Why do you need foil film?

Foil film is used as a vapor barrier in rooms with elevated temperatures - in baths and saunas. This film does not melt and does not release hazardous substances even at a temperature of 120°C. Also, the reflective properties of the film are very important when installing modern steam rooms, because it is necessary to warm up the sauna in a short time and with a minimum of energy consumption.

But foil vapor barrier is justified not only in the sauna. If, when building a frame house, you replace the usual vapor barrier with foil, with the same heating power you can increase the temperature in the rooms by 2°C.

But reflective vapor barriers must be used wisely. Thus, it is not recommended for internal insulation of buildings made of heat-intensive materials (brick and concrete). Frozen walls will only worsen the microclimate. But in a wooden house made of logs or beams, foil film will be very useful for internal insulation.

Reflective vapor barrier is also suitable for an unheated loggia - a film laid under the floor covering will make it warmer. When glazing open balconies, when the entire perimeter is sheathed with sandwich panels that do not conduct heat, foil film will reduce heating costs.

Properties and types of foil films

The foil film not only protects the insulation from moisture penetrating from the premises. When using a foil vapor barrier in a sauna, you can protect the inner lining from mold and rot, which inevitably appear due to constant condensation after the steam room is turned off. Thanks to the reflection of heat, condensation simply does not settle.

The characteristics of foil film depend on the materials from which it is made:

- based on kraft paper - such films are inexpensive and easy to handle, but are hygroscopic and tear easily;

- polymer-based - they are strong and durable, but more expensive;

- with aluminum coating - the thickness of the aluminum layer of these films starts from 0.3 microns, but the smaller the coating, the worse the heat-reflecting properties;

- with aluminum foil - films with a foil thickness of 10 microns or more provide the maximum level of heat reflection (up to 97%), but are susceptible to corrosion.

Thus, it is most rational to insulate a bathhouse using polymer-based films coated with aluminum - they are not subject to corrosion, can withstand high temperatures and are quite durable, which simplifies installation.

Films based on kraft paper can only be used in dry rooms - they are not suitable for the kitchen or bathroom. And for heated floors, films with aluminum foil are better suited, which evenly distributes heat, smoothing out possible cold bridges if the pipes are not laid tightly enough.

Films Ondutis R Termo

Used to protect insulation, wooden and metal structures.

When insulating an attic floor or installing a roof in a residential attic, R Termo foil film allows you to retain heat, reducing heating costs.

Vapor barrier has a water resistance of 1000 mm water column and minimal vapor permeability - less than 10 g/m2 per day. At the same time, it calmly tolerates temperature changes from −40 to +120°C. Strength is indicated by a breaking load of 150 N along and 130 N across - the Ondutis R Termo film can withstand an adult and fairly well-fed person.

Instructions for using vapor barrier Izospan V, C, D

Izospan vapor barrier films are also waterproofing. They do not allow water or steam to pass through. What are the differences between Izospan A and B? The fact is that B does not let steam through, A does. That's it in short.

Made from different materials. There are films, nonwovens and fabrics made of polyethylene and polypropylene. Fabric-based materials have very high strength characteristics. Their use is justified in places where they may be subject to high mechanical loads. Technical characteristics of Izospan vapor barrier films are given in the table.

| Name | Maximum elongation in transverse/longitudinal direction N/50 mm | Vapor permeability | Withstands water pressure, mm.water.st. | Withstands ultraviolet radiation (without protective coatings) for at least months |

| Izospan RS (рс) | 413/168 | No | 1200 | 3-4 |

| Izospan B and B fix | 130/107 | No | 1200 | 3-4 |

| Izospan S | 197/119 | No | 1200 | 3-4 |

| Izospan RM (rm) | 399/172 | No | 1200 | 3-4 |

| Izospan D (D) and D fix | 1068/890 | No | 1200 | 3-4 |

| Izospan DM (DM) | 700/650 | No | 300 | 3-4 |

The main task of these materials is to cut off steam from the insulation as efficiently as possible and at the same time provide protection from moisture. A “side” but important effect is protection against the penetration of mineral wool particles into the indoor air. It is used in the construction of walls, ceilings, roofs, and when constructing concrete floors. Vapor barriers are often part of the “pies” above, simply because they perform other tasks.

Rules for installing vapor barriers

The main task when laying vapor barrier films is to achieve as complete a seal as possible. It is necessary to let as little steam as possible into the insulation. We make all connections reliable using sealing and connecting tapes. The basic rules of vapor barrier do not differ from those described above:

- On the walls and roof we start from the bottom.

- The next canvas overlaps the first by 10-20 cm.

- We make vertical joints with an overlap of at least 20 cm.

Vapor barrier materials are usually installed from the inside of the room

- We glue all connections with double-sided tape.

- We make connections to building materials using mounting and connecting tapes.

- When used for flat roofs and ceilings, the vapor barrier is applied to the walls and sealed there.

In addition to gluing the joints of the canvases, it is also important to use even strips-bars for final fastening of the material. They press the material tightly, sealing at the same time the holes that the fasteners invariably pierce.

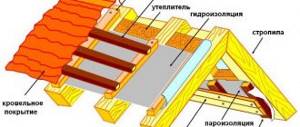

Pitched roofs - insulated and non-insulated

Pitched roofs can be insulated or cold. In any case, a vapor barrier is installed on the attic side. It does not let steam into the insulation and this is its main task for this case. But Izospan is recommended differently for insulated and non-insulated roofs:

- for insulated roofing it is better to use RS, B or B fix, they differ in strength (RS is stronger);

- for non-insulated - D or D fix, DM (DM is stronger than just D).

Application of Izospan vapor barrier for roofing

Izospan RS and B films have one rough side and the other smooth. So, Izospan V and RS should be turned with the rough side into the room. We unfold the smooth one towards the insulation or roofing material.

Flat insulated roofs

When insulating a flat roof, a vapor barrier is laid on the ceiling under the insulation. The purpose of this layer is twofold. On the one hand, do not let steam into the insulation, on the other, cut off moisture from the ceiling in the event of a leak.

How to use Izospan when insulating a flat roof

In this case, it is recommended to use Izospan D and RM, RS. They have sufficient strength to withstand the loads that will certainly arise when laying insulation.

Izospan B: instructions for use for walls

In frame walls, Izospan V vapor barrier is installed on the side of the room. The task of vapor barrier is to let as little steam into the insulation as possible. Whatever gets into it (and it will definitely get in) will come out, since there is a vapor-permeable Izospan A film on the outside. But the less moisture there is, the better.

Izospan A and B - instructions for use for frame walls

In this case, Izospan RS (RS) and B are recommended for use. The strength of RS will be required only if you are planning a break in work and the cladding will be mounted on the walls after some time. The smooth side of Izospan B goes to the insulation, the rough side is directed into the room. This is the basic rule.

Please note that in the diagram Izospan B is nailed to the racks with strips, and sheet wall covering material is mounted on the sheathing strips. This option is good because it allows you to use a strip to isolate the holes made by the fasteners. There is another option - you can attach the film to the stands using a stapler and staples with wide backs. The inconvenience is that the rack will not be visible and it is unclear where to attach the sheet material. But the option is possible, although not ideal.

Attic and interfloor ceilings

A vapor barrier in a wooden floor pie is needed from the lower room. If you look from bottom to top, the sequence goes like this:

- ceiling filing;

- vapor barrier (Izospan V);

- rough ceiling;

- insulation between beams;

- vapor-permeable film (Izospan A);

- floor laid on a counter-batten.

Which Izospan to lay on the ceiling side in the attic and interfloor ceilings

How does the vapor barrier work in this cake? It does not allow vaporous moisture to pass from the room into the insulation. If there is a leak from above, it will also retain moisture, but this is an emergency and the water will not hold for long.

Which side should Izospan B be placed in this case? The rough side goes into the room, the smooth side goes up. When installing, try to damage the panel as little as possible. If a hole has formed somewhere, seal it with tape. Branded is better, but you can also just use a good one, with a high-quality sticky layer.

Basement ceiling

The basement floor is built according to a completely different logic. Here steam will flow from top to bottom. From a warm room with humid air to a cooler and drier underground. And so that moisture penetrates into the insulation as little as possible, we put a vapor barrier on it (the thermal insulation). The steam that gets into the insulation will either fall on the ground in the form of drops, or will be carried away by the wind in a vaporous state.

Vapor barrier Izospan B and RS in the basement

Izospan B and RS are recommended for use. When laying, we turn the rough side towards the insulation, the smooth side faces the room. The films are laid on beams and secured with slats - counter-battens. The flooring is already being laid on them.

For better heat conservation, you can use vapor barrier materials with a metallized layer: RF, FS, FD, FX. In this case, the thickness of the counter rails is at least 35 mm. This is the minimum gap that ensures effective heat reflection.

Screed on concrete base

If it is necessary to level a concrete slab, a screed is often used. To prevent water from the solution from leaking into the ceiling, it is advisable to use waterproofing. This can be a coating or rolled material. The cheapest is film. But you will have to walk on it and it is unlikely to remain intact. Especially if the screed is reinforced. Is it possible to pour screed without film? If you are not afraid of flooding your neighbors below, then you can. Or if you use coating waterproofing. Without it, most likely, the screed will not have the required strength. A certain amount of moisture is required for the formation of cement stone. And it will partially go into the slab, and partially seep through the cracks. What the result will be is unknown. Accordingly, it is advisable to use film.

Application of waterproofing in floors on a concrete base

It is recommended to install Izospan D (D) or Izospan RM (RM) vapor barrier under the screed on a concrete base. These are waterproofing materials of increased strength. It doesn’t matter which side these materials are laid on. But Izospan D has very high strength and it makes sense to use it only if reinforcement will be laid. For a screed without reinforcement, RM is quite sufficient.

If there are significant depressions in the base, it is better to seal them; it makes sense to cut off humps that are too protruding. This will not only increase the chances of preserving the film, but will also make the screed thinner. And this is a significant saving.

Installation of foil films

The installation process of foil vapor barrier is practically no different from the usual one:

- The film is rolled out horizontally and begins to be attached from bottom to top with an overlap (10 cm). It is important not to confuse the inside and outside sides - foil vapor barrier is installed only with the shiny side inside the room.

- It is nailed to wooden structures with a mounting stapler, and to concrete or brick walls - with a special mounting tape.

- If a vapor barrier is being installed for the entire room, first it is laid on the floor with an extension of 10 cm onto the walls, then the walls are sewn up and lastly - the roof insulation.

- To ensure a vapor barrier, all joints are first fixed with mounting tape and then taped with metallized tape. All passage elements are also glued with mounting tape - chimneys, pipes, electrical cable exit points.

- A beam with a thickness of 3 cm is nailed on top of the film - it provides a ventilation gap, which is mandatory for foil films.

In order for the vapor barrier to last a long time, it is better to glue the film together with butyl rubber tape, and use it to seal the places where the film is pierced with nails or a stapler. It is also advisable to additionally fix the overlap with a rough filing board - the adhesive tape may come loose over time.

6 votes, please rate the article:

Izospan A: instructions for use

Group of materials Izospan A - vapor-conducting windproof membranes that do not conduct liquid water. The exception is Izospan A base. This membrane is only wind protection. It does not interfere with the passage of steam and water. Used in the ceiling above a ventilated facade, stuffed from the underground side. Protects mineral wool from blowing and does not interfere with the removal of moisture from the insulation.

| Name | Maximum elongation in transverse/longitudinal direction N/50 mm | Withstands steam density, g/m2*24 h | Withstands water pressure, mm.water.st. | Withstands ultraviolet radiation (without protective coatings) for at least months |

| Izospan AQ proff | 330/220 | 1000 | 1200 | 12 |

| Izospan AQ 150 proff | 270/160 | 880 | 1200 | 12 |

| Izospan AS 130 | 240/130 | 880 | 1200 | 3-4 |

| Izospan AS | 190/110 | 880 | 1200 | 3-4 |

| Izospan AM | 160/100 | 880 | 1200 | 3-4 |

| Izospan A | 190/140 | 2000 | 300 | 3-4 |

| Izospan A base | 170/100 | 1700 | — | 3-4 |

| Izospan AF+ (NG) | 1400/1000 | 800 | 900 | — |

| Izospan A with OZD (RP-1) | 190/140 | 1800 | 300 | 3-4 |

To understand where and how best to use Izospan A, look at the characteristics. Once again: the film is not blown (retains heat), removes steam, and does not allow water to pass through. These properties are needed in the following constructions.

Rules for laying and installing windproof, vapor-permeable membranes

Vapor barrier materials are laid on vertical, inclined and horizontal surfaces. Despite the fact that the designs are different, the installation rules are no different. Here's what to remember:

The basic rule of installation is to make overlaps and carefully glue them

- On pitched roofs and walls, work begins from below. On horizontal roofs - from one of the walls.

- The second layer of material is laid overlapping. That is, one panel overlaps another by no less than:

- 10 cm on walls;

- 15 cm on roofs;

- 15-20 cm in overlaps.

- Vertical joints (if any) have the same dimensions.

- All connections of the canvases are glued using double-sided adhesive tapes.

- The connection to the walls and rafter system is also glued. To adjoin the rafter system, it is recommended to use self-adhesive sealing tape Izospan. For joints - KL, for adjoining the structure KL+.

The task of vapor-permeable waterproofing and windproofing is to allow steam to pass through, but not to allow moisture to enter in a liquid state. Therefore, the strength of the joints is important.

On a pitched roof, on top of insulation

The vapor barrier is laid on top of mineral wool and covered with any roofing material. Let's see how everything works. Here it is necessary that the steam that gets into the insulation from the attic is removed. At the same time, condensation and possible leaks did not enter the insulation. So you need to remove steam and not let water through. This is what Izospan A does.

Application of Izospan A in an insulated pitched roof

The membranes are turned with the logo facing towards you. It is better to lay it not under tension, but with sagging. In this case, condensation, which cannot be avoided on the roof, will flow into the center, and then into the gutter of the drainage system. This way it will dry out faster even in damp times, moisture will be retained less, and there is less chance of it getting into the insulation.

On top of the vapor barrier, slats are placed along the rafters, and then across the sheathing for installation of the roofing material. With this device and the presence of ventilation holes in the roof, the vapor barrier will be blown and dried.

In frame walls on the street side

Typically, indoor humidity is higher than outdoors. And no matter how much we protect the walls, steam leaks into them. These are the laws of physics. And since he hit the wall, he needs to be taken out. So the task here is the same - to let off steam. This can only be done from the street side. So Izospan A in frame walls is also placed on the street side. Here you can use all types of Izospan A, except for the “base”.

Izospan A - instructions for use in a frame wall

When using Izospan A “in its pure form”, it does not matter which side it is laid on. We unfold all other modifications - AS, AQ, AM - so that the logo is facing out.

When insulating walls with mineral wool and for ventilated facades

With external insulation of walls, in ventilated facades, the situation is almost the same as with the frame. Some moisture is seeping into the wall from the room. Then it penetrates into the insulation. Since wet mineral wool is a poor insulator, care must be taken to ensure that this steam is quickly removed. At the same time, it is necessary to protect the cotton wool from getting wet and retain heat as much as possible. That is, the problem is solved by the same vapor-permeable membranes of the Izospan A group.

Application of Izospan A for external wall insulation and in the system of ventilated facades

Any vapor barrier for use in the case of external wall insulation, except Izospan A with OZD, AF+ and base. The installation rule is the same - turn it with the logo facing you. For use in ventilated facade systems, Izospan AF+ is recommended. If a metal structure is used, its strength will ensure that the vapor barrier will not break. If the ventilated facade is covered with wooden blocks, Izospan AM, AS and AQ in any of the options may well be suitable.

Ceiling over a ventilated subfloor

The floor insulated with mineral wool over a ventilated base has its own characteristics. First and most important, for the scheme to work, the subfloor must be ventilated. This means that there must be vents in the foundation. And they must be open even in winter, otherwise you will have wet insulation and cold in the house.

How does this pie work? From the side of the house, moisture and steam seep into the insulation. If you simply line the insulation with mesh or slats, the wind blowing underground will do an excellent job of removing moisture. But at the same time, it will carry away heat and gradually remove mineral wool particles, reducing its thickness. To get rid of heat and insulation from escaping, Izospan A base vapor barrier is used. It allows steam and moisture to pass freely in both directions, but does not allow wind to pass through.

Izospan A: instructions for use in the ceiling above a ventilated subfloor

The following objection may arise. Moisture from the soil will evaporate and enter the insulation. Under certain conditions, it condenses on the membrane, causing the insulation to become wet. Maybe it’s better to use a vapor barrier with waterproofing properties? No. This won't work. If the membrane does not conduct moisture, then the moisture that condenses or gets into the insulation will remain there. Because it will not heat up enough to evaporate and be released as steam. In a couple of years you will have bags of water hanging from the ceiling and completely wet and unusable insulation.

And in order to reduce the evaporation of moisture from the soil, a dense film is placed in the underground, a layer of sand (any kind, but without clay and dust) is poured on it in a layer of 5-10 cm. The film retains most of the moisture, and the sand works as an adsorbent, absorbing fallen condensate. It (the sand) is also dried by the passing wind.

Interfloor and attic floors

In ceilings, steam enters from below and must be discharged from above. Therefore, a vapor barrier is placed at the bottom to protect against moisture, and a vapor-permeable wind barrier is placed at the top. In this case, it also additionally protects against the penetration of mineral wool particles into the room. You need to put Izospan in the same way - the logo should be facing you.

Izospan A for flooring - in interfloor and attic floors

In the interfloor ceiling, to reduce the cost, vapor-permeable Izospan can be replaced with non-woven material (any type of geotextile). Its main function here is to protect against the penetration of small mineral wool particles into the air. But you can do this only if the flooring is sheet material in two layers, with the seams spaced apart. Otherwise, moisture may seep in and then simply the non-woven material will not protect the insulation from getting wet.

In the attic floor, such a replacement is not considered at all - here it is also necessary to protect the heat from weathering. So wind protection is necessary here.

Also note that the vapor barrier is attached to the beams with counterbattens. And the flooring is already laid on them. Counter rails are needed to create a ventilation gap, which is a prerequisite for moisture evaporation. It is important.