Types of bulk blind area

The simplest waterproofing of a blind area is done using clay.

It is laid out around the house with an outward slope, compacted, and then covered on top with other materials, for example, gravel, so that it is not washed away by water.

Depending on the purpose, the following types of waterproofing blind areas are used.

- Bulk.

Consists of 2 layers. A layer of crushed stone 10 cm wide is placed above the bottom layer of compacted clay (20 cm thick). The type of waterproofing is the most common. It is used when draining water from the roof using a drain and in areas with little rainfall. It is awkward to walk on such a blind area. It can also blur over time when the clay gets wet. - Bulk with additional waterproofing protection.

The blind area is made the most difficult. Suitable for protecting houses with basements. Rolled waterproofing for the blind area is laid on a layer of compacted clay with an overlay on the foundation, and then it is covered with crushed stone or pebbles. To prevent the layer from being loose, make a layered “pie”: clay, waterproofing sheet, a 5 cm layer of coarse sand, geotextiles, a 10 cm wide layer of gravel, geotextiles and a 10 cm layer of crushed stone. For a complicated blind area, it is purposeful to use long-term ones based on polypropylene, PVC - films, etc.

Soft bulk blind areas are increasingly being used due to the emergence of high-quality facing materials - paving slabs, artificial stone, etc. They are placed on a layer of sand, they are comfortable and durable.

Soft blind area

The foundation is protected from rain and melt water by a blind area - a waterproof covering that runs along the perimeter of the house with a slope away from it.

The negative impact of water can manifest itself from dampness in the basement to destruction of the foundation due to frost heaving of wet soil.

Frost heaving of the soil occurs in winter due to negative air temperatures and the presence of water or moisture in the soil. It is dangerous primarily due to uneven lateral pressure on the foundation, which can lead to skewing of the building.

Therefore, an absolutely necessary measure in the fight against frost heaving of shallow foundations, along with insulation of the soil, is to protect it from the influx of water and moisture.

In addition to the main task - protection from rain and melt water, the blind area also performs decorative and operational functions, and the architectural and artistic appearance of not only your home, but also the entire local area of your site depends on how aesthetically organic it is made.

Concrete blind area

Traditionally, blind areas are usually made of monolithic concrete. For its manufacture, aggregates are used from available low-quality materials (low-quality cement, sand with a high content of clay impurities), the dosage of which may be inaccurate. This type of blind area is extremely short-lived and often does not serve as protection against soil wetting near the foundation walls.

- Sand

- Geotextiles

- Crushed stone

- Mesh for reinforcement

- Concrete

- Polyethylene film

Flaws

- Frosty destruction. Water, falling on the surface of such concrete, penetrates into its top layer to a thickness of 0.1-5 mm. When it freezes, it expands significantly and destroys this layer. Thus, chips and cracks appear on the surface of the concrete blind area.

- A “rigid” concrete blind area is susceptible to destruction due to soil settlement or building settlement.

- In the case when the concrete blind area does not adhere firmly enough to the wall of the building in the basement zone during the shrinkage process, it “moves away” from the protected building, forming a direct “channel” for the passage of water to the foundation walls.

In light of these shortcomings, there is a need to think about a rational alternative to the classic concrete blind area.

Blind area with Planter membrane

The optimal and cost-effective alternative when arranging a blind area is to use a more mobile, elastic and waterproof material - PLANTER geo - instead of a concrete layer.

This design of the blind area is more technologically advanced during installation. Due to the avoidance of concrete work, which requires significant time for concrete hardening and special weather conditions, its installation can be carried out in any weather conditions, and its durability is comparable to the service life of the PLANTER geo material - more than 60 years.

- Gravel

- Bitumen primer

- Profiled membrane PLANTER geo

- Profiled membrane PLANTER standard

- Waterproofing

- Foundation

The profiled PLANTER geo membrane in the design of a soft blind area copes well with the role of waterproofing, does not develop cracks, does not decompose in the soil, is not susceptible to the germination of plant roots, and is also easy to use.

It is the waterproof properties of the profiled membrane that make it possible to implement the most daring solutions for the design of the finishing coating of the blind area. It, depending on the aesthetic and operational purpose, can be made in the form of a backfill of gravel, plant substrate with subsequent landscaping, or classic paving of paving slabs or paving stones. The last version of the finishing coating will make it possible to make the area along the walls usable, for example, as paths for moving people.

The use of a blind area made from the PLANTER geo membrane allows you to show individuality and aesthetics when decorating the local area, which is especially important for private housing construction.

Advantages

- protection from the negative influence of water;

- protects against frost heaving;

- original decorative solution for the exterior;

- 2 times cheaper than traditional concrete blind area;

- applicable for all types of blind areas (made of gravel, tiles or paving stones, “green” blind areas and insulated ones).

Soft insulated blind area

A rational and well-founded addition to the blind area made from the PLANTER geo membrane would be the inclusion of TECHNONICOL XPS extruded polystyrene foam in its composition. In this design, the membrane removes water from the walls of the building and does not allow it to pass into the surrounding soil, and TECHNONICOL XPS insulation prevents it from freezing. As a result, the soil surrounding the foundation is not subject to frost heaving, and the foundation is protected from destruction.

Insulation of the blind area>>>

Blind area drainage

The key to the effective functioning of foundation protection, regardless of the design of the blind area, is the effective collection and drainage of water both from the roof and from the blind area itself. For these purposes, it is necessary to provide storm drainage and ring drainage.

Step-by-step installation instructions

- Formation of backfill with construction sand (of variable thickness) with a slope from the walls of the house.

- Laying the PLANTER geo membrane with geotextile up (along the fill) with an “overhang” onto the wall (15cm). To attach the “approach” to the wall, you can use PLANTER fixing or PLANTER krep, depending on the presence or absence of waterproofing of the base.

- To join the rolls, an overlap of at least 5 cm is formed. To do this, separate the geotextile and stick double-sided tape NICOBAND DUO or PLANTERBAND DUO in place of the separated geotextile.

- Overlapping the edge of the laid roll with double-sided tape applied with the edge of the second newly laid roll. Forming an overlap of at least 5 cm. Firmly pressing the formed overlap so that the “spike fits tightly into the cell.”

- Bonding geotextiles to form the integrity of the filter layer. Use double or single sided adhesive tape. If the adhesive tape is single-sided, the width must be at least 50 mm.

- Installing PLANTER Profile on the top of PLANTER geo on the plinth. Forming a backfill of gravel or plant substrate on top of the laid membrane. The installation of an edge strip will give an aesthetic appearance.

Asphalt or concrete blind area

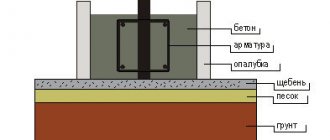

Solid waterproofing of a blind area made of concrete or asphalt is reliable protection against precipitation. A 25 cm deepening is made in the ground around the house. The bottom of the trench should be carefully compacted. Then the formwork is constructed for concrete pouring.

An underlying sand layer 10 cm wide is placed in the trench. It is moistened with water and compacted. A layer of crushed stone 5 cm wide is poured onto the sand, which is also compacted. A road mesh for reinforcement is laid on top.

It is better to pour the concrete solution in one go to ensure the required strength. Afterwards the surface is leveled and a slope of 5-100 is made as a rule. After initial hardening for 2 hours, the blind area is covered with film for 2 days. This is necessary to conserve water, which helps increase the strength of the layer.

The surface can also be asphalt.

The concrete blind area can be laid out from ready-made slabs. It has properties similar to aspic. At the moment, laying paving stones or paving slabs is widely used. To do this, crushed stone is poured onto a clay waterproof layer, then sand, and a hard covering is laid over it.

Preparation

Preparatory stage:

- Drawing up a plan for the blind area, measuring the perimeter of the structure, the size of the roof overhang, identifying the general condition of the soil; marking the future structure on the ground (with twine, pegs).

- Excavation work - you need to remove the soil to a depth of 15-50 cm. Specific parameters depend on the type of soil, the depth of freezing in winter, and whether insulation will be performed.

- Leveling and compacting the bottom of the resulting trench. The surface should not be strictly horizontal - you need a slope of 5-10 degrees away from the house.

- A drainage ditch is dug along the outer perimeter of the resulting trench, with inspection wells every 2.5-3 meters. The minimum distance from the base to the drainage should be about 1.5-2 meters. The slope of the drainage towards the sewage collector is at least 3-5 degrees.

- Backfilling the blind area trench and drainage with sand. Maintaining a slope of 5-10 degrees from the wall. The sand is thoroughly compacted and moderately moistened.

The sand needs to be wetted every 3-5 cm of the layer. For quick compaction it is better to use a vibrating plate. The minimum total sand thickness is 10 cm.

With lawn cover

Waterproofing and drainage

To drain water, small pebbles are made along the outer edge of the blind area. Here you can pave grooves with stone. The bottom is covered with waterproofing. You can simply cut it lengthwise and lay out an asbestos-cement or plastic pipe.

It is performed with a slope towards the drainage well.

You can use ready-made channels or drainage trays with mesh on top.

A budget solution is to use closed drainage. To do this, geotextiles are placed in the drain, filled with crushed stone, and then wrapped with the same fabric on top and covered with sand. Waterproofing under the blind area and small stones is done as one whole so that water does not go into the ground.

Moisture-proof layer

Having installed the thermal insulation, they proceed to installing a moisture-proof layer - a membrane. It may be one of the now common types - with or without geotextiles. The first option is more expensive, but better. It is possible to lay the membrane without covering it with geotextile. It will reduce expenses, but the disadvantages of saving will be revealed:

- Infiltration of the smallest soil particles (if gravel is poured on top, a lawn is laid), sand from the sand backfill (if a tiled path is installed on top of the blind area) into the drainage system. The consequence is a quick failure, the pores in the pipes will become clogged (you will have to remove them and replace them with new ones)

- Subsidence of the top soil layer due to water washout. It will lead to the destruction of the lawn and the paths that will be placed on top.

Purchasing geotextiles separately from the membrane will increase the cost of the work.

To work with plastic fasteners, you need to use lightweight rubber-coated hammers. The use of metal tools will lead to frequent breakdowns of fasteners and damage to the surface of the material being fastened.

The edge of the membrane adjacent to the base is raised to a height of at least 15-20 cm. The membrane is attached to the base either with double-sided fixing tape (polymer-bitumen based), or with a lath or plastic elements (“fungi”).

Before attaching the membrane to the base, it must be thoroughly cleaned, leveled, and waterproofed.

Only after attaching the membrane to the base can thermal insulation be installed. More often - sheets of extruded polystyrene foam with an L-edge. They are first secured with adhesive foam, then fixed at 5-10 points with plastic “fungi”.

It is very convenient to use a cordless impact drill or drill/driver to install plastic fasteners. It will speed up work and improve quality.

The lower edge of the membrane should lag behind the base by an average of 150-200 cm. The specific value should exceed the roof overhang by 30-50%. The lower edge of the membrane is placed in the drainage ditch so that it completely wraps the drainage pipe. A layer of geotextile is first separated from the membrane by 40-60 cm.

Proceed with caution - geotextiles must not be damaged.

Geotextiles are placed on top of a drainage pipe wrapped in a membrane. This is done with the expectation that moisture from the soil will seep through the textile, filter, and flow down the membrane into the drainage pipe. There will be continuous removal of moisture; soil particles and sand backfill will not clog the drainage.

Features of blind area waterproofing

- Waterproofing is selected taking into account weather conditions, soil conditions, the presence of groundwater and the location of the house.

- Waterproofing the blind area around the house can be done at various levels.

In almost all cases, a concrete screed is sufficient. But sometimes you need another level of home protection with the use of roll waterproofing. It is applied with an overlap to the foundation with a height of 15-20 cm. - High-quality protection of the house is ensured by covering the foundation with bitumen mastic and then applying roll insulation to it. If it is made in several layers, each of them is glued to the walls with mastic.

- The blind area is made on the basis of waterproofing cement. They can be bred independently by adding additives.

Waterproofing materials

When choosing the type of waterproofing for the blind area around the house, the material for the work must take into account the design features of the element. Sealing of the plane can be achieved by using:

- Bitumen mastics. They are optimally suited for creating a protective surface on the foundation of a building, and are used for pouring bulk blind areas.

- Roll materials. The film for waterproofing the blind area must be applied when installing it on the wall. It is recommended to combine rolled materials with the application of mastic to the surface to enhance the tightness of the coating.

- Hydrocement (asphalt concrete). Solid slabs of the blind area will create a reliable water barrier against water flows.

- Penetrating compounds (polymers). They are used for surfaces with a porous structure, providing deep impregnation with protective compounds. They are resistant to ultraviolet radiation and sudden temperature changes. Vapor permeability properties protect the surfaces of the material from the formation of mold and mildew.

The process of working with bituminous materials requires special care. The composition should be heated in a deep cauldron, avoiding liquid getting into the fire while wearing special protective clothing. Personal and fire safety rules must absolutely not be ignored. Initially, a low grade of bitumen is melted, completing the process with a higher grade. Violation of the rules will lead to strong foaming.

Painting options for liquid waterproofing are distinguished by the availability of material and ease of installation. The primer layer can be made using bitumen mastic. Next, a polymer, bitumen, or mixed type of composition is applied. If necessary, it is recommended to level and clean the surface to ensure the required degree of surface adhesion.

Treatment involves applying 2-3 layers of paint waterproofing. After the work is completed, the surface is checked for defects. Cracks and areas of swelling of the layer are cleaned and re-treated with the composition.

It is advisable to waterproof the blind area with rolled materials for soft-type construction options. The optimal coating is polyvinyl chloride films. The area where the foundation adjoins the plinth can be treated using bitumen or polymer materials.

Penetrating Foundation Insulation

Waterproofing of the foundation and blind area is done in a complex.

A modern method is to treat concrete surfaces with penetrating compounds containing Portland cement with fillers and active chemical additives. To do this, you should open the pores of the concrete and remove weak fragments. The surface should be moistened before treatment, but not excessively, otherwise erosion will occur (not more than 5 liters of water per square meter). When breeding, all points of the annotation must be fulfilled.

It is important that the impregnation matches the type of surface. It is applied sparingly.

Thin layers will not perform their functions properly, and thick ones will crack. Sealing holes is ineffective here, since the product is intended to improve the waterproofing parameters of the concrete itself. The protective composition fills the pores without allowing moisture to pass through.

What it is?

First you need to understand what a “blind area” is.

Dictionaries represent this word as an asphalt or concrete strip designed to drain rain and floods from the foundation of a building. In addition, she:

- eliminates excess moisture of the foundation and adjacent groundwater, which can erode the structure and cause excessive shrinkage;

- protects the building from overgrown tree roots near the house.

The blind area is a permanent strip along the perimeter of the building with an angle of inclination from the house. This angle allows water to roll down without stopping at the base.

The blind area consists of:

- bedding layer;

- outer layer.

The type of blind area is determined by the type of outer layer. It can be made of clay and crushed stone, concrete, asphalt and paving slabs.

The blind area must have waterproofing to protect it from water, as well as to prevent the foundation from getting wet due to the formation of cracks and gaps. Waterproofing the blind area also allows you to keep basements dry even during heavy rains and in the presence of abundant groundwater.

Advantages of a "backfill path" around the house

The soft blind area has the following advantages:

- reliably protects the foundation from the destructive effects of climatic factors;

- increases the thermal insulation properties of the supporting structure and the entire structure as a whole;

- does not require repair work, unlike a hard “path”;

- does not crack;

- is resistant to seasonal soil movements during freezing and thawing of water (especially important for Siberia);

- combines perfectly with absolutely any finishing raw material, in addition, it allows you to recreate a delightful hedge, a delicate carpet of fragrant plants, pretty paths with a soft border, etc.;

- has a long service life;

- ease of installation, since you don’t have to adhere to the slope from the walls of the structure;

- I'm pleased with the reasonable price of the materials.

Of course, there is also a drawback - this is regular maintenance of the top layer of the structure - getting rid of weeds, cleaning the decorative backfill, mowing the lawn or fiddling with plants. Naturally, it is much more pleasant to take care of a structure than to repair it. In principle, we can say that the soft blind area has no disadvantages.

Dimensions

It is generally accepted that the blind area must be at least 1 meter on all sides around the building.

Its clear dimensions depend on the width of the roof, on the overhangs of its eaves and on the drainage outlet. That is, the width must be 20-30 cm greater than the roof extension.

The blind area can be:

- bulk made of clay, covered with crushed stone on top;

- made of clay and crushed stone, with additional waterproofing;

- made of concrete (with or without reinforcement), which is poured on site;

- from ready-made reinforced concrete slabs.

To waterproof blind areas, different insulation options are used.

Insulation can be: roll, penetrating, mastic, PVC films, membranes can be used.

- Roll insulation (roofing felt, hydroglass insulation) should be used only when the height difference around the foundation is minimal.

- Rolls used for roofing – geotextiles, polypropylene, rubemast.

- Bitumen mastic.

Each layer of 2-3 mm is applied on top of each other. It is necessary to prevent swelling and cracks. - Modern technologies have made it possible to invent another type of insulation - penetrating. This is a substance, the composition of which seeps into the blind areas (whether asphalt or concrete), and clogs the pores and fills microcracks.

- Hydrocements and asphalt concretes.

Types of blind area waterproofing

There are several types of blind area waterproofing depending on.

Clay

This waterproofing option is considered the most economical and comfortable for independent work.

You should start by removing the top layer of soil and filling it with compacted clay, simultaneously tilting it away from the house. The contact points are coated with bitumen.

For complete waterproofing, you can glue a strip of rolled paper to a vertical surface, and then cover everything with crushed stone.

Roll

Most often used for buildings equipped with basements. At first, the clay is also compacted, then the pieces of the roll are laid overlapping on the wall. You can lay several layers of the roll, coating each with mastic.

The layers are rolled with a roller, the weight of which must be more than 70 kg. Soil or crushed stone is poured on top.

Painting room

This is done by applying a primer. You need to wait for it to dry completely. A layer of mastic up to 2 mm is spread on top, the procedure is repeated 2-3 times.

Concrete

It is necessary to dig a groove and install formwork there. Fill the area with concrete; reinforcement can be made for greater strength. Just like everywhere else, when pouring, a slope is formed, and decorative tiles are laid on top.

How to make a blind area correctly

The blind area is a strip that encircles the entire perimeter of the building. Its purpose is not to allow ground and surface water to enter the building, but to divert it to the side. In addition, it performs the function of thermal protection of the foundation.

If you did not build the house yourself, but entrusted this task to professionals, then this detail will already be present. If not, then its construction will cost approximately from 2000 to 4000 per sq.m. And this is only work, without taking into account materials.

You can do it yourself, saving at least 300,000 rubles.

Official construction documents identify approximately 20 types depending on the terrain, soil type, weather conditions, and so on.

The width of the structure must be at least 20 cm from the protruding part of the cornice. In addition, it is necessary to make a slope. Typically, its angle is no more than 10 cm, which promotes better water drainage.

Crushed stone blind area

The simplest type of this construction work is to fill the strip around the house with crushed stone and then compact it, but in this case it will have to be renewed after some time. In about 7 years.

This method is the most budget option. Let's take a closer look at it.

- To begin with, a trench is dug, the depth of which is approximately 20 cm

- Next, clay is poured onto its bottom and compacted.

It is better to take it fatty, since the fat content will improve the function of thermal protection of the foundation. During this procedure, the angle of inclination is also made - After this, waterproofing is laid on the clay layer.

It could just be PVC film - In addition, you can dig a groove along the edge, cover it with the edge of the film and fill it with crushed stone.

In this case, water flowing down the clay will freely move away from the house through the rubble. You can take her out into the storm drain

- A layer of coarse sand is placed on top of the waterproofing, and then a layer of crushed stone.

And then compact the resulting layer - If the level of waterproofing is less than the level of the future blind area, then it must be increased.

To do this, you should use bitumen or several layers of roofing felt.

You can decorate it by rolling out a roll of lawn grass. But it’s better to make a major blind area.

Capital blind area: do it step by step

To make a structure around the house you need:

- Clear a perimeter strip around the house approximately 70 cm to 1 meter wide

- Measure the same distance from the house along the entire perimeter.

For marking, you can use pegs and thread (cord, fishing line, etc.) - Next, you need to remove 20-25 cm of soil and compact the earth

- The next step is the construction of formwork.

To do this, boards are installed along the entire perimeter to block the path of the concrete with which we will fill the structure. - At small intervals, approximately 2.5-3 meters, we install transverse slats.

They need to be coated with bitumen. These are the so-called expansion joints. They will prevent cracks from appearing in concrete

- You will also need to insulate the soil to avoid uneven pressure on the foundation during the cold season. The most suitable material for this is extruded polystyrene foam.

Or crushed stones should be poured onto the compacted earth to a height of approximately 10 cm. Make a so-called pillow. This will allow air to circulate freely and prevent the spread of mold.As in the first option, it is better to alternate crushed stone and sand when filling it. The effectiveness of such a “pillow” will be higher

- The next step is waterproofing.

For this you can use regular plastic film. You need to lay it flat, preferably by aligning all the folds. - Before pouring concrete, a reinforced mesh must be placed on it.

It must be laid over the previous part. In cold weather, it will protect the concrete coating from cracks, and will also provide the necessary strength of the slab with a minimum thickness. The cell size of the reinforced mesh should not be less than 8 cm

Insulation

Another fundamental point when making a waterproofing blind area is its insulation.

Insulation allows you to retain heat in the basement and on the ground floor, increases the operating time of the blind area, and also allows you to save on x, since the height becomes less than the depth of soil freezing.

Insulation can be done in several ways.

- Expanded polystyrene is quite strong, it can be said that it has endless water-repellent properties.

Its weight is so light that its installation is not difficult. This is enough for just 1 layer with a sheet thickness of 10 cm. You just need to take care of protecting the joints with a special film with a waterproofing effect. - Polyurethane foam is extremely frost-resistant. It is able to withstand up to -60 degrees without changing its own properties. It is environmentally friendly and has good thermal insulation.

- Polyfoam has the highest sound and heat insulation.

This may be due to its foam structure and the richness of air inside. has low water absorption, and also has waterproofing ability and light weight. Foam is resistant to temperatures and mold.

There is no need for insulation if your house is built on stilts or has a large foundation without basements. In such cases, insulation is a waste of money.

How reliable and durable is the soft blind area?

Of course, to answer these questions, you need to try the material yourself.

But none of us wants to experiment in construction. And it is right. Here we can cite one fact that will dispel our doubts. We all know how clearly large developers calculate all the details. We do not take into account those whose goal is to save on everything, and then whatever happens. We are talking about those who are making long-term plans and are not going to spend money on constant repairs. Before using any material, they clearly evaluate its capabilities, effectiveness, reliability and their own benefits. There are no small details here. It is these responsible developers who have been using PLANTER Geo membranes for many years. It would seem that this is a material that can be replaced with any cheap one. But large, responsible businesses know the consequences of such savings and, preferring not to take risks, use our profiled membrane. Soft blind area in modern construction

New technologies may be alarming, but concrete has not existed since time immemorial, but appeared relatively recently. Its use has made it possible to make a huge step forward in construction. So is it worth neglecting the latest technologies that are already being successfully used?

Does it look unreliable? Yes, indeed, the concrete blind area looks much more impressive. This is probably where its main drawback lies - its monumentality does not make it possible to adapt to changes that cannot be avoided. For example, soil mobility. And then it becomes clear that it is the profiled membrane that is much better suited for the blind area. And a well-thought-out elastic drainage system is the ideal solution.

- The membrane does not decompose and is highly resistant to chemical reagents (acids, alkalis, salts) contained in the soil.

- Resists root germination and the effects of waste products of microorganisms.

- Reacts to temperature changes absolutely painlessly.

- Prevents frost heaving, leading to the formation of cracks in concrete structures.

- Made from high-density polyethylene without the addition of chemical elements that negatively affect the environment.

Therefore, the blind area with PLANTER Geo will last more than 60 years.

Now ask your neighbor: how long and how well does the concrete option protect the foundation? With PLANTER Geo you can make an insulated blind area by placing heat-insulating boards under the membrane

Insulating the blind area around the house

Insulation of the base and blind area of the foundation

There is a worldview that thermal insulation of the foundation area and the basement of a building is an unjustified waste of money and time. But this is far from true, since in addition to preventing foundation deformation due to weather conditions, thermal insulation has many more advantages :

- Preservation of heat and reduction of expenses for heating the home.

- Savings in foreign currency when installing the foundation, since additional insulation allows you to lay it above the freezing depth of the ground, which significantly reduces costs

- Protection of the base and base of the building from rain and melt water.

- Elimination of displacement of the blind area relative to the walls.

- Extending the service life of basement cladding.

How to insulate the blind area around the house?

The insulation is laid on a bedding layer of painstakingly compacted sand and crushed stone. For greater strength of the insulated blind area, a reinforcing mesh is placed on top. In order to improve the thermal insulation of the house, sheets of thermal insulation are fixed to the base immediately with the blind area. Then the resulting structure is poured.

Of all the heat-insulating materials, polystyrene foam and polystyrene foam are the most popular.

Insulation of the blind area with polystyrene foam

Expanded polystyrene is known as extremely strong, durable and water-repellent. It has a completely insignificant weight, which allows it to be laid with ease and without much difficulty.

In this case, the 1st layer with a sheet thickness of 10 cm will be completely sufficient. One has only to foresee the protection of the joints with a waterproofing film.

Insulation of the blind area with foam plastic

Polystyrene foam, due to its own foam structure and the presence of a huge amount of air in its composition, has the highest sound and heat insulation. Among the undoubted advantages, it is also worth noting low water absorption and waterproofing capacity, low weight of sheets and ease of installation. Mold does not actually appear on it and temperature changes are not reflected.

And so that the insulation does not deform under the weight of the top covering of the blind area, for these works it is recommended to choose one with an increased density.

We will equip a “protective” strip around the house

The whole structure resembles a multi-layer cake, where there are materials for both insulation and waterproofing. Therefore, you need to strictly follow a small plan:

- Dig a trench, the depth of which will coincide with the depth of the foundation.

- Clear it of roots and plant seeds, if any. If this stage is ignored soon, the plants will begin to sprout and break through the waterproofing layer.

- The bottom of the trench must be covered with clay. This layer should be 10 cm. The substance is carefully compacted so that the area near the foundation is 2-5 degrees higher than the far part of the blind area. The slope will allow water to flow away from the walls on its own.

- The wall is coated with liquid waterproofing.

- Lay roll protection against moisture. If joints form, they must be sealed with tape. And, of course, don't forget about the whip on the wall.

- Sand should be poured on top of geotextile or other film. The thickness of this layer is about 10 cm. It is also leveled taking into account the slope and compacted. To quickly cope with this task, you can spill a little water on the sand, but the amount of liquid should be minimal.

- Thermal insulation layer. For blind areas this is as important as for walls. The house loses about 20% of its heat through the floor, so by insulating it and the foundation, you can save warm air in the house and not heat the street. It is important to remember the slope.

- Another layer of sand. The thickness is also about 10 cm and must be leveled and compacted while maintaining the slope.

- Waterproofing again. The installation principle is the same as in the first layer of geotextile.

- To fix the waterproofing layer, you need to pour fine crushed stone on top.

- Decoration.

Waterproofing the blind area of the house

Waterproofing the blind area well protects the walls and foundation of the building from the destructive effects of melted snow and rain. It can be either basic or additional.

Basic waterproofing is an ordinary concrete screed on top of a bedding layer and a heat-insulating layer.

Depending on weather conditions, the amount of precipitation and the proximity of groundwater, the required thickness of the poured solution is determined.

As additional waterproofing, waterproofing, polyethylene films or roofing felt are most often installed. laid on the insulation of the blind area and the walls of the building, which helps to protect the building even more reliably.

No less common is penetrating waterproofing , consisting of a special solution applied to concrete. The composition impregnates the pores of the coating, turning into crystals, which reduces the penetration of water into the blind area to zero.

Protection of the blind area from water.

Development of work production.

Each building and structure consists of separate main parts - foundation, base, roof. High-quality performance of any of the components is not always the key to long-term operation. For example, the foundation of a building must be protected from the brutal effects of precipitation. In this case, the blind area plays the role of a protective structure. The installation of a concrete tape around the perimeter of the building prevents water from entering the basement and onto the surface of the foundation blocks, but in order to completely prevent the penetration of water, it is necessary to waterproof the blind area.

Basic information

Many people give the blind area only an aesthetic function, considering the structure to be something like a sidewalk located around the perimeter of the building.

On the one hand, the judgment is correct. But if the work technology is fully followed, the element will play an important moisture-protective role.

The work begins with removing soil from the wall of the building to a distance of 50 to 120 cm.

The depth depends on personal criteria, but on average this value is about 20 cm. Then the bottom of the trench is filled with sand and spilled with water to compact the sand layer. It is permissible to fill the place with both concrete and a substance of small grade M100. In the case of strong rocky soils, it is permissible not to reinforce the body of the concrete foundation, since the structure does not bear any external loads. But for moving heaving soils, it is recommended to use reinforcing mesh with a rod diameter of 3-8 mm to maintain the integrity of the structure in the event of soil movement.

Also, to prevent the occurrence of cracks, it is necessary to install expansion joints every 2-2.5 m.

They are made either from an ordinary saw in the form of a board placed on an edge, or from a special damper tape, 1-1.5 cm wide. When the ground moves, such sections will work as separate structures, which will avoid destruction.

When filling the formwork with concrete or substance, it is necessary to predict the slope for the flow of water in the direction “from the wall”. Traditionally, its value is 3-5 degrees.

After the concrete has gained the required strength, it is necessary to think about constructing a layer that prevents water from penetrating to the surface of the foundation.

Without this step, the design can really only serve an aesthetic purpose.

Waterproofing for concrete blind areas is often done using rolls. To ensure the best adhesion of the insulating concrete to the surface, the latter must be spilled or coated with bitumen. Next, immediately heat the bitumen and the lower surface of the roll using a gas burner and perform gluing.

Application for waterproofing the blind area must be carried out taking into account that moisture does not penetrate the concrete surface at the joints.

This can be achieved by laying the first section along the edge opposite the wall of the house. Each subsequent layer will thus be higher than the previous one and, taking into account the slope, one can imagine that water will not accumulate and seep through the joints. But as an additional measure, it is permissible to coat the joints with bitumen.

The process of waterproofing the blind area around the house is not limited to just applying a roll to the concrete surface.

One way or another, flowing from the wall of the building and further along the blind area, the water enters the ground, which means that with heavy rainfall, a huge amount of water can still seep to the foundation of the structure. This can be avoided by installing a drainage system, which is an artificial small trench around the perimeter of the entire blind area, made with a constant slope.

The bottom of the drainage ditch is covered either with a soft waterproofing material, or laid with a plastic pipe cut in half lengthwise. It is necessary to predict the final container for collecting water, which, as a rule, is a depression in the ground, made at a significant distance from the surface of the foundation.

How to make a blind area using a profiled membrane.

The blind area is an element connecting the building with the adjacent territory.

It is responsible for removing surface water (rain, melted snow) and man-made water (faucets in the basement, watering hoses) from the building, for protection against flooding and local washout of soil around the foundation. It is customary that the blind area is made monolithic from cement-sand mortar. This approach is generally studied and widespread. As a rule, when creating a standard blind area, there are some features. Firstly, there is a certain difficulty when performing monolithic work. Secondly, soil subsidence and the appearance of cracks lead to a decrease in functionality, aesthetics and the need for repairs.

But modern technologies can offer an alternative way to perform a blind area using a profiled membrane and complete removal of surface moisture from the foundation. Installation of a house blind area made of profiled membranes differs from traditional monolithic ones in its lighter design and cost.

Below we will describe the installation of a blind area with a Planter Geo membrane. Planter Geo is a two-layer fabric consisting of a profiled PVP membrane and thermally bonded geotextile. Its service life is more than 50 years.

Main stages of work:

- Let's prepare the base. To do this, we remove the soil along the perimeter of the building to a depth of 300 mm and a width exceeding the width of the eaves overhang by 350 mm.

- We fill with sand 60-100 mm thick and set a slope of at least 3% from the base.

- On the prepared base we lay insulation made of extruded polystyrene foam of the TECHNONICOL Carbon Eco or TECHNONICOL Carbon Prof type. The thickness of the insulation should be determined based on thermal calculations, taking into account the geography, purpose and method of insulating the building. It is important to note that the slabs are laid in width in such a way as to leave space for laying the drainage pipe.

- We spread the profiled Planter Geo membrane over the insulation. Laying is done in such a way that the canvas is located across the entire width of the blind area and is inserted 500 mm onto the vertical part of the plinth. On the vertical part, we fix the membrane along the edge using a pressure strip, and seal the seams with Nicoband type adhesive tape.

We lay the drainage pipe in the formed “ditch” between the insulation slabs and the adjacent territory. The pipe should be wrapped in Planter Geo fabric. It is laid between geotextiles and a profiled membrane with a specified slope of 2% towards the drainage well. Afterwards, the pipe must be connected to the storm drainage system.- In this case, the insulation of the base should be carried out after installing the profiled membrane.

- It remains to resolve the issue of finishing the blind area. For example, you can make a sand cushion and lay paving slabs on it or lay out a fertile layer of lawn grass.

- The finishing of the base can also be done in any way: gluing porcelain tiles, installing siding, and plastering.

A blind area with a profiled membrane has its advantages:

- no wet processes;

- no technological downtime;

- a reliable solution in terms of draining water from the foundation;

- versatility in the availability of finishing options and solutions;

- ease of construction.

To complete drainage measures, it is recommended to combine drainage systems with drainage systems.

You can purchase materials for constructing a blind area right now.