The cost of building a bathhouse from wood concrete is the same as assembling a structure from wooden beams or logs. However, the use of such a specific material in wall masonry provides enormous opportunities in finishing and planning both inside and outside. And building a bathhouse from wood concrete with your own hands is possible even for someone who has never held a trowel before.

The internal lining can be a standard “bathhouse” - blockhouse and eurolining. An interesting effect is achieved by using a coating that is rare for such premises, such as ceramic tiles.

External walls allow you to apply any finishing and decorate the bathhouse in accordance with the architectural style of the main house. Or cover them with the usual blockhouse under a rounded beam or log.

Wood concrete is an excellent material for the construction of buildings that require good thermal insulation.

It is lightweight concrete with the main binding component - Portland cement. It accounts for 10–20% of the total volume. The rest is filler. Its role is played by crushed wood, sawdust, shavings, flax and hemp fire and other organic waste. All of them are porous and perfectly retain air, and therefore heat. In terms of heat-saving properties, wood concrete surpasses even expanded clay concrete.

Other advantages include:

- frost resistance;

- fire safety;

- good sound insulation;

- rot resistance.

Why is sawdust not used for insulation in its pure form?

Clean, only obtained sawdust cannot be used for insulation of premises for the following reasons:

- walls made of sawdust are a wonderful place for arranging homes for rodents, as well as the appearance of various kinds of microorganisms;

- After some time, the wood material cakes, voids appear in its mass - it begins to rot and more of its thermal insulation properties are lost.

Of course, sawdust is a good solution for insulation - they have a low heat transfer value. However, they must be used wisely, correctly, and only in combination with other binders. This will avoid the negative consequences discussed earlier, and then such insulation will compete with industrial products.

Designing a future bath

A frame bathhouse project can involve the construction of either a small building consisting of a steam room and a dressing room, or a two-story building on a suburban site.

The choice depends on the wishes and financial capabilities of the owner. You can also make a panel bathhouse with your own hands, but without certain skills it will be difficult. When building a modest-sized frame bathhouse with your own hands, a simple strip or column foundation will be sufficient. You will need to purchase dry timber with a cross-section of at least 20x20 millimeters and an edged board. If the future bathhouse must have at least three rooms, then a more serious foundation will be required.

To save materials, you can install an attached veranda under the dressing room, and then inside the small bath building there will be enough space for a washing room and steam room.

The most popular types of binders

Astringent connectors for wood shavings can be substances that are well known to many, such as: Portland cement, clay, gypsum mixtures, PVF glue, as well as cow manure.

Binders in construction

- Clay is the most inexpensive material, and if you have access to nature, it is completely free. It is a completely natural substance, therefore environmentally friendly - during the drying process no chemical reactions are present, only moisture evaporates. Clay is light in weight, quite strong, but fragile and durable. The only drawback is the fact that unfired clay is not resistant to excess moisture - it begins to limp.

If we compare the clay composition with sawdust with others: gypsum, cement, then it is practically not inferior to them.

- Portland cement is the most common binder that is widely used in professional construction. The only negative is the long time it takes to harden (stand up).

Cement using wood chips is excellent for thermal plaster of walls, both internal and external. The risen cement perfectly resists high humidity. Backfill walls are a profitable and reliable way to conserve heat in your home.

- Gypsum is an ideal means for “high-speed” construction for interior wall decoration. This composition sets up almost instantly, and gains strength similar to cement. The hardened mixture is durable and environmentally friendly.

- Polyvinyl acetate is a hardened PVA glue, insoluble in water, very durable, even cruel.

For this reason, PVA is used in places with high humidity, as well as in places with direct contact with water. Cured glue has one remarkable property - it allows water vapor to pass through, so the treated walls will not only be insulated, but will also “breathe”. It should be noted that when the insulation is heated strongly, moisture will come out of the sawdust and it will dry out, but the deformation of the PVA is sufficient to retain the settled wood particles without loss of shape and overall strength.

- For lack of anything better, cow dung will do. It was widely used until the 19th century. The house was insulated using this natural glue. Today, few people use it to insulate their homes, but it is quite suitable for a barnyard. Its strength is certainly lower than that of all the above-mentioned means, but placed in the inter-wall space of an outbuilding it will work for many years.

How to build a budget sauna in the country

Not everyone has the desire or ability to invest a lot of money in the construction of a bathhouse. And in most parts of our country, sometimes it’s simply necessary to warm up. The only way out is to build a sauna inexpensively, with your own hands. There are a sufficient number of building materials and technologies that can be called budget.

If we talk about the construction of full-fledged, albeit small, but free-standing baths, then frame and monolithic are considered the most budget-friendly technologies. Cheap baths are often made on a wooden frame, lined with plywood, OSB, boards - whoever has what. Insulation is placed inside between the two skins.

One of the options for a frame structure is with board cladding

In monolithic construction, the most popular for the construction of baths is arbolite - a mixture of cement and sawdust. Sawdust can be completely free or cost very little. Little cement is required in wood concrete, so this type of construction is unlikely to hit your pocket hard. Removable formwork is placed around the perimeter of the building, the mixture is loaded into it, and compacted.

Sawdust concrete or wood concrete is a warm, natural material that consists of sawdust, sand, cement and water

Polystyrene concrete (granulated foam plastic mixed with cement and water) is not much more expensive, but not everyone likes the use of “chemistry” - foam plastic - in the construction of a bathhouse. However, this material itself makes it possible to obtain a cheap and lightweight building, which, if properly finished, will only delight the owners.

All three technologies provide a combination of low price and good thermal characteristics, that is, heating such buildings requires little fuel, which in baths is the main indicator of efficiency.

This is what polystyrene concrete looks like up close

There are regions where wood is still the cheapest material. It might be cheaper to put a chopped sauna in them. From round timber or from timber - this is optional. The advantage of this solution is that it is a natural material (although it must be impregnated with chemicals to preserve its appearance and protect against diseases and insects).

But chopped saunas have their drawbacks - you can start steaming no earlier than a year after the walls are built and the roof is installed. We must wait until the main shrinkage has passed and only then begin insulation and finishing work. The second disadvantage is that the protective coating must be regularly updated, otherwise the building will become gray and unsightly. But the wooden baths themselves are very good with their special atmosphere.

And you want to build a bathhouse but your finances don’t allow it – is this a familiar situation? Patience is worse than bondage. Russian people are very creative, so everyone who plans to install a bathhouse on their property tries to save money in every possible way. What comes out of this and how to really reduce the budget?

First, let us highlight the desire of all manufacturers to introduce a variety of cheaper bath options. Keeping abreast of the problem, the consumer is offered to purchase mobile structures. The set of such a bathhouse consists of a tent, a stove and a bag. There are lighter options. They do not have ovens, and the temperature is increased by a portable steam generator.

You can install such a structure on any site, and two adults can do it. Depending on the type of mobile sauna, from 3 to 7 people can steam in it. Again, it all depends on your budget. The temperature created inside is acceptable for carrying out procedures – 90°C.

Bathhouse-dugout

Moving away from the purchased option, we can recommend the optimal price-quality ratio in the form of a dugout bathhouse. Such structures are built, or more precisely, swarmed on their own. Hence the first point of saving. The work of hired craftsmen is assessed not in favor of the bathhouse owner.

The second point of savings can be considered an independent basis. That is, a foundation for a dugout bathhouse is not needed. The third point will be to reduce costs for wall materials. The disadvantage is the difficulty of preparing the pit.

Even one person can build such a bathhouse, but in this case the work will drag on for months. Bringing in equipment will speed up the process, but will affect the pricing policy. If time constraints do not bother you, then this option is the most profitable. Unlike a mobile structure, a dugout bathhouse will have a permanent registration, so its location must be decided in advance.

There are many options for constructing and purchasing inexpensive bathhouses. But still, without departing from tradition, we need to talk more specifically about options for reducing the costs of constructing capital structures. Everyone wants a full-fledged bathhouse on their site, to which they are not ashamed to invite friends on their day off.

There is only one way out of this situation - to build a bathhouse that meets all modern requirements and introduce all kinds of economic solutions, of which there are plenty on the construction market today.

Application of various auxiliary components

The principle of operation of insulation is the same - the wood base, containing small inclusions of air in its structure, is mixed with a binder mass, which, after drying and gaining strength, forms a monolith.

Each composition has its own properties: rising time, viscosity, elasticity, which can be transformed with the help of additional substances. Each composition has its own nuances and its own solutions for specific tasks.

- So, to insulate the floor, sawdust is used instead of mineral wool. To increase their service life and reduce the rotting process, they are knitted with PVA glue with the addition of an antiseptic solution.

- If you need to pour it into a mold, add a small amount of Rotbant or TG to the cement-bonded mixture to speed up the setting. So, if you add a glass of gypsum to a bucket of the mixture, the cement will set within 1-2 hours.

- The same method works with lime compounds.

Binders and their proportions

To prepare the sawdust mixture there is no need to experiment, all the recipes have long been known, the proportions have been selected.

Gypsum

To fill, do the following:

- sawdust is placed in the prepared container (no more than 1/5 of the container);

- in a ratio of 1:10 or 1:5, gypsum grade 1 and gypsum grade 2, respectively, are added to the base and mixed;

- add water at the rate of 1 liter per 1.4 kg of gypsum and mix;

- the mixture does not need to stand; it is immediately poured into the prepared form.

For plastering work, the preparation of the working solution differs only in the amount of water: 1 part water to 2 parts gypsum.

The solution must be prepared in small quantities, since it rises quickly, and the prepared solution cannot be diluted. However, you can use a retarder; casein (carpentry) glue is used as the latter.

As an analogue of the casein retarder, you can use hide glue with lime. Retarder recipe: soak 1 kg of glue for 24 hours, add 2 kg of lime and cook in a steam bath for 4-5 hours. The resulting retarder is added to the mixing water at a rate of 1 to 50. The setting time of the solution increases by 20-30 minutes.

Video about super insulation:

Cement

For beginner plasterers, the most preferable option is “mud” with Portland cement. The solution lasts indefinitely, up to 2-3 hours, so you can plaster it slowly. It can also be reanimated, the main thing is not to let it completely dry out or settle. As it thickens, add a small amount of water to the prepared mixture and mix. Sometimes the unused solution is left overnight, filling it with water, but it depends.

To improve (preserve) the thermal insulation properties of the wood base, various plasticizers are added to the cement, which increase the plasticity of the composition. As the latter, use liquid soap, shampoo or inexpensive dishwashing detergent. Adding a soap additive can also reduce the amount of water used. The amount of additive is measured by eye: a cap will be enough for a bucket; after a couple of batches, even a child will figure out the amount of additive.

Insulation using a solution with sawdust and cement, as well as soap solution, is not recommended, since after rising the mixture does not allow moisture to pass through, and you will end up with damp walls, ceiling and floor.

For indoor work, it is better to use industrial additives such as polyplast, fort or superplast - they are more effective than soap or milk.

Milk is used in the same quality as other plasticizers, but it should be remembered that when using it, cement will lose strength.

Plastering walls with a mortar containing sawdust

Lime

A very necessary and useful substance in the household. Lime is an alkali that is a natural antiseptic. However, it can not only wash clothes, but also disinfect shavings from various microorganisms and their larvae. In addition, the alkali will rid the base of the solution of rot and will protect it for a long time from the appearance of unnecessary organisms, including rodents (they are afraid of it like fire).

To use, you only need slaked lime (so as not to injure yourself). You need to mix lime with sawdust in the following proportion: 1 part lime to 10-15 parts sawdust.

Important! Wooden frame walls treated with lime mortar will be more durable. Neither bark beetles nor all kinds of aphids will grow in them.

After treating the sawdust with lime, you can add any other binder.

It is possible to use lime as an adhesive composition, but the performance will be unimportant, and besides, it is better not to use it inside a living room.

Lime will also work

Clay

Another folk forever young material. It has been used throughout human history. By mixing clay with straw you can build a mud hut. The properties of clay are unique, and, in addition, it is very affordable.

Clay as insulation for house walls

The following proportions are recommended for insulating a house:

- For the ceiling and floor - 1 part diluted clay and 10 parts wood waste;

- For insulating walls, for filling internal cavities, - 1 to 5;

- To plaster walls, you need a more viscous mixture - 1 to 2.

The readiness of the clay solution is determined by touch; it should be slightly greasy and elastic. If the pieces stick strongly to the trowel, then the solution must be combined with shavings.

Clay compositions are the most suitable for human life. They are environmentally friendly, durable, the main thing is to protect products made from unfired clay from direct exposure to water. Insulation with clay and sawdust is a common phenomenon.

The life of the prepared composition is endless; if the clay has dried, just add water, and it will be fine again.

You can buy clay at any hardware store, but you can also get it yourself. You should know that the best clay is located at a depth of at least 1.5 meters, since its upper layers may contain particles of plant roots, and this is not welcome.

To fill walls with clay, the composition should not be liquid or even creamy, otherwise drying will last indefinitely. Clay lumps with sawdust should be moist and slightly crumbly so that they stick together when compacted.

PVA glue for walls

To prepare thermal insulation material, you need universal or construction PVA; other brands of adhesive for thermal insulation are not suitable.

The wood raw materials for the mixture need to be dry and, if possible, fresh. There are no clear proportions; the solution is prepared by eye - approximately 1 to 5-10. The smaller the amount of glue used, the lower the heat transfer of the composition. But you shouldn’t be greedy either, because poorly processed shavings will rot and rot.

Advantages and disadvantages of sawdust

Sawdust, considered as a raw material for construction, has its advantages and disadvantages.

Insulating walls with sawdust: pros and cons:

- Price. This is the first thing for which this multifunctional raw material is valued. For many, the price is generally zero, whether there are any financial costs for delivery.

- An environmentally friendly material that, when used correctly, does not emit any harmful substances. Chemical contamination is completely excluded.

- Durable in use. This fact has been proven by human history - many generations of our ancestors used it and did not complain.

- Installation. In order to perform any kind of manipulation with these materials, qualifications are not needed; the work can be performed even by a person who is far from construction.

- Thermal conductivity. A very low score for this parameter. The wood structure itself has tiny air cavities, which is already a universal insulator, plus the fine-grained component of the sawdust itself.

House made from waste from shavings and clay

Disadvantages of wood waste:

- Flammable Increased fire safety measures must be observed.

- Prone to rotting.

It should be noted that the existing shortcomings can be solved in various ways, including those discussed in this article.

Construction from sawdust concrete

Application area

This building construction technology is used in the construction of outbuildings, garages and low-rise residential buildings. A mandatory requirement for walls made of sawdust concrete is subsequent finishing, which has not only decorative, but also protective properties. According to its density and strength characteristics, stone can be divided into two categories: thermal insulation and structural. To create load-bearing walls of a house, it is recommended to use grades of sawdust concrete M25 and higher; the use of less durable compounds is allowed in one-story residential and non-residential buildings.

Design

The construction of a house must be preceded by a design stage. During this period, all key technical decisions are made and material costs for construction are determined. The design of sawdust concrete buildings follows the same rules as for other structures based on lightweight concrete blocks. However, there is no current GOST for this material, and its exact strength must be determined based on laboratory tests.

Wall insulation technology

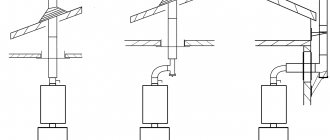

Regarding technologies, the following should be noted:

- backfill method. The mixture is poured onto a solid base or placed inside two surfaces where it is compacted;

- pouring. A relatively liquid solution is poured into a prepared mold, where, as it dries, it acquires the properties of a solid monolith;

- plastering. If the walls are plastered with sawdust mixture, they acquire thermal insulation properties.

Thermal insulation blocks