Wooden houses are attractive for their beauty, environmental friendliness, and affordable cost, but developers are often concerned about one nuance related to shrinkage. Without understanding what this process is, a client who comes to a construction company demands that their housing be built from blocks or other material. A person, due to his inexperience, refuses a luxurious life in a cozy log house and incurs unjustified costs. To dispel all doubts, it is worth understanding how houses are built from timber and logs, what shrinkage is, and how safe it is.

What affects the shrinkage itself?

The first is the material you chose for construction: - Chopped logs

shrinks approximately 7-10%, it will take about a year to settle, sometimes more.

This depends on the quality of cutting and the time of material procurement. - Timber with natural humidity

- shrinkage 3-5%, time to settle - from six months to a year.

— A rounded log

shrinks 5-6%, and interior work can begin in 4-6 months.

Wood is characterized by the ability to change its moisture content depending on changes in environmental humidity and temperature, this is called hygroscopicity. This feature lays the foundation for the unique qualities of a material such as wood, and also determines the features of working with this material. Everyone has heard the phrase more than once that a wooden house breathes. How is it? Wooden walls cannot simply let air through, because then the entire function of the walls is lost. Of course this is not true! The peculiarity is that wood regulates the microclimate of the room due to its special ability to absorb and release moisture. Naturally, wood takes care of providing the most comfortable conditions for humans; in this, no other material can compete with wood. Scientists have proven that humidity fluctuations occur only in the first 5 centimeters of the top layer on both sides of the log. Once the crown wood reaches equilibrium with the environment, the moisture content of the inner layers no longer changes. The dimensions of the tree change due to changes in humidity, and processes of shrinkage or swelling may occur. The amount of shrinkage depends on the direction of the fibers; this feature is associated with the anisotropic layered fibrous structure of wood. During the construction process and in the future during the further operation of the house, the amount of shrinkage is taken into account in the event of a change from the natural state (humidity about 40%) to absolutely dry. In the radial direction this figure is 4%, in the tangential direction - 8%, along the fibers this percentage is so insignificant that it is usually not taken into account.

A new house or bathhouse made of rounded logs or timber seems ideal. But the builders only have time to put the last crown on, when the finished house begins to be affected by its own weight and shrinkage, which leads to compaction of the grooves. This is called shrinkage - a change in the linear dimensions of building elements under the influence of the above factors. Per meter of height, shrinkage can be 10 - 40 mm, this depends on the initial and final moisture content of the crowns.

Uneven shrinkage

The side walls settle more slowly than the ridge and gable walls, since they are lower than the others. The walls from the inside will shrink faster if the contour of the house is closed, that is, there are windows and doors, and when the heating is on. The process is accelerated due to the difference in humidity and air temperature outside and inside the building. In view of this, after building a house from rounded logs, it is strictly not recommended to install windows and doors in the first 4-6 months (close the thermal circuit of the house), as well as heat the house. During this period, maximum ventilation and unhindered air circulation in all rooms should be ensured, this will contribute to the natural drying of the log and natural and uniform shrinkage. Natural and mechanical shrinkage occurs in the first year. Natural shrinkage is affected by the drying of the log and a decrease in its diameter as a result; shrinkage will be 5-10 mm depending on the initial combination. Mechanical shrinkage is ensured by the load of the roof and upper crowns; naturally, the logs are compressed and fit more tightly to each other. In addition, cracking along the moon groove or expansion joint affects a slight change in the cross-sectional geometry of the log, and therefore also affects the percentage of shrinkage upward.

Advantages of profiled timber

The main advantages of profile timber include:

- environmentally friendly material - the beams are not chemically treated, which will protect any family from further exposure to artificial materials;

- the material allows enough oxygen to enter the room, the walls “breathe”;

- additional insulation is needed only in certain cases, since the beams fit tightly due to their special profile;

- walls made of this material are smooth, which eliminates the need for additional processing and finishing of walls;

- due to the correct profile geometry, wall assembly takes a short time;

- the structure is lightweight, so the foundation is not expensive;

- the price of such a house is low.

Mechanical load on walls

It is for this reason that we recommend that all our clients complete the installation of a finished roof at the same time as assembling the house, because... this allows you to accelerate shrinkage through additional mechanical load on the walls, evenly distributing additional (weight of the roofing, snow, wind) loads, which have a beneficial effect on the shrinkage process, sealing the groove joints, eliminating the hanging of log logs and reducing, and in most cases eliminating, possibility of cracks forming. With this approach, labor costs and material consumption for caulking a log house are reduced, and as a result, the overall costs of its construction are reduced. Mechanical shrinkage is especially effective when choosing a tile roofing covering for the roofing of a wooden house made of rounded logs. In more detail, we present this information on the page how to cover a wooden house.

But this approach is applicable if the wooden house has a simple gable roof, and the mandatory installation of the roof using hinged joints, sliding rafter supports and compliance with all roofing technologies on a wooden house that do not interfere with shrinkage processes and compensate for them, preserving the integrity of the structural elements and roof planes. Otherwise, a temporary roof is installed, made of roofing felt or waterproofing film, while the house shrinks, after which they begin to install it in its final form. Therefore, we recommend that you take this feature into account when choosing your future home and strive to simplify the configuration of the roof of a wooden house, which will also have a positive effect on increasing its reliability for the entire service life, due to the absence of obviously weak points of the roof - valleys, joints, kinks and adjacencies.

Comparing types of profiled timber

To begin with, a clear condition should be highlighted: to build a certain structure, profiled timber of dry or natural moisture is used in compliance with technical standards during its installation. Dried lumber is much more in demand. The percentage of moisture in it is 12-15%. This means that when interior decoration is done, nothing will happen to it during the heating season.

It might be said that purchasing it as a wall material is not entirely logical, since the structure of wood is hygroscopic and over time can absorb moisture from the outside. The optimal moisture content of the timber should be 18-20%. With this indicator, the tree almost does not absorb excess moisture and does not dry out to the point of cracking.

If it is possible to achieve such an indicator when purchasing timber with natural humidity and check the readiness of the raw material for use, it is necessary to leave it under a canopy for at least 3-4 months, up to a year, and make sure that critical deviations in the form of twisting, cracks, and rotting do not appear on the log houses . Advantageous cost savings require rescheduling the start of construction. With proper storage, after the curing period, such material will not be inferior to chamber material.

The likelihood of shrinkage will be reduced. Dry wood is better because over time it exhibits 2-3% deviation from the original linear dimensions. If the drying stage has not passed, it may deform by 10%. The difference is noticeable, especially in the completed structure.

Continuing to consider which pieces are better, dry or natural moisture, and comparing customer reviews, it is worth noting that wood that is subject to drying is lighter than usual. This property is noticeable when transporting and laying boards. It's easier to work with him.

Another significant advantage in the direction of dry timber is the destruction of fungus and stopping the rotting process. However, weatherboards can be additionally treated with antibacterial agents. There are plenty of varieties of these impregnations. It is necessary to combat harmful microorganisms first, before the negative manifestation of their activity.

Water is an integral part of the structure of wood, but too much water directly affects the strength of the log. Consequently, in this characteristic, timber with natural moisture is inferior to dried timber. It all depends on how evenly the raw material has dried. Often the core remains under-dried for an obvious reason: the surface dries out faster. Therefore, manufacturers do not always guarantee the same moisture content in different parts of the material.

Let's summarize the above

Any construction, even a bathhouse made of dry or natural moisture timber, must be carried out according to construction technology. Each material has advantages and disadvantages, which should be taken into account initially. Much depends on the load on the walls, the heating system and the care of wooden walls.

Experts in this field can predict further consequences and apply some tricks when building a house: they make a rough roof, make cuts in the workpieces, install casings in window openings, etc. Judging by the reviews, the problems can be solved.

The main thing is to successfully purchase high-quality dry timber, since the process of its production is more labor-intensive and limited than the sale of wood with natural moisture. Current manufacturers produce products that do not fully correspond to the price and specified characteristics.

Use shrinkage compensators

Shrinkage is especially pronounced in the first year after the completion of construction of a log house. Taking this feature into account, modern technologies make it possible to eliminate negative consequences by using new technical solutions for competent work. When talking about this, we mean shrinkage compensators (screw adjustable supports); they are used to adjust the height of supporting wooden posts. For more than 50 years, shrinkage compensators have been successfully used in the construction of wooden houses, log baths and in the construction of wooden roof structures.

The shrinkage compensator is installed between a rounded log and a supporting wooden beam, which is located under the roof of a wooden house. Adjustable screw supports are indispensable at any stage of construction and shrinkage of a wooden house. Compensators allow you to achieve uniform shrinkage of the log structure. In production, they are galvanized and are available in diameters of 20-26 mm.

Such adjustable screw expansion joints are required to be installed when a log post supports wooden walls. Shrinkage compensators are always installed under the pillars that support an open veranda, or the pillars that support the open porch of a wooden house. Screw shrinkage compensators operate according to the following principle: at the maximum unscrewed size, the compensator is installed under a support beam or under a support wooden post. The compensator support platforms are attached to the post or beam using self-tapping screws. The compensator screw is set to the highest possible position.

During the entire period of shrinkage of a wooden house made of rounded logs, it is recommended to tighten the compensator nut in the direction of twisting once every 1.5-2 months, so that the pillar or support beam is lowered by 0.5 - 1.5 cm. In some cases, you can determine “by eye” the distance to lower the shrinkage compensator nut, if you are guided by the deflection arrow of the rafter beam or the floor of the house.

Log sauna with a paw and a bowl: photo

Log steam rooms and saunas differ from ordinary frame and brick buildings not only in their long service life and good thermal insulation. Using log house technology is also a good way to make the design of a bathhouse more impressive and interesting.

Eliminate twisting, skewing and sagging of logs

The walls of a wooden house made of logs, during the shrinkage process, in addition to drying out, also tend to change their shape. The log twists and bends. This occurs along the axis of the load-bearing walls, and not only in the vertical and horizontal planes.

To compensate for the above-mentioned processes and to prevent the structures from shifting from the design level, a log house is assembled on wooden dowels. Without it, during drying due to internal forces, deformation of the log will be inevitable.

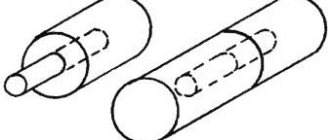

A dowel is a dowel made of wood, which during shrinkage prevents the logs from twisting along its axis.

Complete absence, incorrect installation or insufficient number of dowels will ultimately lead to distortions and logs falling out of the walls.

The dowels are installed, taking into account the length of the log and the location of the doors and windows, in a checkerboard pattern relative to each other. Holes for dowels are made strictly vertically and in the center of the log every one and a half to two meters.

The diameter of the hole is made slightly larger than the diameter of the dowel itself. Its depth should also be greater than the length of the dowel by about 3-4 cm, this provides space for its advancement for shrinkage of the log house. Otherwise, the top log will hang on the dowel when it shrinks, resulting in a gap forming between the logs. The best material for dowels is birch.

Pay attention to openings

To protect and secure the openings during the shrinkage period, it is recommended to leave a bandage using log beams in the center of the openings; they are cut out before the jamb and direct installation of window and door products. This remedy is simple, but quite effective, it allows you to strengthen walls weakened by cutting openings and protect door and window blocks from the effects of shrinkage, which will help avoid the appearance of cracks along the edges of the openings, and also strengthen the ends of the logs from twisting.

Here are some tips to follow when building a wooden house from rounded logs: * use sliding supports and hinged joints; * do not attach the rafters to the log too tightly; * leave a bandage on the walls in window and door openings; * do not place pillars in spacers without screw compensators; * make the depth of the hole for the dowel 3-4 cm greater than the length of the dowel; * leave a compensating gap in the openings between the top log and the post; * leave door and window openings open during the shrinkage period; • - finishing work should begin no earlier than six months later.

It must be remembered that if the shrinkage process is not taken into account and compensatory measures are not taken into account in time, shrinkage can lead to a critical moment when it will simply be impossible to restore or repair a wooden house.

Our designers and builders are very familiar with all the nuances and technologies for constructing a durable wooden house. The key to obtaining a high-quality and stable result is to study the construction experience of our ancestors in combination with the latest technologies and work experience. By contacting us, you can be sure that after several decades your home will delight you with its beauty, warmth and comfort!