To enjoy living in a wooden house, simply building it is not enough. You still need to take care and periodically look after it. After all, wood is not a stone, it is alive, “breathes” and insects and various types of mold and fungi love to feast on them. All this can lead to a change in the appearance of the entire house; the logs can crack, cracks appear, or turn black from attack by biopests. To prevent this, you need to provide it with additional protection in time with impregnations or antiseptics.

Cracking of a log house

It is impossible to completely prevent cracking of wood, but you can minimize the likelihood of their occurrence. The most dangerous thing is not the cracks themselves, but their depth. They can be found reaching up to the middle of the log; they greatly affect the strength of the wood, deteriorating it. Cracks form mainly due to uneven drying of the log house, i.e. The tops of logs dry out much faster than their middles. This happens mainly due to shrinkage of the house, heating system, and exposure to sunlight.

When a house shrinks, cracks appear mainly during the first year. In order for the wood to more easily endure this difficult period, the ends of the logs need to be treated with special compounds that contain lime. They will prevent moisture from rapidly evaporating, which will help minimize the appearance of cracks. For several years after construction, the house cannot be heated; stove heating can also upset the balance between the inside of the log and the outside, which will also lead to the appearance of cracks.

The most dangerous are spring sun rays, so before March it is necessary to carefully treat the outer walls of the log house with protective agents that will not allow moisture to evaporate. The choice of protective equipment must be taken seriously, because low-quality compositions can lead to unpleasant consequences that will be impossible to correct. There is one proven product from the popular company Neomid that can prevent cracking of logs. And it is Neomid Thor Plus, it has already been appreciated by many buyers.

Whitening products

Bleaching of logs is carried out using special bleaching agents, which are divided into two large groups:

- Chlorine-containing products. These include products containing: sodium or potassium hypochlorite, bleach, chlorine dioxide.

- Compositions without chlorine, in which the active substances are ammonia, hydrogen peroxide, oxalic acid and alkalis.

Any composition for bleaching wood operates on the same principle: it causes an oxidative process, as a result of which the coloring pigment becomes discolored and the fungal molecules are destroyed.

Neomid Thor Plus

This product is intended to protect timber, logs and their ends from cracking and rotting. They can be used to process a log house both inside and outside. Suitable for application to residential buildings, bathhouses, gazebos. Thor Plus creates a kind of barrier in the log fibers that can repel water, which protects against excess moisture. A coating is formed on the treated surface that does not interfere with the “breathing” of the wood.

This composition does not need to be diluted before use and does not degrade or alter the natural structure of the wood. It should be applied only in special clothing, because... skin contact with it may cause irritation. It dries completely on Neomid Tor Plus logs within 24 hours.

General recommendations for whitening

So, the main recommendations:

- after bleaching, any composition must be washed off with water;

- acid-based bleach is washed off with an aqueous solution of soda;

- You cannot combine different compositions; the surface can only be treated with one product.

- if the wood is severely affected by fungus, it is necessary to treat it with a more concentrated composition.

- bleaching is most effective if it is carried out at a temperature of 18-20 degrees Celsius and at a humidity of about 60%;

- When processing wood inside the house, it is necessary to ensure ventilation of the room, because Almost all formulations contain components that are unsafe for health. If the treatment was carried out in a bathhouse, it is necessary to dry-heat the room twice before taking bath procedures to remove chlorine fumes.

Below you will learn how to whiten a log house after sanding.

Blackening of the log house

An equally serious problem with a log house is the blackening of wood. But any tree, regardless of its species, can darken, which is quite natural. These two processes should not be confused, because blackening appears after serious mold damage to the log house. And in order to restore the “health” of the wood, you need to carefully sand it, get the same light shade and then treat it in several layers with antiseptic agents. If, after a while, signs of mold appear again in the same place, then you need to pay attention to the conditions in which the wood is located: is it thoroughly ventilated, and does not water get on it from time to time, etc.

In general, it is initially necessary to impregnate the wood during cutting, so it will better withstand both transportation and the construction process. But, unfortunately, many carpenters neglect these actions, which can lead to the appearance of mold even during construction. Therefore, after erecting a log house, you need to carefully treat it with antiseptic protective compounds. And in the future, to prevent the log house from turning black, it is also necessary to periodically impregnate it for preventive purposes.

There are a lot of antiseptics now, so purchasing them will not be a problem. But quality products are much more difficult to find. Many people recommend trying Neomid 440; judging by the reviews, the results of this product are impressive.

Why is this happening?

The question of changing the color of the finishing material is often asked by owners of wooden buildings (you can find out why the lining darkens and how to treat it to get rid of the problem here). When choosing light colors for the lining, there is a possibility that yellow spots and stains will appear on the surface and spoil the appearance of the finish.

- Yellowness appears as a result of the fact that wood contains resin. This component, consisting of yellow substances, interacts with paint particles, dissolves and appears on the surface as rusty spots. This process is especially noticeable in the place of knots.

- Another reason for the appearance of yellow stains is associated with an incorrect technological process for drying the material - this is relevant for finishing materials made from coniferous wood.

Neomid 440

Neomid 440 Eco antiseptic is designed to protect the log house both inside and outside from rot, mold, insects, and fungi. It can be used to process wood located in rooms with a high percentage of humidity. The use of Neomid 440 is suitable both for preventive purposes and for direct control of already emerging biodegraders.

This antiseptic is lying around as a concentrate and must be diluted with water before use. Their ratio depends on the degree of damage, but basically it should be 1 to 9. After treatment, the wood may change its shade slightly, but its structure will remain the same. The bioprotection period of the log house will be at least 20 years.

The use of such agents as Neomid 440 and Neomid Thor plus for preventive purposes will practically eliminate cracking and blackening of the log house. This will allow you to preserve the strength and aesthetic appearance of the entire house for many years.

Sequencing

Specific actions depend on what stage the construction of your bathhouse (house) is at.

Before construction starts

If the logs have just been delivered, and some are already affected by blue staining, they need to be treated with bleach before being placed in the log house. If only part of the materials is affected and there are absolutely clean logs or beams, then it is better to coat only the affected ones, leaving the rest as is.

After treatment with bleach, the surface is treated with an antiseptic (after drying the bleach). Don't forget to process the bowls as well as the ends.

Just don’t get it mixed up: after bleaching, treat not with a finishing film-forming composition, but with a water-based or solvent-based antiseptic (they are not very popular because they are not environmentally friendly). Precisely an antiseptic, preferably of deep penetration, which does not form a film.

If the log did not need bleaching, it is not coated with an antiseptic. The fact is that after drying you will have to sand the frame. And wood treated with an antiseptic does not sand well. If the log is clean, and there is a season ahead with minimal precipitation or low temperatures, then without moisture or heat, fungi will not develop without any treatment.

After drying, the logs or beams are sanded. There is a high probability that all the blue will be removed

After installing the log house, it is covered with a roof and in this state is left to dry out/shrink. There is one point: during this period, you should not cover the cut window and door openings with film. You can fill it with boards, but with cracks so that moisture can escape freely. You can also use vapor-permeable films (if the film has one-sided conductivity, do not confuse which side should be nailed - the rough side facing the street). If the openings are closed tightly, there is a high chance of getting mold or white fungus in addition to the blue. Therefore, take care of ventilation.

Blue of dried logs (timber)

After drying and shrinking, it’s time to polish the frame . This is where the need for bleaching may arise again. If there is blueness, bleach, if not, you don’t need to. Then comes the grinding of the frame. In the process, many minor lesions that the bleach did not remove can be removed mechanically: you will still have to remove the darkened layer of wood, so this may also remove fungus-affected wood.

After the first pass with a grinding machine, the condition of the treated logs is assessed. If there are dark spots, they are treated with bleach again. Only this time you need to act carefully: light spots on wood are no less pleasing than dark ones. Therefore, the sequence is as follows: first, generously moisten the darkened area, and then rub it with a brush, “blurring” the boundaries of the treated area. After the bleach has dried, the frame is sanded with a fine-grain abrasive until smooth.

In case of deep damage, simply sanding is not enough: no one will remove two or three centimeters of wood

Then, they are immediately coated with an antiseptic, fire retardant and finishing composition (for example, Senezh wood protection compositions). You can use combined products, or you can use three different ones. You just need to select compatible compounds.

If it works, take all the products from the same brand: there will be no compatibility problems. If this does not work out, before purchasing a large batch, buy the selected products in small packaging. Use them on some unnecessary piece of wood (cover it with a layer of the last compound applied to the walls) and try how they behave in combination. It is necessary that they do not react and do not stain the wood. For example, some antiseptics in combination with chlorine give a pink color. Also check whether the product lays evenly, does not roll down and how well it is absorbed.

Using the same test, determine how much you like the selected topcoat tone, and how many layers you will need to apply to achieve the desired result.

Before buying a large batch of bleach, antiseptic and paint, test them all on an unnecessary (or invisible) piece of wood

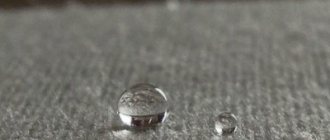

Unfortunately, it is impossible to determine the effectiveness of the protection. Unless you can see if the water will be repelled. After the topcoat has dried, spray the board and see what happens. Drops should roll off but not be absorbed.

How to avoid repeated defeats

Moreover, ventilation is not only indoors. This is also the airflow of the facade, if there is external finishing, and the space behind the internal finishing (nailing the clapboard onto the sheathing). It is equally important to ensure proper drainage of water in wet areas.

With the right approach, the log house looks amazing

For Russian baths, it is very important to dry everything well after the procedures. To do this, create a draft and throw a couple of logs into the firebox. After a couple of hours, most of the moisture will evaporate. Only after this can the bathhouse be closed.