At all times, ceramic tiles have been considered the best roofing material, due to their high consumer characteristics, aesthetic beauty and unsurpassed durability.

However, today, natural tiles, as a roofing material, have lost most of the construction market ( the share of ceramics in the modern market does not exceed 15% ).

This trend is observed in connection with the constant development and improvement of modern materials for roofing. In modern construction conditions, ceramic coating has occupied its stable niche and is used in accordance with its advantages and disadvantages.

We bring to your attention alternative types of tiles:

- polymer-sand;

- flexible (soft);

- cement-sand;

- metal tiles;

- composite.

Construction of the lower roof.

• If the slope angle is less than 16 degrees or increased demands are placed on waterproofing due to the complexity of the roof or climatic conditions, then a lower roof must be installed under the tiles: a continuous deck of edged or tongue-and-groove boards and roll polymer-bitumen or polymer waterproofing.

• To make a waterproof bottom roof, fill a trapezoidal counter-lattice with a thickness of 40...50 mm over the decking, and only then fuse the waterproofing.

• When installing a lower roof, be sure to leave ventilation gaps at the ridge and ridge, similar to the film.

9. Laying the valley groove

• Bend the edges and profile the groove along the block. No special roofing tools are required for this operation.

• Start laying the gutter from the eaves (bottom to top). Place the groove on the flooring or thick sheathing and trim it along the contour of the inner square with a margin of 3...4 cm.

• The overhang aerial element or leveling bar must reach the visible valley line (13...15 cm from the axis of the groove) to securely support the first cut tile.

• Secure the groove to the substructure with six brackets using 2.8x25 mm galvanized roofing nails. You cannot nail the groove itself along its length with nails.

• Stepping back 1...2 cm from the top edge, nail the groove to the flooring with two nails to prevent it from sliding longitudinally.

• The minimum overlap of the next groove on the bottom is 10 cm; when laying, align the transverse ribs of the grooves.

The junction of the valleys below the ridge

• Lay the grooves with a gap of approx. 1 cm, secure them with nails and seal the joint with sealing tape of the appropriate color, profiling it along the edges of the groove.

Installation of joints at the same level for multi-gable roofs

• Lay and secure the grooves with nails. • Equip the ridge with aero elements or Figarol. • Seal the joint of cut ridge tiles with sealing tape or Wakaflex.

Bird and leaf protection

• The best protection against birds, dirt, snow and leaves getting under the tiles is provided by self-adhesive foam strips with water-repellent impregnation.

• If a foam strip is not used, then nail the eaves grille along the edge to the decking with galvanized nails.

The second way to lay the groove is on top of the thick sheathing

• This option is used when installing valleys of dormer windows or valleys over wide pipes, when the groove is released onto the tiles.

• In this case, nail the brackets to additional bars, otherwise the brackets will interfere with the even laying of the tiles. Bend the edge of the groove inside the valley. The foam strip can be trimmed to a height of 30...40 mm.

Release unit for the groove on the ramp

• Glue the outlet of the groove with Wakaflex and begin laying a groove 70...80 cm long with an overlap of the groove on the tile of at least 12 cm. • Use scissors to round the bottom edge of the groove and shape it to the shape of the tile using a hammer handle or a rubber mallet. • Construct valleys in the same way using grooves made of copper, zinc and galvanized steel.

Stage V. Working with the valley

Lay the valleys starting from the eaves overhang, from bottom to top. After laying, it can be trimmed by 3-4 cm to prevent the groove at the top from slipping.

If you need to choose the exact size of the valley, then follow this simple principle:

- if the length of the valley is no more than 4 meters, the width of each half should be 20 cm, and when unfolded, about 55 cm.

- if the valley is long enough, more than 4 meters, then in the unfolded state the steel sheet should be at least 66 cm wide.

Secure the valley to the sheathing with two screws. Trim the tabs on both sides for a tight fit, secure with self-tapping screws, and seal their joint with sealing tape.

Next, roll the edges with a roller to protect against dust and debris getting into the under-roof space:

At each edge of the valley groove, install a self-adhesive foam rubber strip with water-repellent impregnation.

On both sides of the valley, along the entire eaves overhang, an overhang aero-element is attached, which should not extend into the valley further than 10 cm from the edge of the groove, otherwise it will trap debris, fallen leaves and snow melting there.

Make sure that the visible part of the valley is at least 13 and 15 cm. The fact is that if the groove is completely covered with tiles, then rainwater will accumulate in it.

Installation of roof tiles

• Mark a trim line on the valley groove so that the overlap of the tiles on the groove is 8-10 cm. If the width of the groove from the center of the valley is 25 cm, the visible part, i.e.

not covered with tiles, it will be from 13 to 15 cm. • Mark the tiles along the drawn line. If the slope is flat, then you can tile the entire valley and mark the cutting line along a flat block. • Use half shingles to cut full shingles large enough to fit securely. The need for half tiles is approximately 1 piece. into two rows that fall into trimming. • To cut tiles, use a miter saw with a power of approximately 2 kW and a diamond blade for dry cutting of heavy concrete with a diameter of 230 mm. Be sure to use safety glasses and, if necessary, a respirator.

• The highest productivity and best accuracy are achieved when cutting tiles on a water-cooled machine.

Do not cut tiles directly on the valley, as this is unsafe for the roofer and may damage the gutter.

• After cutting, wash the tiles with water to remove dust and secure them to the sheathing with corrosion-resistant screws 4.5x50 mm, copper or zinc wire.

• On valleys, it is preferable to use wire fastening to prevent damage to the tiles from ice that may form on the valley.

• Glue the sealing foam strip along the edge of the groove. When laying tiles on it, use a knife to cut the pressed strip to close the side gaps between the tiles.

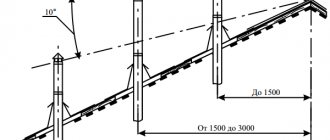

Sheathing device

• Calculate the pitch of the sheathing separately on the left and right gable, because

Cover lengths may not match. Mark the rows with a string, pulling it on the outer counter battens, and at the same time measure the difference in height of each counter batten. When further filling the sheathing, place slats or bars of the required thickness under it, leveling the plane of the slope. If the rafters are of high quality, then fill the sheathing using templates. • For lathing, use sawn softwood timber without wane and passing knots, meeting the requirements of SNiP II-25-80 “Wooden structures” with a maximum humidity of 25%.

Rules for roof operation and repair

A roof covered with ceramic tiles will last for several decades only with proper care. Correct installation is the key to the longevity of the roof, but it is equally important to follow the following operating recommendations:

- Snow removal in the winter season is carried out as carefully as possible using special tools. It is important to avoid strong impacts and the use of sharp devices;

- during operation, painting of the coating is not required, and damaged elements must be replaced with new ones;

- The sealing tape in the ridge area must be replaced as it wears out. To do this, carefully remove the ridge and plugs, lay down the tape and put the structure back together;

- violation of the waterproofing layer can only be eliminated by completely removing the top layers of the roof and updating the waterproofing. Therefore, it is worth choosing the highest quality and durable films;

- Before installing the roof, all wooden elements are treated with an antiseptic and fire retardants to increase the service life of the parts and prevent rotting.

Laying ordinary tiles.

• First, arrange the tiles in stacks of 5...6 pieces.

on all slopes for uniform load of rafters. Secure the first row with galvanized screws 5x50 mm and anti-wind clamps. Lay the tiles from bottom to top along the vertical layout marked on the sheathing. • As a rule, snow-retaining tiles with lattice or logs are installed in the second row. Install ventilation tiles, if necessary, along valleys, ridges, abutments and under the ridge.

• Attach the tiles on the slope with screws or anti-wind clamps in a checkerboard pattern, depending on the wind load and the angle of inclination.

• Moving on a tiled roof is easy and does not require special equipment.

Plastic tiles

This type of material is definitely not natural, but it is just as certain that it is much cheaper. The advantages of this type of roofing material are the same as those of polymer-sand material. The appearance is somewhat different from the usual, but not radically.

On the roof this material cannot be distinguished from natural

Available in two formats: in the form of single tiles or sheets of two or three elements. Working with plastic tiles is much easier: they are two times lighter and absolutely not brittle. Each has locks, with the help of which a single roofing sheet is assembled. Attached to the sheathing with nails.

The installation order differs: they start laying from the ridge, placing the bottom row under the one on top. The material is new, so there is little operating experience. But the price is low and installation is simple, which makes you think and hesitate when choosing.

Installation of a gable overhang.

• For sheathing pitches less than 33.5 cm, use side tiles with a cutout of 11 cm, and for larger pitches, with a cutout of 8.8 cm. Secure each tile with two galvanized screws 5x50 mm.

• The gap between the ends of the sheathing and the inner surface of the side tiles should be 1 cm.

• Another option for constructing gables is using lightweight side tiles made of painted aluminum. In this case, lay the row tiles on the gable overhang flush with an additional 50x50 mm bar.

• Place the side piece over the shingles and secure it to the gable beam with a roofing nail at the top and a screw and sealing washer near the bottom edge. The next element will cover the place of fastening with a nail.

Do not fasten the two lightweight side tiles with an overlap with a screw!

Laying cement-sand tiles - prices

Estimated cost of laying natural tiles per 1 sq.m. non-insulated roof (170-250 m2) new construction:

| Installation of ceramic (natural) tiles | Price |

| Installation of the rafter system in increments of 0.5-0.7 m, oblique cornice | 720 rub. |

| Waterproofing device | 108 rub. |

| Installation of counter-lattice, bar 50x50mm | 108 rub. |

| Installation of step lathing, pitch 31.2-34.5 cm | 180 rub. |

| Installation of natural tiles | 675 rub. |

| Installation of components | 405 rub. |

| TOTAL Price 2196 rub. per m2 | |

Some of these elements may complicate the work or increase the time it takes to complete it, while others, on the contrary, contribute to a more efficient and high-quality performance of roofing work. We are always ready to offer the optimal solution and negotiated price in accordance with the financial capabilities of the customer.

Roofing work with an area of more than 250 m2, as well as replacement, alteration, repair, and reconstruction of the roof are priced individually.

To calculate the budget for installing a roof made of ceramic tiles, just send a roof plan by email or send us a “Request for Calculation” . If there is no drawing, or you are not sure that the dimensions of the house box or truss structure correspond to the drawings, a specialist may visit. He will make the necessary measurements and calculations. You can send a request for calculation directly from the main page of the site and our specialists will contact you.

When calculating materials for laying cement-sand tiles, our managers use specialized software. This allows you to calculate with maximum accuracy the required amount of base material and additional roofing elements, as well as the complete set of the drainage system. It is also possible to view the color relationship between façade-roof-gutter if you have not yet decided on the color of the tiles and façade. Your roof may look different (as in the pictures). The choice is yours!

The “Our Works” page presents some of the roofs built by our company, where you can see objects similar to your roof.

Installation of ridge and spine bars

Calculation of the height of the ridge bar/board

• Place the ridge tiles on the tops of the waves of row tiles cut along the ridge line (at least 2 pieces on each side).

• Measure the distance between the inside surface of the ridge tile and the top edge of the sloped rafter. Take measurements from the narrow part of the ridge tiles.

• Install the spine block or board so that the free gap between its top and the ridge tiles is 5 mm.

• 1 – slanted rafter leg • 2 – counter-batten • 3 – sheathing • 4 – figarole • 5 – fastening of ridge/ridge sheathing • 6 – spine beam • 7 – ridge tile • 8 – ridge clamp

Calculate the height of the ridge beam/board in the same way as the ridge

• Lay ridge shingles on two rows of shingles on each side of the ridge.

• Measure the distance between the inside surface of the ridge tiles and the point where the counter battens meet.

• Install the ridge block or board so that the free gap between its top and the ridge tile is also 5 mm.

Application of spinal ridge sheathing fasteners

• Bend the spinal bar fastening along the corner of the hip at the desired height.

• Install two fastenings at the beginning and end of the ridge, pull the lace along the edges of the fastening areas.

• Nail intermediate fastenings with galvanized nails 2.8x35 mm in increments of no more than 60 cm (4 nails for each fastening).

• Nail the core beam with a minimum cross-section of 50x50 mm to the fastening with galvanized roofing nails 2.8x25 mm.

On a skate

• Bend the fasteners to the desired height and install them under the top sheathing, so when nailing the sheathing, move the nail from the middle of the counter-lattice (rafter leg).

• Install intermediate fasteners with a cord at each joint of the rafter legs.

• When using concrete side tiles, cut the ridge block flush with the cutout in the side of the tile.

Tiling of ridges

• Cut the tiles with a gap of 2...3 cm to the center beam or board for ventilation of the roof and insulation.

• After drilling and cutting, be sure to wash the tiles with water to remove dust, as Figarol or Aeroroll ridge can only be glued onto clean tiles.

• Attach the cut tiles to the sheathing with corrosion-resistant 4.5x50 mm screws or to the core block with copper or zinc wire.

• It is most convenient to fasten the tiles with special stainless steel clamps.

Stage VI. Laying tiles on slopes

So, now that everything is ready, try on the gable tiles on the gable overhang, which should lie with a gap of 1 cm from the front board.

On the sheathing, mark the left edge of the pediment tiles, and to the left of it, mark the position of future columns after 90 cm, at the rate of 30 cm per column.

Using string, apply these markings to the sheathing. Now lay out the lower first row of tiles freely, while carefully checking the position of every third tile using the previously made marks.

The support spike, which will rest on the front board, needs to be knocked down with a hammer, as in this photo master class:

Now fasten each tile of the bottom row with a self-tapping screw through the holes drilled in the ridge, and lay out the first column of gable tiles along the previously marked vertical line. At the same time, fasten each tile at the top with two screws.

After this, lay the tiles on the slope, from bottom to top, along the vertical markings applied to the sheathing:

To walk on a tile roof, all you need is a harness—you can step on it anywhere. Start laying and marking tiles on hip and hip roofs from the middle of the slope. To do this, you will need to find the middle of the triangle: simply lay out a vertical row of tiles from the very top, right in the center, and now lay the bottom row.

After this, mark the vertical rows where you can, and lay the tiles from bottom to top, in rows, starting from the middle of the slope towards the ridges.

Ventilation device for ridges and ridges. Installation of ridge tiles.

Ridge

• If the waterproofing film is laid with an overlap over the sloping rafter leg, then you can use the Aeroelement of the ridge for attics, Figarol or Aeroroll of the ridge. • When maintaining an additional ventilation gap between the film and the rafter leg, use only Figarol or Aeroroll ridge.

Horse

• Use the Coverland aerial element, the ridge aerial element for attics and Figarole.

• If installing ridge shingles over mortar, install vent shingles along the ridge and ridge. Consult with a specialist about the required quantity.

• Select ventilation elements depending on the length of the rafters, the shape of the roof and its complexity.

Laying Aeroroll or Figarol

• Use a dye cord to mark the center line on the spine block or board if they are uneven.

• Roll out the figarol along the marked line and secure with brackets or roofing nails 2.8x25 mm in increments of 30 cm.

• The overlap of the top roll on the bottom should be at least 5 cm. Remember that Figarol can only be glued to clean and dry tiles. It is preferable to work at an air temperature of at least +50 C.

• At lower temperatures, the surface of the tiles must be heated with a technical electric hair dryer. Do not use a gas burner or kerosene lamp.

• Remove the protective tapes from the adhesive rubber strips along the edges and glue Figarol only on the tops of the waves of row tiles.

• After this, glue Figarol over the entire surface of the tiles and roll with a special metal roller.

• The middle ventilated part of the Figarol must not be pressed against the backbone!

Conjugation of the hip ridge with the ridge

• In the upper part of the hip, place the Figarol with an overlap on another slope, and secure the aeroelements of the ridge or Figarol on top of it.

Laying of ridge aeroelements

• Attach the aeroelements to the ridge beam with galvanized nails 2.8x35 mm with a pitch of approximately 30 cm.

• The overlap of the elements is determined by the existing side cutouts.

• Start installation of ridge tiles on the leeward side to reduce the possible blowing of precipitation through the joints of the tiles. Arranging the beginning of the ridge with tiles and an end ridge element • Secure the ridge clamp with two roofing nails or screws, having previously tried on the ridge tiles and the end element.

• Place the ridge tiles in the clamp and secure them to the next clamp using a 5x70 mm galvanized screw.

• Using the longitudinal hole in the clamp, lay the tiles with a gap of approximately 1 cm.

• Secure the end ridge element to the spine beam with galvanized screws or nails.

Application of initial spine tiles

• Install the initial spine tile with a small protrusion and secure it with two galvanized screws 5x70 mm and 5x100 mm through the holes.

• Align the clamps along the center line marked on the Figarol. Secure the tiles with 5x70 mm screws.

Application of hip tiles

• Cut the last ridge tiles to the required length and trim their edges along the seam lines.

• Apply hip shingles and mark their outline on the ridge tiles.

• Cut the ridge tiles 6cm above the marked outline and drill 6mm holes for the screws.

• Install and secure the clamps.

• Secure the hip tiles with three ridge clamps and a 5x100mm screw.

Hip top structure without bell-shaped tiles

• At the top point of the hip, cut the ridge tiles tightly, drill 6 mm holes and secure with galvanized screws 5x70 mm.

• Seal the joints of the ridge tiles with sealing tape for valley joints or wakaflex of the appropriate color and roll them with a roller.

Important! At the junction it is allowed to install ridge tiles with a length of at least 23 cm.

Ventilation and thermal insulation

The technology for laying ceramic tiles involves installing a ventilation system in the under-roof space. This is necessary to ensure that condensation does not accumulate inside the roofing pie, which leads to the destruction of the insulation and rafter system.

There are two options for constructing a roofing pie. In both cases, the main layers are the same:

- Vapor barrier (bottom layer);

- Insulation;

- Waterproofing.

The difference between single-layer and double-layer ventilation is that in the single-layer version there is only one air layer, directly between the waterproofing and the roof. Two-layer means the presence of two layers, the second - between the waterproofing and insulation.

The choice of technology depends on the waterproofing material. Only membranes with a vapor permeability of at least 750 grams per square can be placed directly on the insulation, which will protect the insulation from moisture and drain condensation to the outside.

note

The total height of the ventilation gap must be at least 20 centimeters.

With a two-layer scheme, about two centimeters are left from the insulation to the film. In addition to creating air gaps for roof ventilation, when laying ceramic tiles, special elements are used:

- Skates;

- Cornice.

The types of elements are different:

- Hard aerators;

- Rolled ventilation films;

- Ventilation grates;

- Ventilation tiles.

Elements are selected depending on the type and slope of the roof.

The brand of insulation and layer thickness depend on the region. Examples (for roofs in the Moscow region):

- Mineral wool P175 (thermal conductivity coefficient 0.072) – 40 centimeters;

- Fiberglass (coefficient 0.044) with a windproof membrane - 24 centimeters;

- Expanded polystyrene (0.032) - 15 centimeters.

Installation of connections to pipes and walls using self-adhesive tape BRAAS Vakaflex.

Technical characteristics

Material: polyisobutylene mastic (PIB) with a reinforced aluminum mesh, adhesive tapes made of synthetic rubber 2 cm wide are applied on the reverse side along the edges of the roll. Size: length 5 m, width 28 cm. Temperature resistance: - 40...+100 C to DIN 52 133. Colors: red, brown, black, green. Weight: 5 meter roll approx. 5 kg. UV stability: complies with DIN 16 726.

Tool for working with Wakaflex • Roller • Folding meter • Pencil • Scissors

• Operating procedure

1. Arrange the bottom of the pipe. 2. Make side connections. 3. Glue the top of the pipe. 4. Install a Waka strip with heat-resistant dowels around the perimeter of the Wakaflex. 5. Apply sealing compound K.

• Lay the tiles around the pipe with a gap of 2...3 cm. If necessary, cut the tiles under the pipe to continue the row line and secure them to the leveling bar with 5x50 mm screws.

• IMPORTANT! Tiles and wall surfaces must be clean and dry. If you work at air temperatures less than +5 degrees. C, then use a technical electric hair dryer to warm them up.

Bottom of pipe

• Cut off the bottom strip of Wakaflex (length of strip = pipe width + 5 cm extra on each side of pipe).

• Fold the Wakaflex strip into a corner.

• Remove the middle protective film.

• Remove the protective film from the adhesive strip and glue the top part of the Wakaflex.

• Roll the adhesive strip to the pipe and the entire surface with a metal roller.

• Remove the film from the bottom edge of the Wakaflex and glue the roll only along the top of the waves of tiles.

• Glue Wakaflex onto the entire surface of the tiles using a roller.

• Cut the upper non-adhesive part of the Wakaflex at an angle of approx. 450, without cutting 1 cm to the point of intersection of the slope and the pipe line.

• Glue the cut sections onto the pipe and tiles.

Pipe side

• The side roll of Wakaflex should start from the bottom edge of the already glued strip and end 10...15 cm above the top of the pipe.

• Glue the side roll of Wakaflex to the pipe and tiles, roll it up with a roller.

• Stepping back 2...3 cm from the pipe line, make a cut to the point of intersection of the slope and the pipe. Do not extend the cutting line approximately 1 cm to this point.

• Cut the side parallel to the water drainage line. This piece will be useful to you later.

• Use scissors to round the bottom edges of the side strips to reduce the effect of wind.

• Glue the bottom of the roll and roll it with a Waka roller.

• Cut the top of the side roll towards the point where the line of the pipe and the slope intersect. Do not extend the cutting line to approx. 1 cm to this point.

• Glue the cut pieces onto the pipe and tiles and roll them with a Waka roller.

• Glue the left and right corners of the pipe in the upper part (remaining from the side strips) with pieces of Wakaflex to protect against sliding snow and ice.

• The overlap of the bandage strips on the side of the pipe should be approx. 2 cm.

Top of the pipe

To protect the roof from melt water, make the top roll of Wakaflex double.

• Cut two strips to the required length.

• Remove the protective film from the top strip and apply it to the bottom strip with an overlap of 5 cm. Roll the joint with a Waka roller.

• Place the double roll in the groove with a slight slope in any direction and glue Wakaflex to the pipe.

• Remove the protective film from the top strip and glue Wakaflex to the waves of the tiles.

• Glue and roll Wakaflex over the entire surface of the tiles, with the exception of the lower area (adjacent to the pipe and not covered by tiles) to drain rainwater and dirt.

• Make a cut down parallel to the pipe line, stepping back 2...3 cm from it. Do not bring the cutting line approximately 1 cm to the slope line.

• Cut off the bottom of the roll and use scissors to round the bottom edge.

• Glue the cut pieces onto the pipe and tiles and roll them with a Waka roller.

• If a snow bag may form above the pipe, then to protect the roof from the penetration of melt water during a thaw, bend the upper edge of the Vakaflex in the form of a bumper by 2...3 cm.

• Lay the tiles on Wakaflex.

Working with the Waka bar

Bottom of pipe

• Cut the bottom strip to the required length: The length of the strip is equal to the width of the pipe + 5 cm outlet in both directions.

• Cut the upper part 1 and bend it along the line of the pipe.

• Cut the lower part 2 and bend it along a line 1 cm away from the corner of the pipe.

• Bend the upper flange of part 1 with a hammer to the pipe.

• On the bottom 2, cut a corner parallel to the slope line.

• On the top part 1, mark and drill holes for dowels d 6mm

• Mark along the strip and drill 6x40 mm holes in the pipe.

• Secure the strip to the chimney with heat-resistant dowels and screws.

The fastening step is no more than 20 cm!

Pipe side

• Place the side strip parallel to the slope line and mark on it the outline of the bottom strip and the pipe line at the top.

Top edge of the side bar

• Cut part 1 along the pipe line.

• Cut part 2 along a line 1 cm away from the corner of the pipe.

• Secure the side strip with screws.

The fastening step is no more than 20 cm!

Top of the pipe

• Cut the top strip: Length of the strip = pipe width + 2 cm outlet on both sides.

• Mark the outline of the installed side strips on the top strip.

• Mark the upper part 1 and bend it along the pipe line. To do this, make sequential cuts u and v.

• Bend the lower part 2 along a line 1 cm away from the pipe. To do this, make cuts x and y.

• Cut off the raised edges w and z at the rake angle.

• Mark along the strip and drill 6x40 mm holes in the pipe for dowels.

• Attach the top strip to the pipe.

• Using a construction syringe, apply Sealant K into the flange of the plank along the entire perimeter of the junction.

Appearance of the finished junction

• The upper edge of the Wakaflex is protected from precipitation by a Waka strip, secured to the chimney with heat-resistant dowels and corrosion-resistant screws.

• Sealant K is applied to the flange of the strip - a one-component synthetic rubber that does not contain silicone.

Composition of the roof tile roof pie

The roofing pie for ceramic tiles includes standard elements:

- waterproofing;

- thermal insulation;

- vapor barrier.

The waterproofing layer protects the roofing system and the under-roof space from precipitation and melt water. Thus, it is possible to avoid mold, fungal diseases, rotting wood or corrosion of metal elements. If the angle of the roof slopes is less than 22 degrees, a reinforced waterproofing and ventilation system is required.

It is recommended to use a rolled membrane as a waterproofing material. It does not allow water to pass through, but steam does pass through. Thanks to this, excess moisture from the interior is freely removed to the outside without condensation settling on the surface of the roofing elements. Calculating the amount of membrane is simple. The total area of the roof slopes, taking into account laying allowances, is multiplied by a factor of 1.4.

Installation of waterproofing is carried out from the top from the ridge strip down to the eaves. The rolls are rolled out along the ridge and eaves with an overlap of the next layer by the previous 10-15 cm. Additionally, allowances are left (they are cut off after installation of the roofing):

- 15 cm on gables and eaves;

- 15-20 cm – on protruding roof corners;

- in places where the roof covering adjoins the vertical elements of the roof: walls, ventilation shafts, antenna output, chimney.

The membrane is attached to the sheathing at the overlap points. You can use a special stapler for rolled materials or tape. Additionally, the membrane is fixed with tar paper nails or wooden slats around the perimeter and at the junction points.

In any roof there are so-called “cold bridges” through which heat flows out of the house. To avoid heat loss, install a layer of insulation. There are many types of roof insulation. This can be expanded clay, polyurethane foam, polystyrene foam, foam concrete, foam glass, cellulose and basalt fiber insulation.

For private housing construction, basalt mats are most often used. Placed between rafters. To enhance the effect, you can put it in two layers. In this case, the second layer is laid so as to cover the joints between the mats of the first.

Do not allow the insulation to get wet. To prevent the accumulation of fumes from the interior, a vapor barrier membrane is placed on top of the mats.

Installation of safety and snow retention elements.

• BRAAS safety system elements are designed for roofs with pitch angles from 150 to 520. They comply with the requirements of DIN 18160-5.

Material: hot-painted aluminum, galvanized steel.

Aluminum elements:

• Support / snow retention tiles - 420 x 180 mm; • Grate – 880 x 250 mm; • Safe step - 410 x 250 mm; • Yoke for fastening the footrest and grille; • Support for fastening round timber (logs up to 130 mm); • Support for fastening the snow-retaining grid;

Galvanized steel elements:

• Snow-retaining grid – 200 x 2500 mm; • Connecting clamp for snow guard.

Installation norm

• When the slope angle is no more than 450, it is allowed to install supporting elements through two rows. • At angles greater than 450, it is necessary to install support elements on each row.

Location of support tiles

• For an 88 cm grate - two support tiles through one row and half tile. The pitch along the axes is 60 cm. • For a 42 cm footboard - two support tiles through one half tile. The axial step is 30 cm.

IMPORTANT!

Be sure to install an additional support block under the supporting tiles.

• The thickness of this block should be 2 cm greater than the thickness of the sheathing; the tiles will rest on the supporting block with protrusions located on its back surface.

• Fix the support block at a distance of 230 mm from the top of the sheathing.

• Secure the supporting tiles with two galvanized screws 4.5 x 50 mm.

• Install the yokes onto the support shingles.

• Aluminum safety grilles (880 mm) can be installed next to each other in various combinations on the support tiles. In this case, the maximum gap should not exceed 5 cm; it is recommended to center the gratings.

• In this way, you can use ladders of various lengths (parallel to the ridge line) for convenient and safe operation of stove and fireplace pipes, ventilation shafts, roof ditches, etc.

Snow retention installation

• As a rule, snow-retaining gratings or logs are installed in the second row from the eaves overhang. The maximum pitch of snow-retaining tiles is 90 cm (every 2.5 row tiles).

• If there are increased requirements for reliability, install support bars under the tiles.

• Secure the shingles with the two ribbed galvanized nails included in the kit.

• Place attachments under a grate or log. Grate size: 200x2500 mm, log diameter no more than 130 mm.

• To join the gratings, use connecting clamps (requirement: 2 pcs./joint).

Installation of ceramic tiles

Installation begins from the bottom row. First, nail the cornice strip. It can be metal (purchased along with the tiles) or wood. In the first row and the last, we fasten each element with self-tapping screws. All side elements are also secured.

This is how the tiles are secured to the sheathing

All others are fixed with a specially shaped wire, which is supplied with the tiles. It is passed under the sheathing strip and hooked onto special grooves on both sides. Since there are protrusions on the back side with which the tiles rest against the strip, the fastening is flexible and at the same time reliable. Such a roof, when shrinking, will easily adapt to all movements, while maintaining tightness. You just need to make the rafter system correctly: it must also be movable (floating).

For more information about installing clay tiles, watch the video. The first half discusses the advantages and disadvantages of natural tiles, and the second demonstrates the installation of elements in the bottom row, as well as elements of subsequent rows.