the pattern of tying reinforcement for a strip foundation.

- Take care of assistants, as the knitting process is quite labor-intensive and tedious.

Composite reinforcement

Composite reinforcement refers to non-metallic rods made of different materials used in construction. For more effective adhesion to concrete, the surface of the rods is made rough or covered with sand.

The most common types of composite reinforcement:

- carbon fiber;

- basalt plastic (BBP);

- fiberglass (FRP).

Accordingly, reinforcement is produced from materials: carbon fiber is used in the production of carbon fiber reinforcement, basalt fiber is used for the production of ABP, and glass is used for ASP. They have many advantages: corrosion resistance, high specific strength, and environmental friendliness.

Methods for fixing rods

There are many ways to secure the steel bars of a mesh structure. Ensuring the immobility of the steel bars of the frame for concreting is carried out:

- electric welding, which changes the structure of the metal and does not guarantee the immobility of frame elements;

Rods with a ribbed surface facilitate the knitting process

- purchased metal clamps with a diameter of up to 4 mm, having a loop corresponding to the size of the rods and a clamp (hook). The use of connectors increases productivity, but requires additional costs. Their use does not require the use of tools;

- elastic clamps made of plastic, allowing you to quickly connect the rods. The disadvantage is increased fragility at subzero temperatures, as well as the possibility of damaging the integrity of the fastenings when moving along the frame;

- knitting wire with a diameter of 1 to 2 mm, made of annealed steel with low carbon content. It is optimal to use material with a diameter of 0.8-1.4 mm, which allows you to knit reinforcement for the frame without additional effort. A material with a diameter of 1 mm is not strong enough, and with a diameter of 2 mm the forces increase significantly.

Knitting methods

Knitting reinforcement for a strip foundation using soft and easy-to-use wire is the optimal solution. Let's take a closer look at this option.

Prerequisites: why reinforcement is needed

The foundation is created in order to withstand the load of the structure; It works best with evenly applied pressure. But in practice, the load is too often uneven and internal stresses arise in the foundation. The reason may be both changes in the soil and design miscalculations (unequal weight of individual parts of the structure).

Design errors will definitely become noticeable Source homeklondike.site

Concrete has excellent resistance to axial compression and weak resistance to tension. Reinforcing bars have natural plasticity and compensate for the lack of concrete. The latter, in turn, protects the metal from corrosion.

During operation, concrete (which resists compression) and metal (tension) are able to most effectively resist multidirectional loads, protecting the structure from destruction. Correctly carried out reinforcement not only increases strength, but is also a means of saving: it allows you to reduce the cost of concrete (reduce the massiveness of the foundation).

Knitting methods

Methods of fastening steel frame elements are carried out:

- Completely manual, which requires physical effort, but provides reliable fastening at low cost.

- Using semi-automatic methods that facilitate and speed up the fixation process, requiring additional acquisition costs.

If the rods are tied manually and fastening with loops is used, the elements will have to be connected separately

The manual fastening option is carried out using the following tool:

- wire cutters or pliers, the working surface of which is rounded;

- a self-made hook from a welding electrode or rod with a diameter of 3-4 millimeters;

- a manual reversible device, the rotation of which is carried out by reciprocating movement of the handle;

- special pliers, the operating principle of which is similar to a reversible tool;

- a purchased crochet hook, the use of which is one of the simplest options.

Semi-automatic methods of fixing frame rods are carried out using the following devices:

- An automatic knitting gun that ensures high efficiency and quality of work.

- A screwdriver or electric drill equipped with a special attachment that allows you to quickly tie steel bars. You can use a regular nail bent at a right angle.

Let's consider the features of the main types of manual and semi-automatic tools, with the help of which a bunch of reinforcement for the foundation is carried out.

Crochet hook

Hand tools can be:

- make it yourself from a durable rod or electrode;

- purchase in specialized stores.

A practical and versatile option is a crochet hook.

Advantages of a manual device:

- Ease of operation.

- Cheapness of the tool.

The disadvantages include:

- Low efficiency of work performance.

- The need to apply certain physical efforts.

Crochet

Despite a number of disadvantages, many developers prefer hand tools. With the help of a crochet hook, the reinforcement for the foundation is knitted reliably. To use a hand hook, you should first study the methods of tying reinforcement.

Video

Video about how to quickly learn to knit.

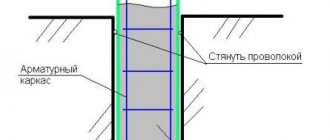

The technology for constructing a grillage frame structure is no different from a strip structure. Here are the same schemes and methods of knitting structures from reinforcement. As for the frame for a columnar foundation, one must take into account the fact that the frame itself in these structures is a vertical structure with vertically installed main rods, which are connected to each other by rods of smaller diameter.

This is if the frame has a rectangular cross-section. Therefore, exactly the same knitting is carried out here as in slab or strip bases. If the cross-section is circular, then the longitudinal rods are one rod rolled into a circle. It is tied to vertical elements in certain places of the frame, taking into account the installation step.

Hand knitting technology

Let's look at how to properly tie reinforcement to a foundation using a hand-held device.

There are several methods of knitting under the foundation. Let's consider a proven method, guided by which, perform the work according to the following algorithm:

- cut a steel wire with a diameter of 1.2-1.4 mm and a length of about 20 cm for each attachment point;

- bend the wire in the middle of the segment;

- place diagonally at the point where the rods meet;

- insert the working part of the hook into the resulting loop;

- pull into the loop, using a hook, the ends of the wire located on the opposite side of the loop;

- rotate the hook in the loop until the connection is strong.

When performing work manually, control the tightening force. By twisting the wire with increased tightening force, you can break it.

Wire is most often used, because it is a reliable and proven option.

Metal fittings

The most common type of pipe used when laying a foundation is metal reinforcement. Rods of different cross-sectional diameters are available for sale - from 12 to 40 mm. They are widely used in construction, in particular, for laying foundations for large, heavy buildings.

The cost of a product directly depends on its characteristics, namely:

- rental method,

- steel grades,

- surfaces (corrugated or smooth).

Rods with a corrugated surface have a higher price. This type has stiffening ribs, which allows the products to better adhere to concrete.

Metal fittings

Manual reversing device

A reversible tool, designed for manual twisting, is a screw working element that rotates when the handle of the device is moved back and forth. The tool handle contains a screw rod and a reversing mechanism.

How to tie foundation reinforcement using a reversible device? It's simple:

- insert the hook of the device into the wire loop;

- move the handle towards you in the axial direction;

- move the handle to its original position;

- rotate the hook again without re-fastening the tool, pulling the handle towards you.

Advantages of the device:

- Fast wire tightening.

- Possibility of use in places with difficult access.

- No fatigue when performing work.

- Long service life when lubrication is carried out.

- Ease of operation.

The only negative is the increased cost compared to a traditional hook.

The principle of action is similar for pliers used for knitting. The working planes fix the ends of the wire and twist them when moving the pliers. The use of reversible devices reduces the duration of the process of fixing bars and makes operations easier.

A knitting gun that independently grabs the structure and ties it

Automatic knitting gun

Using a gun ensures a strong binding of the rods for the base. The use of an automatic device has many positive aspects:

- there is no need for individual cutting of wire, which is pre-wound on the tool drum;

- the material is used rationally, since there is no waste representing wire cuttings;

- high efficiency of the device - the loop tightening cycle takes no more than 1 second;

- the ability to perform tightening work with one hand and support the bars with the other, without the help of auxiliary workers;

- guaranteed quality of loops;

- adjustment of tightening force and length of segments;

- Possibility of operation from a rechargeable battery;

- Equipped with an extension cord that allows you to tighten the hinges without bending over.

Disadvantages include:

- Increased costs for purchasing a gun and special wire.

- The need to train workers how to knit reinforcement for the foundation.

- Difficult to use in corners and places with limited access.

Despite the set of advantages, in some cases, work on fixing rods can only be done using a hand hook.

To speed up the process, use a drill with an attachment

A few words about the features of strip foundations

The strip type of foundation can be safely called universal, the most common, making it possible to construct buildings from almost any building materials. The widespread use of this foundation design is explained, among other things, by significant cost savings, simplicity and accessibility of its independent arrangement, as well as the fact that the strip foundation has been comprehensively tested by the very wide practice of its many years of operation.

The strip foundation rightfully occupies a leading position as the most popular type of foundation for buildings among developers

Such a foundation itself is a reinforced concrete strip, which can have different widths, thicknesses and heights. These parameters depend on the design of the future building - the size of the walls and the material from which the walls are planned to be built, the overall massiveness of the structure, the condition of the soil at the construction site and a number of other important factors. But in any case, the strip foundation is installed along the perimeter of the future structure, has a closed contour, which is intended for the further construction of load-bearing walls. If necessary, this type of foundation is supplemented with internal lintels, which become the basis for the construction of intra-house capital partitions on them.

The depth of the tape base can vary significantly, depending on the specific circumstances. Thus, in case of unstable upper layers of soil at the construction site, the base of the strip base is completely buried below the freezing level or is performed in combination with a pile foundation. If the soil is dense, or when it is planned to build a building with a small overall mass, then it is quite possible to get by with a shallow strip foundation.

The foundation strip can be deep or shallow, sometimes additionally reinforced with monolithic piles

Be that as it may, the requirements for complete and high-quality reinforcement are equally important for any type of strip foundation. Only under this condition will the foundation optimize the load from the walls of the house on the ground along the entire perimeter of the building, which minimizes the risk of subsidence of the building, distortion and deformation of all its component building structures.

How to fill a strip foundation with your own hands?

In this publication we will not delve too deeply into the intricacies of the design of such a base. to the issues of calculation and sequence of work on independent construction of a strip foundation .

General recommendations

Having decided on the tool used for knitting, having prepared the necessary materials and performing the work, follow the following recommendations:

- ensure the same distance (4-5 cm) from the horizontally located elements of the reinforcement frame to the soil, using wooden pads or non-metallic supports. The rods should not touch the ground at the bottom of the trench;

- the immobility of perpendicularly located steel rods when fixed with wire can be ensured by using a simple device that clamps the ends of the rods with boards;

- Do not drive vertically located rods intended for fixing horizontal rods into the soil. Use non-metallic coasters, which will prevent contact of the rods with the ground and reliably protect it with concrete from corrosion processes;

- check the reliability of fixing the frame elements using wire. Errors in fixing the rods have a slight effect on the location of the reinforcement contour during manual filling. However, the use of a concrete pump that supplies the composition under pressure can affect the location of the elements, pushing them apart or displacing the structure;

- Additionally, check the reliability of the fastening of the rods in the corners of the frame, which are a vulnerable area of any foundation. The ends of the rods located at right angles, which must have bends, are not allowed;

- the criterion for correctly performed knitting work is the immobility of the spatial structure under the influence of human weight;

- Ensuring the design of strengthening the assigned tasks is possible with the correct selection of the assortment of rods, determining the location and number of elements, according to preliminary calculations.

Remember, knitting the spatial structure rods only provides fixation of the frame elements. When pouring concrete, fix the reinforcement contour motionless, which guarantees the required performance characteristics of the monolithic foundation.

Scheme

The constant movement of soil puts serious pressure on the strip foundation. In order for it to firmly withstand such loads, and also eliminate the sources of crack formation at the planning stage, experts recommend taking care of the correctly chosen reinforcement scheme. The foundation reinforcement scheme is a specific arrangement of axial and perpendicular rods, which are assembled into a single structure.

SNiP No. 52-01-2003 clearly discusses how reinforcing materials are laid in the foundation, with what steps in different directions.

It is worth considering the following rules from this document:

- the step of laying the rods depends on the diameter of the reinforcement product, the dimensions of the crushed stone granules, the method of laying the concrete solution and its compaction;

- working hardening step is a distance that is equal to two cross-sectional heights of the reinforcing tape, but not more than 40 cm;

- transverse strengthening - this distance between the rods is half the width of the section itself (no more than 30 cm).