Waterproofing an entire structure is a set of measures taken at different stages of construction to protect certain structural elements of a building from their characteristic effects of moisture - ground or atmospheric.

Since each of the structural elements (foundation, walls, floor and ceiling, roof) has implementation options, we will not be able to talk about how to waterproof a bathhouse in each specific case. But the principles are universal, and that is what we will outline below.

If our website already contains materials that more fully cover certain issues, then a link to them is provided in the text.

Is it necessary to organize ceiling insulation?

Heated air masses rise upward. The lack of a good thermal insulation system allows moist air to:

- Settle in drops on the ceiling. If the question of how to insulate the bathhouse ceiling was not resolved in time, the drops formed at the top will periodically fall down, spoiling all the pleasure of the bath procedures.

- Reach the roof, attic and ceilings, damaging them.

- Increase resource consumption for heating.

Organizing a functional and comfortable space Source stroyfora.ru

Having decided how to insulate the ceiling in a bathhouse, it is possible to cope with the following difficulties:

- Uncomfortable stay due to falling drops from the ceiling.

- Destruction of the structure itself.

- Unreasonably large consumption of resources to maintain the required temperature.

Advice! In order to solve the problem in the optimal way, you need to know the technological qualities of the materials and the procedure for performing the necessary work.

What is ecowool insulation?

Let's start with the fact that ecowool is a cellulose thermal insulation material. It is made from finely chopped waste paper , boric acid , borax (mineral) and lignin (a sticky compound found in almost all plants). All these elements are non-toxic, harmless and environmentally friendly.

This cellulose insulation is used not only for its intended purpose, but is also successfully used as a good noise and moisture insulator. Typical places of application are walls, floors, floors, ceilings in houses with cold roofs. In the renovation of old buildings, ecowool insulation is convenient for filling hidden cavities that require thermal insulation. It is recommended for use in damp areas. Fungus and mold are not dangerous for it, since the boric acid included in the composition prevents the development of microorganisms.

Ecowool is supplied to the construction market in pressed dry form, packed in bags. Before use, the briquettes fluff up and the material increases in volume by 3-4 times. After watching the video below, you can imagine the process of making “paper insulation.”

Main stages: everything you need

To understand how to properly insulate the ceiling in a bathhouse, you need to understand that the work being carried out must resolve the following issues:

- Vapor barriers.

- Thermal insulation.

- Waterproofing.

Only high-quality materials Source banya-ili-sauna.ru

With proper organization, several layers are created. The bottom one is vapor barrier, the second one is thermal insulation and the final one is protection from water. All multilayers must be securely fastened in such a way as to prevent deformation.

Choosing the type of thermal insulation: all options

The specifics of the building must be taken into account when carrying out hydro-, heat- and vapor barrier work. Based on this, it is much easier to choose a ceiling in a bathhouse - what is best made of will depend on the following characteristics of the materials:

- Moisture resistance.

- Fire safety.

- Resistant to various temperatures, even high.

- Ease of installation.

- Weight.

Carrying out work from the attic side Source stroytorg.zp.ua

Mineral wool is the most popular option

In the process of solving the problem of how to insulate the ceiling in a bathhouse from the attic side, the choice often falls on mineral wool. This term itself combines several of the following types.

| Name of mineral wool type | What is it made from? |

| Slag | Blast furnace slag |

| Stone | Rocks that have undergone special treatment, including basalt |

| Glass wool | Glass fibers |

The advantages of using this material to solve the question of how to insulate the ceiling of a bathhouse:

- low thermal conductivity;

- no flammability;

- low weight;

- ease of installation;

- preservation of parameters during temperature changes.

Work must be carried out with the protection of the skin Source www.garrityinsulation.com

In addition to the listed advantages, it is important that mineral wool does not attract mice and does not serve as a favorable environment for the development of mold. It is sold in two release forms:

- Rolls.

- Separate panels.

Mineral wool also has disadvantages:

- content of phenols harmful to health;

- small particles of material can damage the skin, mucous membranes, eyes, and respiratory tract;

- moisture absorption.

Material in the form of individual panels Source vsparket.ru

The weaknesses of mineral wool during operation can be circumvented if the work is carried out correctly in compliance with all insulation requirements. When working on insulation, safety precautions must be observed to avoid getting the material on open areas of the body, in the respiratory system, or in the eyes.

Foam plastic: there are more disadvantages than advantages

This material is rarely chosen due to significant disadvantages:

- flammability;

- release of acrid smoke during combustion;

- lack of resistance to high temperatures.

Foam plastic is not the best option Source www.beboss.pro

During operation in a bath, foam plastic will be exposed to high temperatures. Since this circumstance is enough for the material to begin to decompose, expanded polystyrene is not the best choice, despite its good thermal insulation properties.

See also: Catalog of companies that specialize in baths

Expanded clay: cheap and long-lasting

This thermal insulation material consists of small clay, porous and smooth pebbles. Expanded clay is a good choice in terms of thermal insulation, which has many advantages:

- Almost endless service life, as the material does not break down.

- Environmentally friendly.

- Non-flammability.

- Does not create a favorable environment for the development of microorganisms.

- Easy to install.

- Has a low price.

For your information! Expanded clay absorbs water, but much less than all types of mineral wool.

Expanded clay is a good option Source stavstroi26.ru

The oldest type of insulation: sawdust with cement

This type of insulation was especially relevant before the advent of modern building materials, for example, mineral wool and other materials that had already become familiar. However, even now it is quite possible to use this option.

The composition is collected in the following ratio (the quantity is determined by the area):

- 1 part cement;

- 10 parts well-dried straw;

- 1 part lime.

Another way to insulate the ceiling in a bathhouse from the attic side in the “old-fashioned” way:

- Dry ingredients are mixed.

- The required amount of water is added. The composition should be moderately thick so that it is well distributed over the surface and there are no voids left.

Advantages of the method:

- Environmentally friendly.

- Cheapness.

Mixing dry ingredients Source banya-ili-sauna.ru

Disadvantages:

- lower thermal insulation qualities compared to modern materials;

- labor intensity of the process;

- there is a high probability that additional treatment will be required to seal the cracks formed as a result of drying.

Important! The hay, sawdust or straw that is used must be very well dried.

Ecowool: is natural material always the best?

If you are looking for how to insulate the roof of a bathhouse so that the materials are as environmentally friendly and safe as possible, then ecowool will give many competitors a head start.

Cellulose is used in the manufacturing process of ecowool. To prevent natural fibrous material from serving as a breeding ground for pathological microorganisms and mice, it is subject to mandatory additional processing.

Advantages of ecowool:

- light weight;

- environmental friendliness;

- good adhesion to the surface;

- high thermal insulation.

Ecowool for insulation Source prouteplenie.com

See also: Catalog of companies that specialize in engineering systems

But the material also has disadvantages:

- ecowool has the property of absorbing moisture, which requires very reliable hydro- and vapor barrier;

- installation complexity, requiring special skills and equipment.

For your information! Ecowool is applied using the so-called “wet method” - spraying.

Insulation technology

The choice of a suitable method of ceiling insulation is determined by the design features of the bathhouse building - the presence of an attic, attic, flat or pitched roof.

In practice, the following options for insulating a bath ceiling are used:

- Hemmed - for large baths.

- Flooring – for small-sized buildings.

- Panel - for various types of structures.

The main requirement for arranging ceiling bases is the presence of properly installed waterproofing and vapor barrier - reliable protection of the insulating material from high humidity.

Flat ceiling

The floor ceiling structure consists of 5 cm thick boards mounted on the bath walls. It is used for buildings with a cold roof up to 250 cm wide.

Insulation of the ceiling in a bathhouse with a cold roof, in which an attic is provided, is carried out using sawdust, clay or expanded clay.

All do-it-yourself ceiling insulation work is carried out step by step as follows:

- Sheets of vapor barrier material (film or roofing felt) are laid overlappingly on the ceiling flooring and secured with metal staples or nails.

- Next, install thermal insulation protection - mineral or basalt wool.

- If bulk insulation is used - expanded clay, sawdust with cement or clay, an additional edge should be installed around the perimeter of the ceiling surface. The thickness of the layer of loose insulation is 30 cm.

- The multilayer structure is covered with waterproofing material - polyethylene film or membrane.

- Finally, a wooden flooring made of boards or plywood sheets is installed.

false ceiling

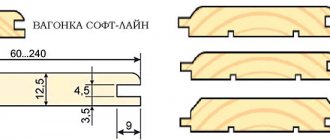

The hemming type design ensures the creation of a practical bath ceiling. The boards are mounted to load-bearing floors from inside functional rooms and from the attic.

Multilayer thermal insulation is installed between the floorings. The installation process includes the following steps:

- A vapor barrier film or membrane is laid on the ceilings with an overlap of 12 cm, overlapping the wall surfaces. The canvases are fixed with thin wooden slats, which are stuffed in compliance with minimal technological gaps. A double layer of vapor barrier and insulation material is laid over the steam room.

- A wooden lining, pre-treated with antiseptic impregnation, is mounted on the ceiling structure to the slats.

- The load-bearing beams in the attic are insulated with expanded clay, basalt or mineral wool. Thermal insulation is laid in a dense layer without gaps or cracks. The height of the insulating layer is 10 cm.

- A waterproofing protection is mounted on the heat insulator with an overlap of 12 cm, with the joints tightly sealed.

- Finally, the installation of wooden flooring from boards or plywood is carried out.

Selection of material for waterproofing and vapor barrier

Additional protection from steam and water is necessary, no matter what insulation is chosen. Without it, moisture will reach both the insulation and the supporting elements, damaging them.

Vapor barrier can be provided by the following coatings:

- aluminium foil;

- geosynthetics, etc.

Geosynthetics for waterproofing Source stroimsami.online

Advice! If there is a choice, it is recommended to give preference to those materials that have a layer of foil.

For waterproofing use:

- roofing felt;

- plastic film;

- special films.

Laying roofing felt in the attic Source sk-sota.ru

For your information! Dense polyethylene and roofing felt are a cheaper option compared to special types of coating.

Different types of ceilings: features of the work

Depending on the type of ceiling in the bathhouse, the list and nature of the work required to organize insulation is determined. Types of ceilings:

- Panel.

- Hemmed.

- Grazing.

Each type has its own nuances. If you decide to independently implement how to insulate the ceiling in a bathhouse with your own hands, then even a step-by-step guide will not help if you lack the skills and tools. Trusting professionals is the best solution. In this case, it is quite enough to have general information about the procedure for performing work and materials.

How to waterproof a bathhouse

We will not divide the waterproofing inside and outside the bathhouse. It is more effective to consider the waterproofing features of each of the structural elements:

- foundation;

- floor coverings;

- walls;

- ceiling coverings;

- roofs.

We waterproof the foundation with our own hands

The most typical option for constructing a bathhouse foundation would be a shallow strip foundation . Of course, this does not mean that baths are not built on others. But if others are made of concrete, then the same materials and methods are applicable to them (see the section on types of foundations). If the foundation is made on brick pillars, then they are also waterproofed like concrete.

The exception is metal pile foundations. We assume that the piles are supplied already waterproofed and factory painted.

As for concrete, the variety of methods can be divided into two categories:

- you need to invite specialists with equipment;

- You can waterproof the foundation yourself.

Now we are talking about the second case. However, you should not think that everything will come down to bitumen and roofing felt. They, of course, are still used quite often, but they are not the only options for independent foundation waterproofing.

So, you can use classic roofing felt and bitumen mastic. You can take mastic with polymers (it is liquid without heating), and roofing felt is not on cardboard, but on fiberglass. You can use cement-based mastics (with or without polymers). You can apply penetrating insulation - compounds that close the pores of concrete from the inside.

Or you can even add modifiers directly to the concrete solution, which will significantly improve the grade of concrete and its strength characteristics.

What to look for when choosing waterproofing? There are types that are destroyed by the slightest displacement of parts of the foundation and are not intended to protect seams - this is, for example, purely cement (without polymers) waterproofing. Polymer can also be used on seams. About the types of materials for waterproofing here.

Another important point is what column of water a particular waterproofing can hold “for pressure” and “for lifting”. This is to be clarified with the seller or manufacturer. For example, cement insulation does not hold up at all.

ATTENTION! Groundwater puts pressure on the foundation from the outside. Therefore, they press the outer layer of insulation against the base, and if they managed to penetrate through it, then they try to tear off the inner layer of insulation. Hence “to press” and “to break away”.

It is also important to know how long this or that waterproofing coating is designed for - for pure bitumen they say up to 7 years, because it cracks from frost. Others - see manufacturer's warranty.

Bathhouse from the inside: floors

When the foundation is covered on all (!) sides with a layer of waterproofing, you can begin to build walls, and at the same time make a ceiling that will serve as the floor.

Spill floor (more details here)

There are two types of floors in the bathhouse: pourable and non-spillable. The first type involves you walking on a floor with wide cracks through which water spills down. There is either drainage at the bottom, but there is no drainage, that is, the water simply goes under the bathhouse, which is acceptable for summer bathhouses, or there is a drainage system and a concrete screed on the ground.

Dry floor (more details about the scheme here)

The second type means that there is no wooden floor with wide gaps, but there is either a solid wooden floor, or uncoated concrete floor

You can read in detail about how to properly waterproof a bathhouse with your own hands for all the types of floors described above in the article: Waterproofing the floor in a bathhouse.

On stilts

Despite the fact that we said above that most often the piles are supplied with a factory waterproofing anti-corrosion coating, the work on waterproofing such a bathhouse is not limited to this level.

In short, you need to lay the logs along the grillage, cover them from below with a mesh (this is cost-effective against all kinds of rodents), then put a layer of wind protection or a vapor-permeable membrane (this is effective if the insulation is mineral wool), on it - a layer of insulation (mineral wool), then a layer of vapor-impermeable film (vapor barrier), and then lay the floor you want.

Insulation of the floor and related work on its waterproofing (including waterproofing a bathhouse on stilts) is well discussed in this article.

Walls inside

Before you start building a wall, you need to make sure that the wall material does not come into contact with the foundation . In most cases, this is done by laying a layer of the same roofing material or other waterproofing between the wall and the base.

IMPORTANT! Do not neglect this stage, because it will not allow the wall material to draw moisture from the foundation (this applies to concrete varieties of the latter).

Further waterproofing measures depend on two things:

- what material are you going to build the walls of the bathhouse from?

- Will there be internal insulation?

Baths built from foam blocks, gas blocks, and, in general, from cellular concrete, urgently require To do this, they are covered with plaster.

ATTENTION! Applying plaster to walls made of cellular concrete should be done in accordance with the technology, that is, apply it inside first and wait the required time for the blocks to dry before applying it outside, while the plaster must be vapor-permeable.

Wooden and brick walls do not need waterproofing, but they could use hydrophobization (in other words, impregnation).

Frame walls can be sheathed with various materials, so the need for waterproofing will be determined by the sheathing material.

As for the insulation, mineral wool is, of course, most often used inside the bathhouse. But it has such a disadvantage as deterioration of thermal insulation properties when wet. Therefore, efforts must be made to protect it from water .

Frame wall pie. Read more about insulating frame walls here.

To do this, the layer of insulation, which is closer to the wall, is covered with waterproofing of vapor barrier is made (a film or foil that does not allow anything through itself at all) skips).

For more complete information, we recommend that you read this article.

Ceiling

An interesting point: the suspended ceiling is made identically to how the floor was made on joists. That is, logs, which are the foundation, are stretched from wall to wall and secured. A rough ceiling board is sewn underneath them. A layer of vapor barrier - some kind of film - is placed on top of the formed niches.

ADVICE! Above the steam room, do not use flammable materials or those that smell when heated, as well as those that are deformed from high temperature.

Next, the insulation is laid and covered with a layer of waterproofing on top. The structure is covered with a rough and finishing floor on top. Either the lining is immediately hemmed from below, or foil is stuffed and the lining is placed on it.

Waterproofing for a bathhouse on the ceiling thus depends on the insulation used. The above is true for mineral wool.

In addition to false ceilings, there are floor ceilings. They are distinguished by their simplicity and ease of design. In essence, these are just boards on which lies a layer of lightweight insulation. (Light so that the boards can withstand.) The length of the boards should not be more than 2.5 meters.

More details about this type of ceiling here.

Vapor barrier and waterproofing of the ceiling

So, it all depends on the chosen insulation. Unfortunately, the choice for a bath is not too wide. Instead of mineral wool, you can use expanded clay or vermiculite. Expanded clay, of course, partially absorbs water (like a brick), but its thermal insulation properties depend on the voids in the ceramics; water does not change them. Water is also not a hindrance for vermiculite.

Bulk insulation requires a substrate and nothing more. As already mentioned, vapor barrier and waterproofing of the bathhouse ceiling are measures taken to protect mineral wool.

The ceiling is actively involved in both heat exchange and humidity transfer - warm and vapor-saturated air is located near the ceiling, seeps through it into the attic and from there to the street. The attic can be cold and warm (for example, residential). But in any case, the task is to make the ceiling so that it conducts as little heat as possible.

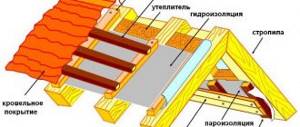

Vapor barrier, waterproofing of bathhouse ceiling. Explanation of the diagram here.

As for water vapor, for better preservation of mineral wool, the penetration of moisture should be prevented as much as possible - seal the joints of the vapor barrier, for example. But they will not be effectively removed through the ceiling only if your ventilation works well .

Regarding the vapor barrier and waterproofing material: polyethylene/polypropylene film is good as a vapor barrier everywhere except in the steam room. In the steam room, you can use foil for this purpose. Pay attention to the temperature regime of the vapor barrier.

In essence, all vapor barriers are polymer films that differ in thickness, level of vapor permeability, tensile strength and the presence/absence of an anti-condensation layer.

Vapor barriers can be of the membrane type, which means that water vapor is prevented from entering, but it can escape from the insulation. These are advanced technologies, because previously vapor barrier differed from waterproofing in that it did not let anything through at all.

Waterproofing on the other side of the insulation is also a film, but capable of releasing water vapor to the outside. This is achieved either with the help of many small holes, or at the level of the membrane structure of the material. Hole films are bad because they become clogged with dust over time. The membrane is not afraid of dust, but is more expensive.

Roof

Waterproofing the roof of a bathhouse is the protection of the under-roof space from the penetration of raindrops and melting snow. Therefore, the film directly under the roofing material is mandatory.

Explanation of the diagram here

Video

You can watch the explanation of the diagrams in the video.

As for the roof... It is believed that even the roof of the garage should be insulated in order to reduce temperature differences between the roof and the attic. But if you have a cold attic, but at the same time a perfectly insulated ceiling, you can not insulate the roof and do without a second layer of waterproofing.

If the decision is made to insulate, then the pie is the same as usual - the vapor barrier looks inward looks , and there is a layer of mineral wool between them.

ADVICE! On the roof, the use of antiseptics to increase the safety of wooden structural elements is very desirable. In general, use them wherever there is wood and there is no direct human contact with this wood - beams, joists, sheathing, etc. This applies to strong antiseptics.

The structure of the roofing pie partly depends on the structure of the roof itself and its slope. To understand this issue, read this article. It contains a lot of practical recommendations.

Briefly about the main thing

The choice of the type of insulation organization and the materials used should be based on the following main points:

- the established budget;

- bath area;

- structural features of the structure;

- planned frequency of use of the bathhouse.

By adhering to all the above recommendations, you can organize a functional and high-quality ceiling, which will reduce the cost of fuel for heating the room. And it will last for many years.

Ratings 0