With ISOVER you decide what to insulate with: stone wool or quartz-based mineral wool.

Are you used to independently deciding and controlling all issues related to the construction and arrangement of your home? Great! Here you decide how to insulate your home. Whether you prefer basalt wool or quartz-based mineral wool is your choice. ISOVER's priority is to produce high-quality thermal insulation and a wide product line so that everyone can find the optimal solution for insulating any type of structure. And if you are faced with the issue of insulation for the first time, ISOVER experts will help you understand the types and features of mineral wool and choose the optimal solution for any type of structure. After all, only ISOVER produces in Russia both quartz-based mineral wool and basalt wool. What are the similarities and differences, which is right for you? Read and decide. To insulate their home, apartment or cottage, many choose thermal insulation, focusing primarily on price. When choosing the cheapest insulation, the purchase often brings a number of inconveniences during the installation process and additional costs: at least for fasteners, because the material does not hold in the structure on its own, and at most it will take a year for a new repair. After all, low-quality insulation slips or crumbles over time, which leads to heat loss, increased heating bills and high costs for new repairs. All this can be prevented by making the right choice of material for insulating your home and understanding the installation technology. Let's consider the most popular insulation today - mineral wool or, as it is abbreviated, mineral wool. According to GOST 31309-2005 and the National Standard REN ISSH 9229, the term “mineral wool” is used as a unifying concept for insulating products produced on the basis of different types of fibers. For example, mineral wool based on stone fiber, fiberglass or quartz fibers. Different types of mineral wool have their own production characteristics that affect the quality and properties of the insulation. Let's take a closer look at the good old classics - stone wool, and the new, ambitious and very promising quartz-based mineral wool for the Russian market. These two areas were united by the world leader in insulation and noise protection - ISOVER. With 80 years of experience in this field, ISOVER became the first Russian manufacturer of mineral wool based on both basalt and quartz. Knowing everything from the stage of product development, extraction of raw materials, to production, installation and disposal, ISOVER experts are ready to provide objective information about different types of mineral wool. Therefore, if you have to insulate a house, cottage, apartment, bathhouse or any other building, a comparison of mineral wool based on basalt and quartz will be relevant and useful.

Criterias of choice

The choice of mineral wool for insulation should be carried out according to the following criteria:

- thermal conductivity. It is individual for different types of mineral wool. When choosing, you need to focus on the lowest value of the indicator, but remember that it is not advisable to buy thermal insulation material with a heat transfer coefficient of more than 0.050 W/(m K). In this case, it is better to opt for insulation made of polystyrene foam or expanded polystyrene;

- specific density. This parameter is important for several reasons. Firstly, it determines the thermal insulation properties of the material, secondly, the rigidity of the insulating layer depends on the indicator (whether it will settle or not), thirdly, the density forms the weight load on the insulated structures - the higher it is, the more weight the roof, ceiling and walls. For example, mineral wool for insulating walls under decorative plaster should have a specific density of at least 150 kg/m3, for siding - 100-125 kg/m3, indoor partitions - 75-90 kg/m3 (here mineral wool serves rather as a protection against air noise than insulation);

- thickness. The indicator affects heat and sound insulation properties, strength and protection from high temperatures, including open fire. Experts believe that the thickness of mineral wool for insulating walls inside a building should be in the range of 5.0-15.0 cm, external - 5.0-20.0 cm, floor - 2.0-5.0 cm, pitched roof and attic ceilings - 5.0-20.0 cm, flat roofs - 3.0-17.0 cm;

- hygroscopicity - important to consider when determining places for insulation. For example, glass wool for foundations, external insulation and balconies is not recommended due to increased environmental humidity or the likelihood of condensation;

- vapor permeability and fire resistance - you can ignore the indicators, since all types of mineral wool allow the walls to “breathe” and do not burn;

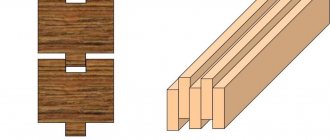

- shape of the insulation - when choosing between rolls and slabs, it is necessary to take into account the geometry of the insulated surface so that the number of connecting seams is minimal;

- the arrangement of the fibers should be chaotic (there is mineral wool on sale with a vertical fiber direction for floor insulation);

- tensile strength and flexibility - data will be required only if pipes are insulated or combustible structures are protected from a hot chimney.

Attention: the considered indicators for domestically produced products can be found on the packaging. There they are tabulated and have the appearance shown in the photo.

Imported products are generally marked with a code that looks like this: MW-EN13162-T5-CS (10) 40-TR15-WS-DS (TH)-MU1, where:

- MW - shows the type of insulation, namely mineral wool, but without specifying the origin of the fibers (it is impossible to see whether it is glass wool or basalt wool);

- EN13162 - standard;

- T5 - the amount of deviation of the finished product from the declared thickness. Less is better;

- CS (10) 40 - compressive strength. In the example given, at a pressure of 40 kPa, the insulation will reduce the thickness by 10%;

- TR15 - tensile strength under mechanical load perpendicular to the plane of the mat or roll. Indicated in kPa;

- WS - shows the amount of water absorbed during a short-term immersion, expressed in kg/m2. The indicator should not exceed 1 kg/m2;

- DS (TH) - shows by what amount the linear dimensions of the insulation will change when heated to 70oC compared to a temperature of 23oC (when purchasing mineral wool, the indicator can be completely ignored);

- MU1 - vapor permeability. Presence is indicated by the number “1”, absence – “0”.

Composition and method of production of ISOVER mineral wool based on quartz and basalt

In both cases, natural ingredients . The basis of basalt-based mineral wool is a rock melt, and the main component in the production of quartz-based mineral wool is quartz (70% of quartz-based insulation consists of the same component). These types of mineral wool differ in both the composition and properties of the fibers, which are formed as a result of the melting of raw materials at extremely high temperatures. In basalt wool they are shorter, while in quartz-based mineral wool they are long, light and elastic.

An interesting fact: more than 50 years ago, ISOVER developed the TEL technology for the production of mineral insulation using quartz melt, which is now successfully used all over the world. In 1957, in France, experts, which by that time had been producing and supplying ISOVER thermal and sound insulation for 20 years, invented an innovative technology for creating long, strong and elastic mineral wool fibers. They look like cotton candy and are created in a similar way. It is the cotton candy production process that underlies the creation of quartz-based mineral wool. The inventor of the new technology, Frederick Rosengart, saw a machine for making this delicacy at a fair and made a prototype for quartz. During the experiments, a lot was turned upside down, including the device itself (in the production of mineral wool fibers, they are now blown from top to bottom) and even the name of the technology (renamed from LET to TEL). This innovative approach allowed mineral wool to retain maximum heat in the house, and the word ISOVER to become a household word for defining high-quality thermal insulation in many countries around the world.

But no matter what raw materials and what technology are used to produce mineral wool insulation, they are all aimed at creating warmth in the house. However, there are a number of key characteristics of mineral wool that are important to pay special attention to.

Stone wool production, factory process technology

The English phrase for basalt insulation, when literally translated into Russian, sounds like “mountain wool”. Imagining the appearance of the insulation, and knowing that the raw materials for production are gabbro-basalt rocks, we can agree with this definition.

For the first time, erupted and frozen fibers of volcanic lava, as if whipped and similar to tufts of wool, were found 15 centuries ago. They can be considered the prototype of modern stone (basalt) wool, which was put into production back in 1897 on the American continent. For the average consumer, insulation became available later. In our country, its popularity and stable sales growth have occurred over the past three decades. It's time to find out what the technological process for obtaining “mountain wool” is.

Production: from crushed stone to thermal insulation. Visual diagram of the factory process

Multi-stage technology consists of artificially replicating the complex natural conditions of erupting lava at a plant producing insulation. 1500°C is the temperature of the furnace, into which crushed volcanic stone of the basalt group falls and is brought to a liquid lava-like state.

Basalt is a stone that retains heat

The molten mass flows from the feeder holes into the nozzles of special blowing devices. Compressed air (9 atm.) breaks the jet into small drops, which are given enormous acceleration. Scattering at the exit of the nozzle, the melt particles elongate and, after instant cooling, turn into small thin fibers. This stage of insulation production is well demonstrated in the initial segment of the presented video material:

When depositing the resulting piece fibers, the necessary binder composition is sprayed into the chamber volume to combine all the fibers into a solid “carpet”.

Next, the base of the future insulation is treated with liquid compounds that help increase its vapor permeability, water-repellent characteristics and density. At the next stage, the “carpet” enters the heat treatment chamber, where polycondensation occurs at 200°C. Now the canvas can be cut and sent for packaging.

Cutting fabric into standard slabs

Mineral wool. Characteristics and properties.

- Thermal conductivity , i.e. how warm the material is.

The lower its value, the less you will need to pay for heating . In the ISOVER product line made from quartz-based mineral wool, the warmest material is ISOVER Warm Walls Strong, and the warmest material based on basalt wool is ISOVER Warm Wall Master.

- Durability

According to the conclusion of the NIISF RAASN: “With a correctly designed and executed design, ISOVER products can be used for at least 50 years while maintaining the main operational characteristics in the climatic conditions of the Russian Federation.” Read about the research>>

- Non-flammability

Both stone and quartz do not burn, therefore all mineral wool without additional coatings belongs to the group of non-combustible materials. Watch a video about how ISOVER materials passed the strength test:

- Insulation quality

ISOVER mineral wool made from quartz, as well as from basalt, is always at a high level. At ISOVER factories, both raw materials and finished products undergo multi-stage quality control. In addition, ISOVER constantly undergoes mandatory and voluntary product testing, and is also the first and, to date, the only manufacturer of heat and sound insulation materials on the Russian market that has confirmed the compliance of its products with GOST. This is evidenced by certificates that are publicly available on the website. View certificates>>

- Areas of use

The areas of application for stone wool slabs and quartz-based thermal insulation are the same. They are suitable for specialized insulation and sound insulation of walls, roofs, attics, floors, ceilings with a separate product, for example, ISOVER Warm Walls Strong, ISOVER Warm Roof Strong, and for comprehensive insulation of the entire house with one solution - ISOVER Profi, ISOVER Shumka, etc. d. Note that only at one plant in Russia, the ISOVER plant in Yegoryevsk near Moscow, there is a crimping technology that allows the production of rigid mineral wool from quartz with high mechanical strength for use in professional construction in the structures of plaster and ventilated facades, flat roofs and three-layer reinforced concrete panels for multi-storey construction.

- Health safety

The environmental friendliness of the materials is evidenced by the natural raw materials used for the production of thermal insulation based on quartz and basalt. In addition, ISOVER received the highest rating for environmental friendliness of products and production - EcoMaterial Absolut Plus and now its thermal and sound insulation is recognized as an environmentally friendly high-tech material. The ISOVER plant uses a completely closed water consumption cycle, thanks to which there is absolutely no discharge of process water into water bodies. Of no small importance is the absence of storm and drainage drainage: all water from roads, roofs and the neighboring Saint-Gobain plant is collected, undergoes a purification process and is sent back to the plant. This in turn helps the company reduce water consumption from city systems. Therefore, the plants have minimal impact on the environment. Another confirmation of the safety of mineral wool is open data on the impact of insulation on the environment. This information can be found in the environmental product declaration on the website.

- A distinctive feature of quartz-based mineral wool is its light weight , which facilitates the installation process, as well as the elasticity of the material, due to which the slabs and rolls are compressed several times. This in turn provides significant savings when transporting thermal insulation. It is even possible to transport the required volume to insulate a small room in a passenger car.

- Form stability

However

That is why ISOVER paid special attention to the FORMAL STABILITY of the produced mineral wool. Thanks to special development, all ISOVER thermal insulation and sound insulation materials meet the three NOTs: DO NOT break, DO NOT slip, DO NOT crumble, for at least 50 years. The guarantee of dimensional stability allows you to simply install mineral wool insulation into the frame with a small allowance without the use of any fasteners. Many foremen, when testing quartz-based ISOVER mineral wool, were happy to note that to insulate a wall or pitched roof, you do not need to spend time, effort and money on fasteners in the form of ropes and nails, construction fungi or additional beams.

Well-known manufacturing companies

Among the suppliers of mineral wool of this type, several large companies stand out. Their competition, the desire to constantly improve quality and not inflate the cost of goods, only benefits the potential consumer.

Mineral wool TechnoNIKOL

An example of the quality of a domestic product that has entered the international market. The brand's network of representative offices includes more than three dozen countries. Options for manufactured products belong to several lines: private and professional construction, fire protection options, technical insulation.

The most popular domestic brand of insulation

Basalt wool Knauf

The production of stone insulation is only one of the lines of materials, finishing and complex systems produced by the company. But the quality of the produced insulation does not suffer from this, and the offered range helps to solve any problem.

Rockwool products

The Danish brand is famous for the quality of its product brands. Of the company’s 28 factories, 4 production complexes in the Russian Federation operate for Russian consumers. Rockwool's assortment includes several series of products for various purposes: insulation for roofs, facades, apartments and buildings, fire protection, noise reduction, insulation of engineering systems, oil and gas complex structures.

Other manufacturers of insulating materials made from basalt fibers - Ecover and ISOROC - are not lagging behind in the struggle for buyers. The first young enterprise is located at the source of raw materials (in the Urals) and is rapidly progressing. And the Tambov plant of the ISOROC company, after large-scale modernization, guarantees product compliance with industry and world standards.

Proven technology and the latest generation industrial equipment make it possible to produce highly efficient mineral heat insulators that reliably insulate any surfaces and laid communications. Stone wool made from basalt rocks helps to obtain a higher level of protection. If you need to provide a class of thermal insulation protection that meets the most stringent standards, you need to pay attention to this material.

ISOVER Warm Roof Strong

To insulate walls, choose a specialized product ISOVER Warm Walls Strong with Formostability technology, which guarantees stability in the structureFor the roof, use the material ISOVER Warm Roof Strong with technology AquaProtect, which provides the material increased moisture resistance Mineral wool creates maximum warmth and comfort in a house or apartment. The material is made from natural components: quartz, soda, limestone. Recommended for use even in medical and children's institutions, because mineral wool is a safe material for human health and the environment.- Maintains a comfortable temperature in the house thanks to the low thermal conductivity coefficient

- Does not require additional fasteners during installation due to high elasticity

- Has enhanced moisture resistance

- Easy to use - already cut into slabs for standard frame spacing

- Safe for human health and the environment

- Belongs to the group of non-combustible materials (NG)

- Features enhanced moisture resistance thanks to AquaProtect technology

- Reliably fixed in the frame without creases or slipping due to the high elasticity of the material

- There is a minimum of waste when insulating a roof with different rafter pitches

- It is convenient to cut the roll into the required sizes thanks to special markings on the packaging

- Safe for human health and the environment

- Belongs to the group of non-combustible materials

- Pitched roofs and attics

- Insulation of walls from the inside

- Insulation of walls from the outside: insulation under siding/cladding/cladding bricks

- Frame walls

- Insulation of balconies and loggias

- Pitched roofs and attics

- Insulation of walls from the inside

- Insulation of walls from the outside: insulation under siding/cladding/cladding bricks

| Parameter | ISOVER Warm Walls 50 mm. | ISOVER Warm Walls 100 mm. | ISOVER Warm Roof 50 mm | ISOVER Warm Roof 100 mm | ISOVER Warm Roof 150 mm |

| Mineral wool thickness, mm | 50 | 100 | 50 | 100 | 150 |

| Mineral wool width, mm | 610 | 610 | 1220 | 1220 | 1220 |

| Mineral wool length, mm | 1000 | 1000 | 4100 | 4100 | 4100 |

| Quantity per package, m2 | 6,1 | 3,05 | 10 | 5 | 4,88 |

| Quantity per package, m3 | 0,305 | 0,305 | 0,5 | 0,5 | 0,735 |

| Quantity per package, pcs. | 10 | 5 | 2 | 1 | 1 |

| Thermal conductivity at temperature (10±2)0С, λ10, no more (W/(m•K), GOST R 31924 | 0,034 | 0,034 | 0,034 | 0,034 | 0,034 |

| Flammability group, GOST 30244-94 | NG | NG | NG | NG | NG |

Basic rules of work

Mineral wool is mainly used to insulate exterior walls, attics and roofs. To insulate the foundation, it is better to use inexpensive, but at the same time high-quality polystyrene foam. It is more rigid and does not allow water to pass through.

If the correct installation technology is not followed, this will significantly affect the result. The material will quickly become unusable, and its high price will hit the budget hard in case of repeated repairs.

Before use, it is necessary to treat the facade with an antiseptic. This will prevent rotting and extend the life of the material. Foam concrete or brick must be cleaned of old paint and plaster before installation. The best time to carry out work is summer.

Before installation, it is necessary to remove window casings and door jambs. After installation, you will have to purchase new window and door cladding, as the thickness of the walls will increase noticeably.

There are two main methods of insulation:

- Dry. It is used only with frames made of wood or steel (lathing). The insulation is installed in the cells of the frame.

- Wet. In this case, installation is carried out using glue and disc dowels.

Glue and dowels are used more often in cases where it is planned to apply a finishing layer. The surface of the insulation can be puttied or plastered.

Dry installation

A frame is used for installation. The slats are installed so that the gap between them is 2 cm less than the width of the wool. This allows you to achieve maximum packing density. All work starts from the corners and smoothly moves to the center. In order for the result to be of the highest quality and the installation to be even, it is necessary to use a level and a cord that is stretched between the corners of the wall.

If a roll is used during installation, then installation is done from top to bottom. The slabs are installed only from bottom to top. The canvas must be secured with construction tape. To fix the result, holes are drilled and dowels driven into them.

The final stage is the installation of counter rails. This allows you to create a ventilated gap. The installation principle is to prevent the mineral wool joints from matching the corners of window and door openings.

If it is necessary to make the insulating layer thicker, the slabs are laid in several layers. It all depends on the need and preferences of the owner.

Wet method

The principle of this installation is to install the insulation on an adhesive solution that attaches the mineral wool to the wall. It is important that the glue allows steam to pass through well, otherwise condensation may accumulate in the material.

A layer of adhesive solution is spread on the wall using a notched trowel. After this, the slab must be pressed as much as possible against the wall. Once the row is installed, it must be additionally secured with disc dowels.

The final stage: glue is again applied to the insulation layer and the reinforcing mesh is fixed. This further strengthens the mineral wool slabs. After this, you can plaster and perform decorative work.

Reviews on the use of ISOVER materials in the construction of houses:

_____________________________________________________________________________________________________

Vitaly Tikhonov, foreman: “My brother and I decided to make a children’s room in our parents’ house on the attic floor. It was a bare frame of the rafter system, where the wind flowed freely. We chose a material based on mineral wool, since it is safe for humans, and this is very important for us, since this is a children's room where our children will be. Working with ISOVER materials is very simple and convenient. It is good to fill the space between the rafters, since due to the elasticity of the insulation, it fits tightly to the structure. After completing the work, we were satisfied with the result: it became more comfortable to be in the room in hot weather, sound insulation increased, and, importantly, the materials we used are non-flammable.”

READ OTHER REVIEWS

__________________________________________________________________________________________________

We hope that we have helped you understand the advantages, similarities and differences between quartz- and stone wool-based mineral wool, understand the main characteristics and properties of mineral wool, and now you can make an objective choice to ensure that your home is always warm and comfortable. Live long in a warm house!

Did you like the article? Share it on social networks.

Performance characteristics

Since mineral wool is able to cope with increased loads, it is used in the construction of standard structures, as well as when installing insulation followed by the production of a heavy concrete screed (in this case, it is recommended to choose durable slabs 5-20 cm high).

Healthy! The service life of the insulation is 20-30 years.

If we talk about the density of the material, it depends on the shape of the mineral wool:

- the minimum density for light slabs and loose wool is 30-40 kg/m3;

- a little more for soft slabs - 50-75 kg/m3;

- for mats this figure is 50-85 kg/m3;

- semi-rigid slabs – 75-125 kg/m3;

- the highest density of cylinders is 200 kg/m3.

The material is not flammable, but the maximum temperature also depends on the shape of the product. For mats it is +700 degrees, for cylinders, light, soft and semi-rigid slabs this figure is +400 degrees. For rigid slabs +100, and for loose wool the limit reaches +600.

Mineral wool has high density and thermal insulation characteristics. They may differ depending on the specific type of material.

Mineral wool brands

The characteristics of the insulation can be determined by the markings:

- P-75. This is a flexible material with a density of 75 kg/m3. Mineral wool P-75 is usually used for horizontal surfaces that are not planned to be loaded, as well as for structures and communications with a very slight slope. This type of material is suitable for roofing, ceilings, attics, heating and ventilation pipes.

- P-125. The density of this composition is 125 kg/m3. Mineral wool of this type differs from the previous one in that it has improved sound insulation. Also P-125 is more flexible mineral wool. It is considered the best solution if the house is built from gas or foam blocks. P-125 is used for insulating facades, balconies, and interior partitions.

- PZh-175. This mineral wool has the highest rigidity. Thanks to this, it is excellent for loaded as well as vertical structures. The density of PZh-175 is 175 kg/m3. Mineral wool meets the minimum fire safety requirements and provides excellent noise protection. Typically, the material is laid on surfaces made of wood, concrete or steel.

- PPZh-200. This material has the highest density - 200 kg/m3. In addition, PPZh-200 is a non-flammable composition, so it can be used in the construction of retail departments, warehouses and other facilities. However, installation is only possible on flat surfaces, which will only be subject to static loads. This material is not flexible, as it contains an internal reinforcing layer.

Also, when choosing the best material, you should pay attention to its rigidity.

Selection of mineral wool

If you go by the rigidity of the composition, then you should pay attention to the following nuances:

- Soft insulation is best suited for insulating pipes, chimneys, and roofing “pies”.

- Semi-rigid mineral wool is more often used for insulating facades. Also, mineral wool of this type is often placed between sandwich panels.

- Rigid compounds are optimal for flat surfaces made of metal or wood.

The thermal conductivity indicator is selected in accordance with temperature indicators in winter. It is also worth considering the thermal conductivity of the building walls themselves. As a rule, mineral wool is purchased with a small margin of “temperature stability” in order to be prepared for any weather conditions. But you shouldn’t be too zealous either, since in this case the material will cost more.

Also, do not skimp on the manufacturer. It is better to give preference to Ursa, Rockwool, Paroc, and Isover. Germany has the most stringent requirements for insulation materials, which is why their quality is much higher.