A vapor barrier for a bathhouse is necessary to create a barrier against steam escaping through the walls and ceiling to the outside. This is necessary for the steam section of the bathhouse, because the traditional Russian bathhouse includes the procedure of warming up the body with steam, and even with a broom.

But for some people, a hot bath is contraindicated. Therefore, in the steam room there are places for those who like to steam - specially equipped shelves almost under the ceiling, where it is hottest, and there are places for moderate stay - the lower shelves.

Many baths were built as a single room: a steam room, a washing room, and a dressing room. A special feature of the Russian stove is the closed-type stove-heater - the main attraction of the Russian bathhouse. The stove takes a long time to warm up, and its design is such that the heat stays in the bathhouse for two days. This is where the reason lies: why the ceilings in the Russian bathhouse were always dry.

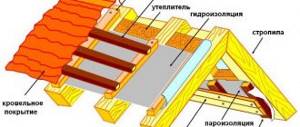

To preserve heat, the roof and walls of the Russian bathhouse are made of carefully caulked walls : moss and flax tow were used. The ceiling is made of wood from thick blocks (half logs) tightly fitted to each other. The vapor barrier for a bathhouse on the ceiling was done as follows: oiled paper was placed on top of the blocks and a layer of clay mixed with dry sawdust was laid. The result was a kind of additional thermal insulation. The attic of the bathhouse was ventilated, brooms were stored there and herbs were dried.

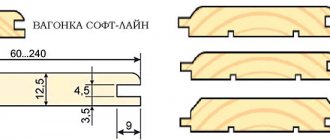

The material for the construction of the bathhouse was also taken into account - moisture-resistant wood species : cedar, larch, oak. Aspen, alder, and linden tongue and groove boards were used for finishing.

Building materials that are used today in the construction of baths must be additionally protected from moisture penetration. This concerns, first of all, the protection of insulation in the construction of ceilings and walls. And the heating technology in modern baths is completely different. It also affects the formation of condensation in the bath insulation.

It is possible to choose the right vapor barrier and determine which one is better, but you need to study the nature of the conversion of warm air into condensate.

Why is vapor barrier necessary?

Currently, most bathhouses have interior walls lined - this is beautiful, useful and prestigious. The walls are usually covered with natural clapboard. From the designer’s point of view, everything is great, but from the builder’s point of view, there are big problems.

- An additional “heat-protective” wall is formed between the load-bearing wall and the steam room. This is good, it minimizes heat losses, but it causes condensation.

- Due to the low thermal conductivity of wood, the temperature difference between the lining and the wall is large. This situation needs to be looked at from two sides. The good thing is that the steam room retains heat. The bad thing is that steam easily passes into the forcing joints, and the relative humidity of the wood increases.

Diagram of the construction of bathhouse walls with vapor barrier

Diagram of the installation of brick walls of a bathhouse with vapor barrier

Now we come to the main problem. If the temperature of the lining is so high that condensation does not form given the existing humidity, then the wall temperature is below the dew point. Condensation forms on cold walls and is absorbed into all materials of external walls: wood blocks, brick. Due to the fact that natural ventilation between the sheathing and the wall is almost completely absent, water does not evaporate. As a result, the wood begins to rot, the red brick crumbles, and the concrete materials transfer moisture through micropores to all adjacent structures.

Dew point table

Dew point in the wall

Here you can clearly see how the dew point in the wall of the house will shift

Prices for vapor barrier

vapor barrier film Yutafol

Which vapor barrier is best for a bathhouse?

Which vapor barrier is better? One that will protect the insulation and block the leakage of steam to the outside. Having considered the characteristics of foil Aerolam Super Alumet above, we can safely say that it is the best for the ceiling in a bathhouse. It is suitable for baths of the traditional Russian type, and for modern baths, which differ from saunas only by the addition of steam.

Before deciding which vapor barrier to choose, you need to proceed from the preferences of the bathhouse owner. If the bathhouse maintains a traditional temperature of 60-70 degrees , then instead of foil, a regular PVC vapor barrier film , but if the bathhouse temperature is 100-110 degrees , then it is better to replace the film with foil .

The topic of vapor barrier for a bathhouse is extensive, but there are postulates, truisms that should not be deviated from, the main thing is to prevent condensation conditions . The main protective agent can be not only foil material, but also natural materials, you just need to correctly understand the nature of condensation formation and act consciously.

Advice. Always leave air gaps between layers of vapor barrier, insulation, and attic flooring. Air gaps not only enhance thermal protection, but also disperse small amounts of moist air within their volume, preventing condensation from forming.

Additionally, you need to build in an adjustable ventilation duct to ventilate the room after washing.

Vapor barrier and wall insulation

But these are not all the reasons why you should use a vapor barrier. Let's touch on the issue of insulating the bathhouse. Insulating the outside is a waste of money and time. Until the insulation “shows its effectiveness,” no one will wash in the bathhouse. The heating time for the sheathing and walls is several hours. Only then will the internal heat “reach” the insulation outside the external walls and it will be able to “work”. The effect will no longer be during the heating of the steam room, but during its cooling after washing. To “enjoy” the effectiveness of external thermal insulation, you need to stay overnight in the steam room.

It is necessary to insulate the bathhouse from the inside

This means that for steam rooms, insulation needs to be installed only inside. But here too a problem arises. Most often, mineral wool, glass wool or polystyrene foam are used as insulation. The latter is not environmentally friendly and emits harmful chemical compounds, especially during heating. Sanitary authorities categorically do not recommend using it for steam rooms. What remains is mineral wool or glass wool.

Mineral wool insulation

Mineral wool as insulation

Mineral wool has two “unpleasant” properties. First, with increasing relative humidity, thermal conductivity characteristics decrease significantly. This is what some “experts” write, although the characteristics increase, thermal conductivity increases, and heat saving decreases. Do you feel the difference? Three times - cotton wool takes a very long time to dry, there is almost no air movement in it. Which is natural, otherwise the heat would not be retained in the room. Insulation is always attached to the walls, regardless of the material they are made of. And prolonged contact with wet wool has an extremely negative effect on all building materials. Here is another reason why you need to use a vapor barrier in a bathhouse.

Condensation on mineral wool laid without a vapor barrier

Mineral wool absorbs condensation and moisture

If you understand these issues, you can familiarize yourself with various vapor barrier materials and their physical characteristics.

Prices for mineral wool

mineral wool

How to do

The above does not exhaust the issues related to waterproofing. But a complete coverage of the topic is hardly possible. Let's look at a couple more questions that are often asked.

How to make a frame bath

If you are making a frame bathhouse with mineral wool insulation, then there is a high probability that you will use the same mineral wool to insulate the floor. And mineral wool differs from extruded polystyrene foam, which was mentioned above, in that it requires protection from moisture. Those, in fact, don’t like it .

In general, polystyrene foam should not be used in a bathhouse, but if it is in the floor and under a concrete screed, it is completely fireproof . But in a frame bathhouse, the floors are often made on joists and stilts.

The video below shows an option on how to cover a floor with slate sheets . But it's your choice. We are talking about waterproofing the floor in a frame bath.

So, it’s correct to make the layer at the very bottom from a one-sided waterproofing membrane, which releases water vapor from the insulation to the outside, but not to the inside. And on top the insulation is covered with a vapor barrier, which does not allow anything to pass through at all - neither steam nor water. These are two layers of waterproofing designed solely to preserve mineral wool .

Then you can do it as in the video - before laying the tiles, cover the subfloor (in essence, slate simply replaced the concrete screed) with mastic waterproofing for bathrooms, and then lay the tiles on the mastic. Why do we consider the use of mastic justified here? Because below is mineral wool.

Types and characteristics of vapor barrier materials

There are quite a few of them; we will focus only on a few of the most frequently used ones. Let's start again with a little “educational education”. Some amateur builders do not fully understand the difference between vapor barrier and waterproofing materials. After all, steam is the same as water. Why should some materials be used for vapor barrier and others for waterproofing?

Vapor barrier and waterproofing. Differences and Similarities

The fact is that water molecules and steam molecules have different sizes. Based on these characteristics, manufacturers produce materials with different micropore diameters. Some do not allow steam molecules to pass through (vapor barrier), while others do not allow water molecules to pass through. This means that vapor barrier materials can also be used as waterproofing, but the latter cannot be used in the same way. Recently, the production of vapor-waterproofing fabrics has begun; they consist of two layers with different micropore diameters. When installing such materials, you need to monitor the location of these sides so as not to install “exactly the opposite.”

Anti-condensation multilayer vapor barrier “Brane D Super” Tyvek Solid is a single-layer waterproofing material with high vapor permeability that protects against precipitation and wind

ISOSPAN FX reflective heat-hydro-vapor barrier

Izospan RS

Izospan fx

Prices for Izospan

Izospan

What vapor barrier materials are produced?

| Material | Description |

Ordinary polyethylene film. | The cheapest, but pretty good option. It has another significant advantage. The films are produced in sleeves with double walls, the sleeve width is up to three meters. By cutting the sleeve in half, you get a sheet of continuous film more than five meters wide - quite enough to cover the wall of a bathhouse with a continuous material without overlays. |

Glassine, roofing felt and other bituminous materials. | They are rarely used in baths due to the likelihood of unpleasant odors. |

Pure aluminum foil and aluminum coated multi-component materials. | Used most often, multi-component materials have a small layer of thermal protection or special fibers to prevent condensation from draining. |

| Liquid rubber. | An excellent vapor barrier material that can be applied to surfaces of any complexity and configuration. |

| Liquid polyurethane foam insulation. | In addition to their main tasks of insulation, they have a sealed outer surface that does not allow steam to pass through. Universally applicable, characterized by high performance characteristics. |

Which floors need waterproofing?

The floor in the bathhouse is made either on logs or on a concrete base . The concrete screed base can be:

- not covered with anything;

- pourable floors can be made on top of it;

- tiles can be laid on top of the screed (with or without underfloor heating).

Let's first consider the options for waterproofing a concrete floor in a bathhouse.

Concrete

The concrete floor in the bathhouse is made directly on the ground . To do this, the soil is removed to the required depth, leveled, compacted, and a sand or sand-gravel cushion is poured on top.

For more information about floor installation, see the article about insulating floors in bathhouses.

ATTENTION! The first layer of waterproofing of a concrete floor in a bathhouse is a film or roofing felt, which is placed on top of a sand cushion.

A layer of heat insulation is laid on a base lined with waterproofing . extruded polystyrene foam to be very good for the latter (possibly with increased load resistance) - it is not afraid of water at all.

However, options for installing a concrete floor may differ from each other. , a rough concrete base is poured onto a sand and gravel bed . In this case, waterproofing can be covered with a sand cushion, or it can be done on top of a rough concrete base - which is better?

We believe that waterproofing protects concrete , so it should lie on a sand bed so that the concrete does not draw water from the ground. For the same reason, it is better to overlap the waterproofing on the wall - so that the concrete is surrounded by it at the ends.

So, if there is a rough concrete base, then a heat insulator is placed on it, which can be covered or not covered with plastic film .

The next layer is reinforced concrete screed. For reinforcement, it is good to use a mesh of welded rods. The choice of cell size depends on the load on the floor - 50 mm for the most loaded, 200 mm for the least loaded, you can take 100 mm as the average.

So, if the reinforced screed is left as is, there will be an unprotected concrete floor. Why is this bad? Concrete absorbs water, and if after this the temperature drops below zero, the water in the pores will freeze, the ice will widen the cracks, and the concrete will lose some of its strength. Each freeze-thaw cycle will increase the damage.

What can be done in this situation? The cheapest way is to reinforce concrete with pure cement. Or cement with the addition of liquid glass. (Ironizing is the application of a thin layer of cement either a few hours after pouring the screed or the next day.)

Ironing can be considered an old and reliable method of waterproofing concrete. In addition to this, there are other methods, but let's look at them in relation to the washing room.

In the washroom

How to waterproof the floor in a bathhouse where water flows freely onto the floor? For example, in the sink?

Let's assume that you still don't want to put tiles on this floor, preferring, for example, a poured floor or ladders. Protection of the concrete screed under the poured floor is very desirable.

And if you don’t iron it, as suggested earlier, then to waterproof the floor in the bathhouse in the washing room, you can use more expensive options - cover it with cement waterproofing, cement-polymer, bitumen-polymer, or penetrating - this is when, when the impregnation dries, crystals are formed inside the concrete, filling pores and cracks. We reviewed all these types of waterproofing materials here.

All this is significantly more expensive than just cement and liquid glass, but even more reliable.

In a sink under tiles

The tiles, of course, do not allow water to pass through, so why spend money on waterproofing the bathhouse floor under the tiles?

In fact, the main purpose of such waterproofing is bathrooms in multi-storey buildings, where there is a risk of flooding of neighbors below, and waterproofing reduces this quite significantly , especially expensive and high-quality ones.

In a bathhouse where the floors are arranged with a slope towards the drain, the water does not stagnate, and it turns out that there is no good reason to spend money on waterproofing under the tiles . (This is if you have waterproof polystyrene foam as a thermal insulator.)

If this is not an argument and you want to do everything according to the rules, then we recommend liquid bitumen-polymer mastics , which say that they are suitable for your purposes and the time after which you can start laying tiles. Also, to waterproof the floor of a bathhouse sink, you can use cement compounds , which can be rigid or elastic. Both are suitable.

IMPORTANT! Remember that you will not be able to install tiles on pure bitumen or roofing felt. She doesn't stick to him. No adhesion. And one more thing: when choosing waterproofing, be guided by the smell, too; after all, it is better not to use anything that has a strong odor in the bathhouse (this primarily applies to anything that contains bitumen).

Wooden

A solid wood floor is designed completely differently than a concrete screed floor. The latter is done directly on the ground. And solid (we clarify so that you do not confuse with pouring) wooden ones are made on logs stretched from one wall to another, due to which there is no contact with the ground.

Do these floors need waterproofing? Of course, protection from water is very desirable for them, as well as protection from fungi that cause rotting. But is it right to call it waterproofing? We think that it’s quite possible, if we don’t talk about waterproofing a wooden floor in a bathhouse strictly in terms of terminology. Because in the latter case it must be covered with roofing felt and/or mastics