Recently, building your own bathhouse on a personal plot has become increasingly popular. Various materials are used for these purposes, but one of the most popular options is a bathhouse made of timber. In this article we will look at how to insulate a bathhouse from the inside.

A bathhouse made of timber is not only built using a special technology, but also requires a careful approach to insulation. You can make thermal insulation with your own hands, you just need to carry out the entire technology correctly. The choice of insulation plays a big role here.

What is a log bathhouse made of?

Old Russian compact bathhouse in a modern presentation

At the moment, like hundreds of years ago, the Russian bathhouse is built from wooden beams. Constant technological growth could not leave this industry without innovative solutions. As a result, the conventional log house was replaced by more modern types:

- log house of profiled and glued timber;

- log house made of rounded logs.

With the introduction of new materials, the technological process of the procedure has also changed. Thus, a powerful log of a log house was insulated only between the crowns. While a rounded product requires a more scrupulous approach. Especially considering the fact that the bathhouse is used all year round. Regardless of the ambient temperature, a properly constructed structure should retain heat. The thermos effect is the ideal result of high-quality insulation.

To do all the work perfectly, you need to master the skills of a builder; you need, as it is now fashionable to say, “to be in the know.” The effectiveness of bath insulation procedures can largely be guaranteed during its construction. There are a lot of nuances: from the optimal thickness and height of the windows, to the correct location of the steam room relative to the dressing room and soap bar. Therefore, it is recommended to act correctly while developing the project.

Material selection

the quality of the insulation of the dressing room determines the preservation of the temperature in the steam room itself

The question of how to properly insulate the dressing room is quite important, since the preservation of the temperature in the steam room itself depends on the quality of the dressing room insulation.

As a thermal insulation material for the dressing room, it is necessary to choose an inorganic moisture-resistant material, since organic materials, with constant contact with water, quickly rot and mold.

The following is used as insulation:

- perlite;

- Styrofoam;

- extruded polystyrene foam;

- polyurethane foam;

- mineral wool;

- glass wool

The ideal thermal insulation material for a dressing room is polyurethane foam, since due to its qualities such as durability, moisture resistance, sound insulation, inertness to chemical and biological influences, fire resistance, it provides reliable insulation of the room, eliminates sharp temperature differences between the dressing room and the steam room, and ensures air circulation .

When spraying polyurethane foam, a monolithic coating without joints is obtained; the material has high adhesion, which allows it to be sprayed directly onto the walls and ceiling of the room.

What is better to insulate: mineral wool or polyurethane foam from Ecothermix? We recommend watching the video below so as not to torment yourself with reasoning:

How do you insulate a timber bathhouse?

Main groups of insulation for a bathhouse

Of course, high temperatures always run in a log bathhouse. As a result, incorrectly selected cladding material can be dangerous due to polymer fumes and even burns. Any product suitable for work of this kind must necessarily meet all the requirements for many technical characteristics.

Moisture resistance, fire safety, environmental friendliness and of course naturalness - everything must be up to par!

The inside of the room is lined only with deciduous wood, which does not release essential oil or resin when heated. The only exceptions can be Siberian pines or cedars. In addition, the following natural materials have long been used as effective insulation:

- clay;

- expanded clay;

- peat;

- jute;

- flax fiber;

- tow;

- moss.

Modern analogues can completely reduce heat loss in a room. Moreover, both alone and in tandem with those described above. The range of synthetic materials for bath insulation is quite diverse, on sale:

- magnesite slabs;

- gypsum fiber;

- non-flammable mineral insulation;

- honeycomb;

- expanded polystyrene.

In addition, aluminum foil, kraft paper, and NPP foil-laminated polypropylene (foil penotherm) are often used as vapor barriers. Waterproof the room with glass hydrosol, bitumen mastic, and polyethylene film with a density of 140 microns. It is also possible to use ordinary euroroofing material, but not in the steam room.

Synthetic insulation

Expanded polystyrene is a durable, moisture-proof material, suitable for floors and ceilings in bathhouses

The best candidates for modern insulation are synthetic. Natural heat and moisture insulating materials are inferior in parameters and are more expensive. The correct use of synthetic materials allows the frame to remain a “thermos” and not release heat to the outside.

Expanded polystyrene

Expanded polystyrene and polystyrene foam are the best in terms of price-quality characteristics. The lightness and low cost of the material make it possible to use the material in finishing. It is easily shaped, cut, installed, attached to any surface with glue, nails and other fasteners, and does not absorb moisture. However, there are several restrictions that prevent widespread use of bath insulation:

- deformation at high temperature;

- release of phenol when heated;

- flammability.

All disadvantages are associated with use in heated rooms. The material can be used for finishing dressing rooms or external walls. The joints between the sheets are glued together with polyurethane foam or special silicone.

Mineral wool

Mineral wool is suitable for the dressing room, corridor, attic, where the humidity is lower. Not suitable for steam room

Mineral wool is widely used in construction. This is a universal insulation for a bath - low price, fire safety, biological resistance. Considering the lightness of the material, installation is very simple. It must be taken into account that it loses its thermal insulation properties when wet. Therefore, mineral wool for a bath should be used together with steam-waterproofing. This type of insulation is classic for a bathhouse, dressing room, washing area inside and outside. It is not suitable only for a steam room.

Glass wool

The insulation is similar to mineral wool, but is made from molten glass. Available in the form of slabs and rolls. Immune to temperature changes. Over time and during installation, the glass melt crumbles, so the heat insulator is not suitable for cladding interior spaces without some kind of separating layer. It is widely used in insulating bath walls inside the frame along with mineral wool.

Glass wool, even when used with a vapor-proof film, is not suitable for covering the ceiling. Wet material instantly loses its thermal insulation properties and can damage the ceiling beams.

Basalt fiber

Basalt wool is used with anti-moisture impregnations

Basalt insulation is considered the safest. The material is made from rocks. Therefore, it can withstand high temperatures, does not burn, does not emit harmful substances, and is resistant to moisture.

A service life of 30 years, excellent sound insulation, and simple installation make this material a priority over other heat insulators. Temperature fluctuations and high humidity do not disturb the thermal insulation. She is not interested in rodents and does not have insects.

The material does not have many disadvantages - high price and heavy weight. Suitable for insulating horizontal surfaces - floors and ceilings.

How to properly insulate a roof?

Scheme of a properly insulated roof structure

The question of whether it is necessary to insulate the roof of a bathhouse or not can only arise from an inexperienced owner. Experts know that high-quality insulation of this area will reduce heat loss by as much as 30%. Work is carried out along the perimeter of floors and slopes in the following order:

- At the first stage, the object is waterproofed - if this requirement was ignored during the construction of the building, a moisture-proof and vapor-proof membrane will still have to be laid over the rafters. True, now, for this it will be necessary to dismantle part of the roofing material.

- Next, all roof elements are treated with an antiseptic - if such a procedure has not been carried out previously.

- After preliminary preparation, the insulation itself is installed directly - slabs or rolls of balsat fiber have proven themselves exclusively on the positive side.

- The final stage involves internal covering of the laid material - even an ordinary vapor barrier film that is attached to the rafters will do; ideally, the structure is sheathed with clapboard.

Next to the roof, you can think about how to insulate a bathhouse made of timber from the outside.

Insulation of ceiling floor and roof

Thermal insulation of all surfaces in the bathhouse, technologically, has a few differences. They consist of only a few nuances, and the basic rules apply to both walls and floors with a roof.

For example, as already mentioned, the insulation of a bathhouse starts from the top, that is, from the roof and ends with the floor, there are several reasons for this. Firstly, it’s more convenient, you see, it’s easier to go down systematically than to rush from wall to roof, and then to the floor.

Secondly, all surfaces must have uniform thermal insulation. That is, the heat-insulating materials must fit tightly to the same elements, but on a different surface, and the vapor barrier must also overlap onto the next surface.

For example, the thermal insulation of the roof and ceiling should be adjacent to each other, the vapor barrier on the ceiling overlaps the walls in order to subsequently connect it with the vapor barrier on the wall using aluminum tape.

In turn, the thermal insulation and vapor barrier of the walls are connected to the floor in the same way. By following this technology, it is possible to achieve uniform thermal insulation and complete sealing of the room so that steam does not leave the room. The latter is especially true for the steam room.

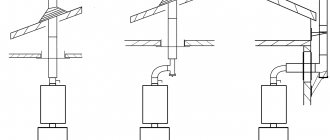

Option for insulating a bathhouse complex from the outside

Sealing seams is a mandatory process when insulating.

There are many ways to protect a building from the negative effects of the environment, but a system of ventilated facades is rightfully considered one of the most effective. This is an ideal solution for rooms with high humidity, because this design boasts not only excellent energy-saving functions, but also high vapor permeability.

Important! Any work on insulating a new bathhouse can only begin after the building has completely settled; this process takes on average no more than six months.

When preparing for work, first of all you need to take care of the insulation. Experts recommend using mineral fiber-based slabs in structures with ventilated facades.

Particular attention should be paid to the corners of the building, because it is through them that the most heat is lost - reduce the number of joints in this area as much as possible!

Do you want to know how to do everything strictly according to technology? See instructions:

- Prepare the walls - the process begins with a thorough cleaning of the surface, after which it is necessary to caulk the seams, and at the end treat the walls with an antiseptic. If rot is detected, the log is rehabilitated or replaced if the defect is severe.

- Install the brackets - they are installed on top of a layer of poranite or roofing felt.

- Install the sheathing panels on pre-prepared fasteners - they can be made from galvanized profiles or timber with antiseptic impregnation. The first option is less susceptible to deformation, but in cold weather it acts as a conductor of cold, so it would be more advisable to give preference to wood.

Advice: when assembling the frame, take into account the size of the insulation, and also take into account the required margin between the insulation layer and the edge of the wooden structure, it should be at least 2 cm!

- Place the insulation into the resulting cells - you can prevent the material from falling out with additional fixation with disc dowels.

- Cover the structure with a windproof superdiffusion membrane - only a vapor-permeable film is suitable, which does not allow moisture to accumulate under the skin.

- Finally, cladding is carried out with facing material.

Another option for the correct outdoor “warm pie”

Very often, in an attempt to save money, consumers strive to insulate a bathhouse only from the outside, even one made of logs.

Is this right or wrong? The answer can be yes if the premises are located in a region where there are no harsh winters. Moreover, the material used for construction by and large does not play any role, the main thing is to carry out the work strictly according to technology. If in a village or city -20 in January is far from the limit, of course it is necessary to additionally insulate it from the inside!

External insulation

It is important to remember that thermal insulation of a log building must be carried out outside and inside. Caulking on the street side is carried out during the construction process. External work is carried out taking into account the powerful atmospheric influences on wooden walls and coverings.

You need to place the insulation for the bath between the logs while laying the crowns, fixing it to each lower crown. The procedure should be repeated after a year, during which time shrinkage will occur and the external cracks may increase. Over the next five years, the insulation usually does not change. At the end of this period, restoration of the outer heat-insulating layer may be necessary.

Caulking and subsequent restoration are often carried out using natural raw materials, but modern sealants for external use are more effective. Special compositions designed for cracks of different sizes are used together with flax wool and jute. Insulating the outer part of a bathhouse frame in this way can be effective for a long time.

How to insulate a bathhouse from the inside?

All work on internal insulation is divided into three stages: floor, walls, ceiling. Often the procedure begins with a pre-prepared base. Its base can be either concrete or ordinary soil. In the latter case, you will need to make a sand and gravel cushion on the ground with a layer thickness of no more than 40 cm.

Creating a warm base

Which wooden bathhouse is the warmest, with a dirt or concrete floor? Of course, the option with cement mortar is more modern and practical, so we will insulate it.

- Cover the concrete base with roofing felt or bitumen mastic;

- Secure the support bars under the joists;

- Install the logs on the supports so that their ends meet the walls;

- The resulting cells between the logs are filled with expanded clay;

The thicker the expanded clay layer, the lower the level of heat loss

- Cover the floor frame with waterproofing film;

- Install insulation between the joists, put mineral wool in the steam room, and foam plastic or expanded polystyrene in the dressing room;

- On top, the structure is covered with a vapor-proof membrane;

- Afterwards, a rough version of the floor is knocked down, onto which the desired material is mounted.

Please note: ceramics and solid boards are used most often in the bathhouse, tiles are not afraid of dirt and deformation due to moisture, although wood swells, it is warmer.

Wall decoration

This algorithm of actions will help you figure out how to properly insulate a steam room, dressing room and other rooms in a wooden bathhouse:

Do it right! All work on wall insulation is carried out from the ceiling to the floor!

- Initially, the surface is impregnated with biocidal impregnation;

- Next, the seams are processed - place the material in the grooves between the beams and caulk it thoroughly;

- Apply a moderate layer of sealant on top of the fabric;

- Afterwards, a special frame is installed, similar to what was done outside;

- A heat insulator is placed in it - only material resistant to high temperatures can be installed in the steam room; gypsum fiber, magnesite boards and mineral wool will do;

- A vapor barrier is placed on top - is it worth using foil? It’s not just worth it, it has practically no alternative, well, if you don’t take into account the innovative foil penotherm;

- Next, a frame is mounted to secure the cladding, taking into account the required two-centimeter gap from the vapor barrier layer.

There is no need to rack your brains for a long time about how to insulate the ceiling. From the inside the procedure is similar to the walls, but from the attic it looks a little different.

Ceiling insulation

A little outdated, but still effective ceiling insulation.

Experts say that to minimize heat loss, sealing the outside of the ceiling is mandatory! Let's look at this simple technique:

- Place fiberglass on the ceiling to prevent moisture from entering;

- Mix a solution with high thermal insulation qualities - for this you will need clay, chopped straw, water and sawdust. All ingredients are mixed until thick in one to one proportions;

- Fill the space between the beams with mortar, controlling the level of moisture insulation on the inside of the ceiling;

- Leave the work for several weeks until the solution dries completely;

- Then, dense insulation and a moisture-proof membrane are laid;

- A thin cement screed is poured on top - fixing it.

At this point, the complex of work on capital insulation of the bathhouse can be considered completed. Many will wonder whether it is necessary to make so many unnecessary movements for the sake of short-term pleasure? Anyone who wants to feel the real heat of an old Russian bathhouse will definitely say - it’s a must! Moreover, such leisure also has a healing effect.

Insulation of a steam room in a wooden bath

Just as in most cases a wooden bathhouse does not need any insulation other than sealing the cracks, its steam room is able to perform its functions without additional effort. Unless the owner sets the task of making a sauna out of a bathhouse, which differ in temperature and air humidity. But even in this case, it is enough to simply lay a layer of foil or foil-coated kraft paper without installing any insulation.

The foil is placed behind the lining, but never end-to-end, but with a ventilation gap so that the lining can dry out. There should also be an air gap between the foil and the timber wall. If you are making a “thermos” from a steam room, you should not use coniferous wood in the lining, so as not to get burns from the resin.

Let's put it this way : insulating a steam room in a wooden bathhouse, if we don't talk about using foil, is a very strange event.

Do you need foil in the steam room?

The debate about foil will never end; it has many supporters and opponents. But, as a fact, a steam room with foil becomes hotter, and the steam in it becomes harsher . Therefore, it is a matter of the owner's taste. On the other hand, mistakes during its installation can be costly; if the wood gets wet, mushrooms and rot will develop. As experts say: try steaming without foil, you will always have time to put it on.

Find out more about the use of foil and foil insulation in baths.