The arrangement of a recreation area on the shore of a reservoir or on a slope assumes that the floor in the bathhouse on screw piles will be installed taking into account the characteristics of alluvial or sedimentary soil. It is these rocks that make up the soil on the banks of a river or pond, slopes, and hills.

The foundation for a bathhouse on screw piles is suitable for location on a slope, so it is possible to adjust the height of the pile

Advantages of a foundation on screw piles

Installing a floor in a bathhouse on screw piles is much easier to do than on a massive foundation. Advantages of this design:

- the foundation can be installed very quickly with your own hands;

- screw piles noticeably compact the soil, ensuring the stability of the entire structure;

- the foundation is convenient to repair if necessary;

- installation of screw piles is easy to do using modern devices and devices;

- the foundation can be installed in any weather;

- screw piles provide effective automatic ventilation of the underground space of the bathhouse;

- the service life and reliability of the pile foundation are quite long;

- a properly installed floor will protect the walls of the bathhouse on screw piles from the absorption of sediment and melt water from the soil;

- a screw foundation can be installed on unstable soil, which swells and swells during the season of heavy rainfall.

The foundation for a bathhouse on stilts can be installed even in winter

A screw pile foundation is installed very quickly.

The advantages of a pile foundation make its installation quick, and its operation reliable, simple and convenient. The main thing is to first study the properties of the soil in the area chosen for the bathhouse, carry out all the calculations correctly and carry out the necessary work in strict accordance with the instructions.

Screw piles must be selected depending on the type of soil

Scheme for installing a screw pile in the ground

Screw piles are installed for all load-bearing walls and elements

When to use a pile foundation

In most cases, a pile foundation for a bathhouse is built on a soil composition that is not capable of providing the necessary stability to the building. Such places include:

- quicksand;

- sandy soils;

- peat bogs;

- loams excessively saturated with water.

In such areas, the piles must be lowered to the level of the dense soil layer so that all the load forces created by the structure are transferred to it.

It is recommended to use a pile foundation on soils that freeze below the one and a half meter mark in winter. To fill a strip base, large volumes of excavation work will be required, while installing piles will cost much less.

The next option when it is necessary to arrange just such a foundation is if the site allocated for construction has complex terrain. To level it, you have to incur unplanned and very significant costs, and it is better to build the foundation on pile supports.

Pile foundations are also used on dense and difficult-to-cultivate soils, when digging a foundation pit is difficult and quite expensive.

What is the floor in the bathhouse made of?

The floor in a bathhouse on screw piles can be made from different materials. Concrete screed and coniferous wood are mainly used. Installing a concrete floor will require significant material costs. However, such a floor is resistant to constant exposure to moisture. Therefore, the concrete floor in the bathhouse will last for decades. Wood is a lower cost material. However, when exposed to moisture, a wooden floor quickly deteriorates. Treatment with an antiseptic will significantly slow down this process. But after 7-10 years, the wooden floor will need to be replaced.

Scheme of fastening various floor materials to a pile

The concrete floor in the bathhouse is most resistant to moisture

The advantages of a wooden floor are not only the low cost of the material. If necessary, you can replace damaged elements without completely changing the coating. If you regularly re-treat wooden components with an antiseptic, you can almost double the service life of such a floor. The optimal option is when a concrete screed is made in rooms of high humidity - steam room and washing room. You can make a wooden floor in the locker room and rest room, because the humidity level here is much lower.

It is better to place a wooden subfloor in a bathhouse in the locker room area

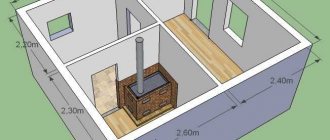

General layout of the floor of a frame house

The upper frame of beams on the fundamental supports is also lags , which in itself reduces the cost of the construction budget. The structural floor pie in a frame house on stilts has the following diagram:

- Rough floor. The basic base is assembled from the sheathing and bottom filing. The substrate used is: edged board, chipboard, OSB or multilayer plywood.

- Waterproofing. The best option is a perforated membrane, an alternative is film.

- Insulation. Options for thermal insulation material: basalt wool, extruded polystyrene foam, expanded clay.

- Vapor barrier. Prevents the formation of condensation and wetting of the insulation layer.

- Substrate. The choice of further technology depends on the type of floor covering.

If you plan to lay parquet, laminate or floorboards, then lay multilayer plywood . For decoration with tiles or linoleum, a dry screed is suitable. The “water floor” system is installed in a self-leveling screed.

Preparatory work

So, the foundation is installed and the walls are erected. Now we are making the floor in the bathhouse on screw piles. You need to thoroughly prepare for this work, study the technology, purchase everything you need, and invite assistants.

For work you will need the following materials:

- tongue and groove board;

- beam;

- fastening material - nails, etc.;

- cement;

- coarse sand;

- expanded clay and/or other bulk materials;

- roll waterproofing;

- antiseptic composition;

- mineral wool or other insulation.

Tools and equipment for work will require:

- construction mixer;

- tank for mixing the solution;

- wood hacksaw;

- grinder saw;

- construction knife;

- hammer;

- mittens, work clothes, rags.

The list of necessary tools and materials can be specified after it has been determined from what material and in what way the floor in the bathhouse will be installed on screw piles.

Floor insulation: general rules

Before installation and insulation of the floor, it is necessary to carry out an antiseptic treatment of all wooden components of the finished structure. A special composition for this can be purchased at a construction supply store. An antiseptic will protect the wood from the penetration of harmful microorganisms that can destroy it.

The depth of floor insulation depends on the premises of the bathhouse

If a bathhouse on screw piles will be used in winter, floor insulation begins with laying insulation between the supporting elements of the building. Most often, mineral wool (layer thickness 25 cm) or polystyrene foam (layer thickness 15 cm) is used for this.

Scheme of insulation of a concrete floor in a bathhouse

If the thickness of the beams is insufficient for laying insulation, additional bars are attached to them perpendicularly. Waterproofing is pre-installed. On top of it, between the beams, the bottom layer of insulation is laid out. The top layer is laid between additional bars. Next, another layer of waterproofing is laid, on top of which the finishing floor is mounted. An insulated layer in a bathhouse on screw piles will extend the service life of the structure and significantly increase the comfort in the bathhouse.

Scheme for insulating a wooden floor in a bathhouse

Stages of work execution

To install a screw foundation for a bathhouse, you need to perform the following algorithm of actions.

Determining the depth of immersion

This value depends on the level of dense soil layers. The fact is that the construction of a “hanging” version of the foundation ultimately ends in subsidence or deformation of the grillage part, which entails the destruction of the outer walls.

Conventional calculations to determine the bearing capacity of the soil allow one to establish reliable data that shows only the current situation at the construction site. If the groundwater level changes, seasonal movements, or frost heaving, all your calculations will lose their relevance.

There is only one, but the most correct way - test drilling or complete installation of one pile support. The desired value will be the depth at which the pile begins to contact the dense soil layer.

Determination of height above the soil surface

The height of the upper parts of pile supports is influenced by the following factors:

- snow level in the winter season;

- water flooding during floods and rains;

- location of groundwater.

You can find certain data in the current SNiPs, others will have to be clarified at geological exploration or meteorological stations.

The main goal is to raise the bathhouse on a pile foundation to such a height as to eliminate or reduce the degree of negative impacts. As a rule, the bathhouse is raised above ground level by forty to sixty centimeters, which is quite enough to prevent the walls from coming into contact with snow and water.

This condition does not apply when building a bathhouse on a site with a slope or uneven terrain. In this case, the height is determined by the smallest indicator.

Base installation

Effective insulation of the floor in a bathhouse on screw piles is done using a base, which is mounted around a pile-screw foundation. The plinth reliably closes the free space under the bathhouse floor from the penetration of cold air and significantly improves the appearance of the finished building.

The empty space of the plinth is covered with some panels

The main materials for the base are thermal insulation boards and decorative panels. An additional layer of heat insulation is laid between them. Typically, penoplex, polystyrene foam and similar materials are used for this. Sealing the joints between the panels after assembling the base is done using polyurethane foam.

To reduce heat loss, insulate the basement under the bathhouse

You can insulate the base of a bathhouse using penoplex.

Types for building a foundation for a bathhouse

As a rule, a bathhouse is not a large object, and this is the main condition when choosing a foundation. Driving posts will require special construction equipment, the rental of which is expensive. In addition, each driven reinforced concrete pile will have to be capped. It turns out that this type of foundation is suitable for the construction of a mago bath, so many people prefer screw and bored options.

Bored

This option is used for almost any small object, which includes a bathhouse. There is only one difficulty here - drilling wells.

The bearing capacity of a bored pile column is formed as a result of work in two planes - from the support located on the underlying soil layer and from the interaction of the side surfaces of the column with the soil in contact with them.

Distribution of load-bearing capacity: from 50 to 75% - supporting, 50 - 25% - lateral.

Differing in similar features, the bored column may not reach a durable soil layer located at great depths, but fulfill its functional purpose thanks to the work of the side parts. In this case, the piles are called “hanging” and it is not recommended to use formwork structures for their installation.

You can construct formwork from steel, asbestos-cement or plastic pipes, use box-section structures for this, but in this case the cost of constructing the foundation will approximately double, because in addition to the formwork you will need piles that maintain load-bearing capacity. The concrete solution is poured directly into a well drilled in the ground.

Taking into account the fact that the bathhouse is not capable of creating a significant load, calculations for installing bored pile supports will not be needed. But there is a simple technique that you still have to use:

- the diameter of the wells should be twenty to thirty centimeters, the drilling depth should be from two to two and a half meters. If this condition is not met, this means that the pile has reached a dense soil layer, and it can be left at that depth;

- pile supports are installed at corners, external walls and internal partitions;

- installation step - no more than three meters (for a bathhouse 6 x 4 m, if there is only one load-bearing internal wall - 9 supports).

If wells of the specified diameter cannot be constructed, it is allowed to reduce their diameter to ten centimeters by installing small supports in triangles in increments of 30 - 40 cm.

Small piles are united by a common concrete cap.

Screw

Such supports are suitable for any small structure. Their load-bearing capacity depends on support on dense soil.

Among the main advantages are:

- maintaining the integrity of the surface layer;

- speed of foundation construction;

- reasonable installation costs.

The pile, which is a steel pipe with blades, is screwed into the soil composition. On the upper sections of the pipes, supporting metal frames (grillages) are installed, on which the structure rests. It turns out that the bathhouse seems to “hang” in the air. Screw supports are positioned every two and a half to three meters, without fail - at corners and load-bearing walls. Pile diameter – from 108 mm.

Technologically, the process does not cause difficulties, but there are certain features:

- the pile should be buried at least 1.6 m, for which it will be necessary to conduct a study of the soil composition;

- during the screwing process, abrasions will inevitably appear on the walls of the pile, which will lead to corrosion of the metal;

- installation of piles must be carried out strictly vertically, the heads are aligned along a single horizontal line. This entails additional measures to trim or build up installed supports;

- since the bathhouse on a pile-screw foundation is raised above the ground, the water supply and drainage for the bathhouse will have to be carefully insulated;

- for greater stability, builders recommend reinforcing the piles before concreting them;

- When performing work in the winter season, preliminary drilling should be carried out, reaching the freezing point of the soil.

Installation of a pouring floor

The optimal solution is considered to be a poured floor in a bathhouse on screw piles. In the cold season, it is necessary to carry out mandatory insulation of the entire structure.

A large amount of water gets on the floor in the bathhouse, so it is necessary to increase its moisture resistance and trouble-free removal of used water. To do this, it is necessary to equip a special drain ladder. Through it, water will flow into the sewer pipeline or into the drainage system.

Diagram of a pouring floor in a bathhouse

Installation of the pouring floor begins by laying logs on the grillage. They are placed strictly horizontally without tilting. Edged boards made of coniferous wood are fastened to the logs with nails. Gaps 7 mm wide or more are left between them. Even if the wood swells, the gaps between the individual elements will still remain. Used water will pass through them freely.

To protect the subfloor from the accumulation of water, you need to install a concrete screed in it in the shape of a cone with an inclination towards the sewer or drainage system.

Advice! To avoid the appearance of unpleasant odors and/or harmful microorganisms, the concrete structure must be regularly washed, cleaned and treated with special compounds.

To prevent anything from rotting and moisture from accumulating, it is necessary to install a concrete bowl with a drain in the bathhouse

Dry wooden floor in the bathhouse

The dry floor is laid from boards in 2 layers. First, the subfloor is installed. A waterproofing agent is placed on top of the boards. Then the insulation is laid. On top of it - 1 more layer of waterproofing. Finally, a finished floor covering is laid. For this, a tongue-and-groove board made of durable softwood is used. Individual floorboards must be laid close to each other without cracks or gaps. When laying the finished floor, a slope to one of the corners of the room is required. A hole is made here under which the siphon is attached. This will help you easily remove used water during use of the bath.

Concrete floor in the bathhouse

Before pouring a concrete floor, it is necessary to carry out preliminary work in a bathhouse on a screw foundation:

- laying water supply and sewerage pipes;

- installation of a ladder on which the finishing floor will be laid;

- forming a cushion of bulk material under the base of the bathhouse building;

- laying roll waterproofing on foundation sections;

- laying insulation.

Scheme for preparing concrete mixture

Nuance! It is better to fill the pillow for forming a floor cake from bulk material of different fractions, which must first be completely dried.

Insulation of concrete floor

The concrete floor in a steam bath on screw piles begins to be insulated when the screed sets and hardens. The following is usually used as insulation:

- extruded polystyrene foam;

- expanded clay;

- perlite;

- mineral wool.

Insulation materials for bathhouse floors: perlite, expanded clay, expanded polystyrene, mineral wool

Before laying the insulating layer, it is necessary to completely clean the surface of the concrete floor from foreign objects, dust, debris, etc. then lay a roll of waterproofing material. Fractional insulation is applied as part of a special mixture. After it dries, a cement screed is poured on top.

Tile insulation requires sealing the joints between panels after installation. This is usually done using polyurethane foam. After it dries, a 2nd layer of roll waterproofing agent is applied. To evenly distribute the load on the floor in a washing bath on screw piles, in a steam room or in another room, a reinforcing mesh is laid.

You can insulate a pouring floor in a bathhouse using expanded clay; it must be laid before the concrete screed

How to do it yourself?

After drawing up the project, carrying out preparatory work and purchasing building materials, you can proceed directly to installation work.

The first stage is creating markings on the site . It is necessary to designate the places where the screw supports will be installed, carefully checking all distances and angles.

At the designated points, shallow excavations of 15-30 cm are made. This will avoid spontaneous displacement of the piles at the very beginning of their screwing into the ground. The distance between the support points should be 2-3 meters, depending on their size, bath area and bearing capacity of the soil.

To screw in piles manually, long metal crowbars are used , which act as levers. This work should be done by two or three people. If it is possible for special equipment to enter the site, installation can be carried out mechanically. This will make it possible to save time and effort.

Screw piles must be immersed in the soil to a depth of at least 1.5 m. The structures are screwed into the ground until their tips reach the dense layers of the earth. At the same time, it becomes much more difficult to rotate the piles manually, which is a sign of the final immersion of the support.

During the screwing process, it is necessary to carefully ensure that the structures are located in a strictly vertical position. Only minor deviations of 1-2 degrees are allowed .

When all the supports are installed and leveled in height, they are concreted from the inside. Concrete mixture is fed into metal pipes, which should preferably be mixed immediately before pouring.

When the cement-sand mixture has finally hardened, caps are installed on the upper parts of the piles. Next, the strapping is installed. For a wooden bathhouse, the best choice would be a timber structure.

Boards of a given thickness are fixed along the entire perimeter of the foundation, which must be firmly connected to each other to prevent spontaneous displacement of the pile supports.

An important point is the arrangement of the foundation for the stove . Brick, cast iron and steel fireboxes place a fairly large load on the surface of the base, so they cannot be built directly on the floor. Additional foundation structures must be located underneath them.

In addition to the main pile-screw foundation, it is necessary to equip a concrete foundation. Its area does not have to be large.

The dimensions and area of the additional foundation are selected taking into account the width and length of the furnace that will be built on it.

To prepare the foundation for a massive furnace, you should prepare a foundation pit in the selected area according to pre-made calculations. Its depth should reach the level of soil freezing.

A sand and gravel cushion is poured onto the compacted bottom. The layer of crushed stone should be at least 15 cm, the layer of sand - from 20 cm. On top of the sand layer, you can fill another layer of crushed stone of the same thickness.

Next, wooden formwork is installed around the perimeter of the furnace foundation, and a reinforcement frame is placed in it.

The next stage is pouring concrete. The upper level of the base should be approximately 5-6 cm below the floor that will be installed in the bathhouse. When the concrete has completely hardened, you need to remove the formwork and treat the walls of the furnace foundation with waterproofing - for example, tar. At the next stage, you can begin installing the log house .

As a rule, when building a wooden bathhouse, it is installed on a metal grillage. This design is created according to a simple scheme: rigid metal channels or I-beams are fixed to the pile heads along the entire perimeter of the foundation, as well as in its central zones. These elements are connected to the heads using electric welding.

The grillage will create a reliable support for the wooden elements of the bathhouse and will perform a load-bearing function, so for its manufacture you need to use metal structures with good anti-corrosion treatment.

Floor tiling

Ceramic tiles can be laid on top of the wooden floor in the bathhouse. In this case, instead of boards, fibreboard, fiberboard or plywood are used for the rough coating.

In the washing compartment you can lay tiles on the floor in the bathhouse

Ceramic tiles are laid on top of the laid sheet covering. This is done in the usual way. Under the tiles, you can lay a system heated floor in a bathhouse on screw piles. You can use a hydraulic or electric infrared option.

In the locker room you can install a heated floor in the bathhouse

Electric heated floor installation

Water heated floor diagram

Why choose screw supports for self-assembly?

Constructions of this type are best suited for doing construction work yourself.

Firstly, when using screw piles, the use of expensive special equipment is not required , which for various reasons cannot always be delivered to the site (for example, due to the impossibility of driving to the construction site). Pile supports can be screwed into the ground yourself with the participation of one or two assistants, using lever mechanisms.

Secondly, such designs are initially sold ready-made. Piles can be installed immediately after they are delivered to the site.

For comparison, bored and drilled supports are created on site. This requires additional time for the concrete to harden and gain strength.

Preventive measures

A bathhouse on screw piles has a high level of moisture; special preventive measures will help make the floor inaccessible to fungus and mold, which inevitably appear in a humid environment. During the construction process, all structural elements used must be coated in several layers with a special antiseptic composition.

To prevent the floor from rotting longer, it is necessary to cover it with an antiseptic against fungus.

It is imperative to use high-quality waterproofing materials. This can be roofing felt or plastic film. These measures will help increase the service life of the structure and protect it from rotting and premature destruction.

Scheme of waterproofing the floor in the bathhouse

If pockets of rotting of the wooden material are noticed, the entire structure must be dismantled. Damaged elements need to be replaced.

Nuance! After thorough drying, treat all components with an antiseptic and dry again. Before assembly, you need to coat the wooden elements with wax or water-repellent varnish.

Selection of structural elements and materials

The reliability, durability and thermal efficiency of the floor largely depend on the materials used. Let's consider acceptable options and indicate unacceptable solutions.

Attention to the quality of floor beams

In frame house construction, wood is mainly used for tying screw piles. Usually softwood lumber is used: larch, pine and spruce.

Useful: Correct vapor barrier in a frame house

The main requirement is the use of dried materials . The moisture content of the timber should not exceed 12%, otherwise deformation of the structural parts may occur after their installation.

Arrangement of the grillage is possible in several ways:

- Laying a monolithic beam measuring 20*15 cm. When constructing a two-story house, you can use a beam 20*20 cm.

- Grillage made from assembled boards. A budget option. Each beam is formed from two to three boards. The output should be a beam with a cross section of 20*15 cm.

When the boards are securely fixed, the “batch” method is not inferior in strength to strapping made from solid beams .

Bottom trim options

When choosing material for the base, you must remember that it is not advisable to overload screw piles. Therefore, the skin should be strong enough, but not heavy. Its main task is protection from wind and moisture.

What's suitable? Here are several options:

- OSB. An affordable material that has good strength, but is vulnerable to water. Before installation, it requires treatment with a composition designed to protect wood. The weak point is the joints of the slabs. They must be coated with acrylic sealant.

- Chipboard. Easy to process, but like OSB it is vulnerable to moisture. Inferior to the previous material in terms of environmental friendliness.

- Multilayer plywood. It is permissible to use only moisture-resistant sheets marked FK or FSF. The composition contains formaldehyde resins - they increase the resistance of the material to aggressive environments.

Very often, ordinary flooring made of boards with a cross section of 5*10 cm is used to install a subfloor. This option cannot be called economical, but its strength and environmental friendliness are beyond doubt. The main requirement is pre-treatment of the wood.

Insulation is the basis of floor insulation

When choosing a thermal insulation material, the main focus is on the possibility of its operation in a humid environment. The most rational solutions:

- Mineral wool . The best solution is basalt fiber mats. Pros: environmentally friendly, non-flammable, low thermal conductivity, resistance to deformation, minimal water absorption - 2%. Over time, stone wool shrinks by only 5% - with proper installation, cold bridges do not form at the joints with the joists.

- Extruded polystyrene foam . Leader in insulation properties. Additional advantages: elasticity and resistance to deformation, lack of water absorption, biostability, ease of installation. Disadvantages: high cost and flammability.

- Expanded clay . A budget alternative to sheet insulation. It is somewhat inferior in thermal insulation characteristics to mineral wool and expanded polystyrene. An important plus is fire safety.

Foam plastic is sometimes used to insulate the floor in a frame house on screw piles. Main advantages: good thermal protection and low cost. However, upon contact with moisture and under the influence of low temperatures, the material loses its structural integrity. This solution is applicable in warm regions.